Drive system of three-face rotation workbench

A technology of rotary table and transmission system, applied in the field of transmission system, can solve problems such as low production efficiency, inability to meet large-scale batch production, etc., and achieve the effect of stable structure operation and accurate positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention is described below in conjunction with accompanying drawing.

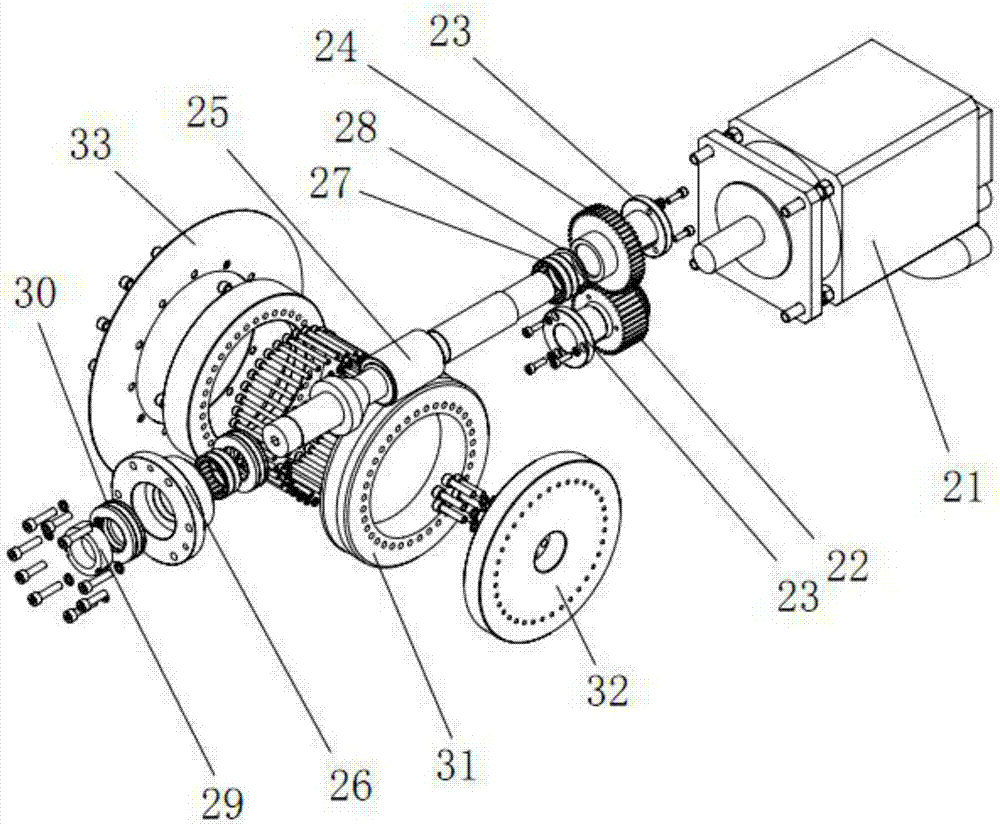

[0012] like figure 1 As shown, a transmission system of a three-sided rotary table according to the present invention includes a servo motor 21, a worm assembly and a worm gear assembly; a large spur gear 22 is arranged on the rotating shaft of the servo motor 21, and the outer end of the large spur gear A pulley tightening ring 23 is provided; the worm assembly includes a small spur gear 24, a worm 25 and a bearing sleeve 26, the small spur gear 24 is arranged on one end of the worm screw 25 through a needle bearing 27 and a circlip 28, and the bearing sleeve 26 passes through The precision nut 29 and the cylindrical roller thrust bearing 30 are arranged on the other end of the worm 25, and the outer end of the small spur gear 24 is also provided with a pulley tightening ring 23, and the small spur gear 24 cooperates with the large spur gear 22 through the pulley; The worm gear assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com