Patents

Literature

63results about "Fibre cleaning/opening by beater arms" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

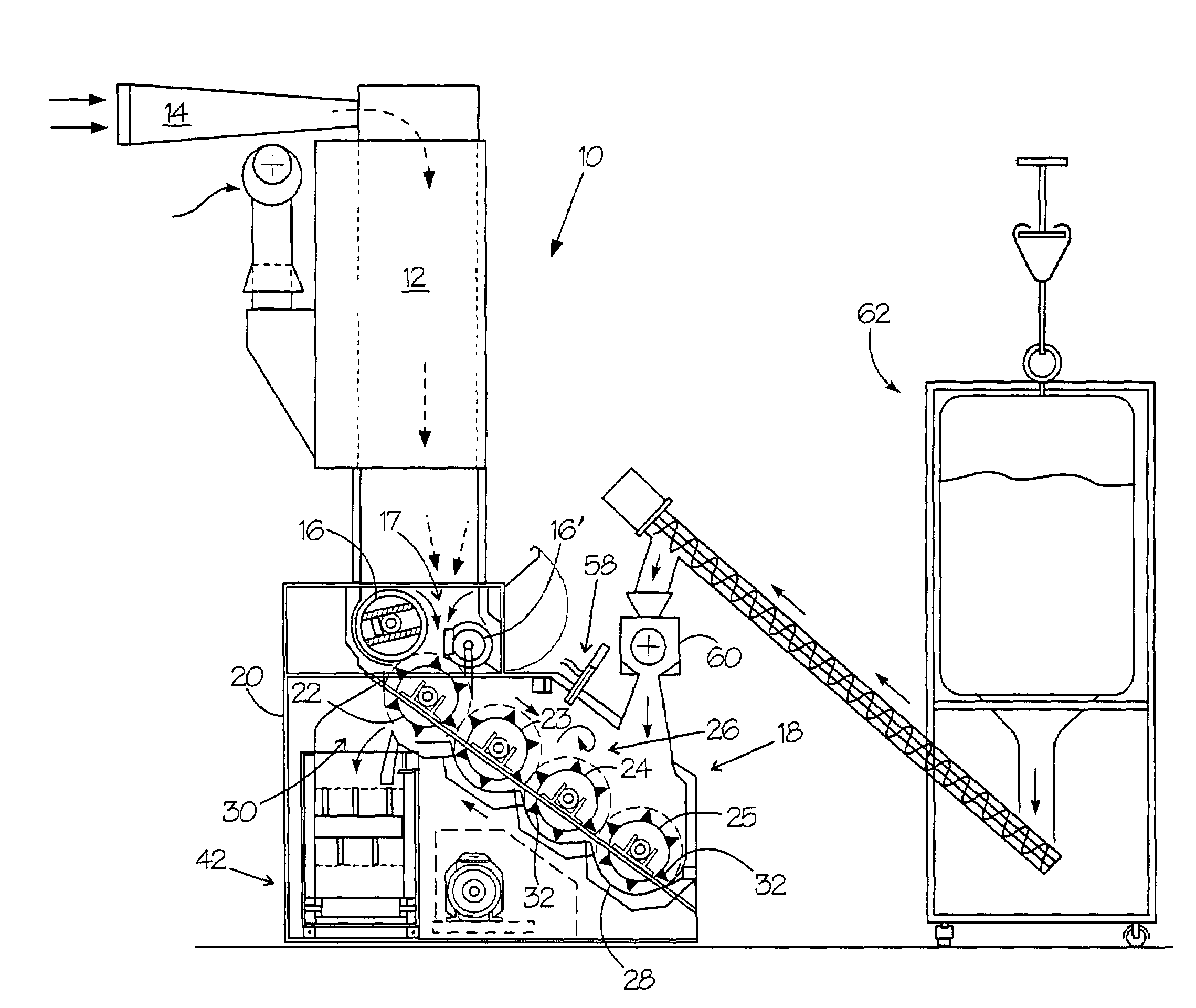

Process for making bamboo fiberfill and articles thereof

InactiveUS20090101294A1Small sizeNon-fibrous pulp additionNatural cellulose pulp/paperFiberEngineering

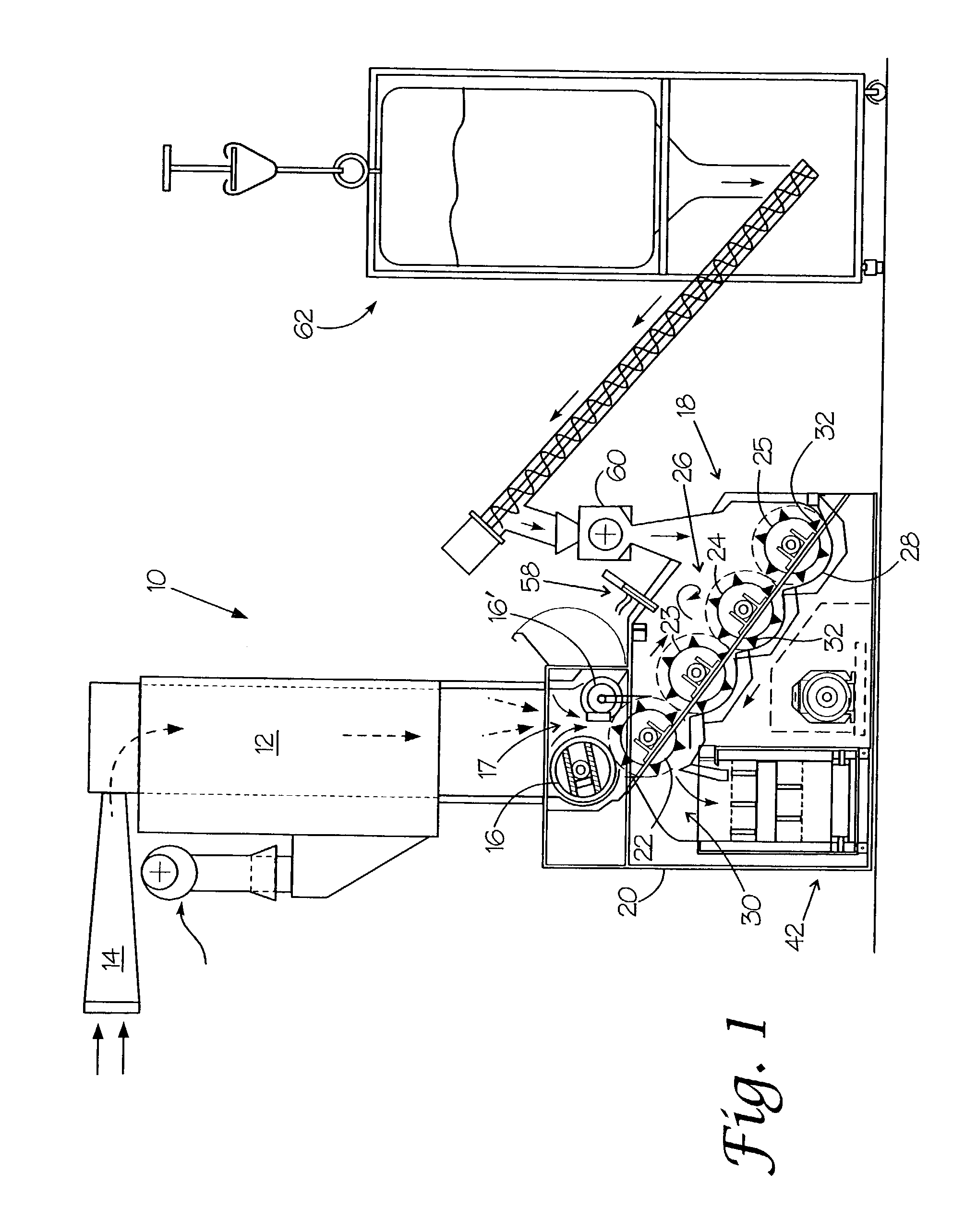

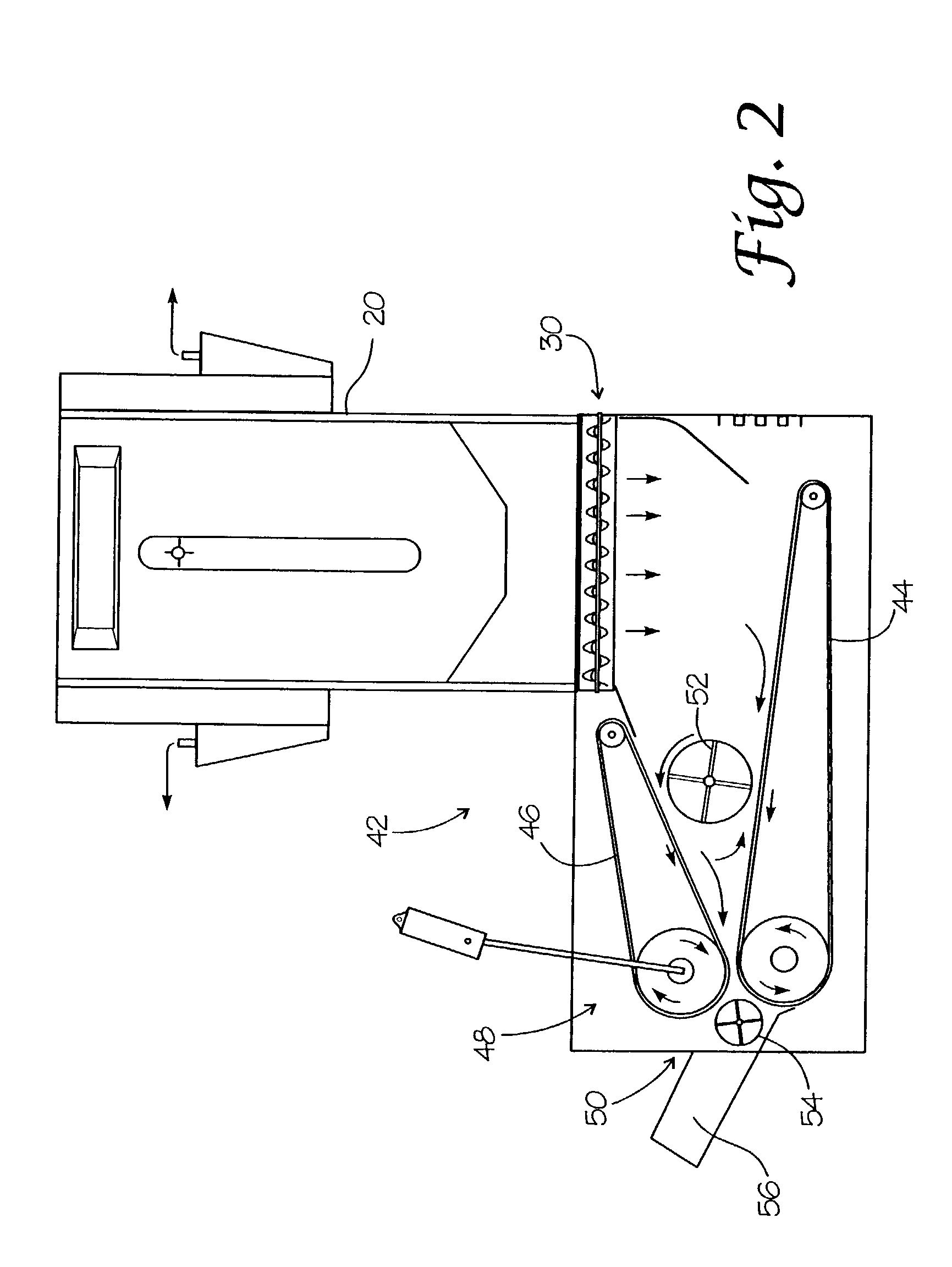

A process for producing bamboo fiberfill from raw bamboo fiber includes, obtaining a bale of the raw bamboo fiber, picking up and separating the raw bamboo bale fiber into tufts of bamboo fiber with a bale opener, feeding the bamboo fiber tufts into a blending hopper configured to blend the bamboo fiber tufts, feeding the blended bamboo fiber tufts into a beater configured to open the bamboo fiber tufts, and feeding the opened bamboo fiber tufts into a fine opener configured to reduce the size of the opened bamboo fiber tufts and refine the opened bamboo fiber tufts into the bamboo fiberfill, wherein the bamboo fiberfill has a fiber length of about 30 millimeters to about 60 millimeters and a linear density of about 0.5 denier to about 5.0 denier.

Owner:FAIRFIELD PROCESSING CORP

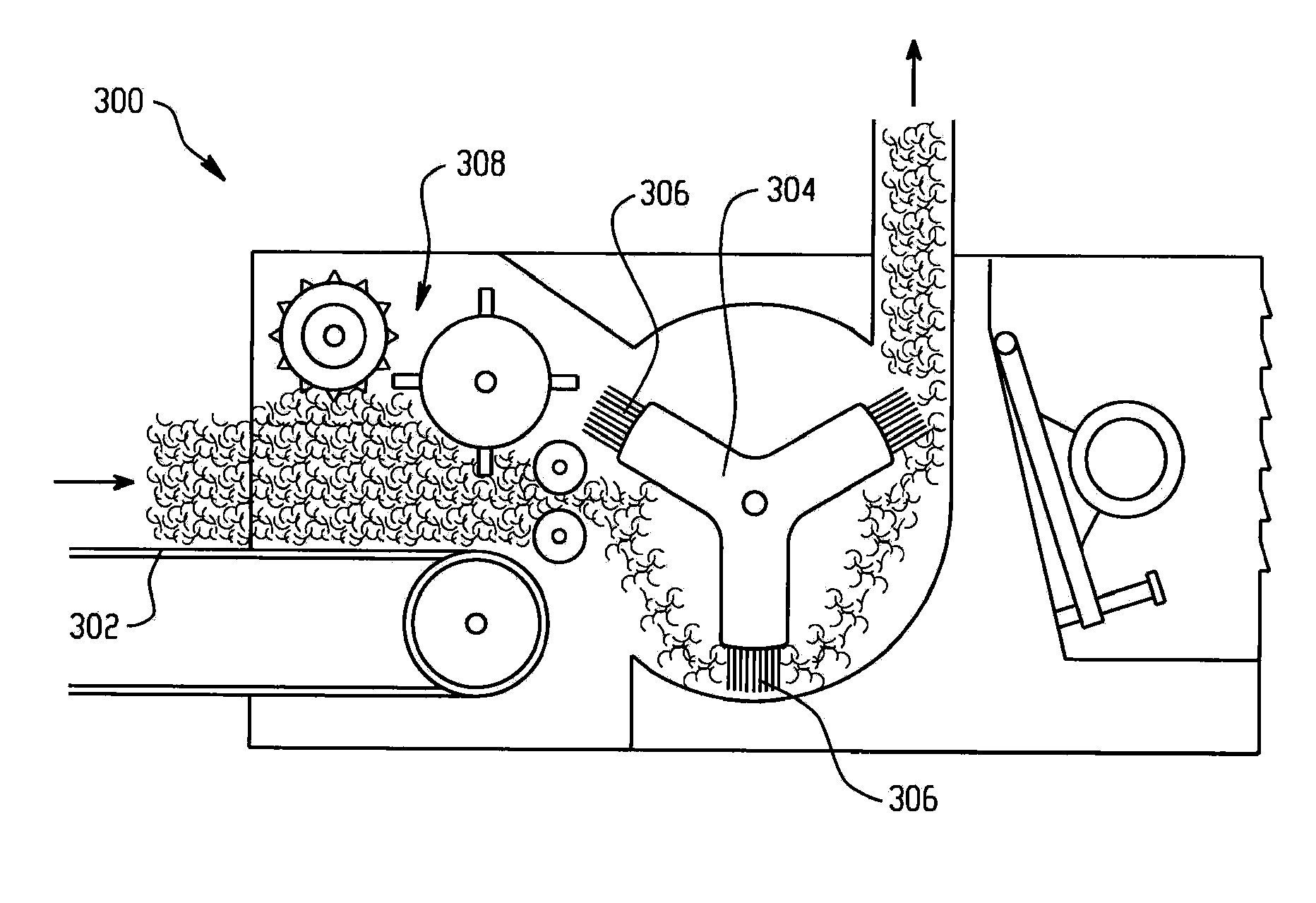

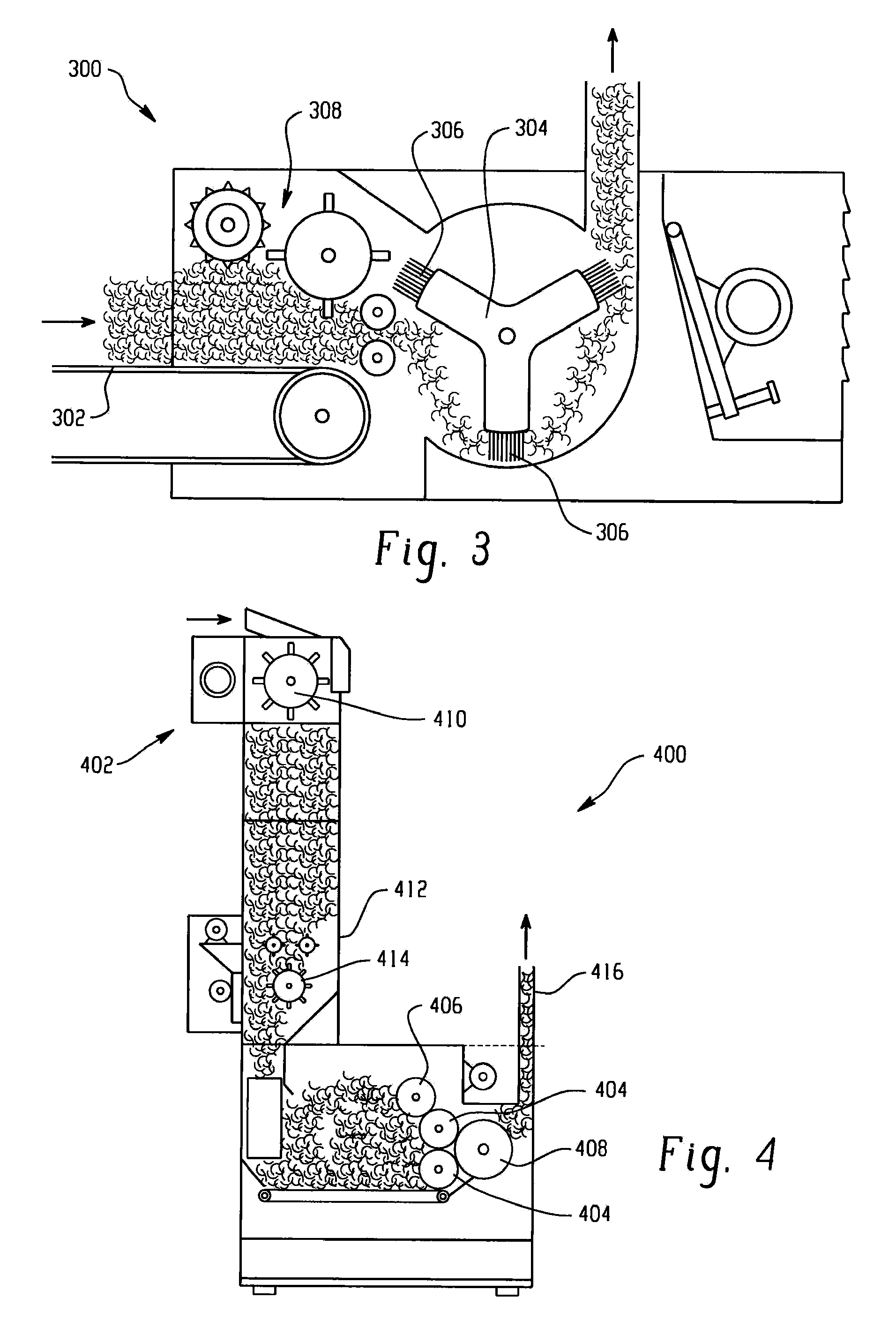

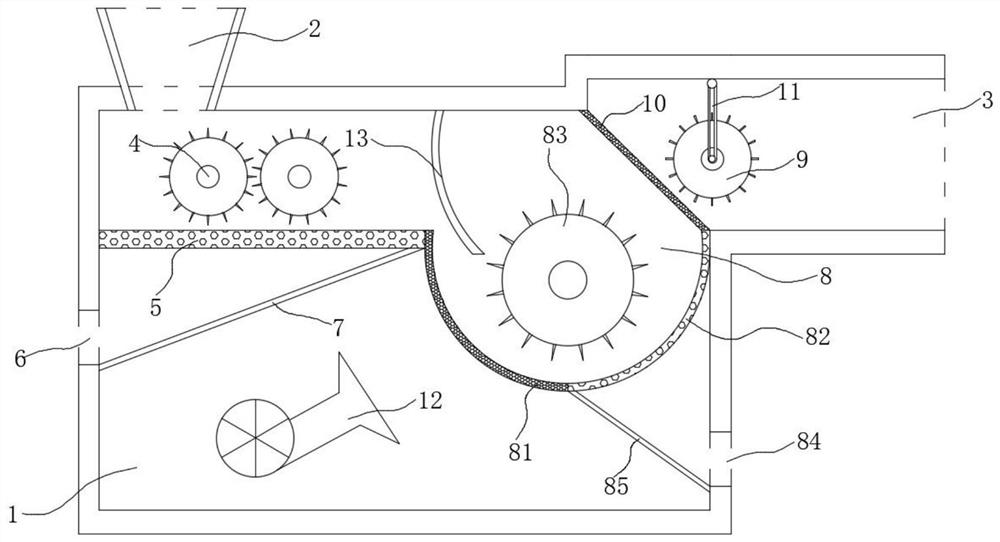

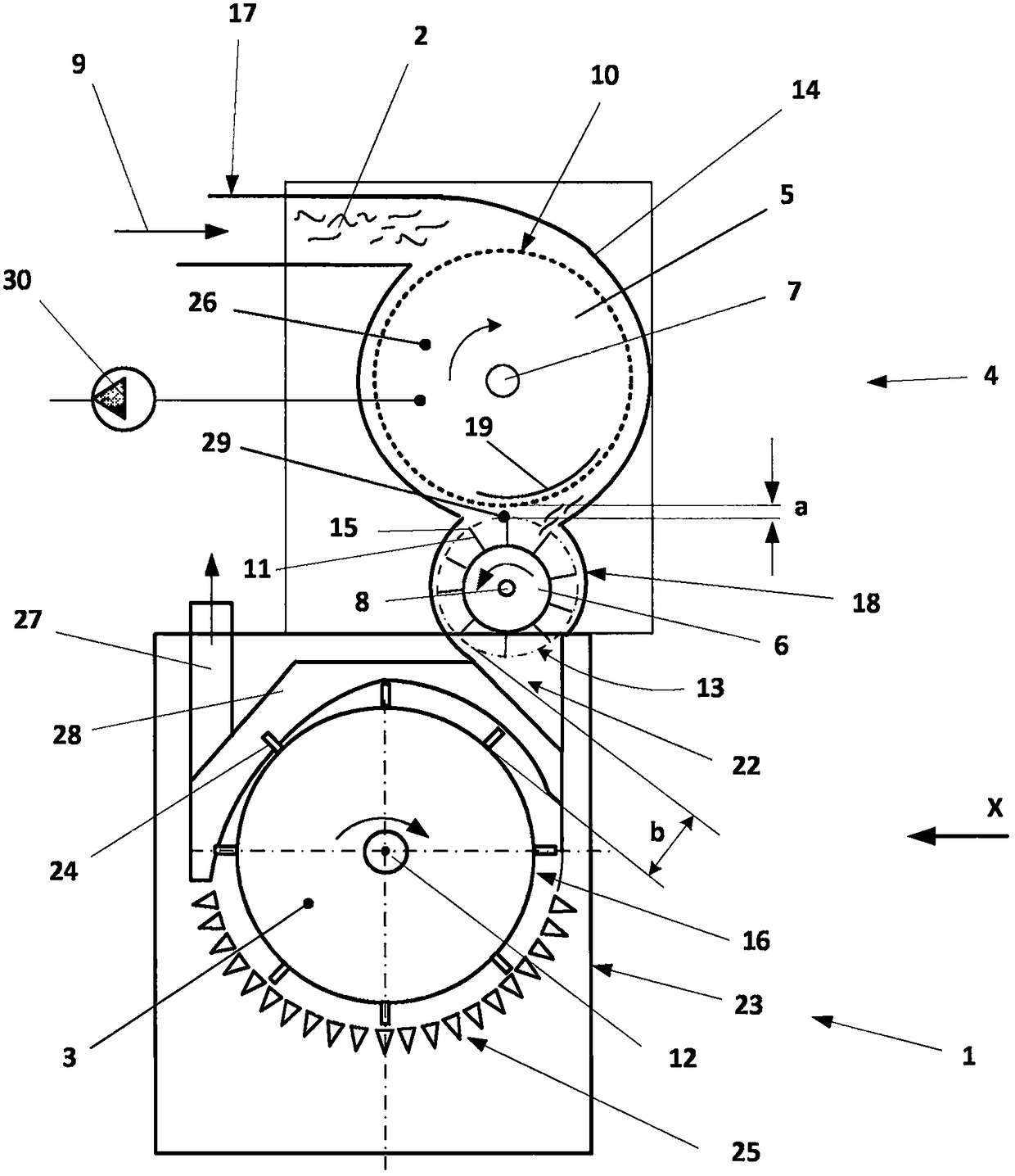

Fiber mixing and opening machine

InactiveUS7032273B2Fibre cleaning/opening by beater armsFibre cleaning/opening by toothed membersFiberMechanical engineering

A fiber blending, opening and cleaning arrangement which includes a feed section for delivering a blend of fibers onto a first opening and blending operation, comprising an array of parallel opening and blending rolls rotating in one direction and arranged along an incline and in adjacent positions. The fibers are passed over the rolls in a first direction and under the rolls in a section direction while being also moved along a sinusoid path. Upon existing the array of rolls, the fibers fall into a fine opening and blending operation which fully mixes the fibers.

Owner:PINTO AKIVA

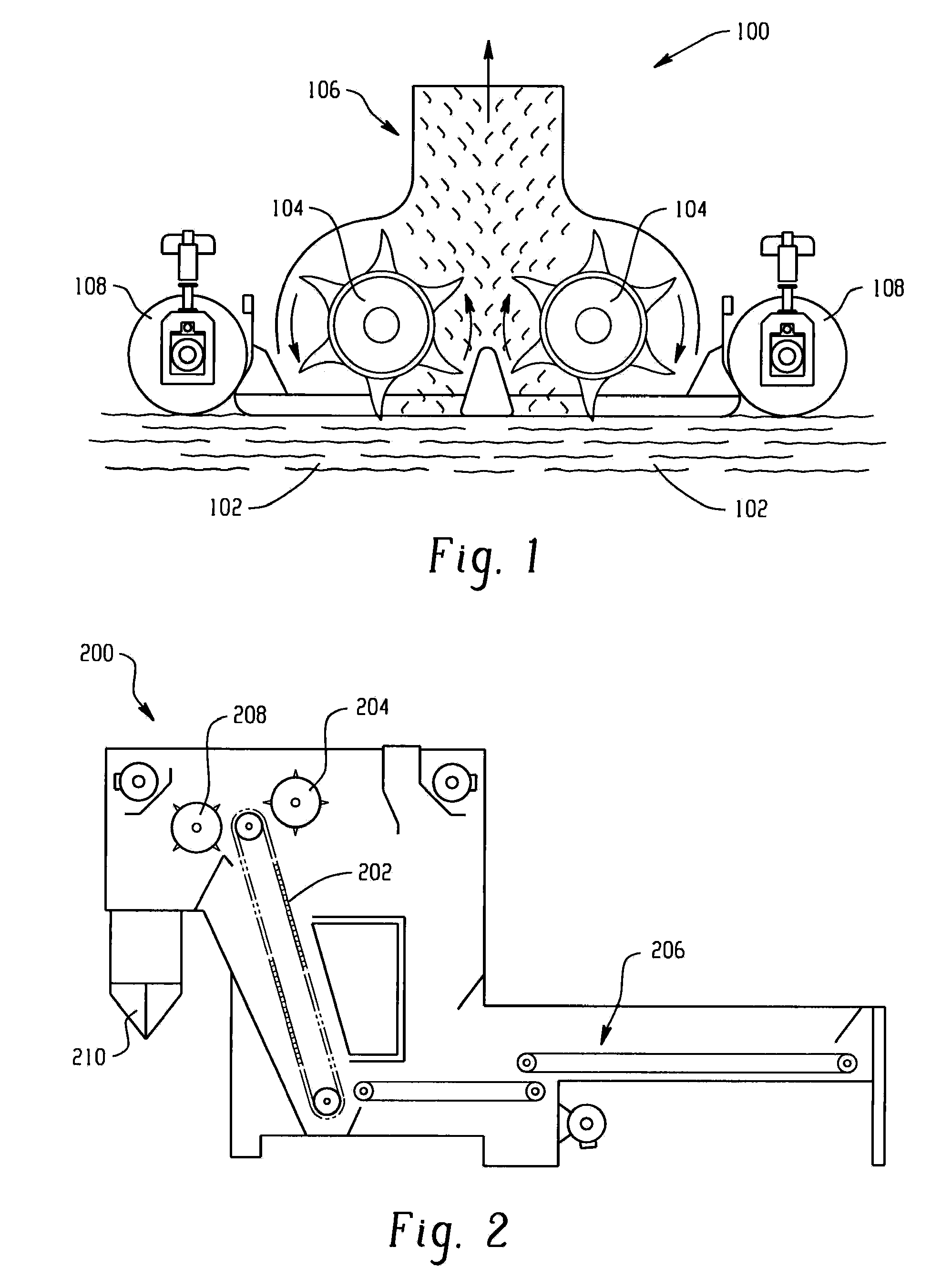

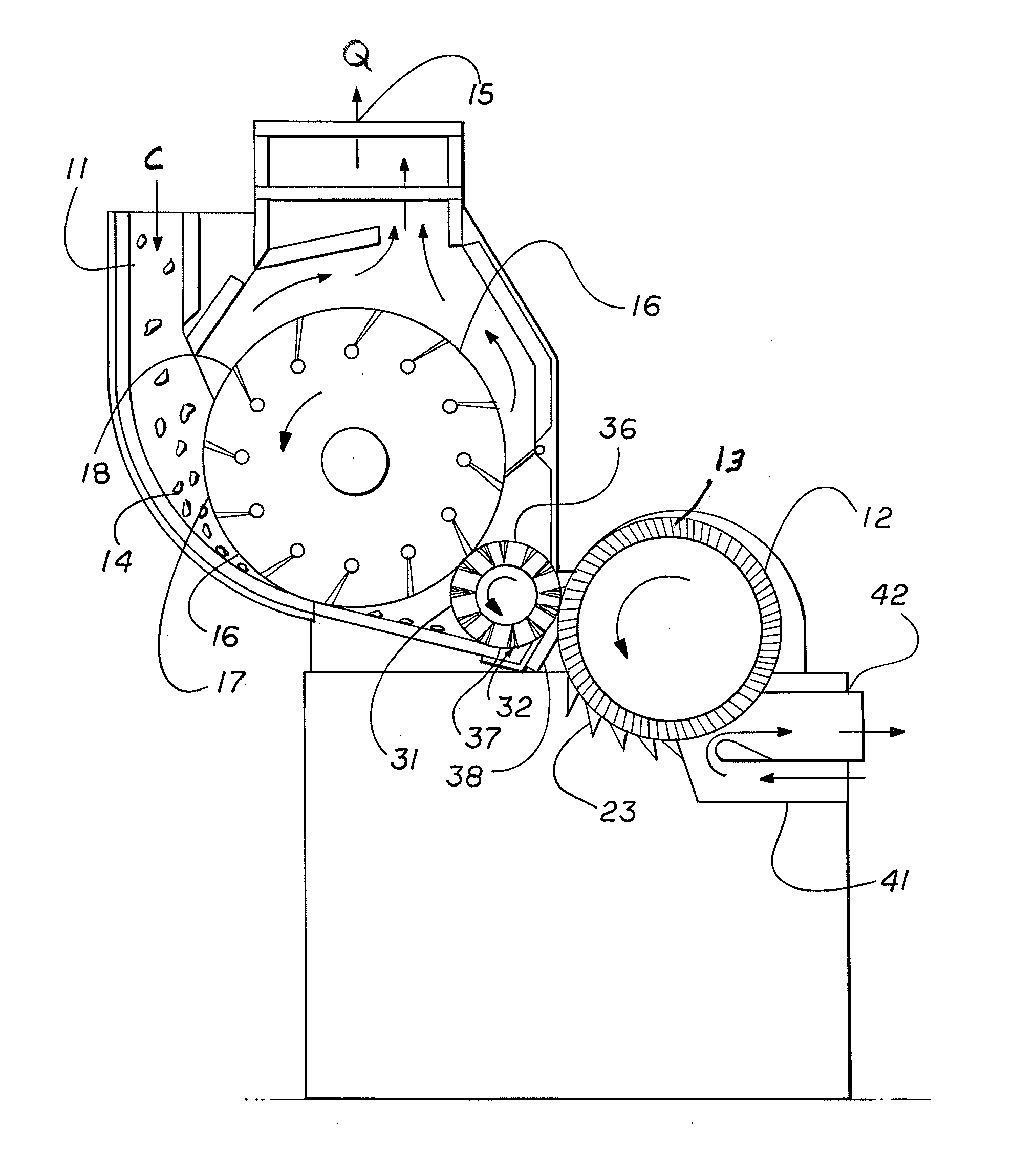

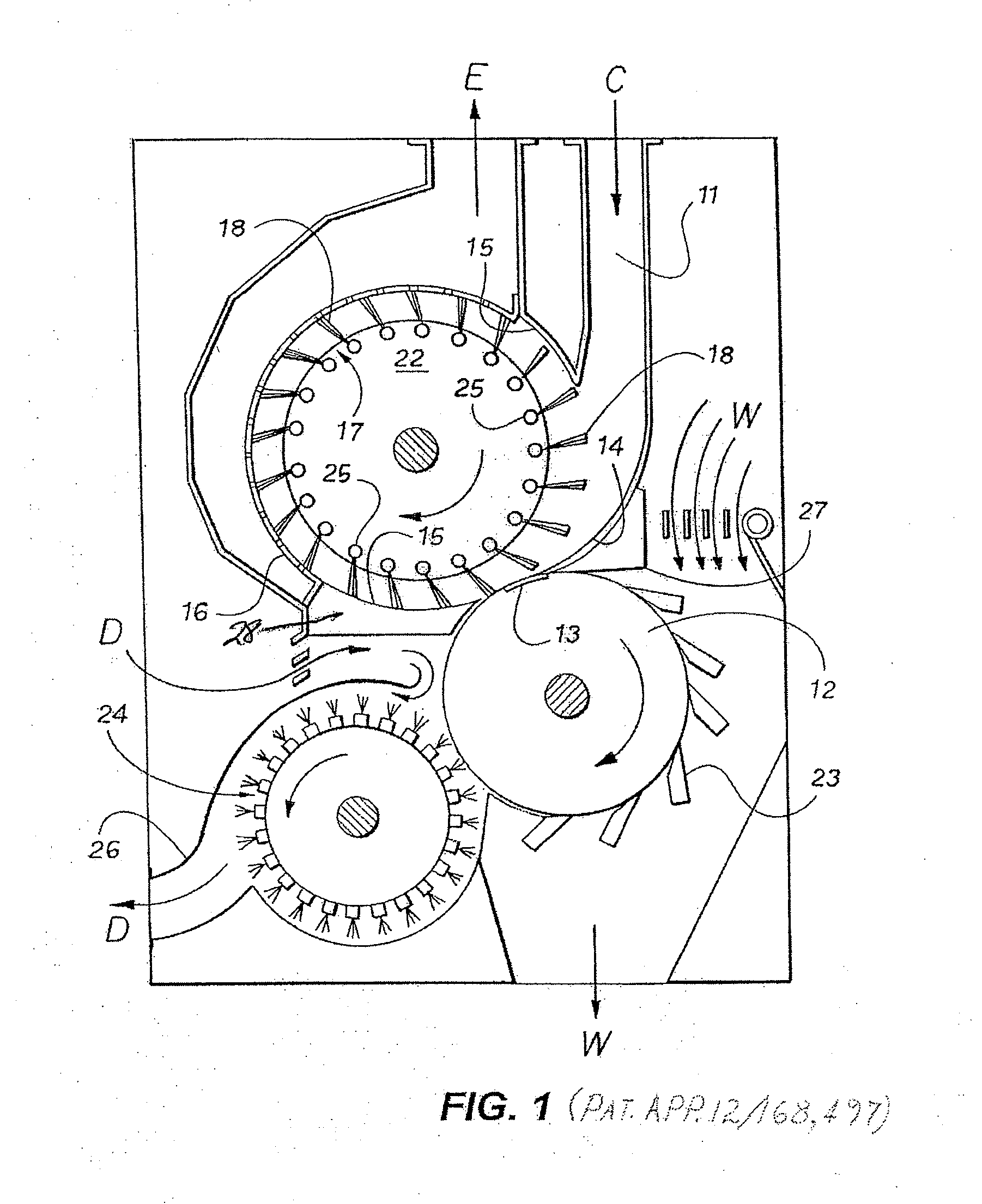

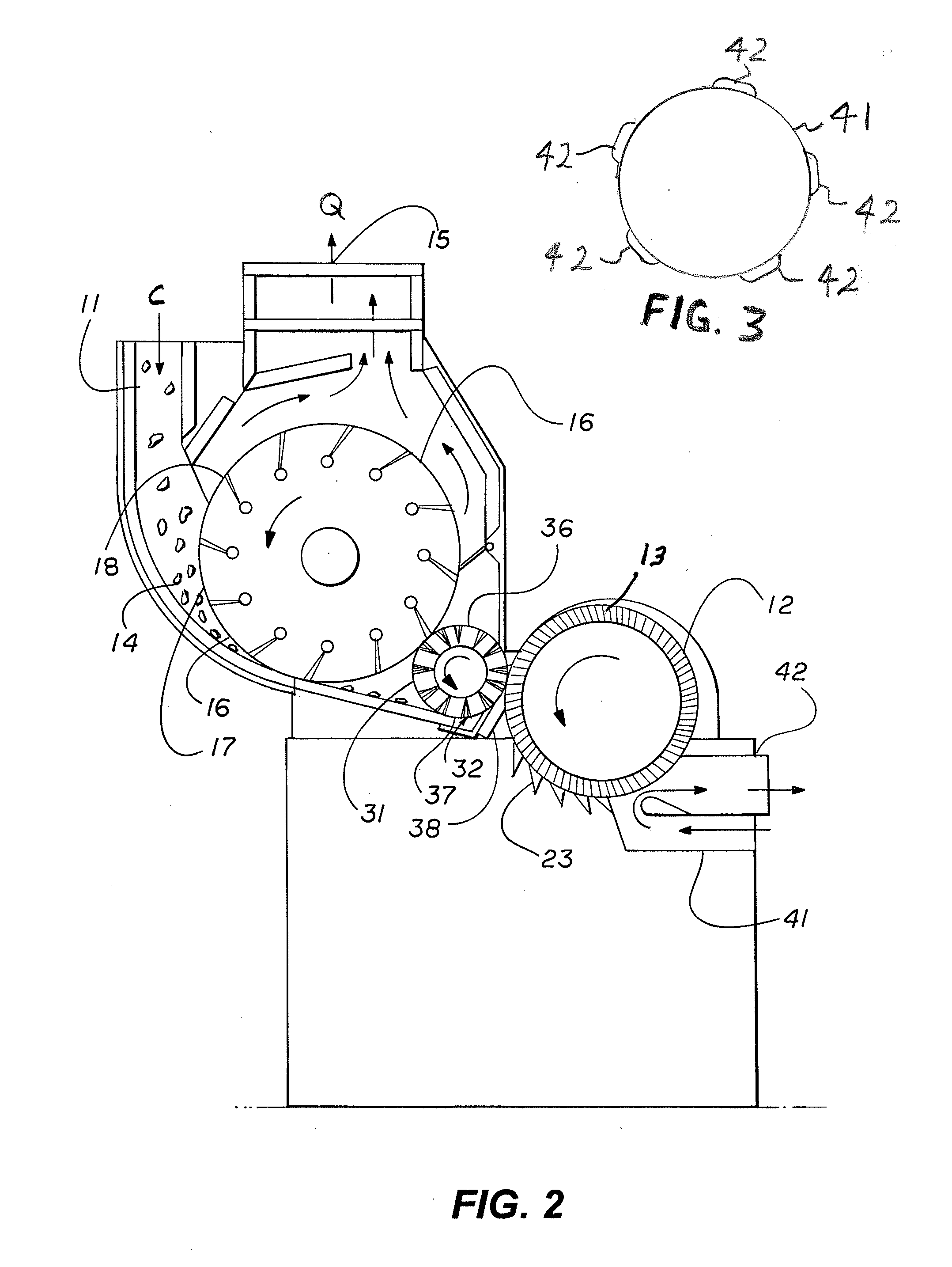

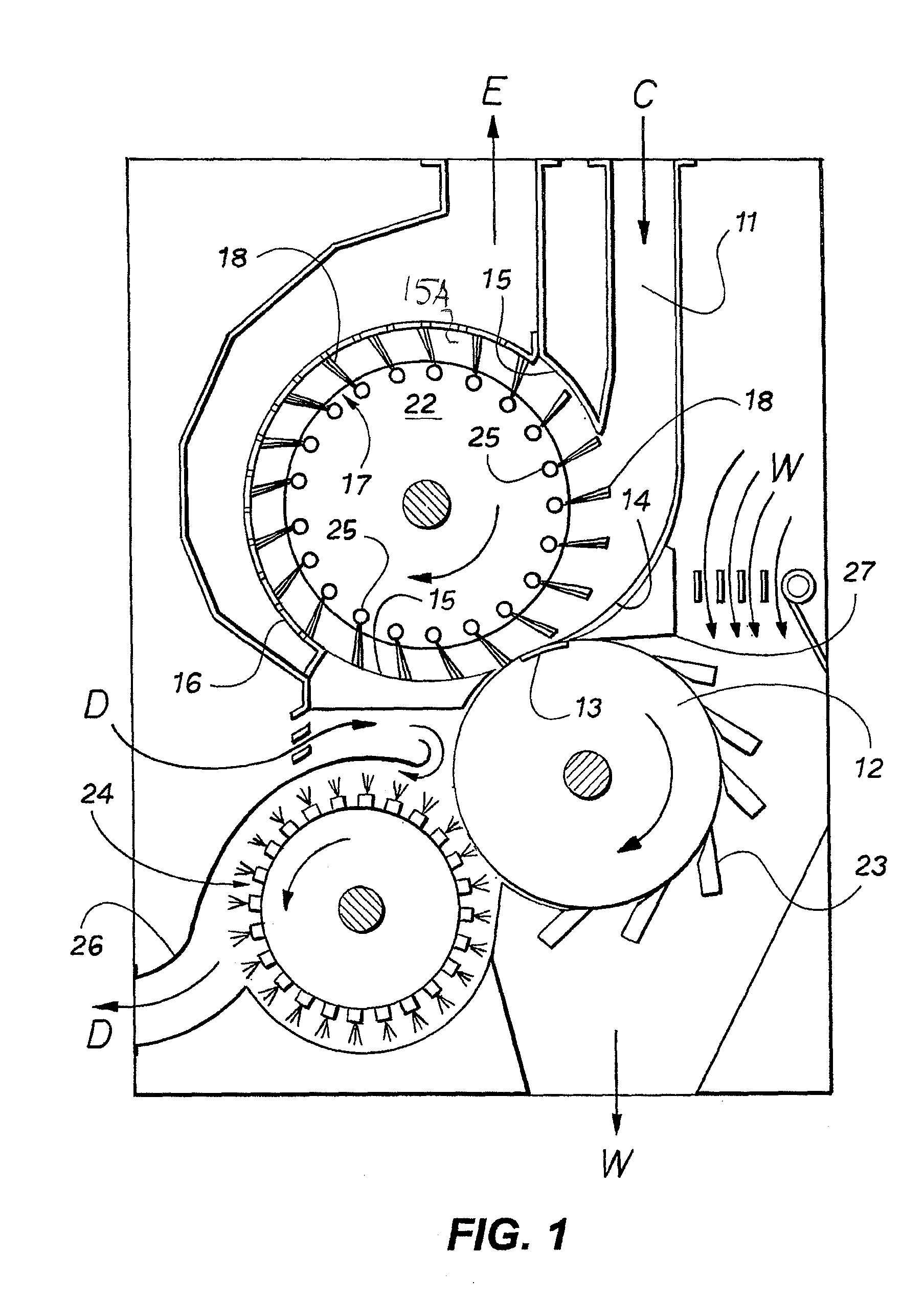

Method and Apparatus for Separating Foreign Matter From Fibrous Material

ActiveUS20090172918A1Simple methodEliminate needMechanical impurity removalLubricating devicesForeign matterFiber

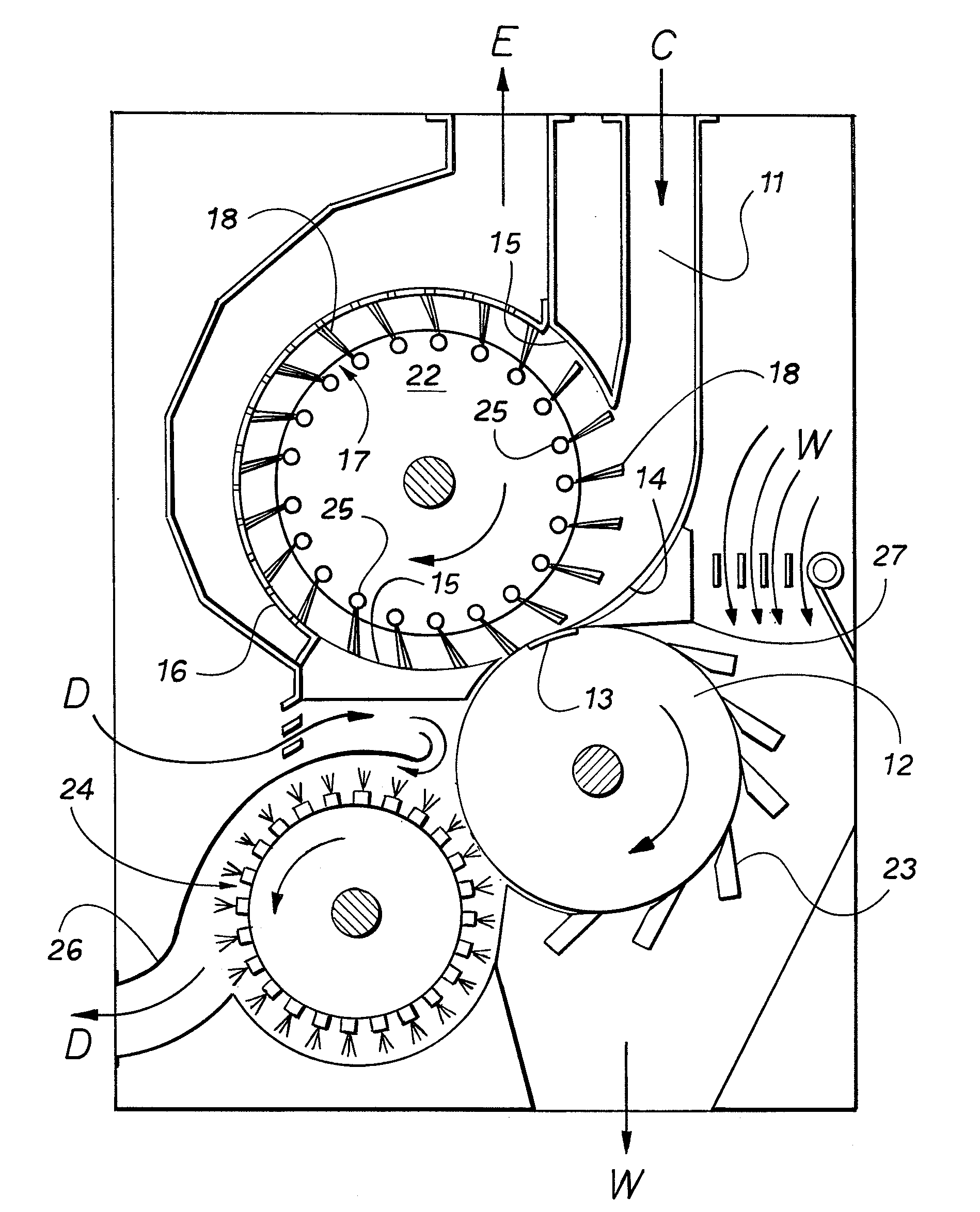

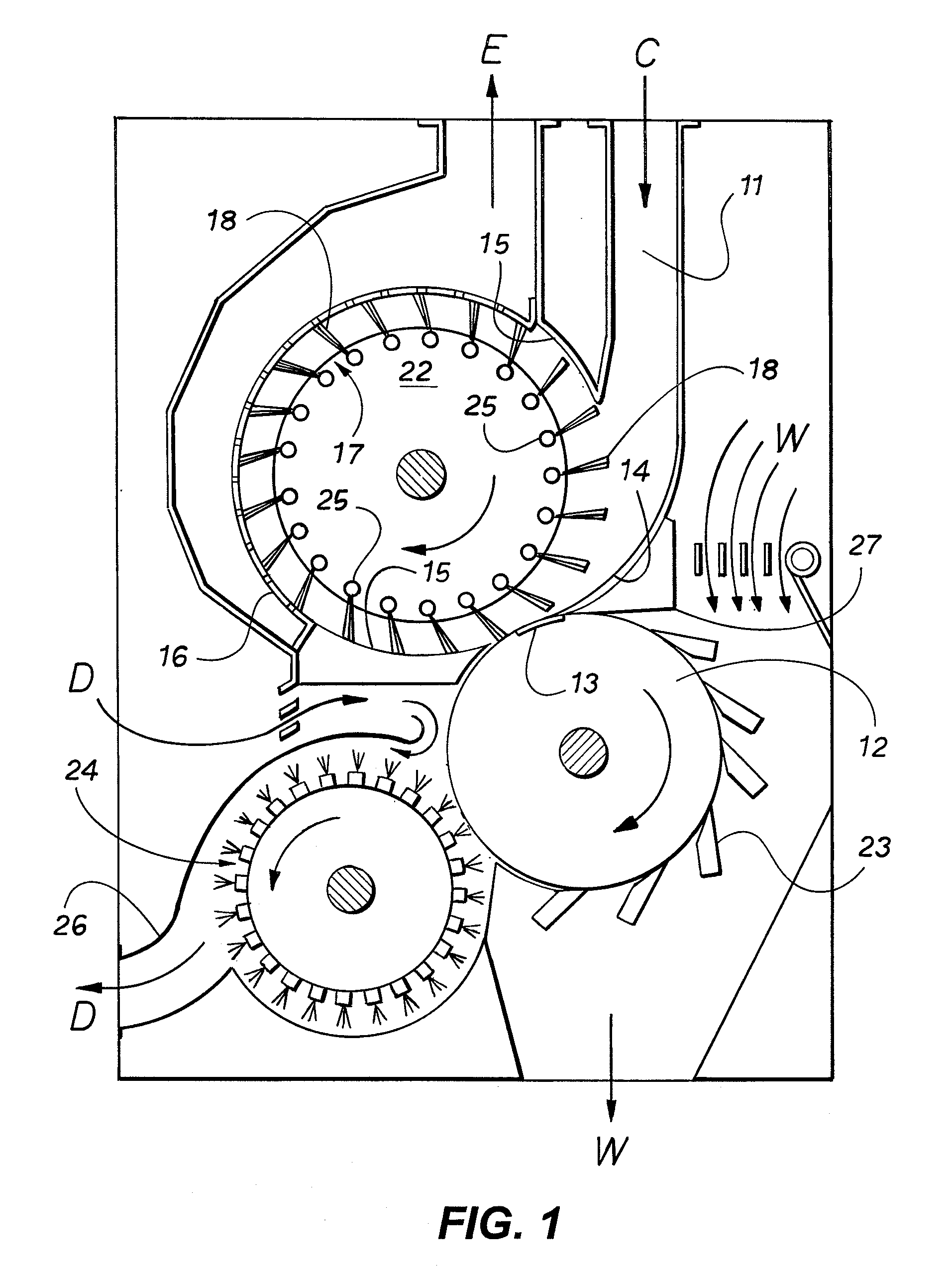

An apparatus for cleaning foreign matter from separated tufts of fiber uses a revolving open reel type structure mounted within a porous housing to separate a conveying air stream from tufts of fiber conveyed thereby and deliver the tufts to a toothed cleaning cylinder which passes beneath a plurality of cleaning bars. The open reel utilizes brush like outer surfaces to sweep tufts of fiber from the housing back into the air stream adjacent the cleaning cylinder.

Owner:LUMMUS INDS

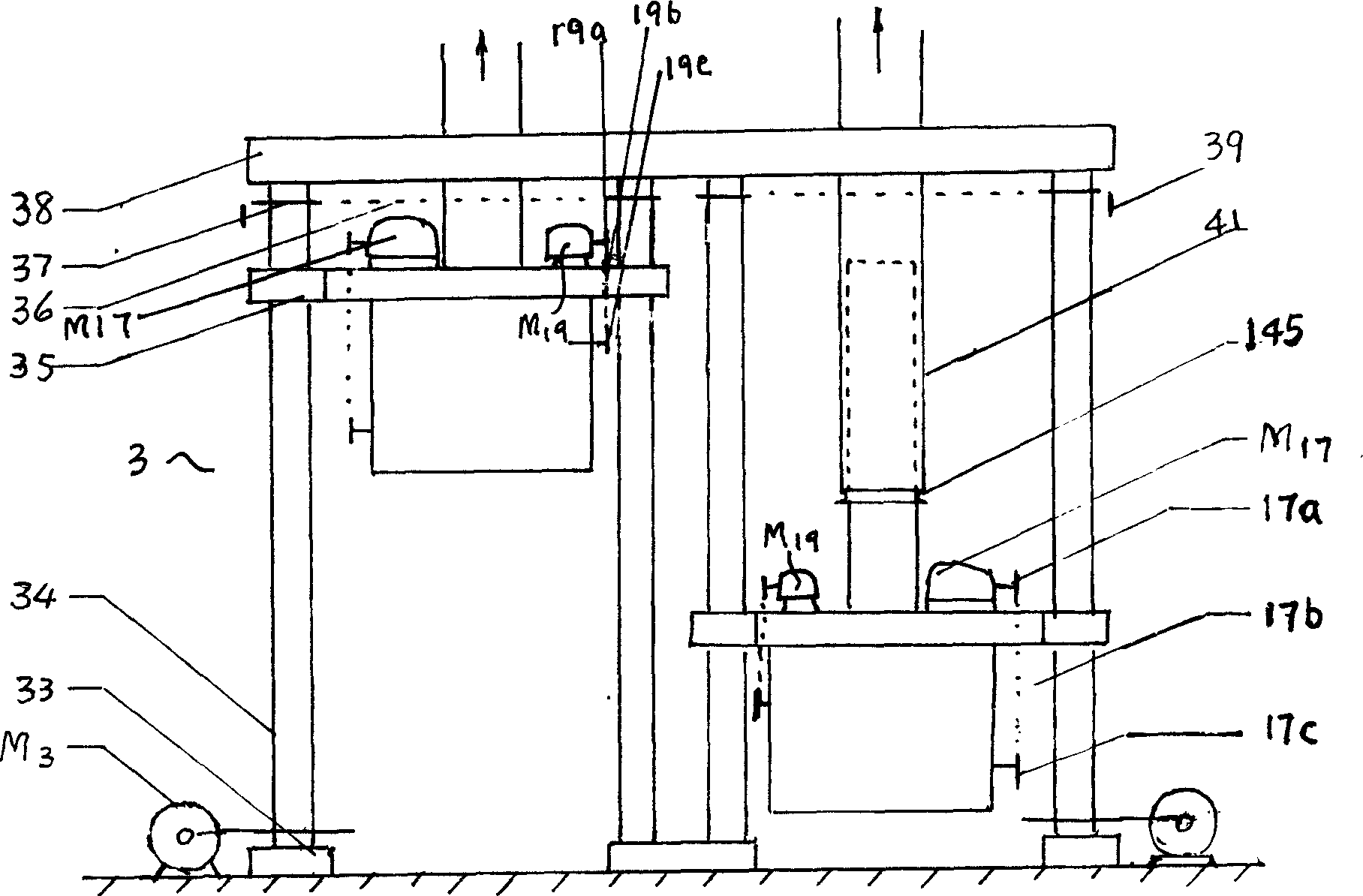

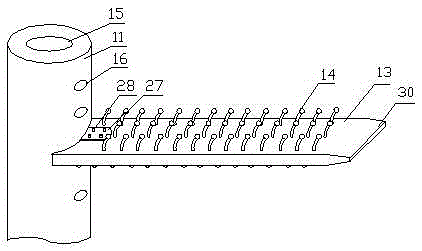

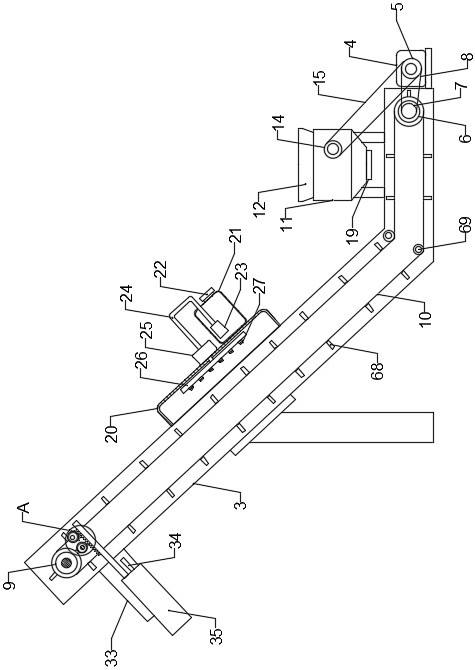

Bale plucker

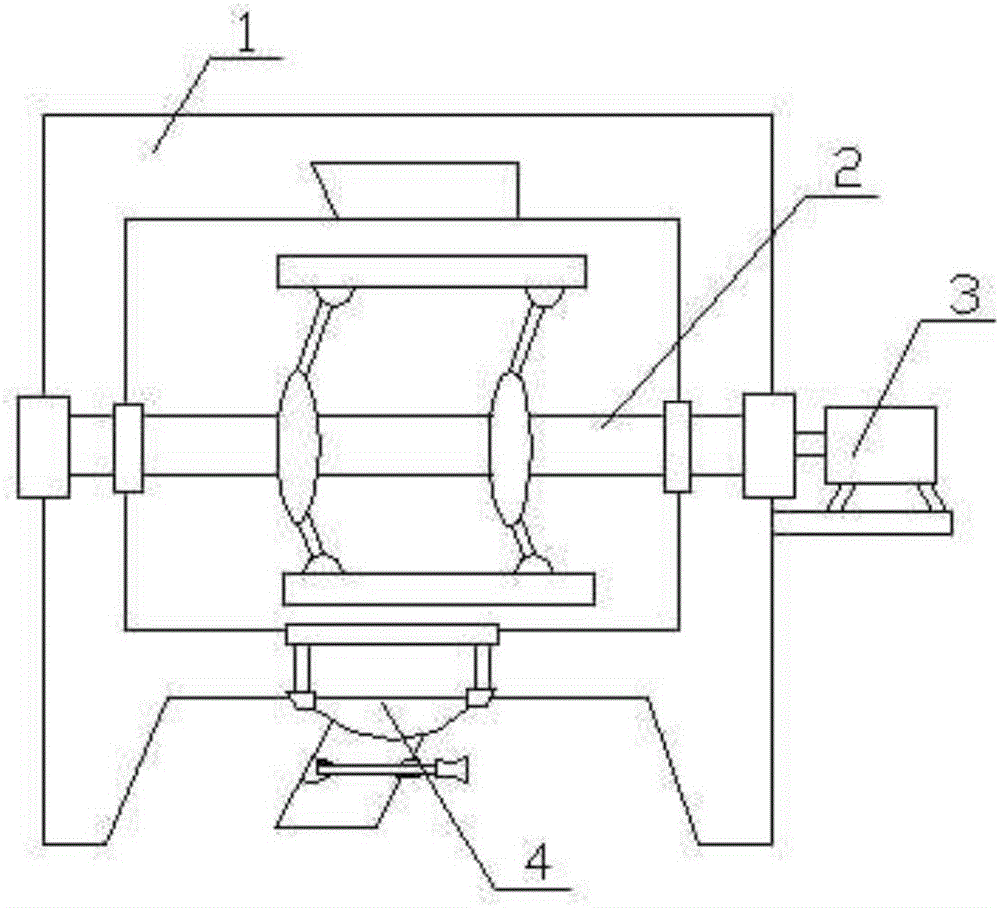

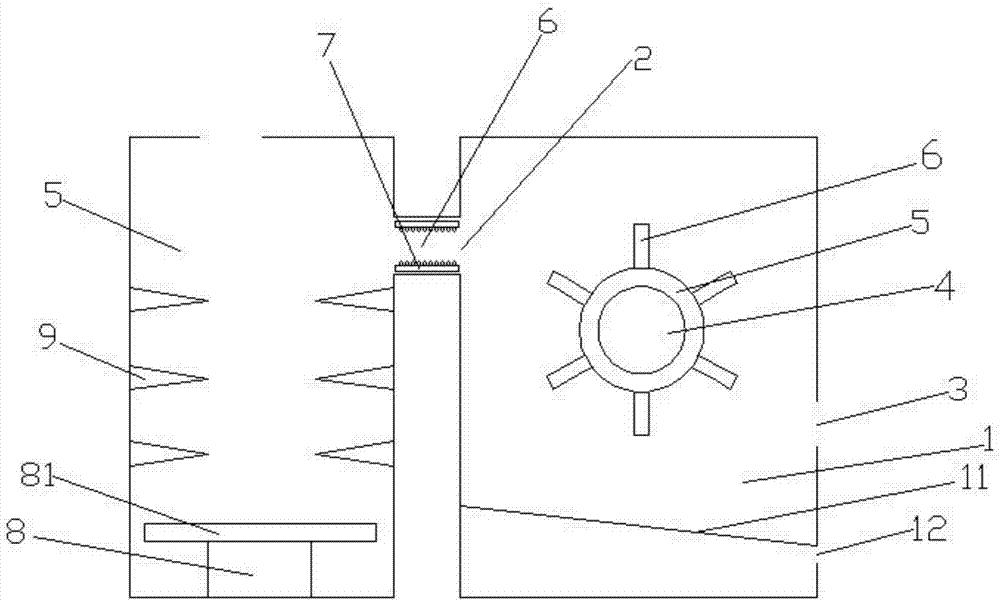

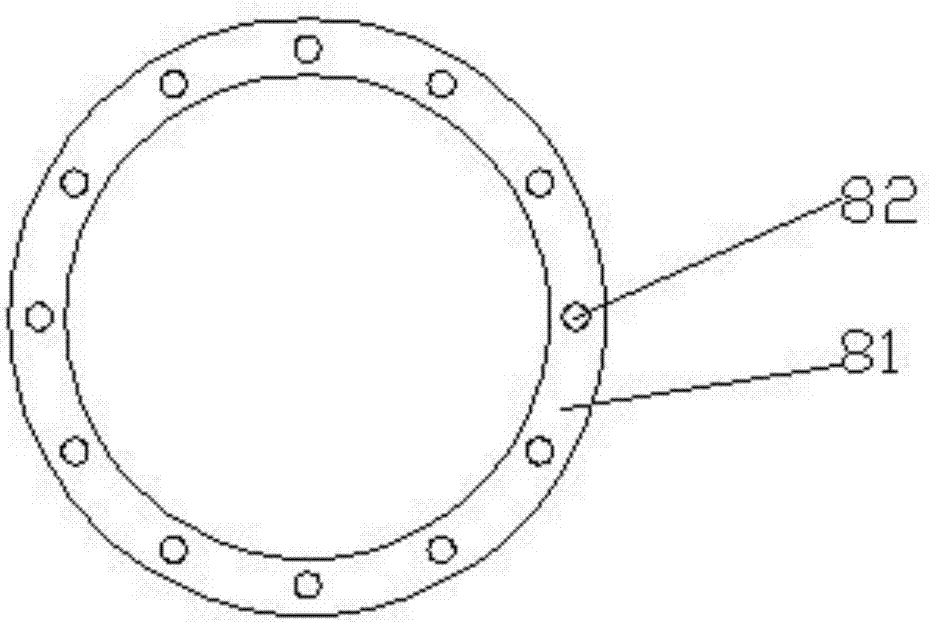

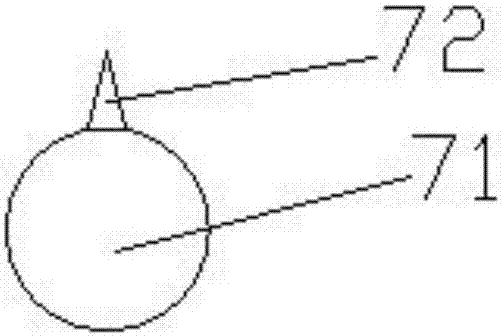

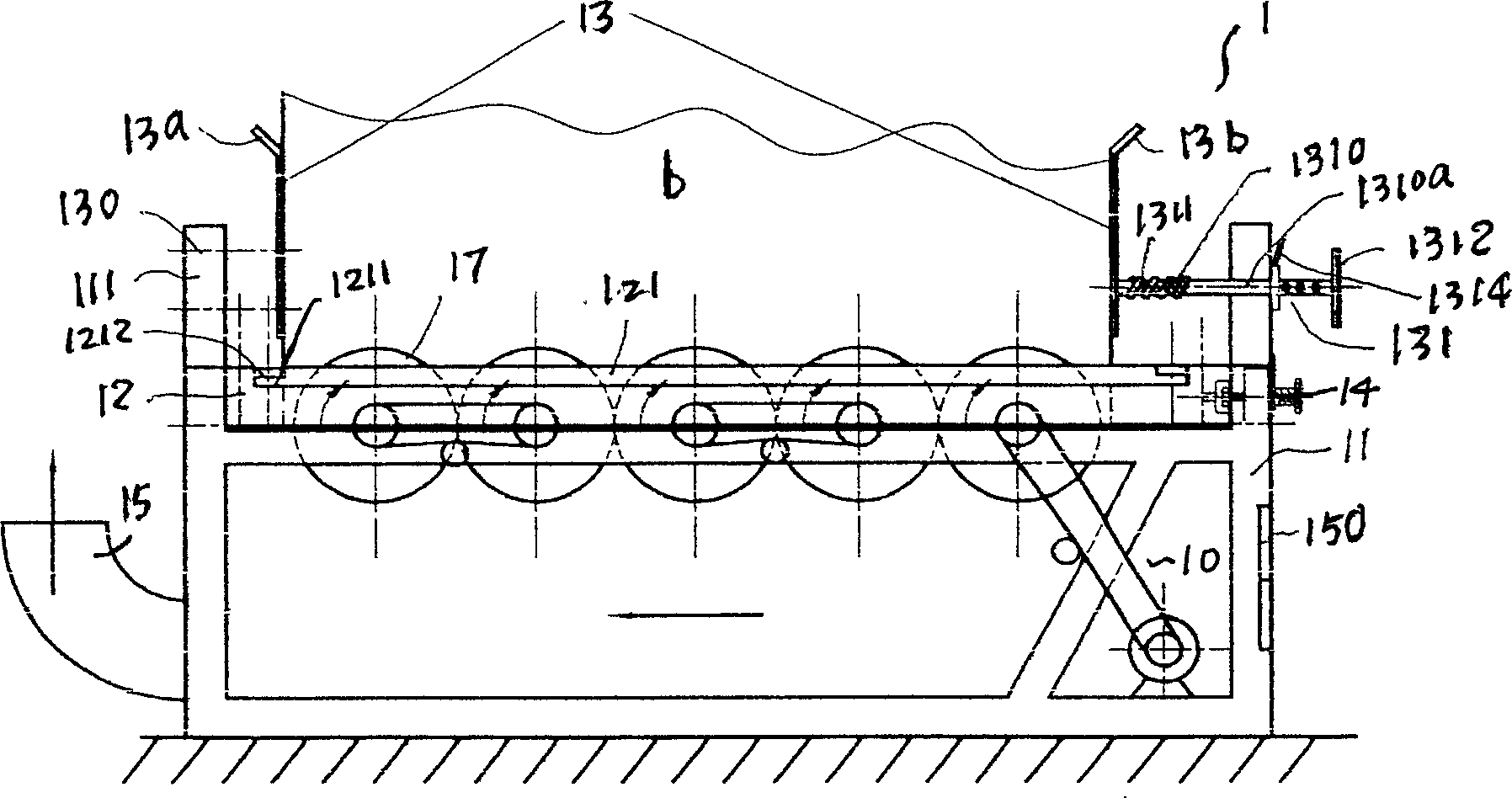

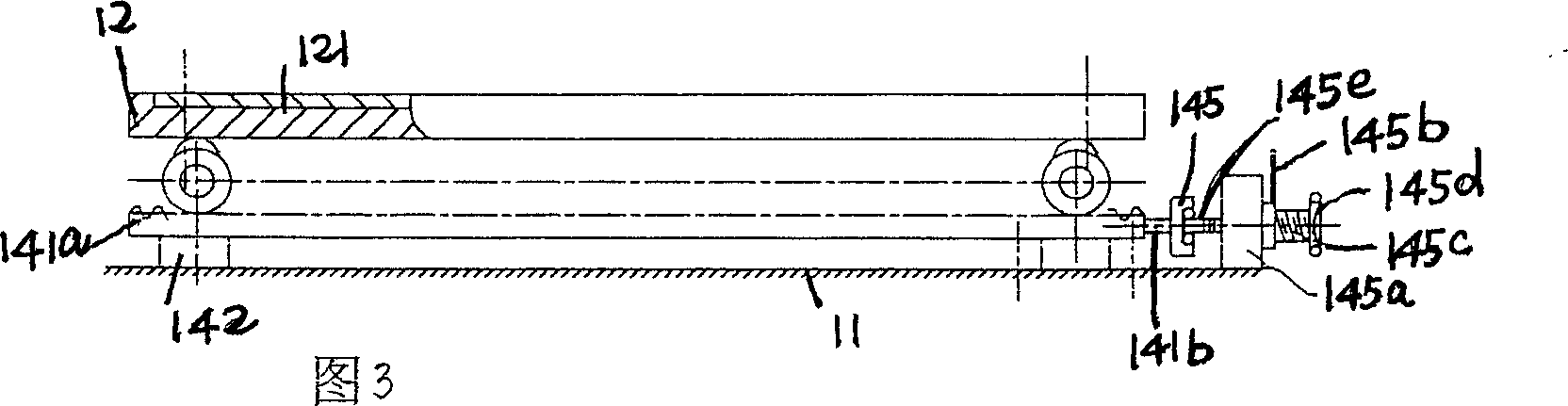

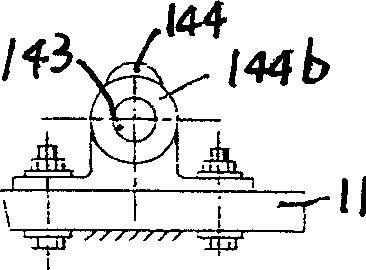

InactiveCN1508304ASignificant advantagesSignificant beneficial effectFibre cleaning and opening machine combinationsFibre cleaning/opening by beater armsFiberReciprocating motion

The invention is a package catcher, composed of the cotton catching head group linked by cotton table and cotton feeding pipe, and the riser, the cotton catching head only making lift motion and the cotton table able to move back and forth on the trolley wheel; two cotton catching heads become a group, the cotton beam output pipe and two down-inclining dropping boxes set on the case of the cotton catching head, and the cotton catching beater and purifying beater set inside the cotton catching head. The purifying beater can make on-line elimination of the impurities carried by the cotton beam such as cotton seeds, cotton scraps and so on.

Owner:吕恒正

Method and Apparatus for Separating Foreign Matter from Fibrous Material

ActiveUS20100306966A1High speed separation and cleaningSimple methodMechanical impurity removalVegetable fibre separation from seedsForeign matterFiber

An apparatus for cleaning foreign matter from separated tufts of fiber uses a transfer cylinder intermediate a revolving open reel type structure mounted within a porous housing to separate a conveying air stream from tufts of fiber conveyed thereby and a toothed cleaning cylinder to separate air flow through said revolving reel from said cleaning cylinder such that air is not drawn through said cleaning cylinder into said porous housing.

Owner:LUMMUS INDS

Sliding rail type dust-free fiber wool opener

InactiveCN105386161AWon't tangleReduce the burden onFibre cleaning/opening by air draught arrangementsFibre cleaning and opening machine combinationsFiberEngineering

The invention discloses a sliding rail type dust-free fiber wool opener which comprises an auger conveyor and a housing. A feeding port is formed in the upper portion of the housing, a discharging port is formed in the lower portion of the housing, and the housing is internally divided into a coarse opening area and a collecting area. A second motor is arranged on one side of the feeding port and connected with a stirring shaft, a stirring paddle is arranged on the stirring shaft and provided with protruding circular wool opening balls, an air channel is formed in the stirring shaft, air outlet holes are formed in the side face of the stirring shaft, an impurity area is arranged below the coarse opening area, at least two sets of wool outlet holes in the vertical direction are formed in the side face of the coarse opening area, vertical rails are arranged on the side face of the collecting area, wool loosening blocks are connected to the rails, wool loosening hooks are arranged on the side faces of the wool loosening blocks and are in an anchor type, air nozzles facing inwards are arranged on the side face of the housing, a suction fan is arranged on the outer side of the discharging port, and a control box is arranged on the outer side of the housing. Materials produced through the sliding rail type dust-free fiber wool opener are fluffy, fine and soft, the burden of equipment is small, production efficiency is high, the phenomenon that many materials are wound on the inner wall of the wool opener can be avoided, and thus the service life is long.

Owner:盐城瑞德棉业有限公司

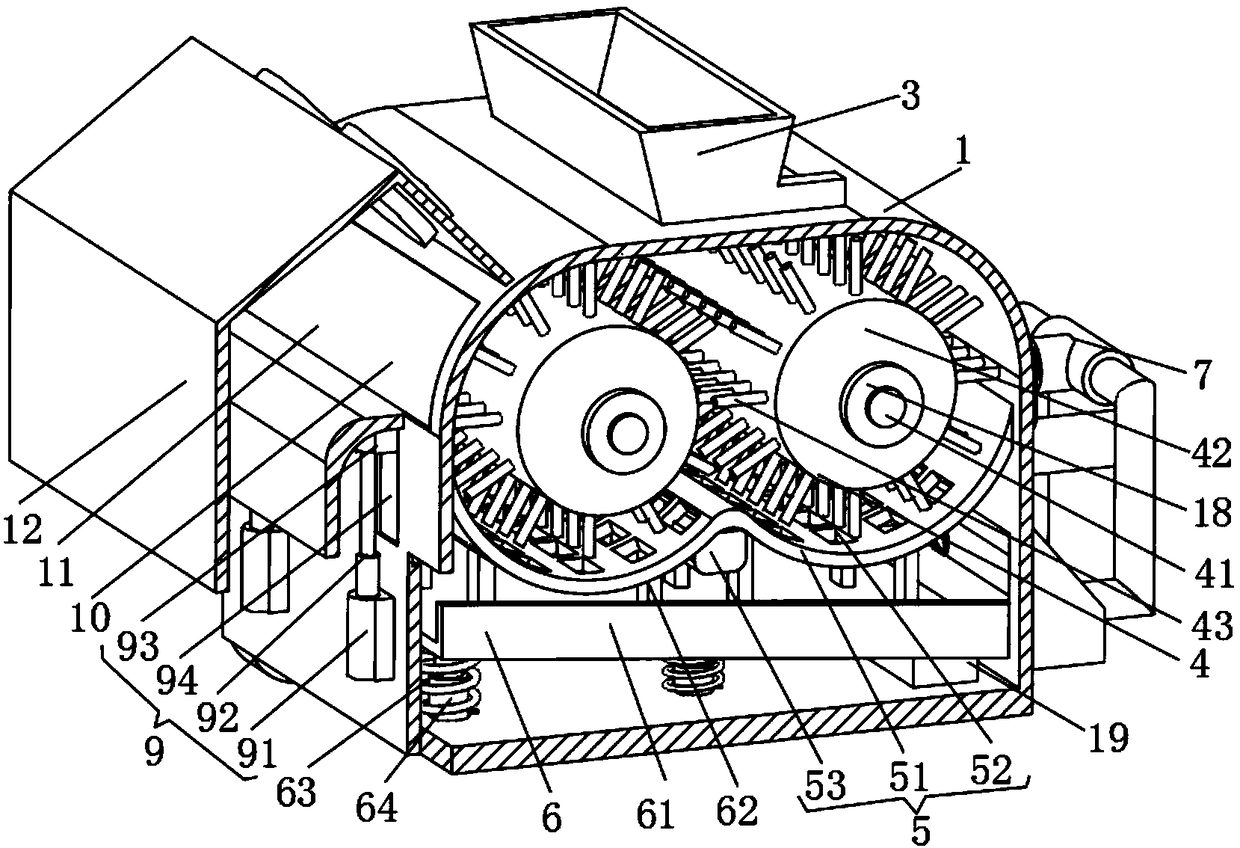

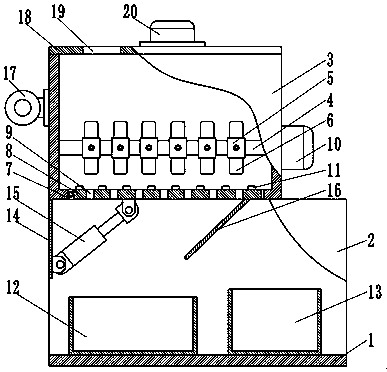

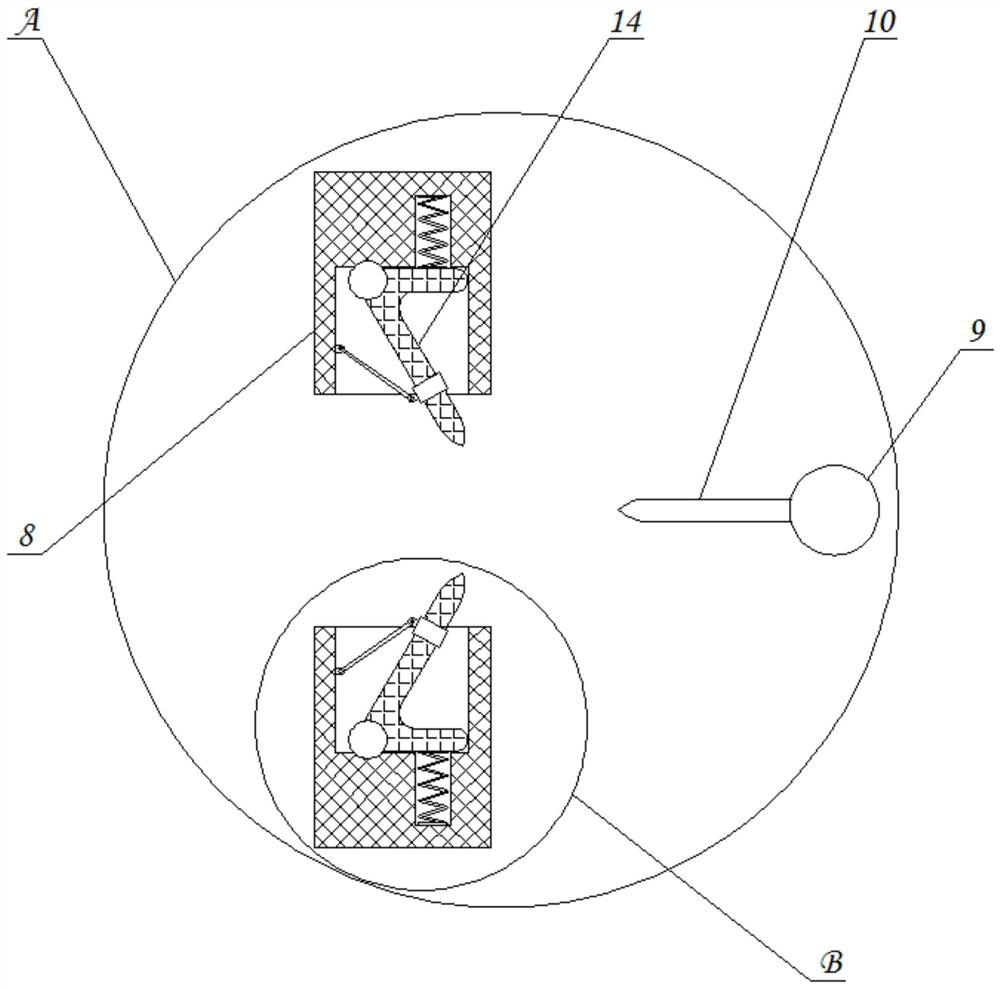

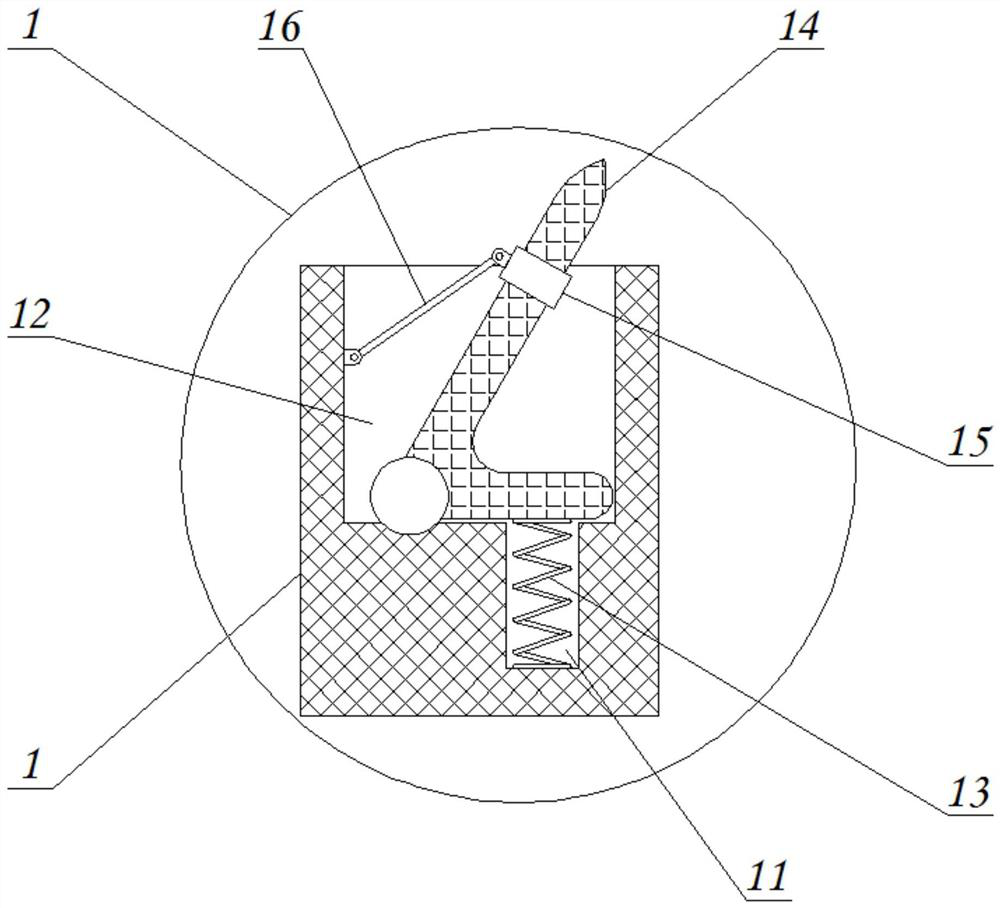

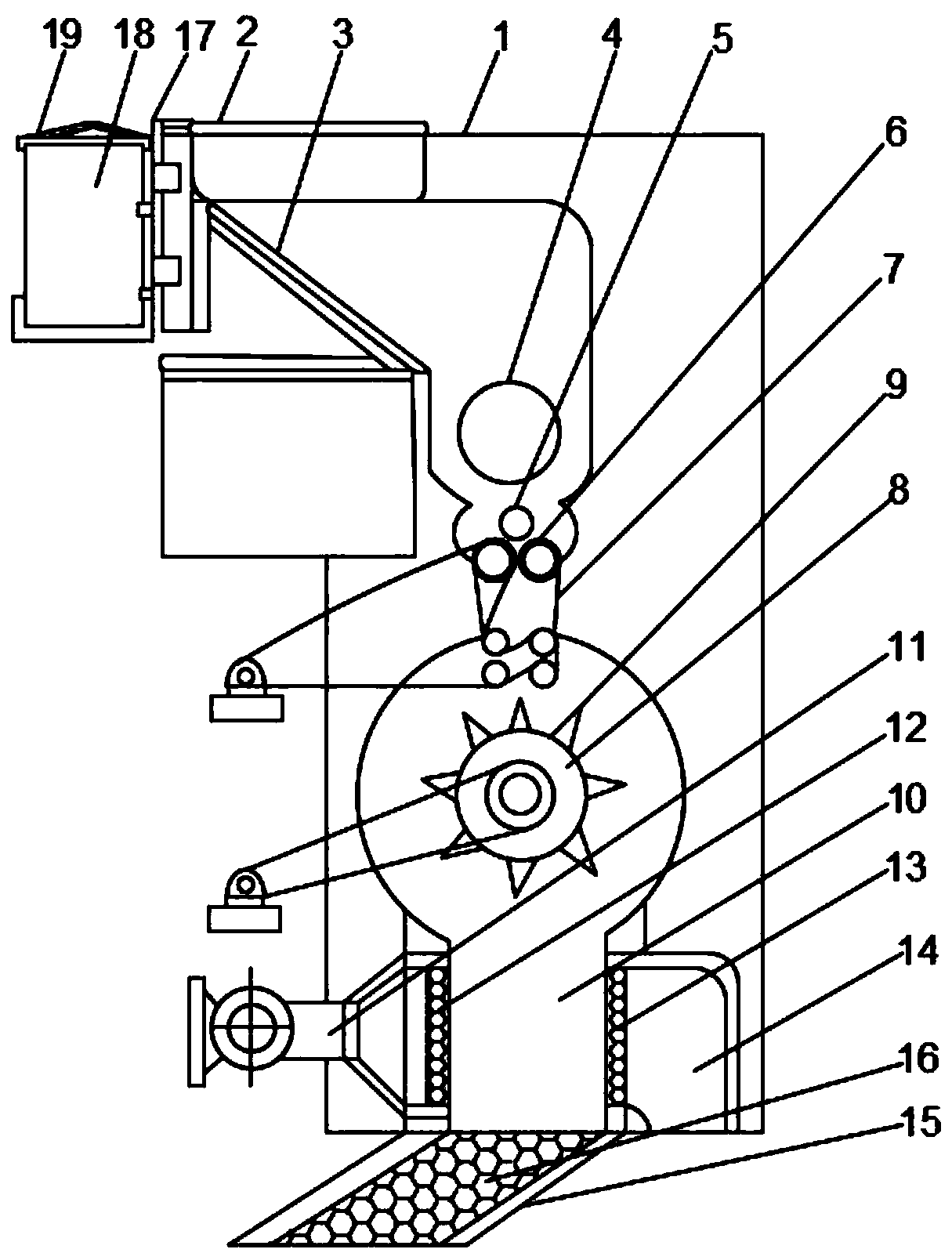

Automatic cotton cleaner with high cotton cleaning efficiency

InactiveCN108708003APrevent throwingImprove securityFibre cleaning/opening by beater armsFibre cleaning/opening machinesEngineeringCaster

The invention discloses an automatic cotton cleaner with high cotton cleaning efficiency. The automatic cotton cleaner comprises a shell body, four castors are rectangularly arranged at the lower endsof the side surfaces of the shell body, a rectangular feeding port is formed in the middle of the upper surface of the shell body, a feeding device is arranged on the upper surface of the shell bodycorresponding to the rectangular feeding port, the lower end of a feeding hopper of the feeding device is connected with the rectangular feeding port, two symmetric cotton cleaning devices are arranged at the inner upper end of the shell body, and a driving device is arranged on the rear surface of the shell body corresponding to rotating shafts of the cotton cleaning devices. According to the automatic cotton cleaner with the high cotton cleaning efficiency, impurities in cotton can be cleaned, impurity cleaning speed can be adjusted, the impurities can be recycled in a concentrated manner, environmental pollution caused by the impurities is prevented, cotton bales can be opened, subsequent processing of the cotton is facilitated, working efficiency can be effectively improved, and time is saved.

Owner:林峰

Four-roller raw cotton opening and impurity removal device for textiles

ActiveCN110396734AHave the effect of hittingAvoid wrappingFibre cleaning and opening machine combinationsFibre cleaning/opening by beater armsPulp and paper industryImpurity

The invention provides a four-roller raw cotton opening and impurity removal device for the textiles and relates to the technical field of cotton thread spinning. The four-roller raw cotton opening and impurity removal device for the textiles comprises a frame, opening stirring rollers are fixedly connected into the frame, and a first filtering plate is fixedly installed on the portion, below theopening stirring roller, in the frame; a second filtering plate is fixedly connected to the portion, below the first filtering plate, in the frame, a draught fan is fixedly connected to the left sideof the frame, a dust collection box is arranged at the bottom of the second filtering plate, and a finished product collection box is arranged at the right side of the frame. According to the four-roller raw cotton opening and impurity removal device for the textiles, when raw cotton is stirred and pulled, the effect of hitting the raw cotton can also be achieved, the opening effect is improved, separation of impurities from dust is accelerated, in the rotation process, stirring rods can retract, the situation is avoided that the raw cotton winds the stirring rollers, cotton batting which leaks down can be recycled again, and waste of the raw cotton is avoided.

Owner:杭州余杭丝绸制造有限公司

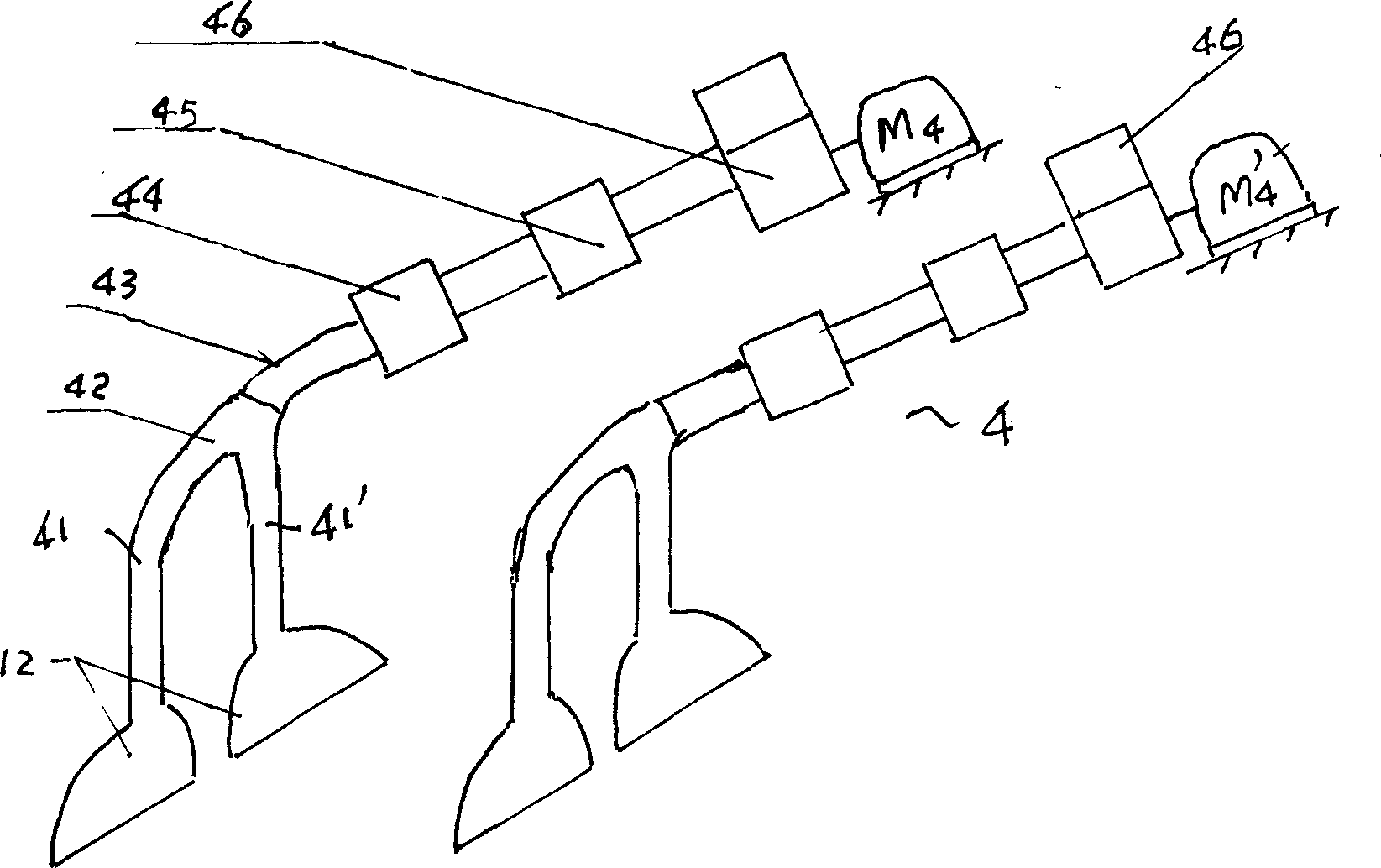

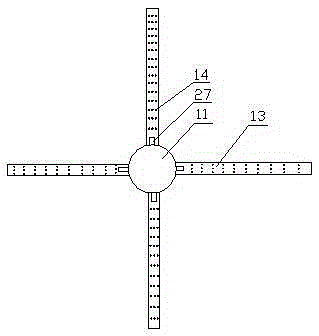

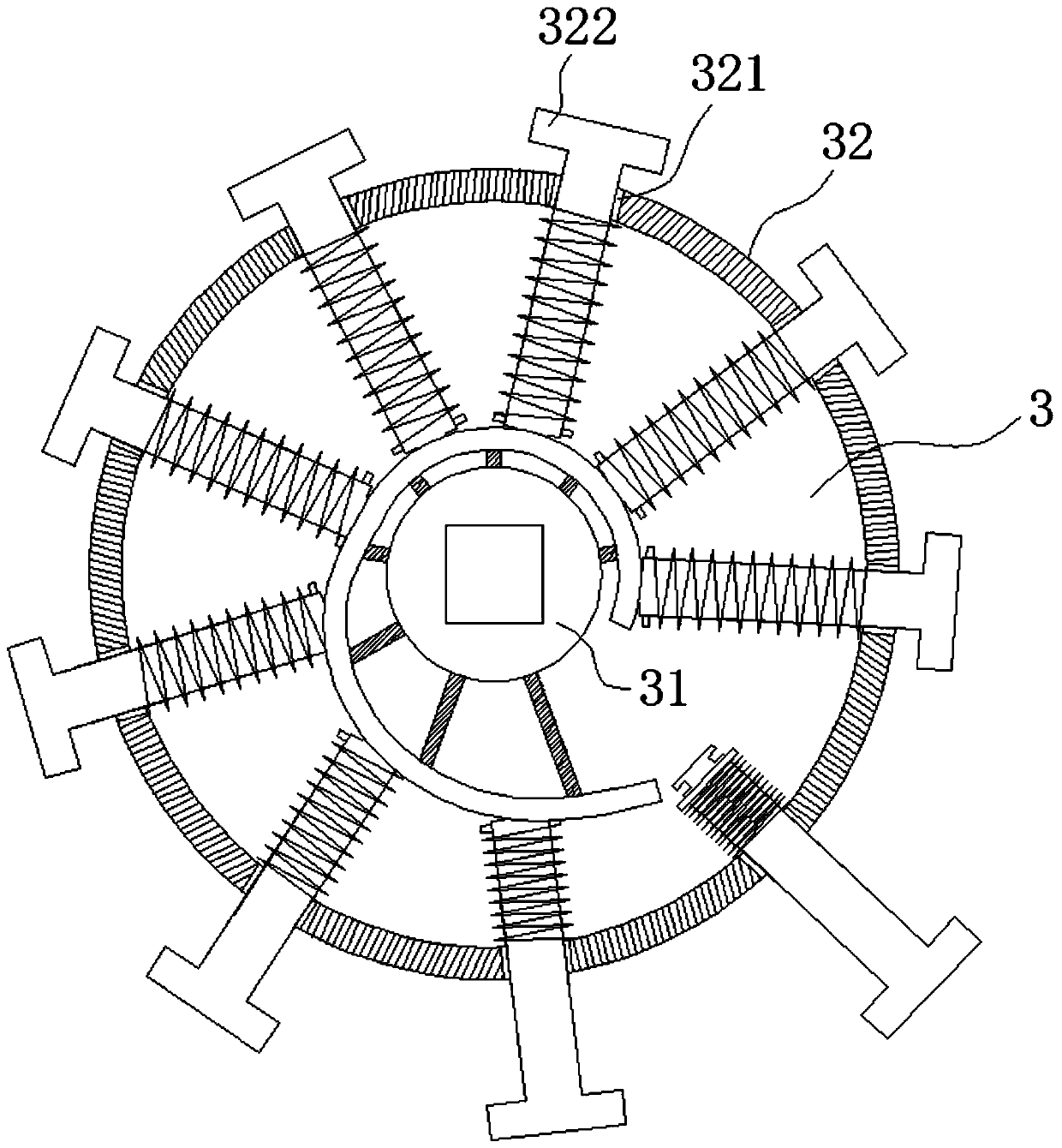

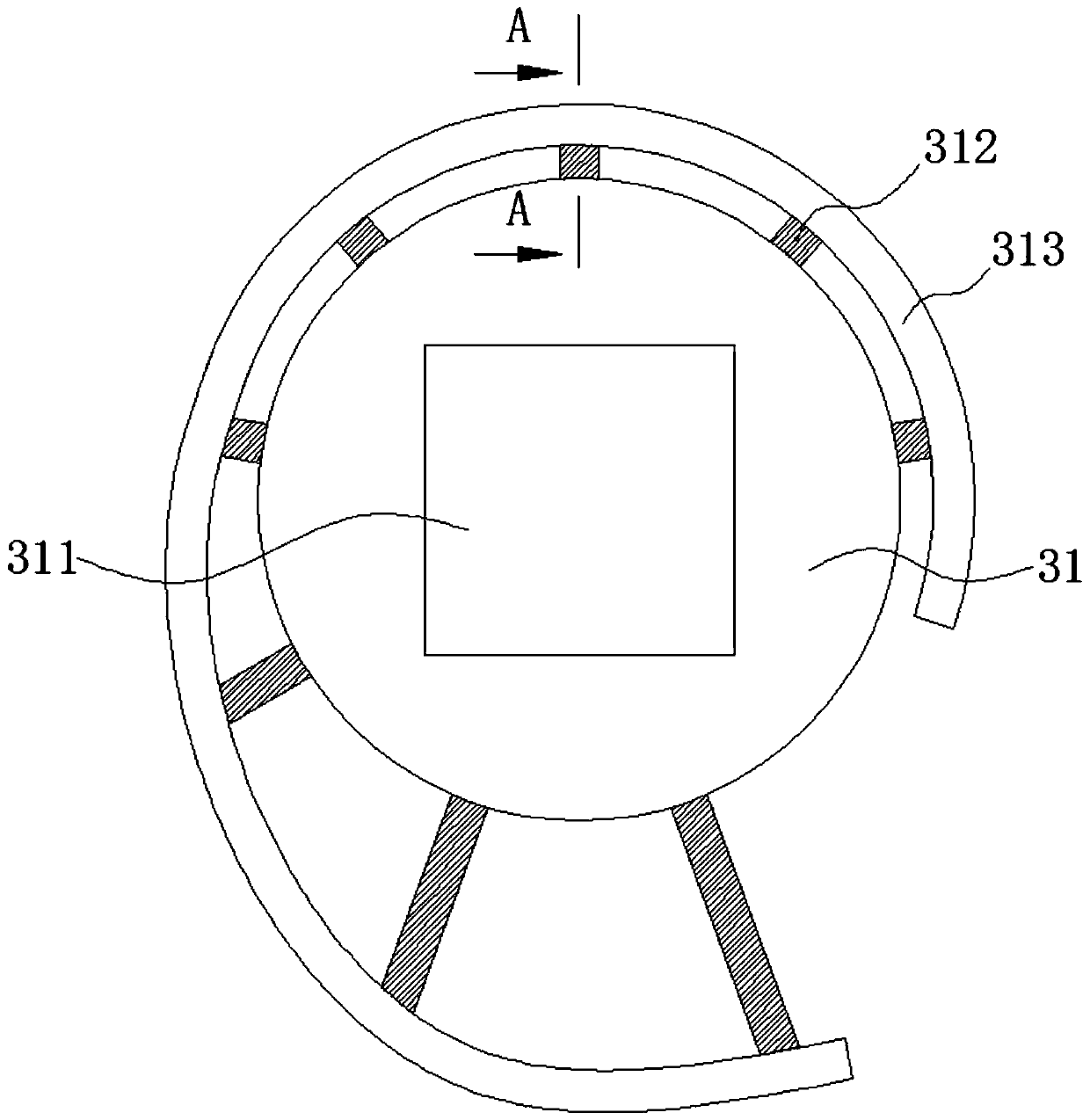

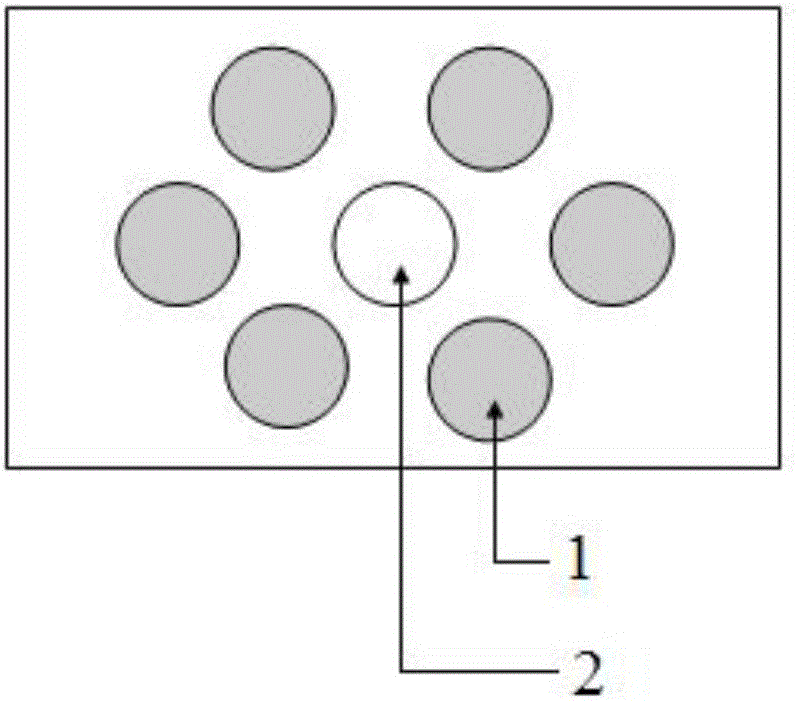

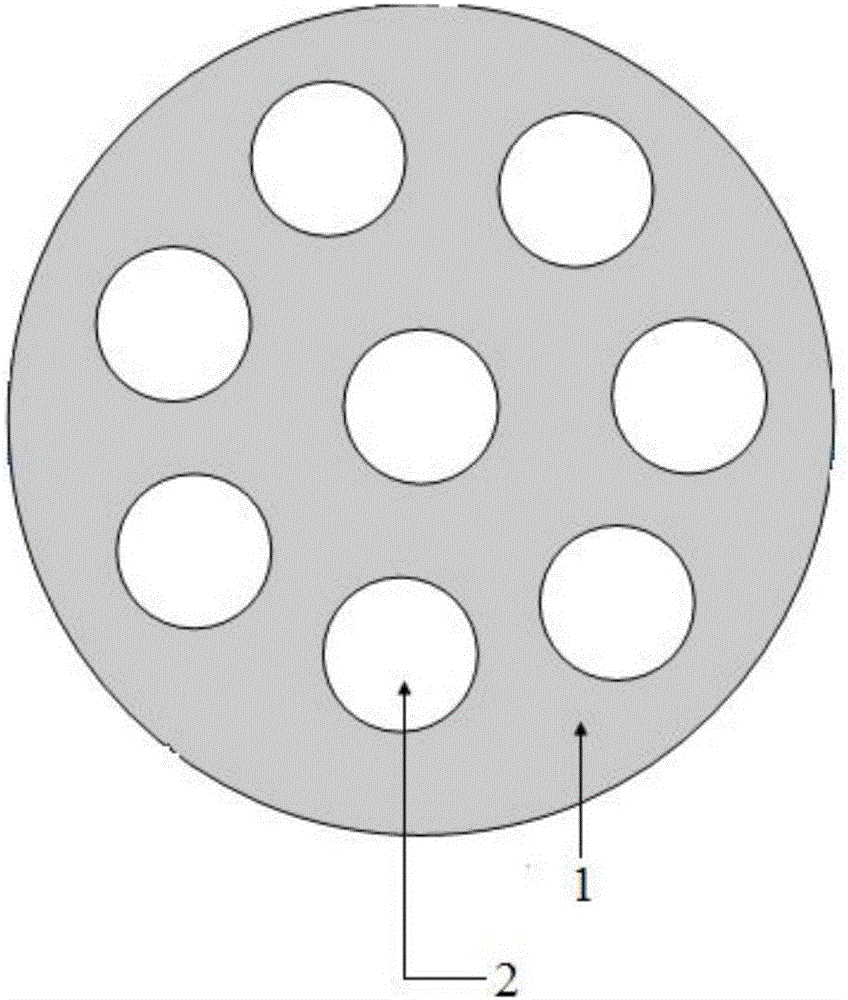

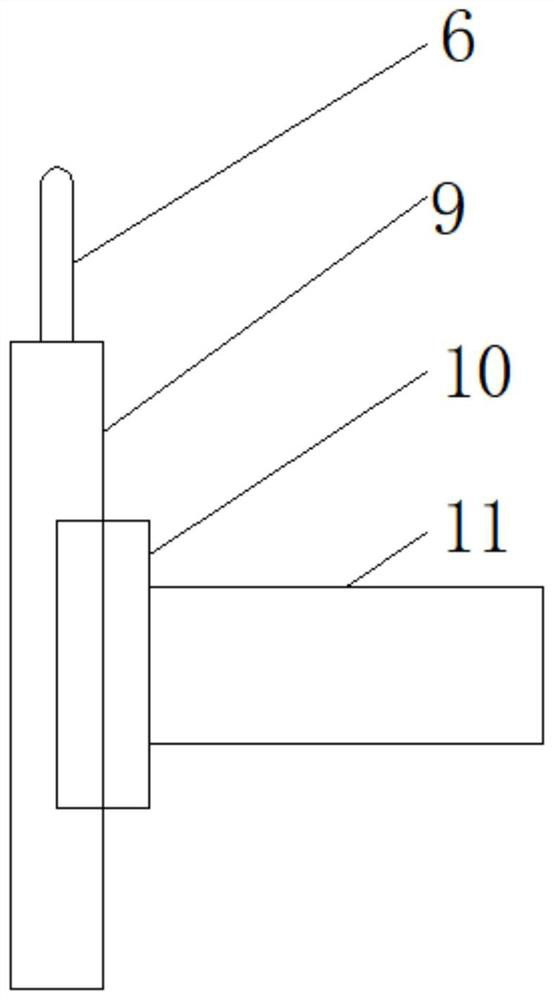

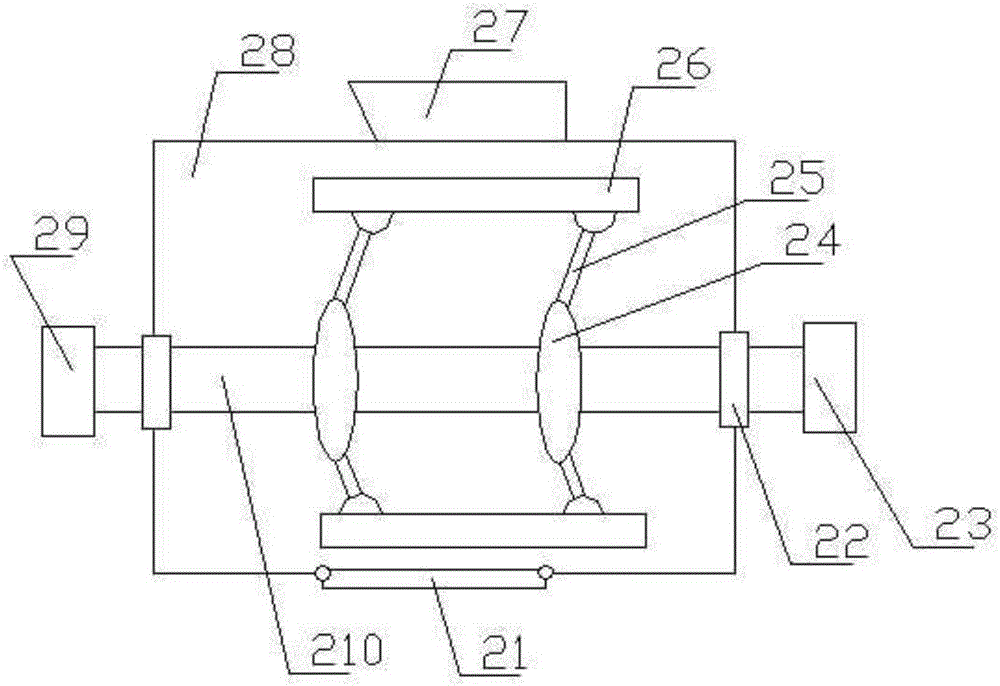

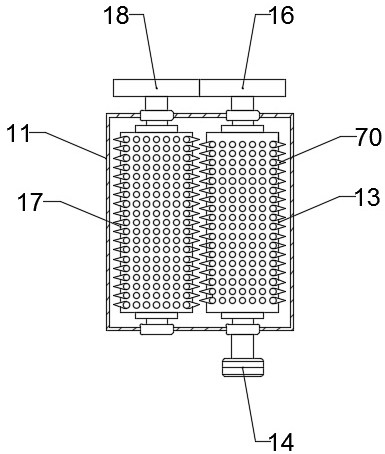

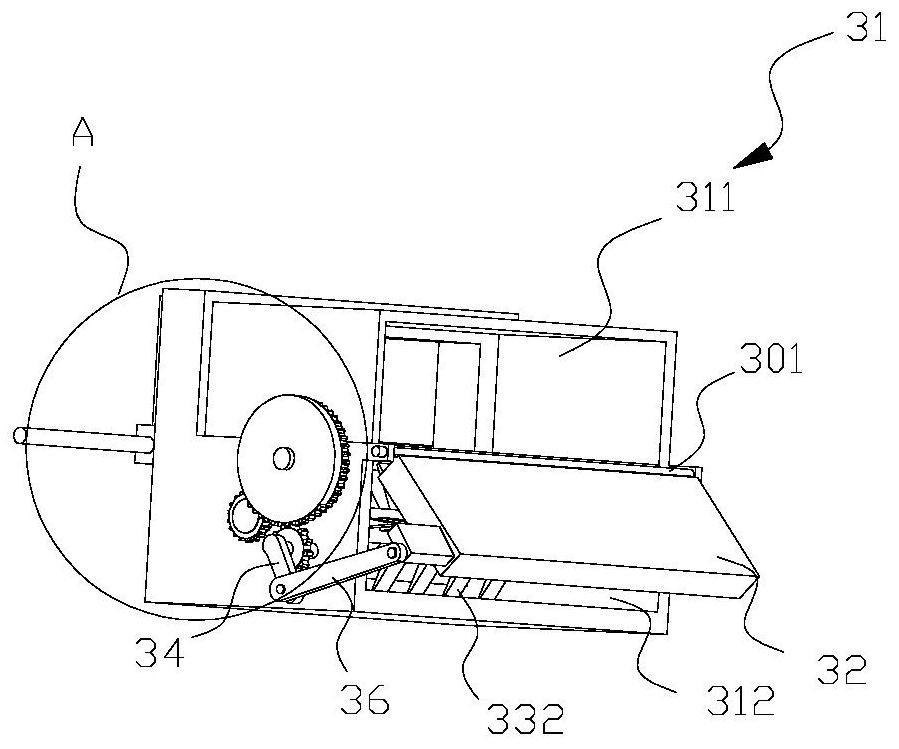

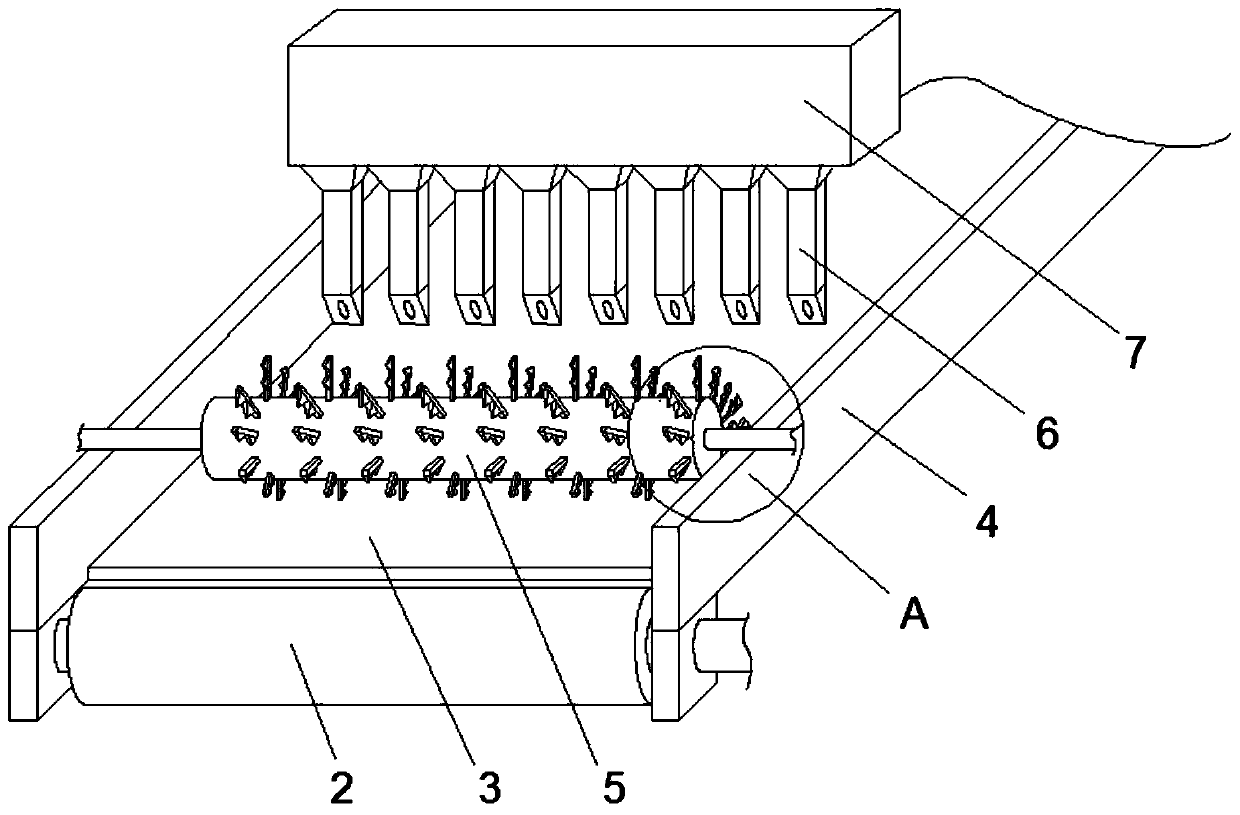

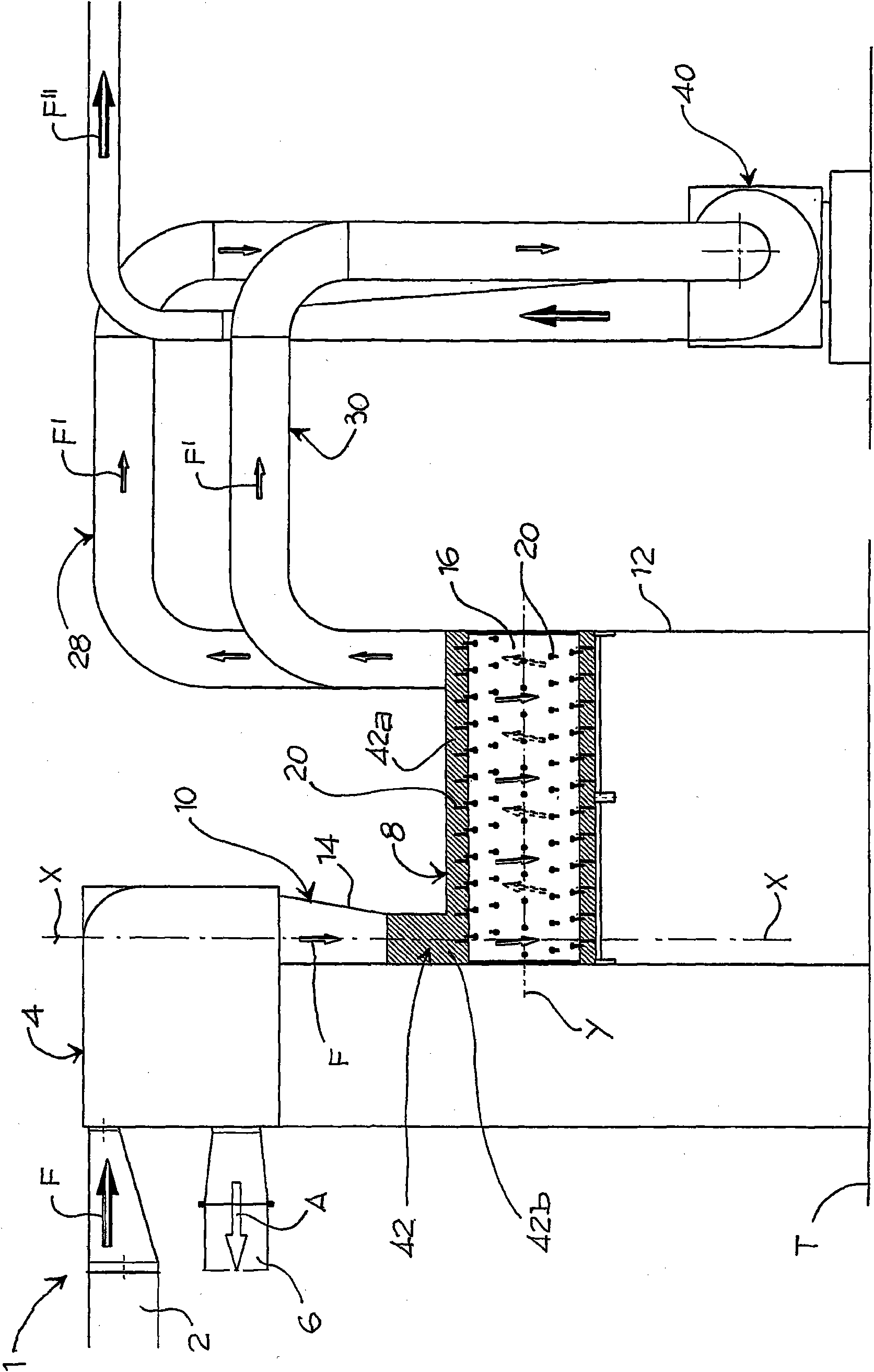

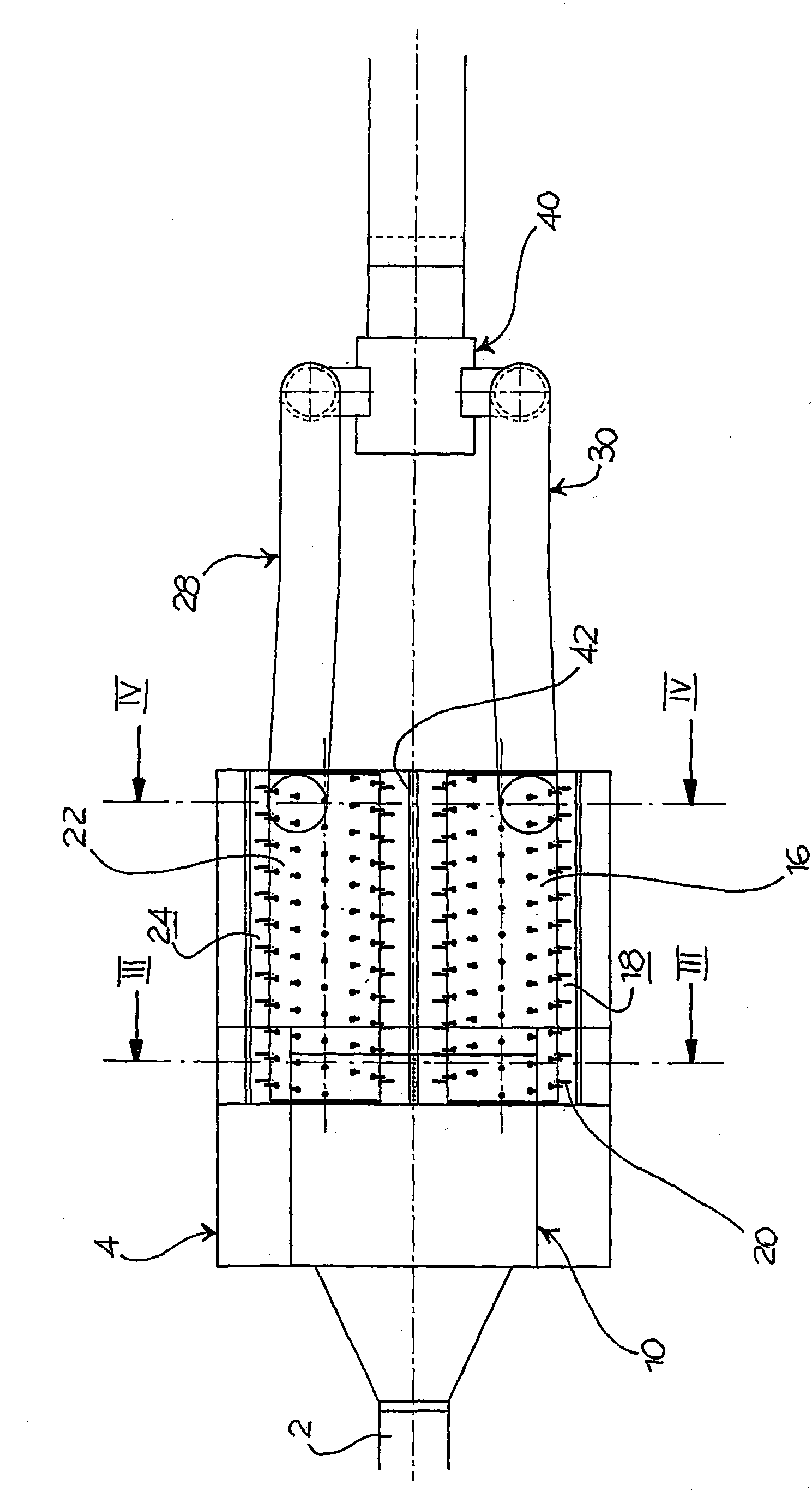

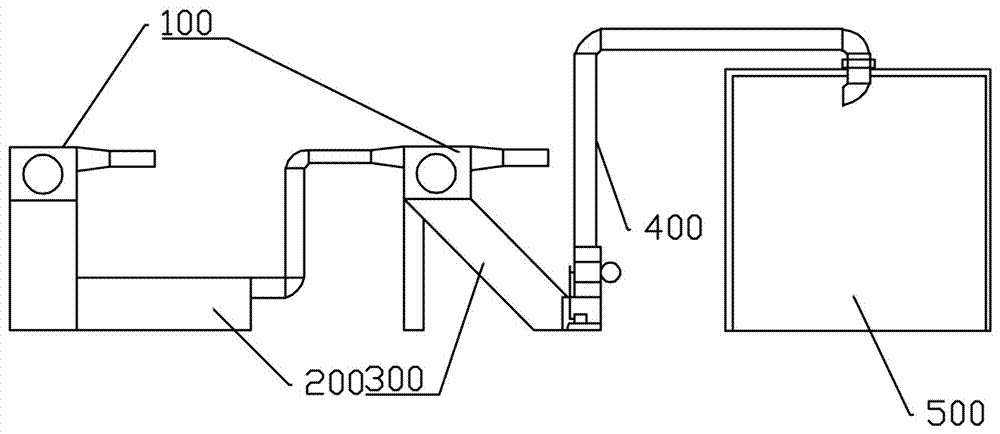

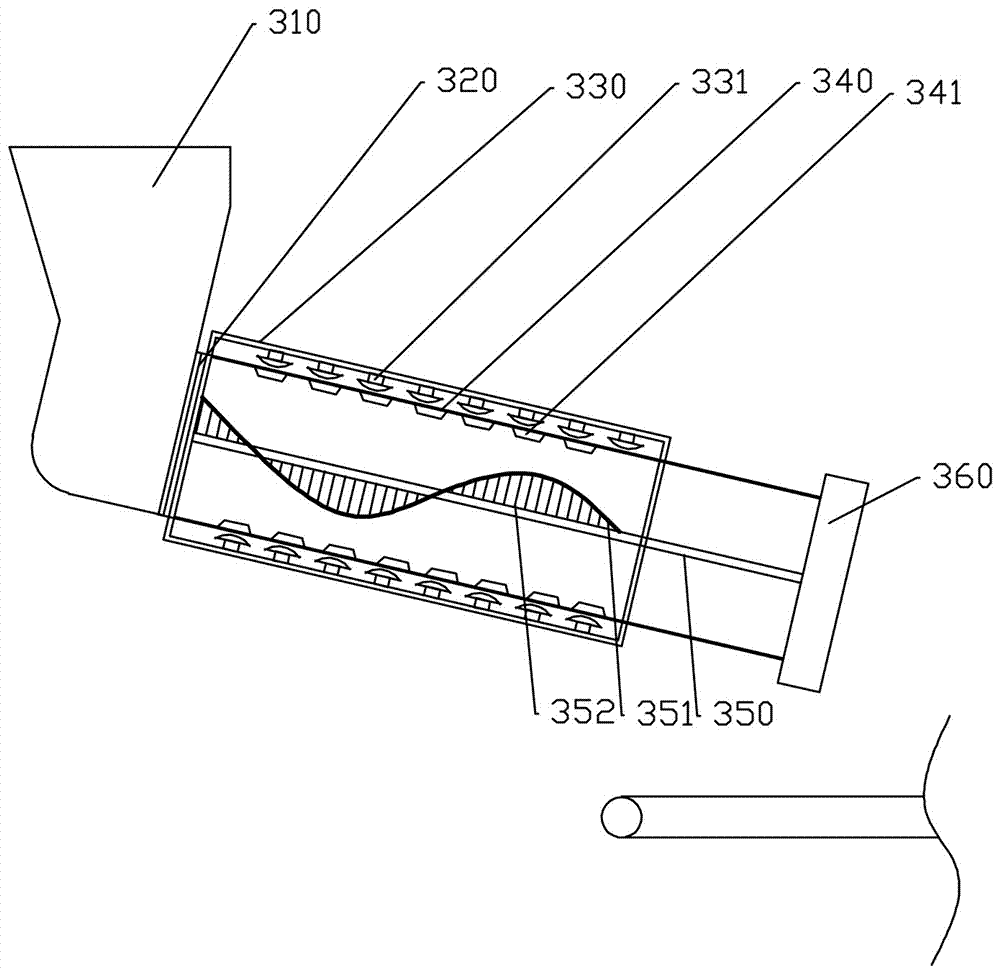

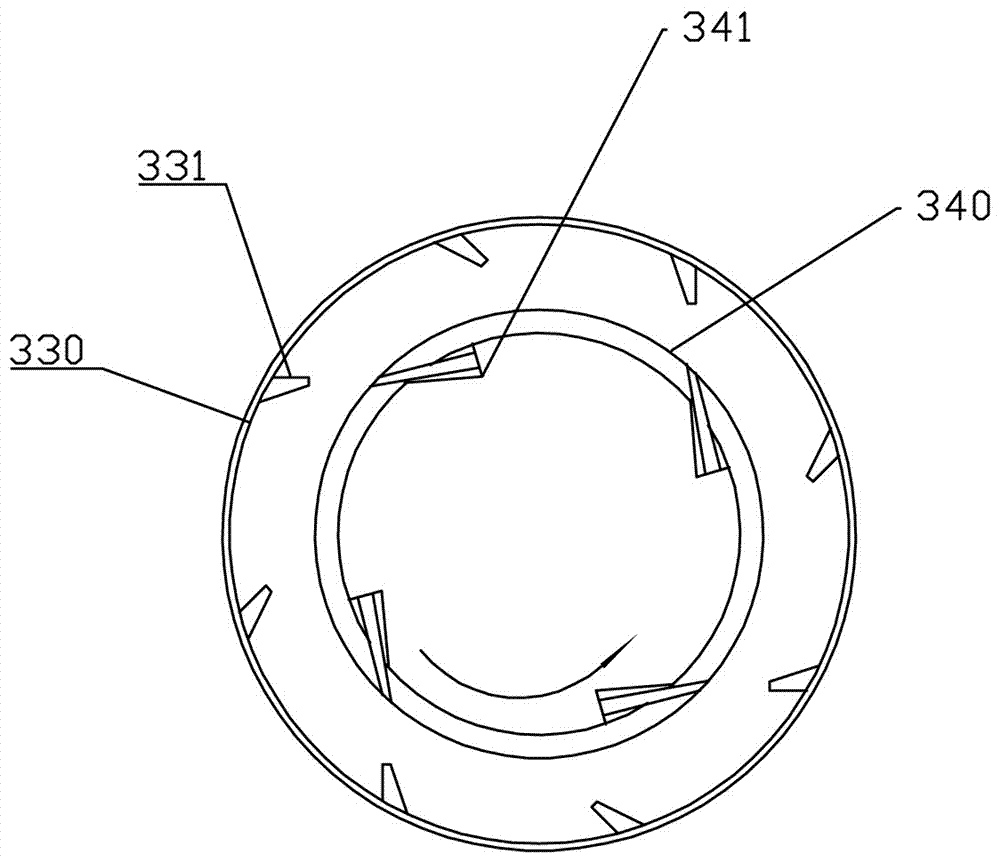

Opener for fibre in tufts on a carding preparation line, opener fibre, and method for processing fibre dundle

ActiveCN102912479AFibre cleaning/opening by beater armsFibre cleaning/opening by toothed membersHelical lineMechanical engineering

The invention provides an opener for fibre in tufts on a carding preparation line and the opener for fibre comprises a first opener roller (32) and a second opener roller (52) beside the first. The first opener roller (32) is fed by a two transversally separate fibre flows (Fl,F2), which proceed axially towards the ends of the first roller, passing then onto the second roller and proceeding axially towards the centre thereof, from where they are expelled. The opener roller (32, 52) has portions fitted with pegs positioned along axially symmetric, respective imaginary helical lines.

Owner:马佐里有限公司

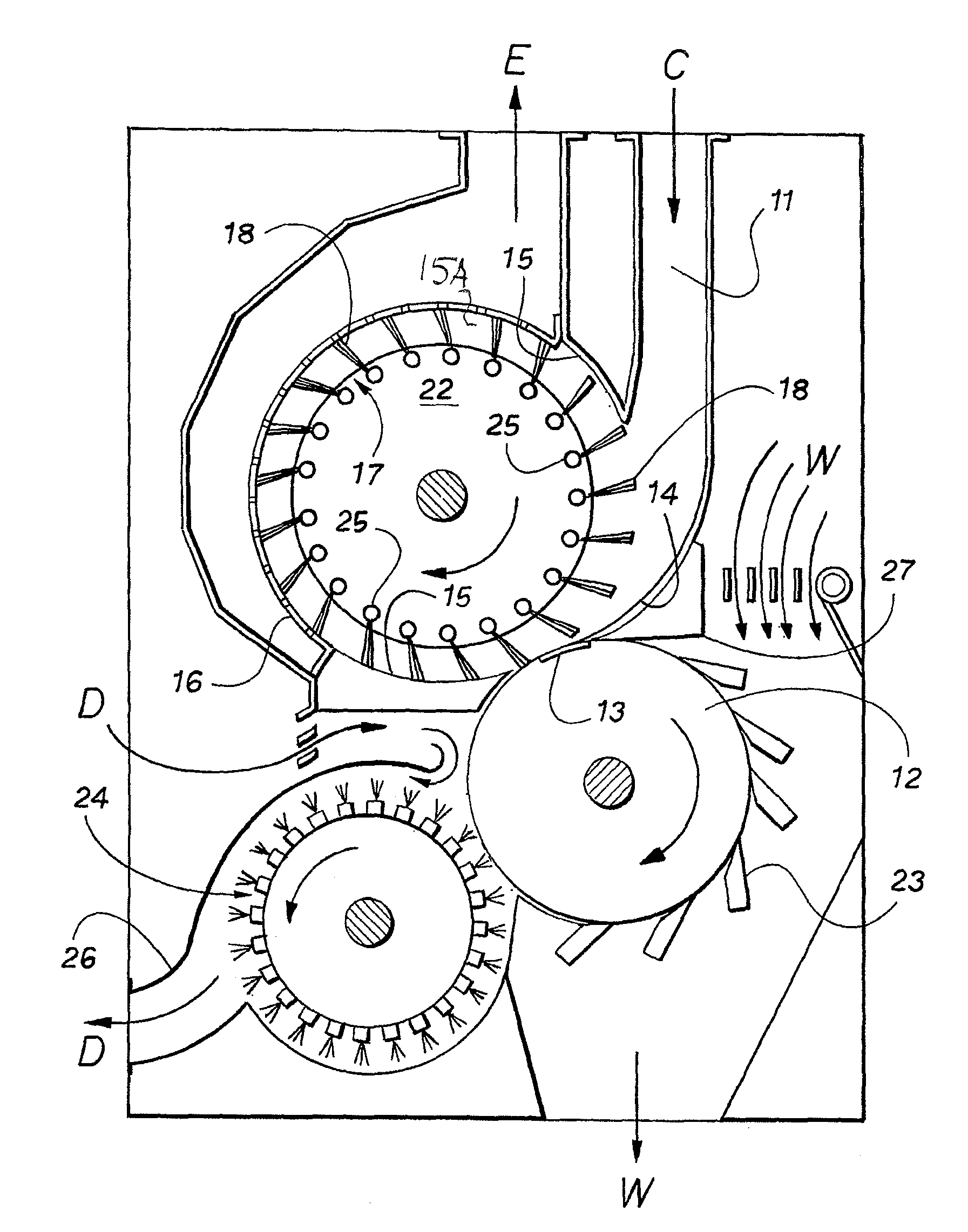

Method and apparatus for separating foreign matter from fibrous material

ActiveUS7779514B2Simple methodEliminate needMechanical impurity removalVegetable fibre separation from seedsForeign matterFiber

An apparatus for cleaning foreign matter from separated tufts of fiber uses a revolving open reel type structure mounted within a porous housing to separate a conveying air stream from tufts of fiber conveyed thereby and deliver the tufts to a toothed cleaning cylinder which passes beneath a plurality of cleaning bars. The open reel utilizes brush like outer surfaces to sweep tufts of fiber from the housing back into the air stream adjacent the cleaning cylinder.

Owner:LUMMUS INDS

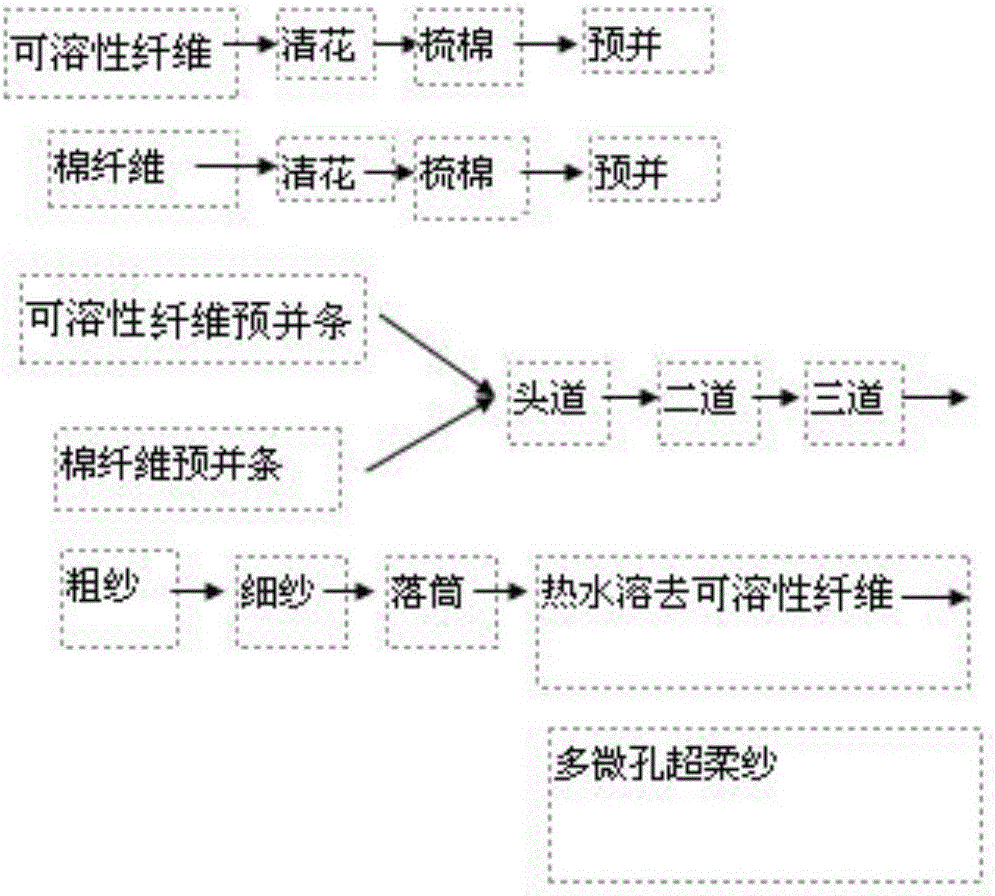

Method for preparing multi-micropore super-soft yarn

ActiveCN105970387ASimple preparation processGood flexibilityFibre cleaning/opening by beater armsDrafting machinesYarnCarding

The invention belongs to the technical field of fiber spinning and particularly relates to a method for preparing multi-micropore super-soft yarn. The method comprises the steps of first causing cotton fibers and soluble fibers to respectively undergo blowing, cotton carding and pre-drawing to manufacture cotton fiber pre-drawing strips and soluble fiber pre-drawing strips; causing the cotton fiber pre-drawing strips and the soluble fiber pre-drawing strips to simultaneously undergo breaker-drawing through a feeding device and finally undergo secondary drawing and third-time drawing sequentially, and finally manufacturing the final product through roving, spinning, winding and water solution processes. By adoption of the method, the soluble fibers can be placed in the cotton fibers successfully, and the multi-micropore super-soft yarn is formed.

Owner:LOFTEX CHINA LTD

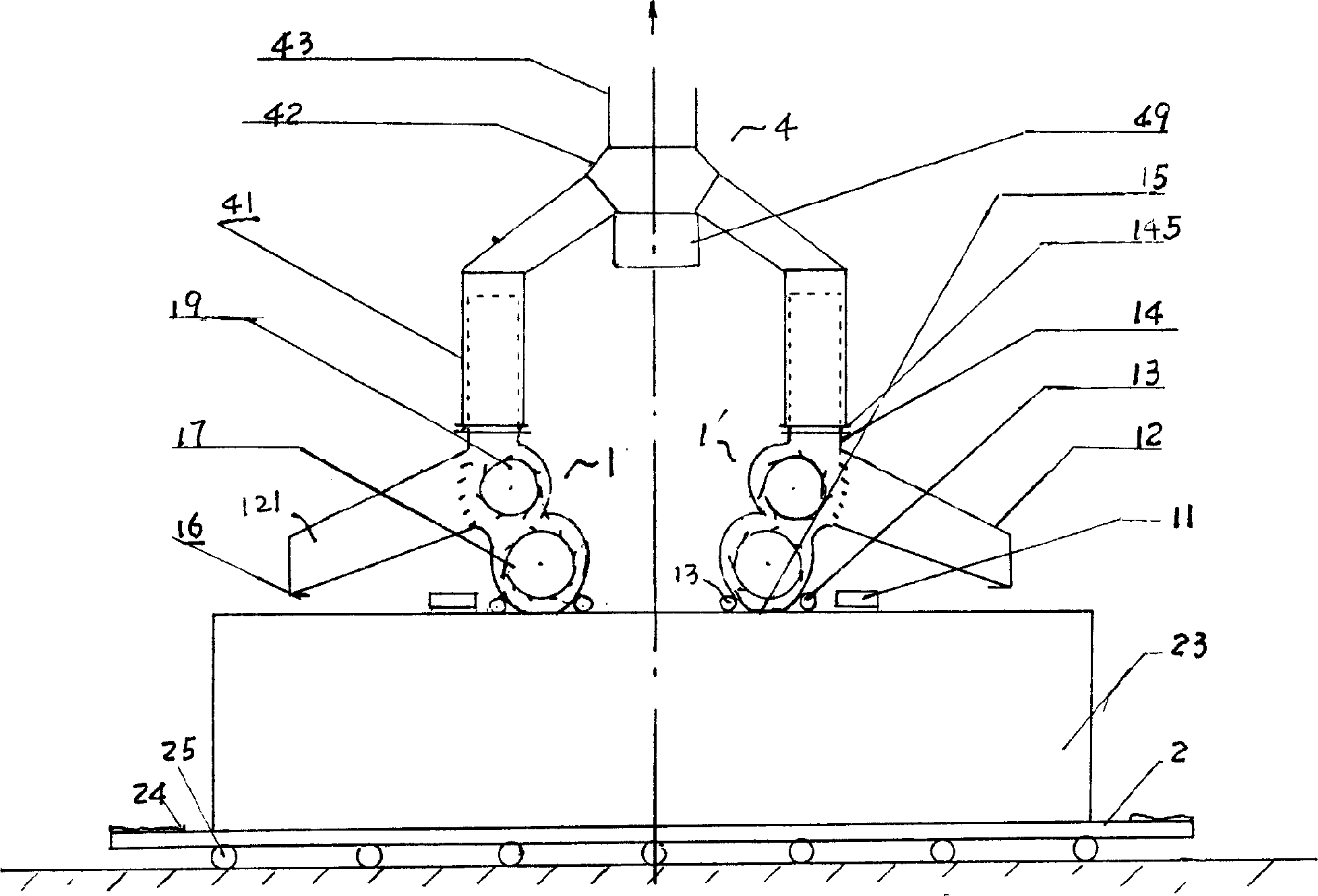

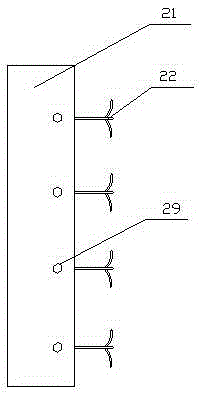

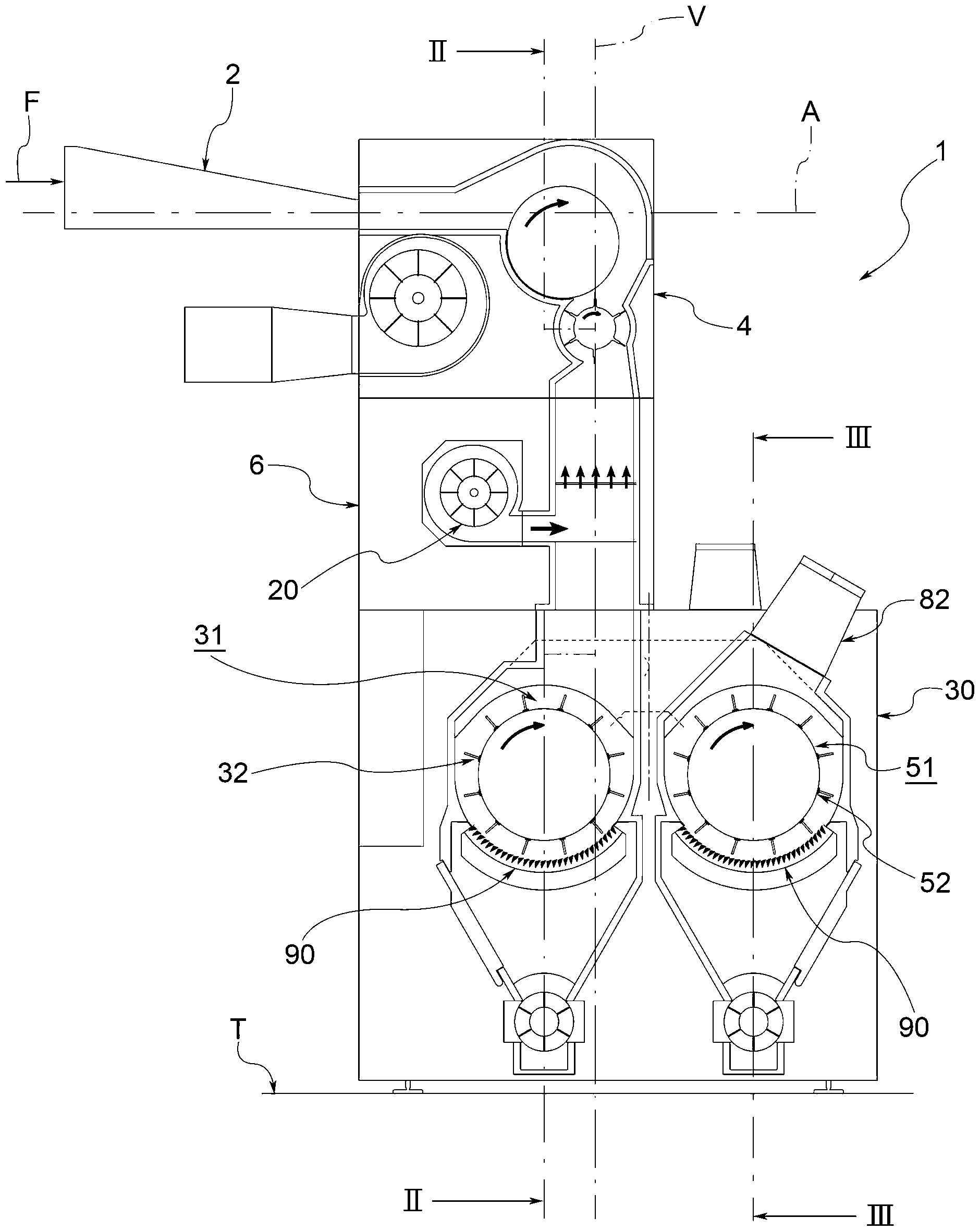

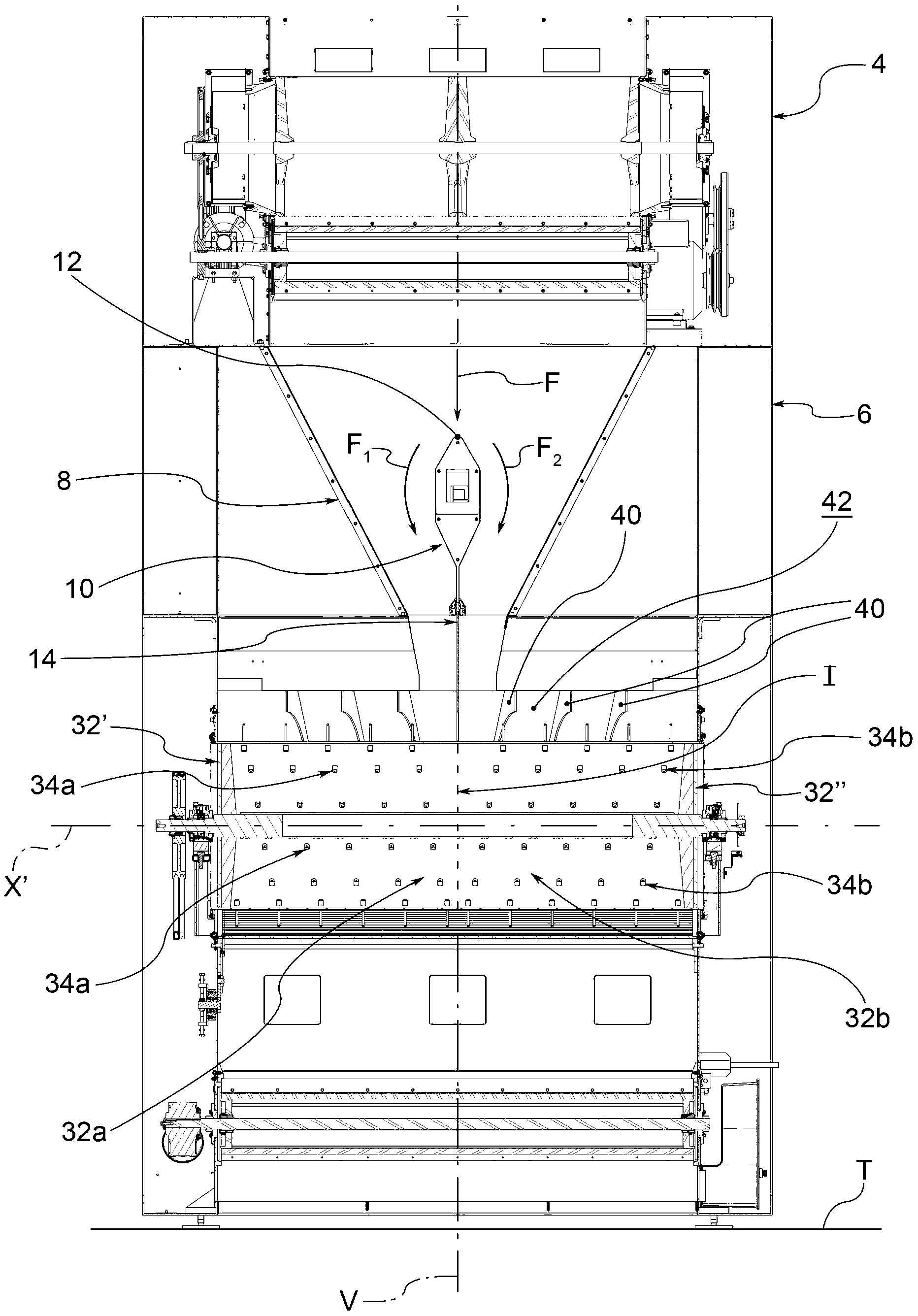

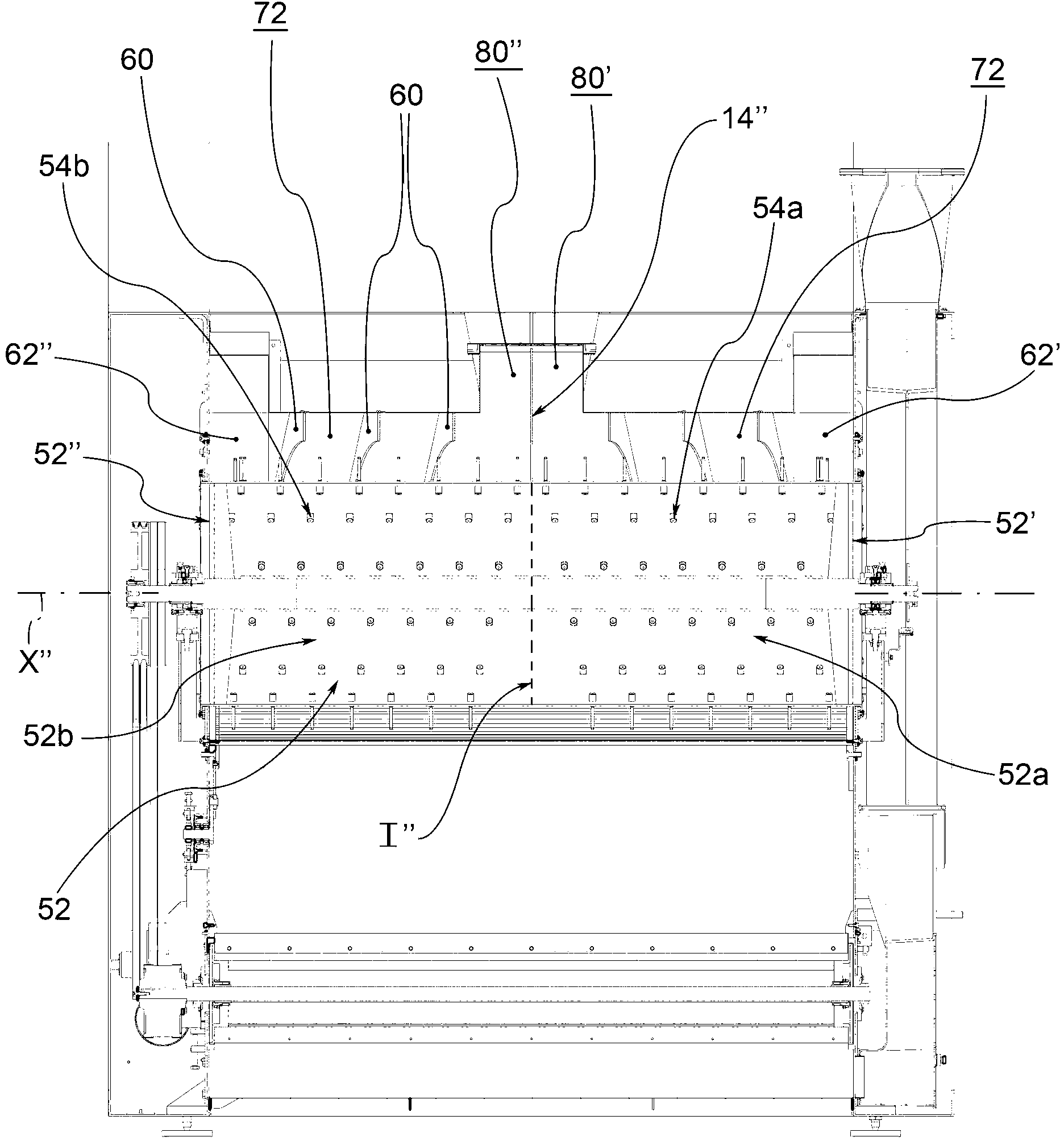

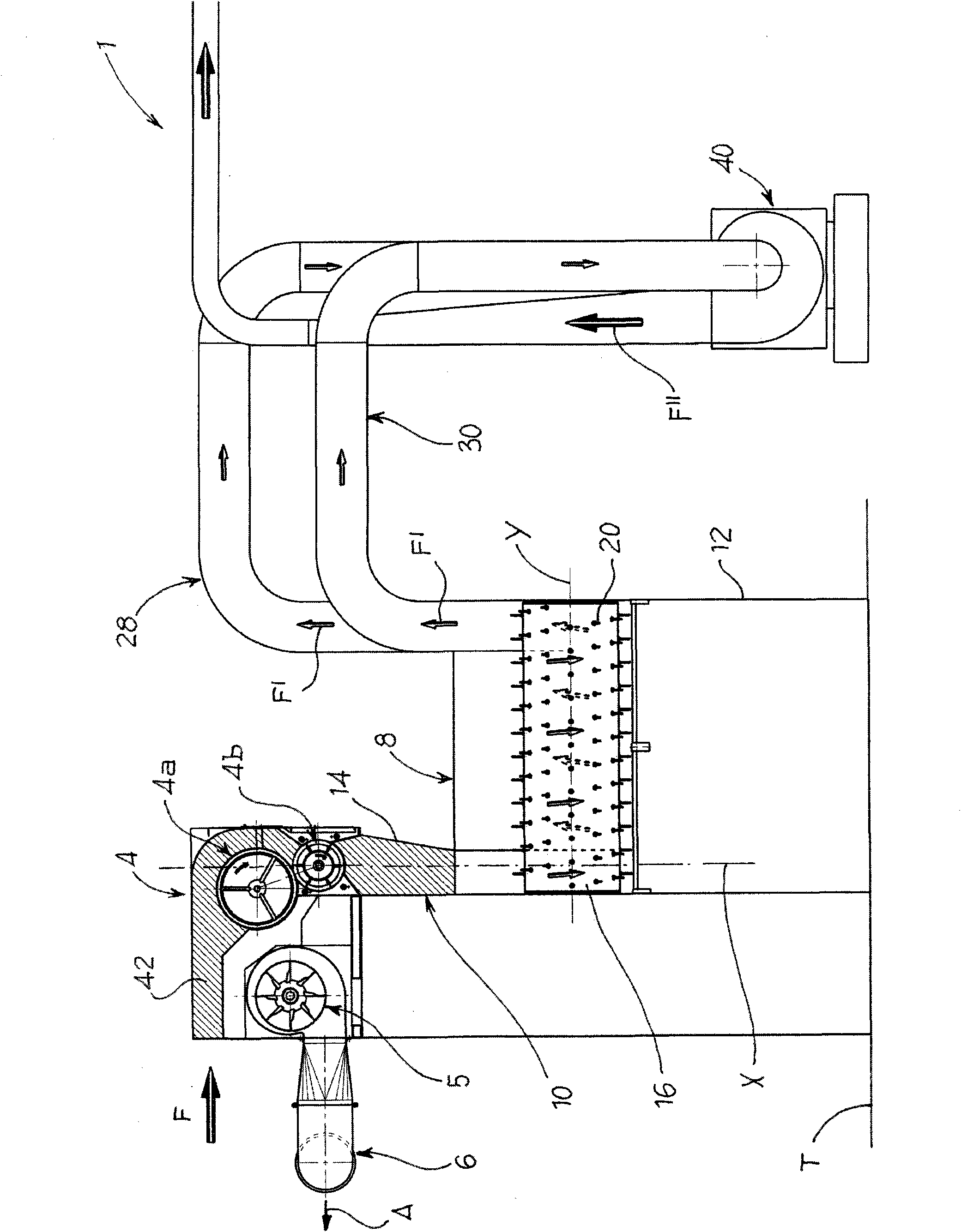

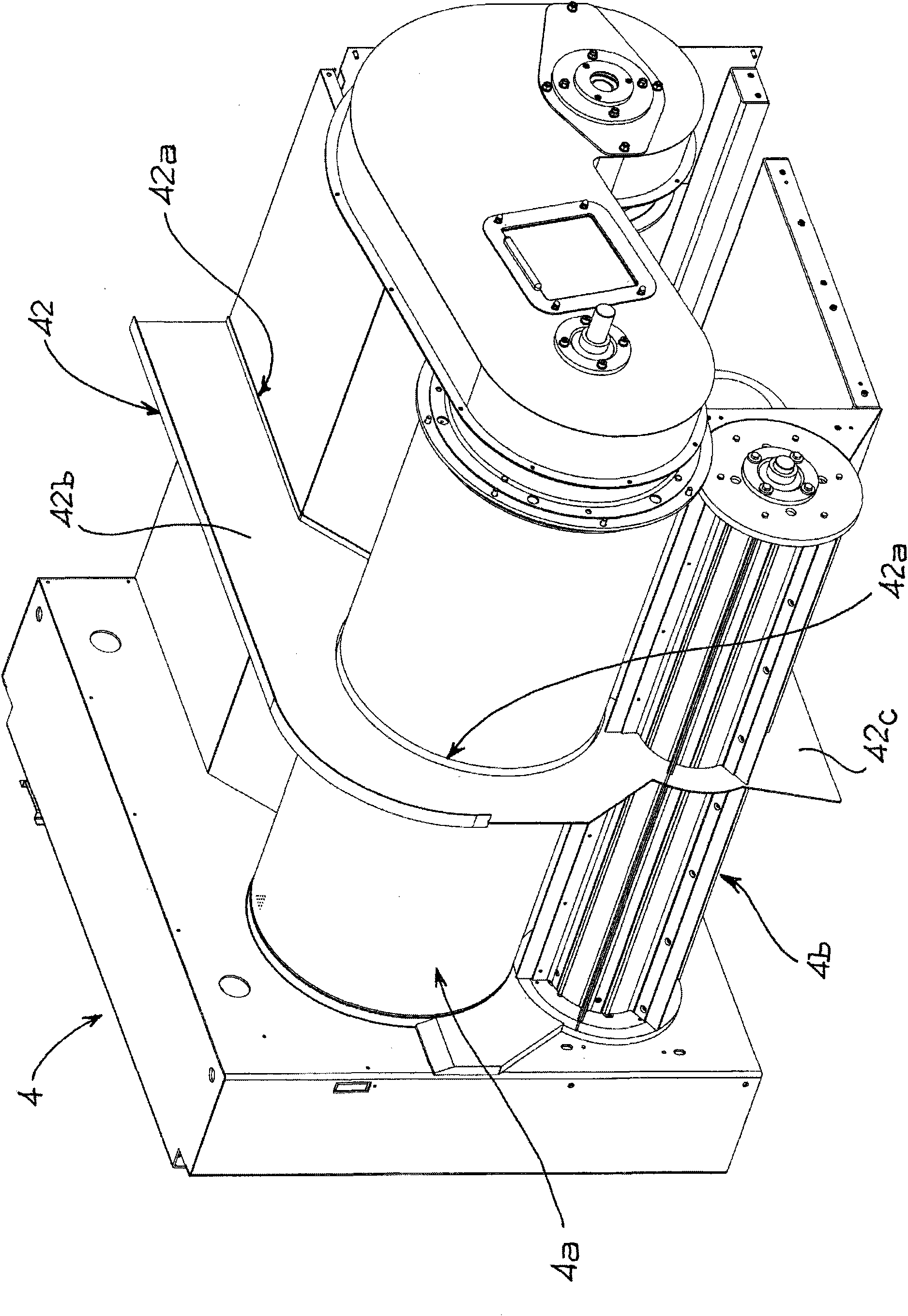

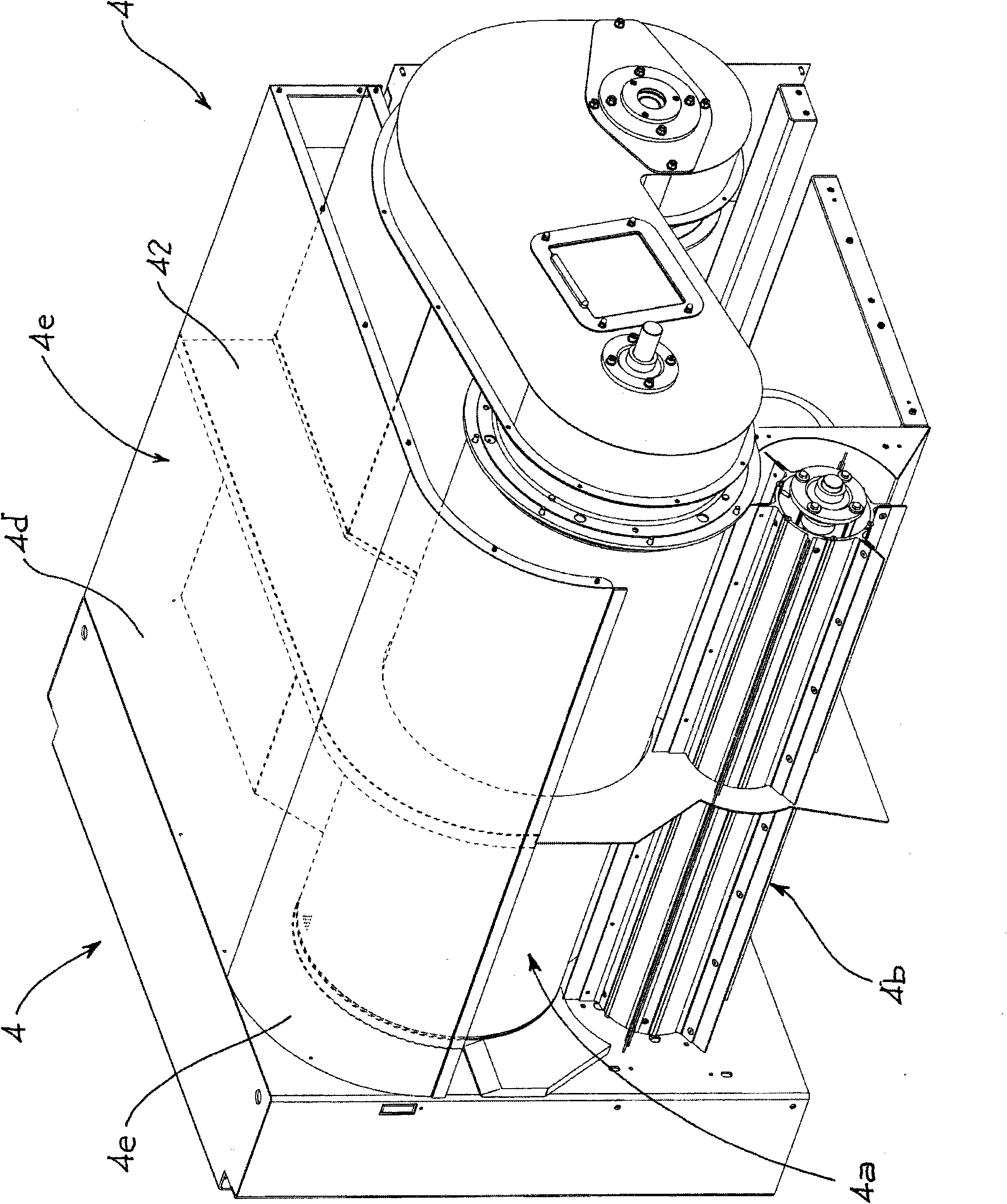

Feeding device of a fibre preparation line for carding

InactiveCN102031597AFibre cleaning and opening machine combinationsFibre cleaning/opening by beater armsProduction lineFiber

A feeder device (4) of a machine on a processing line preparing fibre for carding, comprising a cleaner roller (4a) and a feeder roller (4b), downline of the cleaner roller, and separation devices for separating or keeping separated the incoming flow of fibre into two or more flows of fibre to feed to the machine downline.

Owner:MARZOLI SPA

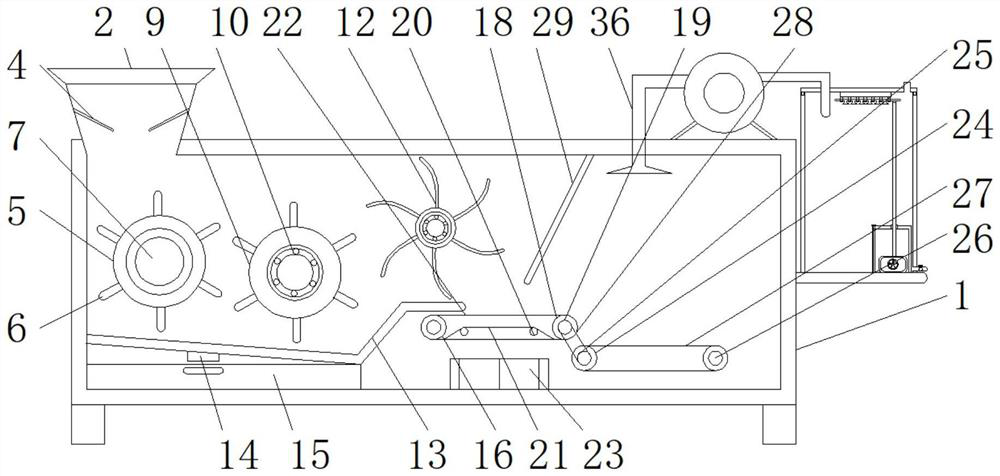

Cotton cleaner with automatic feeding and dust removal functions

PendingCN112647163AFunctionalAvoid shockSafety devices for fibre treatmentFibre cleaning and opening machine combinationsAgricultural engineeringDust control

The invention discloses a cotton cleaner with automatic feeding and dust removal functions. The cotton cleaner comprises a machine body, a first roller, a second roller, a connecting column, a driven roller shaft, a second roller shaft, a first motor, a second motor, a dust removal device and an automatic feeding device, wherein a feeding hole is formed in the left side of the top end of the machine body, cotton beating rods are welded and fixed to the periphery of the first roller, cotton beating rods are welded and fixed to the periphery of the second roller, a bearing is fixed to the left side of the connecting column, a third belt wheel is fixed to the left side of the driven roller shaft, a fourth belt wheel is fixed to the left side of the second roller shaft, a fifth belt wheel is fixed to the output end of the first motor, a sixth belt wheel is fixed to the output end of the second motor, and the sixth belt wheel is in rolling connection with the second belt wheel through a third belt. According to the cotton cleaner with the automatic feeding and dust removal functions, a baffle is arranged, the falling speed of cotton is reduced through the baffle, and the situation that the feeding hole is blocked due to the fact that the falling speed of the cotton is too high is avoided.

Owner:宿迁至诚纺织品股份有限公司

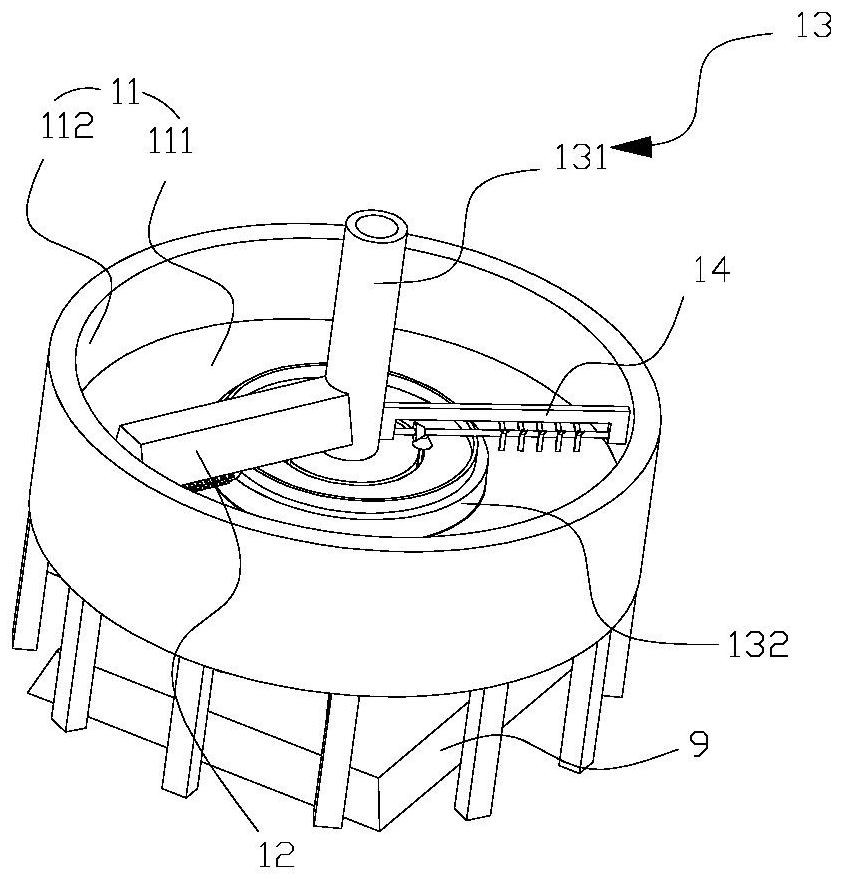

Full-automatic opener for garments

InactiveCN106012112AEasy to installLow failure rateFibre cleaning/opening by beater armsFibre cleaning/opening machinesDrive shaftPulp and paper industry

The invention relates to the technical field of openers, in particular to a full-automatic opener for garments. The full-automatic opener for garments comprises a machine frame and further comprises a discharge component arranged at the lower portion of the machine frame, a motor and a main stirring component arranged inside machine frame and connected to the motor in a rotating mode. The main stirring component comprises a stirring barrel, a feeding inlet formed in the upper side of the stirring barrel, a transmission shaft, an integration piece arranged on the transmission shaft in a rotating mode, a stirring rod arranged on the integration piece, an outer scraper plate arranged at the upper end of the stirring rod, a locking ring arranged on a transmission shaft in a rotating mode, a first bearing ring and a second bearing ring arranged at one end of the transmission shaft, and a discharging cover arranged at the lower portion of the stirring barrel. The full-automatic opener for garments is convenient to operate, convenient to adjust and high in opening efficiency.

Owner:姚雅珍

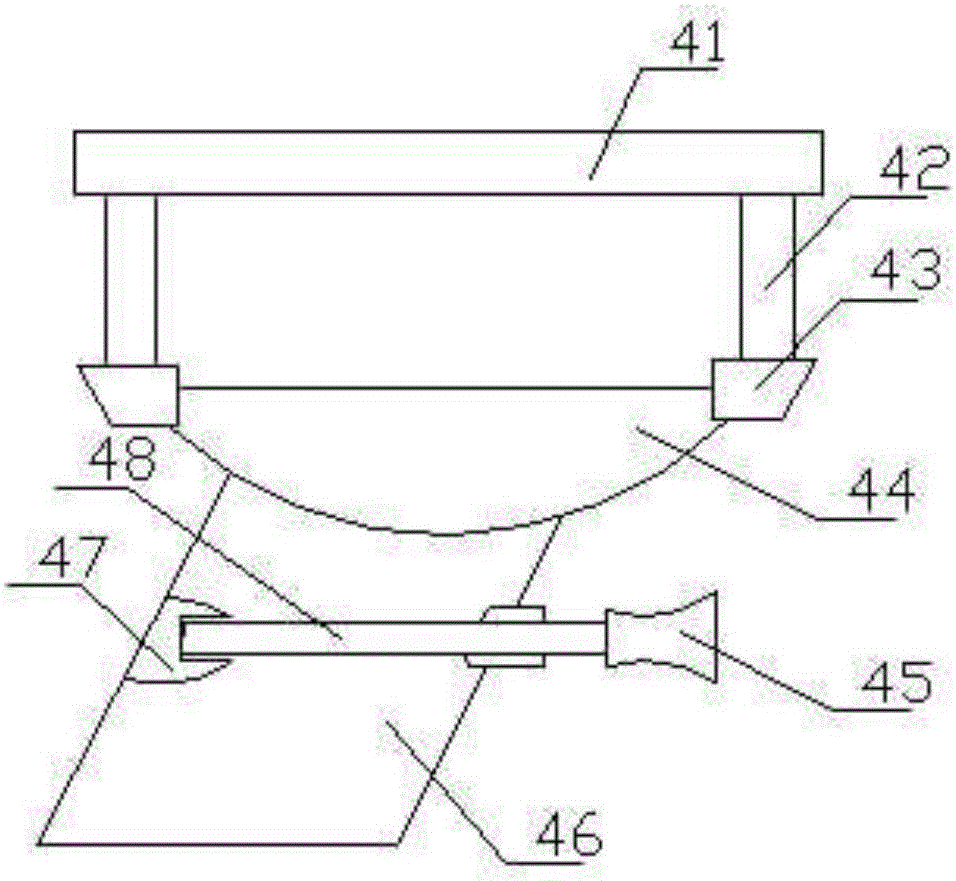

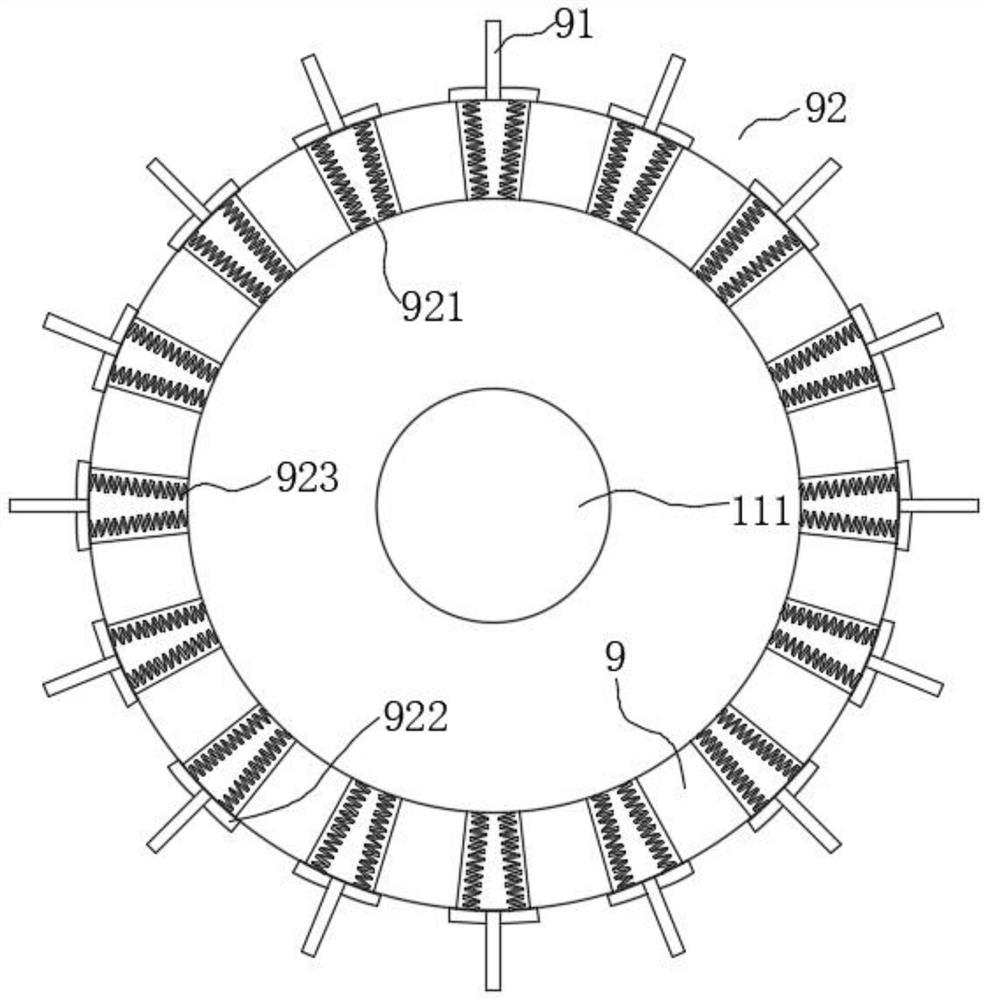

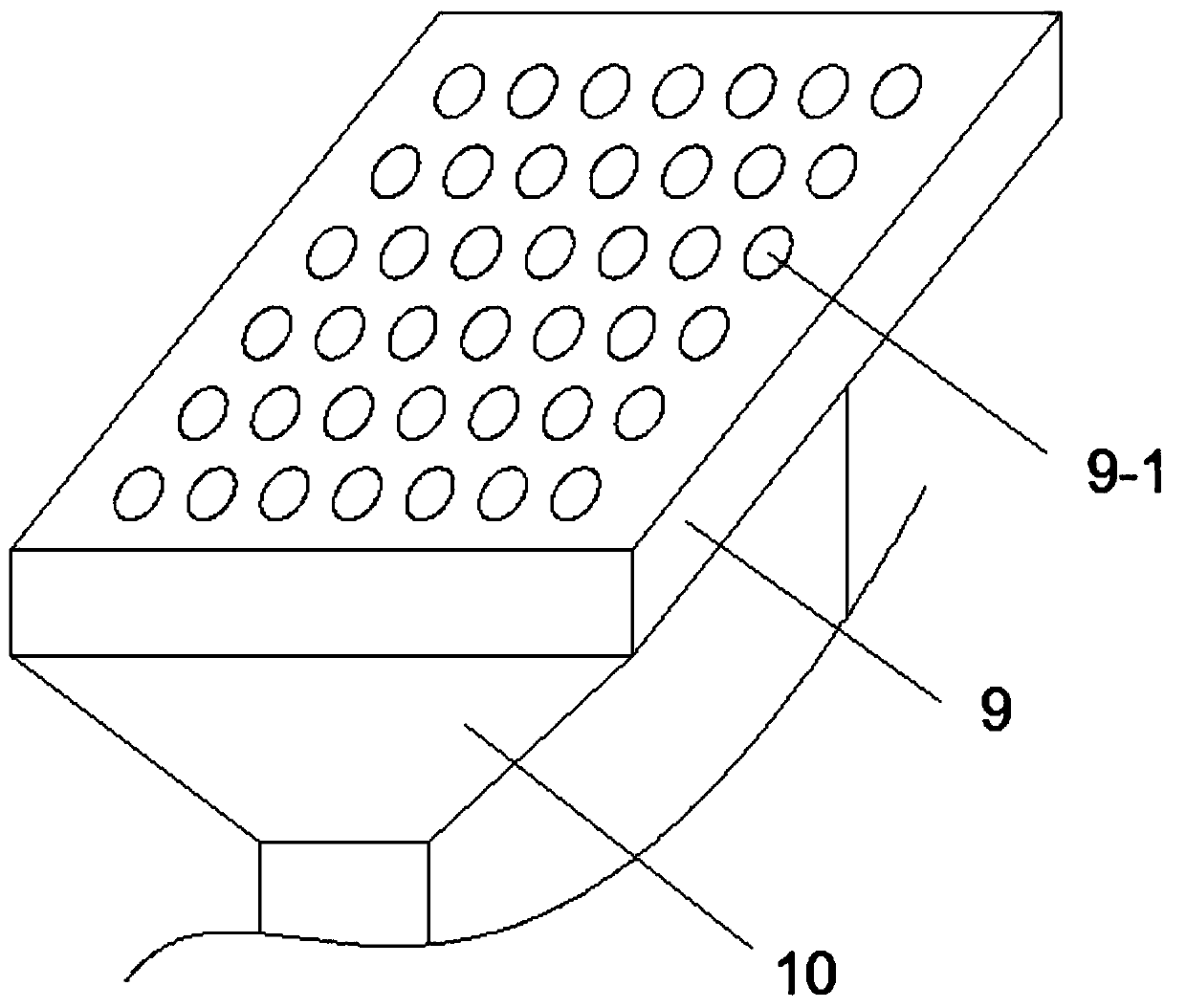

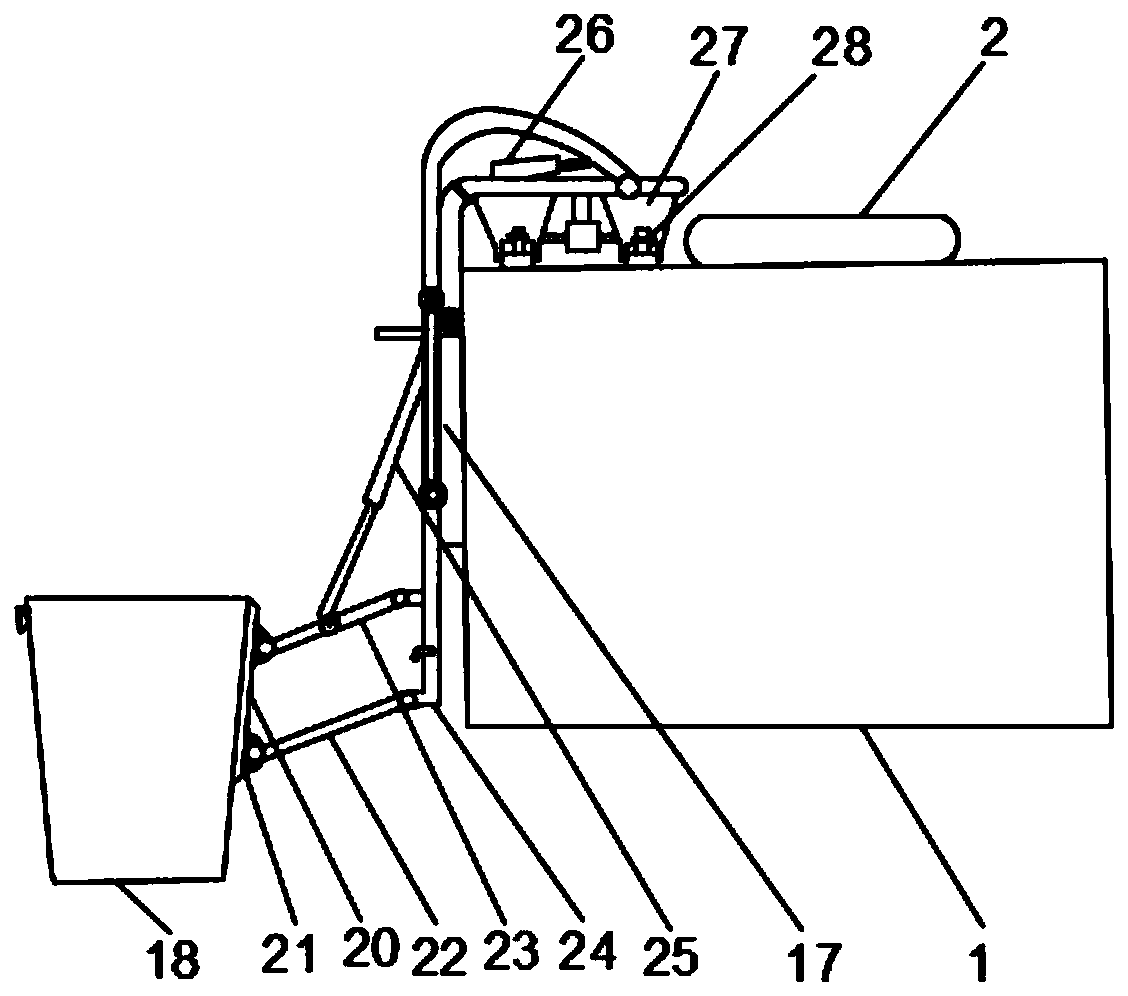

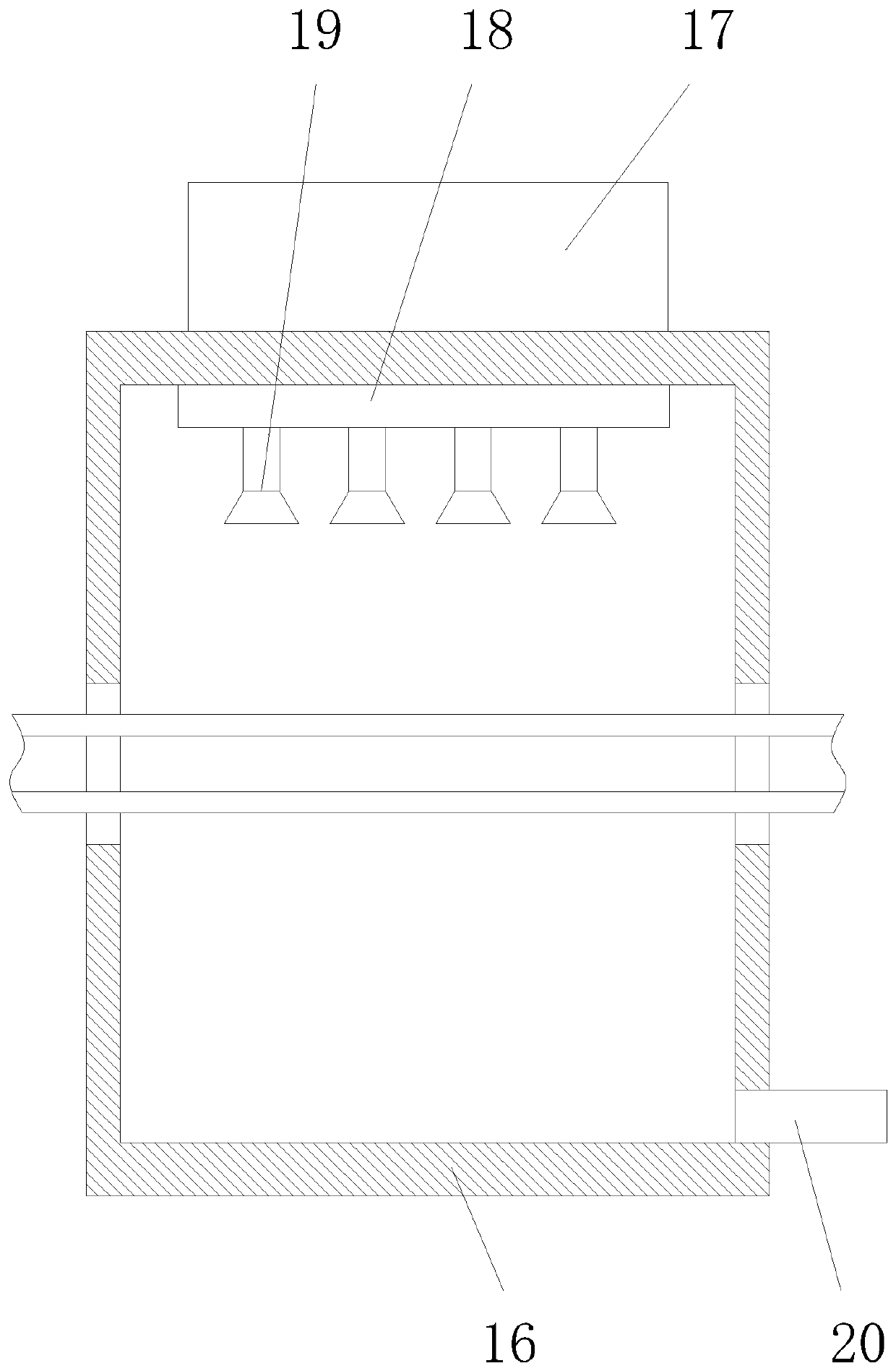

Flock grabbing device for cotton yarn production

PendingCN111621881ARealize automatic feeding processLabor savingLubricating devicesFibre cleaning and opening machine combinationsYarnAgricultural engineering

The invention discloses a flock grabbing device for cotton yarn production. The flock grabbing device comprises a mounting base and a rotary bin movably mounted on the mounting base. A feeding mechanism is arranged on one side of the rotary bin, and a rotary mechanism is arranged at the bottom of the rotary bin. A flock grabbing mechanism is arranged on the rotary bin. The flock grabbing device has the advantages that automatic feeding of flocks can be achieved through the feeding mechanism located on one side of the rotary bin, the labor force of manual feeding is reduced, and feeding is moreuniform; the flocks can be subjected to pre-breaking and opening treatment through a feeding box, a spraying head can carry out spraying and humidifying on the flocks, the rotary mechanism can drivethe rotary bin to rotate, and feeding and flock grabbing are convenient; the flock grabbing mechanism can grab the flocks in the rotary bin; and during flock grabbing, the rotary bin is adopted for carrying out rotary flock grabbing, and the safety of equipment is improved.

Owner:邱县付东纺织有限公司

Spinning process of airflow-imitated super-soft yarn

ActiveCN112921450APrevent disengagementAvoid entanglementFibre cleaning/opening by beater armsFibre cleaning/opening by toothed membersYarnFiber

The invention provides a spinning process of airflow-imitated super-soft yarn. The super-soft yarn spinning process comprises a machine body, a feeding bin, a discharging bin, a feeding roller, a first filtering plate, a first slag discharging opening, a first slag guiding plate, a cotton loosening and impurity removing mechanism, a discharging roller, a second precise filtering plate, a beating mechanism and an air blower, wherein the feeding bin is fixedly installed on one side of the outer surface of the upper end of the machine body, the discharging bin is fixedly installed at the upper end of the outer surface of one side of the machine body, the feeding roller is movably installed at the upper end of one side in the machine body, the first filtering plate is fixedly installed on the inner surface of one side of the machine body and located below the feeding roller, and the first slag discharging opening is formed in the middle of the outer surface of one side of the machine body. According to the spinning process of the airflow-imitated super-soft yarn, the phenomenon that the discharging roller is wound by cotton fibers during cotton discharging can be reduced, the blocking situation of the filtering plate can be effectively reduced, the situation that impurities are thrown into the feeding roller due to the centrifugal force of the cotton loosening and impurity removing mechanism can be prevented, and the risk of secondary cotton clearing of the cotton fibers is reduced.

Owner:新疆巨昊纺织有限公司

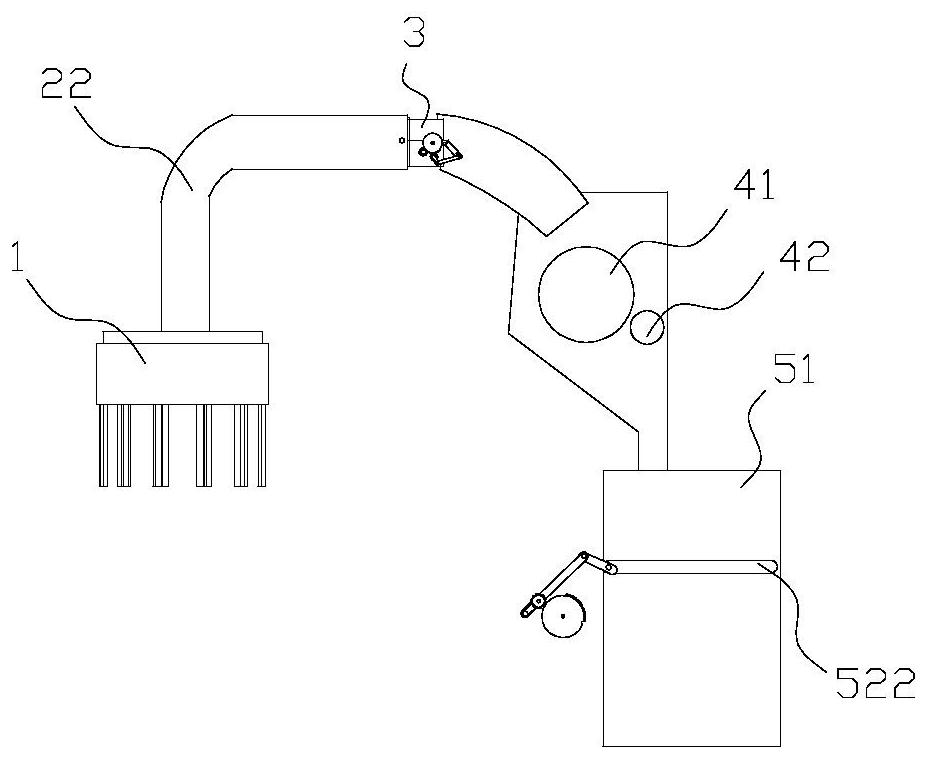

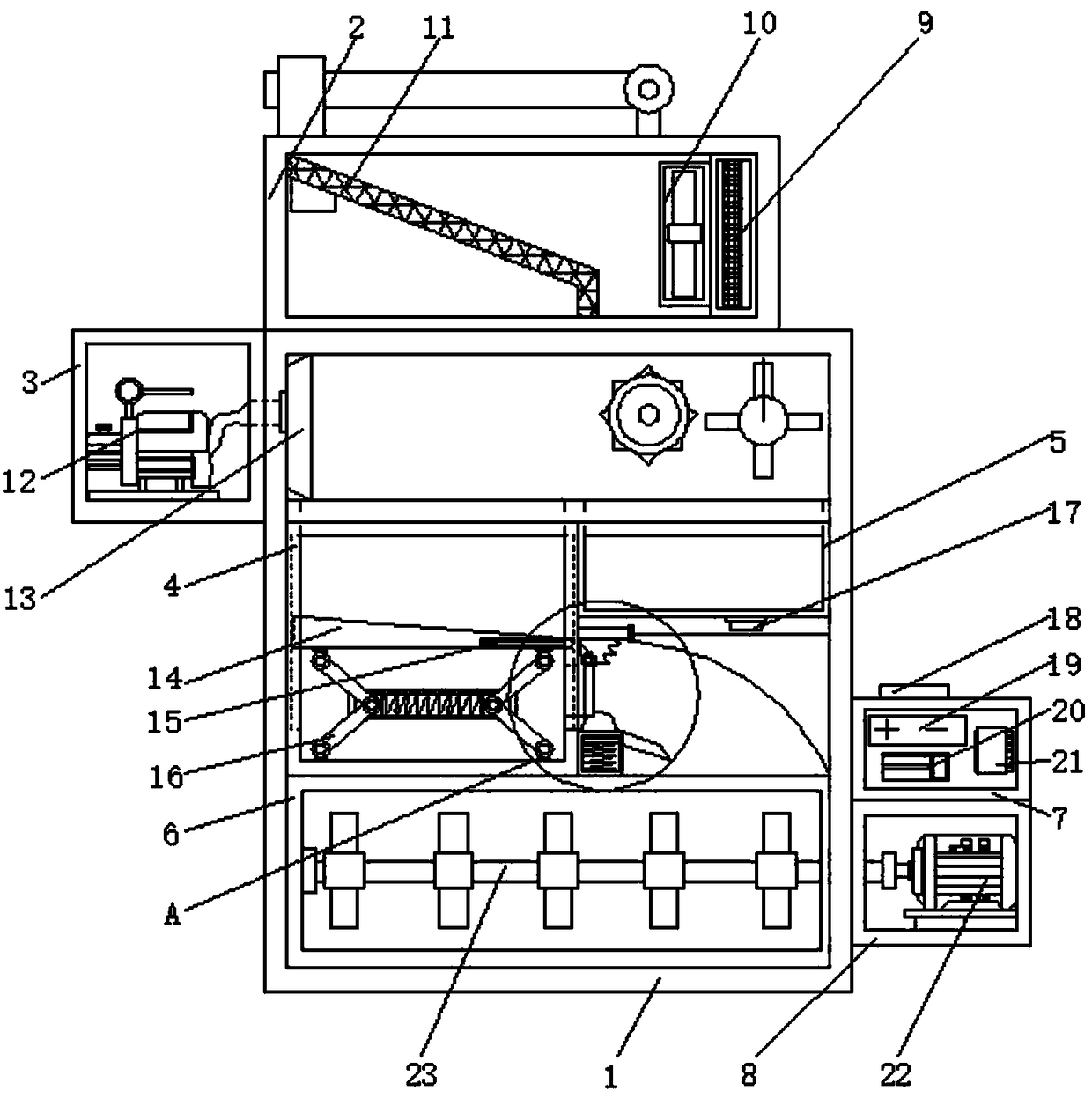

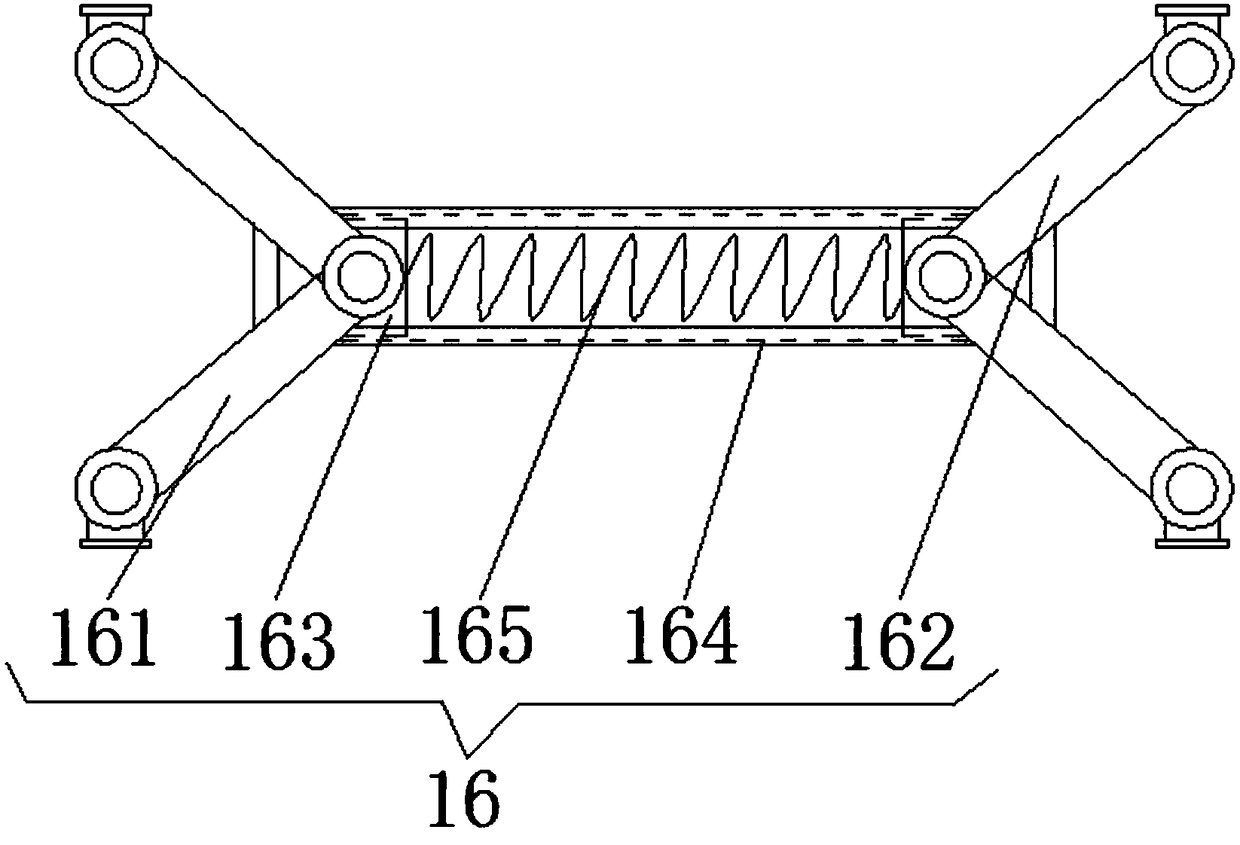

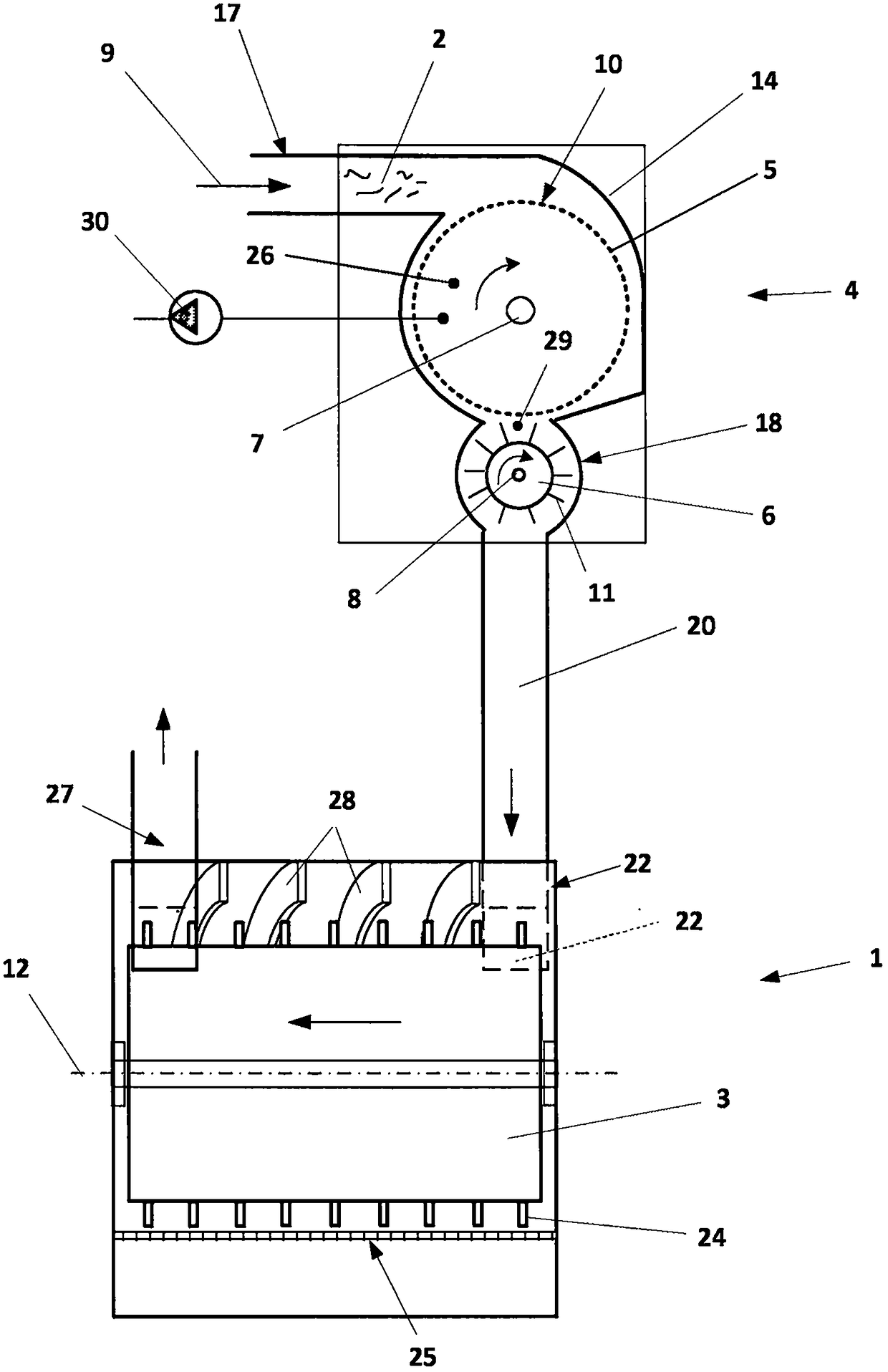

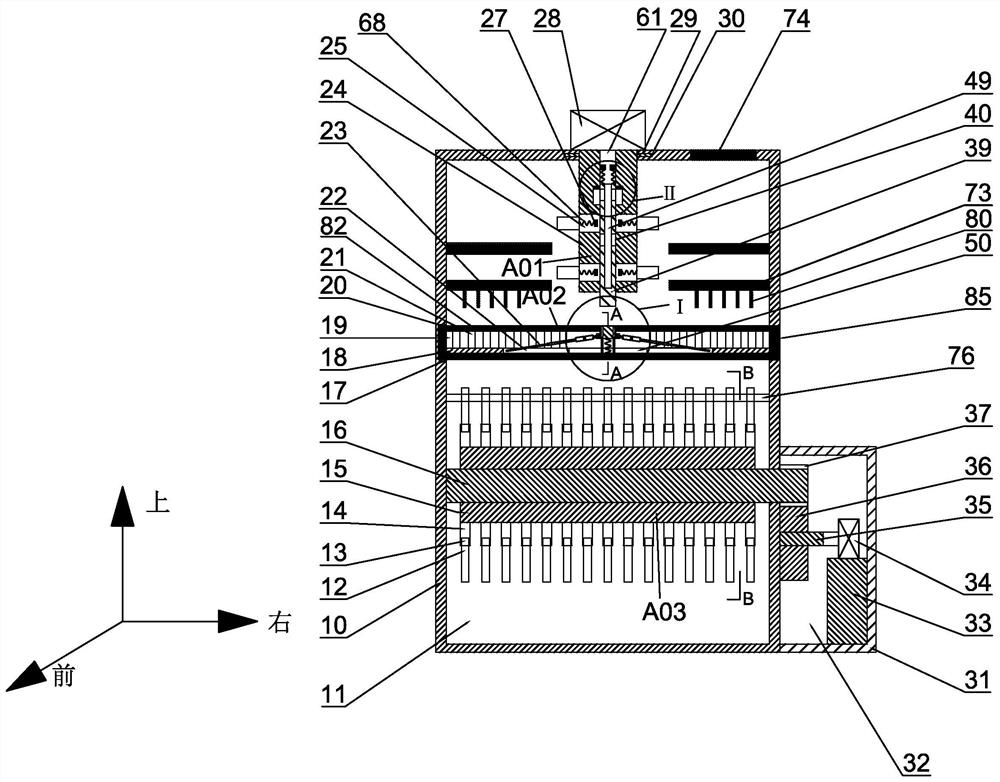

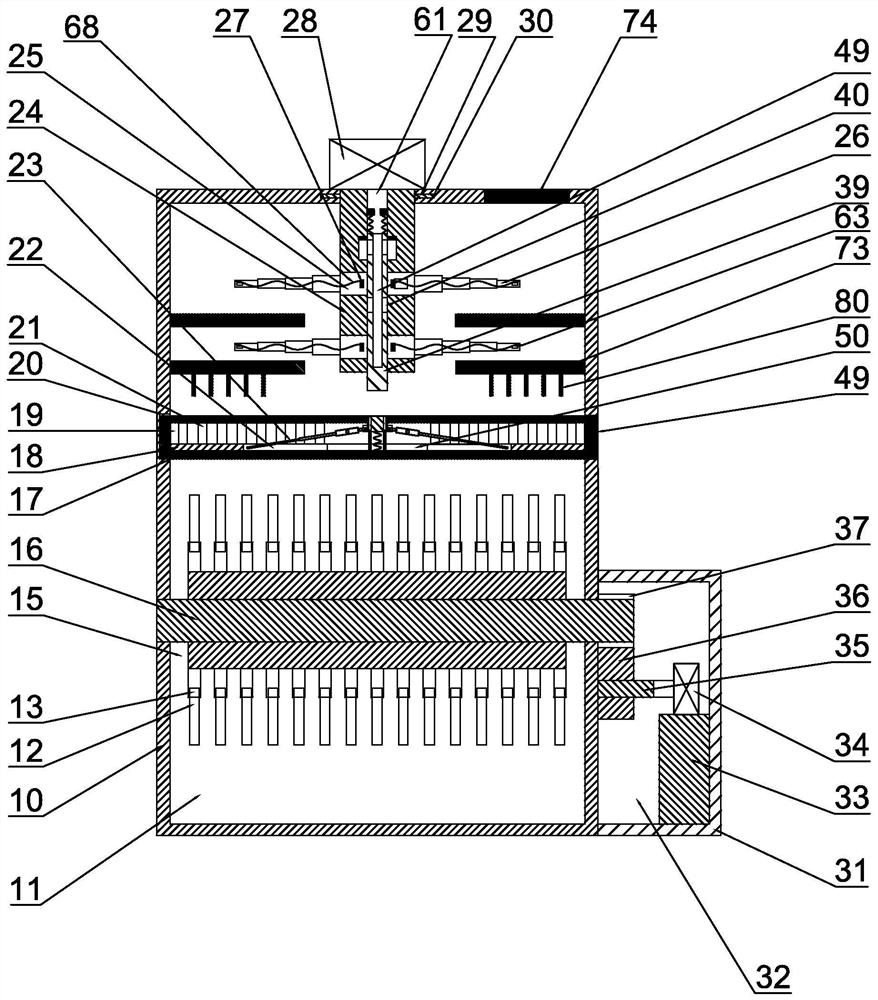

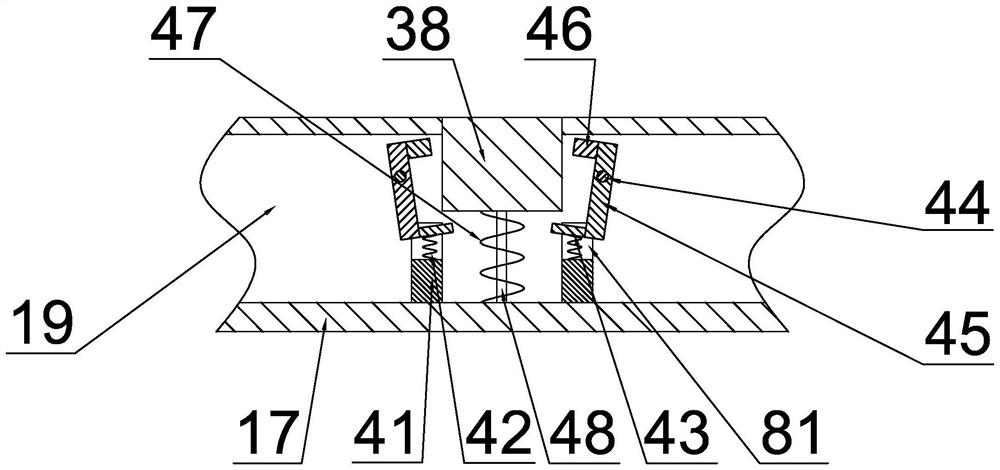

Fiber opening and feeding device and cotton opening, dispersing and mixing mechanism for spinning

ActiveCN112941671AImprove opening strengthImprove operational flexibilityFibre cleaning/opening by beater armsFibre mixingFiberSpinning

The invention discloses a fiber opening and feeding device for textile fabric production. A cotton grabbing mechanism is used for grabbing fibers in a fiber placing bin; after an opening beater rotates for multiple circles, a main driving arm rotates for one circle to enable a discharging plate to swing back and forth once, and one-time opening and closing movement of the discharging plate is completed; a two-way switching valve plate is arranged on a conveying channel in a running fit mode, and when the two-way switching valve plate is rotated till the two-way switching valve plate is closed on a feeding port of a first conveying and feeding channel, a feeding port of a second conveying and feeding channel is opened; and when the two-way switching valve plate is rotated until the two-way switching valve plate is closed on the feeding port of the second conveying and feeding channel, the feeding port of the first conveying and feeding channel is opened. The invention further discloses a cotton opening, dispersing and mixing mechanism for spinning. The fiber opening and feeding device has the advantages that fiber opening modes are flexibly switched according to actual requirements of fibers, so that the opening degree of the fibers before the fibers enter the next process such as a cotton condensing device is ensured.

Owner:福建宇邦纺织科技有限公司

Sorting device for rapidly sorting impurities in velveteen

InactiveCN108193327AFast fallImprove sorting efficiencyFibre cleaning/opening by air draught arrangementsFibre cleaning/opening by beater armsEngineeringImpurity

The invention discloses a sorting device for rapidly sorting impurities in velveteen. The sorting device comprises a bottom plate and two vertical plates. The top end of the vertical plates is provided with a box with an upward opening which is fixedly connected. A rotation shaft is horizontally installed in the box. The rotation shaft is alternately sheathed with a plurality of shaft sleeves. Anouter ring of each shaft sleeve is provided with a plurality of blades in an array mode. The bottom of the box is provided with a square hole. One side of the square hole is hinged with a rotation plate. The rotation plate is provided with a plurality of rows of through holes. A magnet block positioned on the upper plane of the rotation plate is installed between every two neighboring through holes. The bottom plate is successively and alternately provided with an impurity storage box and a velveteen storage box from left to right. Through the above mode, the sorting device for rapidly sortingthe impurities in the velveteen is capable of performing the interaction of the stirring of the blades, the blowing of a fan and the vibrating of a vibration pump on the velveteen to be sorted, enabling an impurity particle material to be rapidly dropped down from the through holes, enabling the scrap iron impurities to be adsorbed on the magnet blocks, and improving the sorting efficiency and quality.

Owner:SUQIAN CHAOBO TEXTILE CO LTD

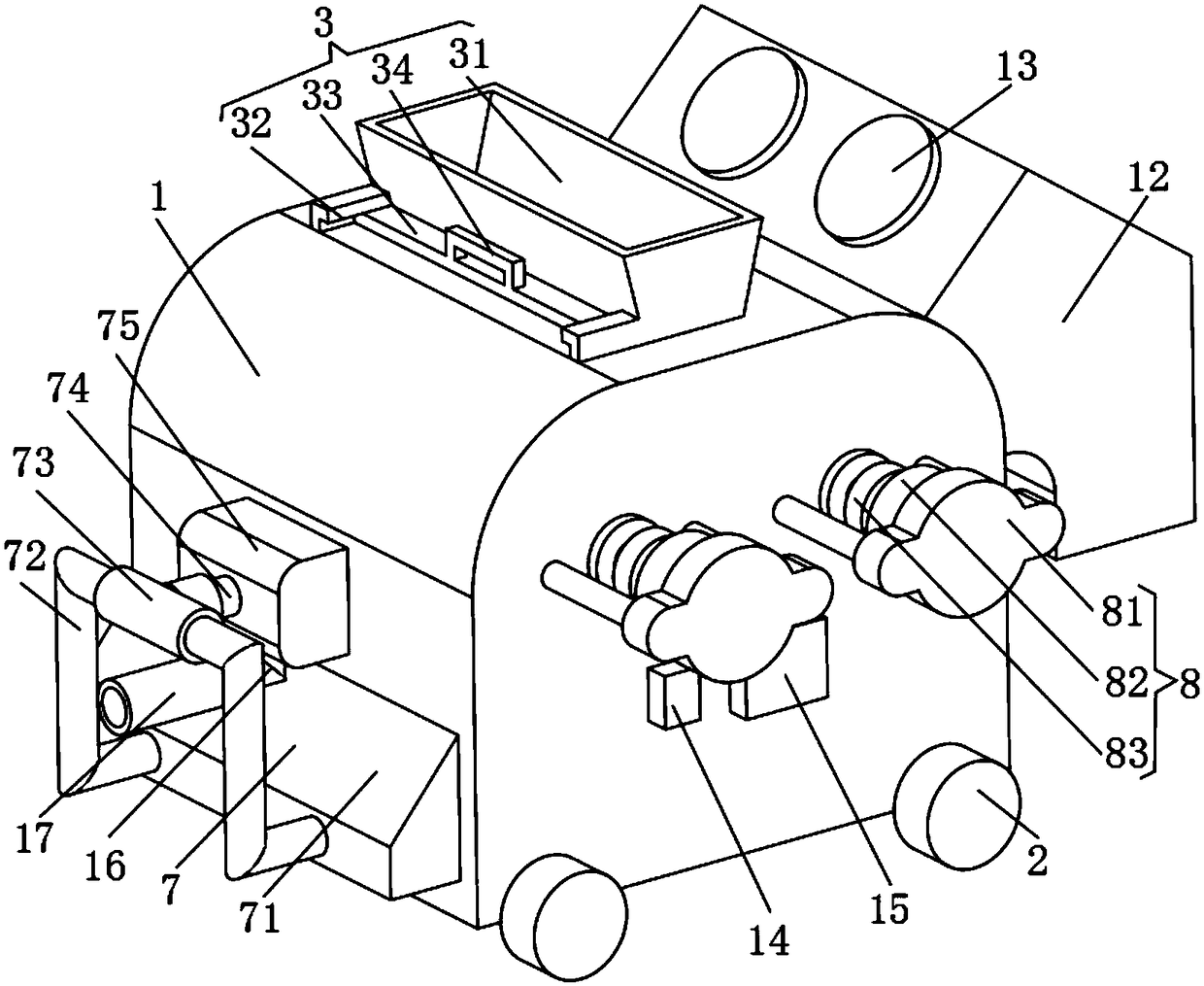

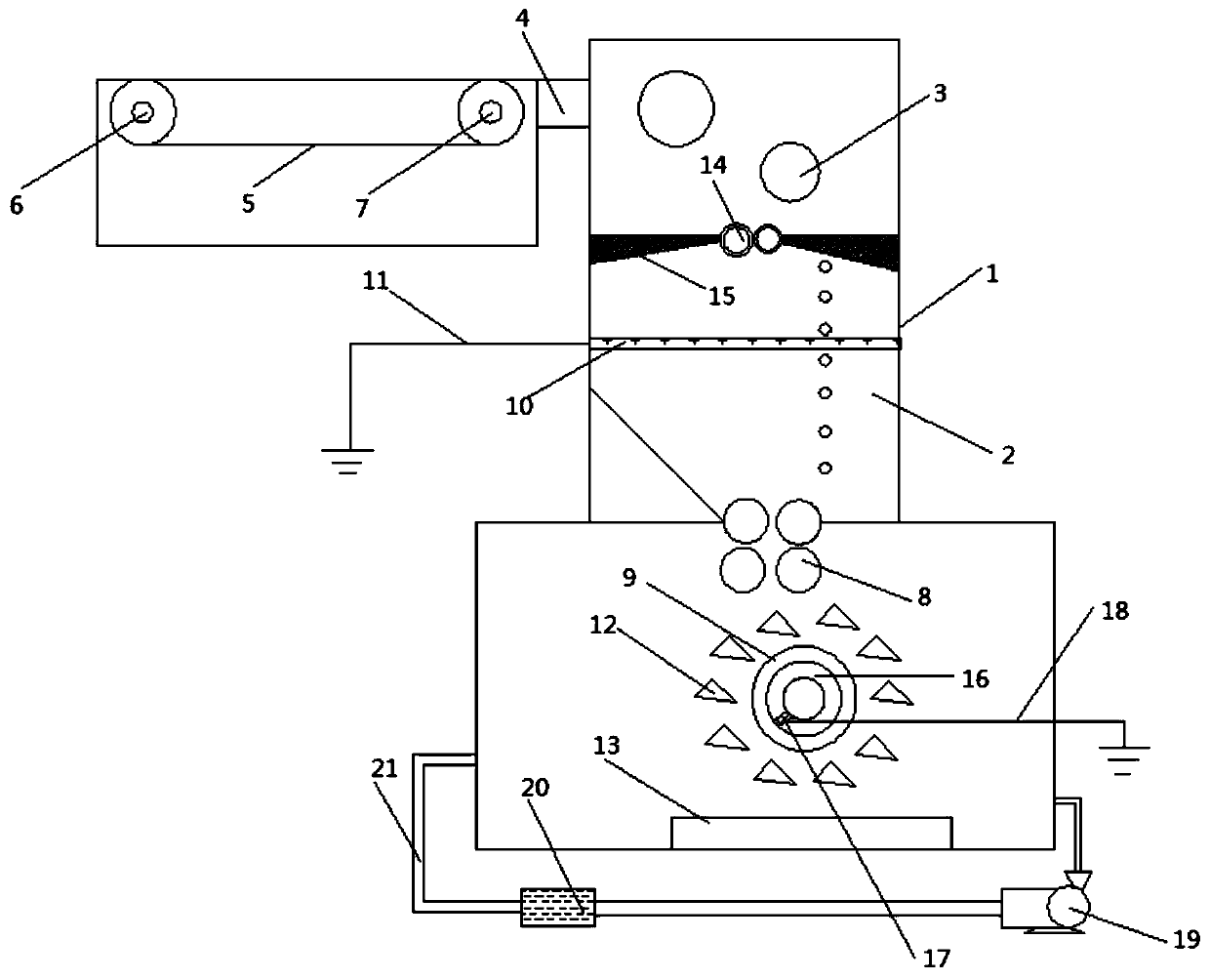

Novel multifunctional opener

InactiveCN110714241AEasy to operateReduce homeworkFibre cleaning/opening by beater armsFibre cleaning/opening machinesElectric machineryDrive motor

A novel multifunctional opener comprises a rack, a cotton conveyor device and a stand hopper; a condenser is arranged above the stand hopper and provided with a cotton inlet; the cotton conveyor device is connected with the cotton inlet and comprises a conveyor belt, a drive roll, a driven roll and a drive motor, the conveyor belt is connected with the driven roll and the drive roll, the drive motor is also connected with the drive roll and the driven roll, and the drive motor refers to a semi-servo motor; feeding rollers and opening beaters are arranged under the stand hopper sequentially; anelectrostatic eliminating net is arranged in the stand hopper, and one end of the electrostatic eliminating net is grounded through a ground wire.

Owner:邳州市苏鲁粮种繁育专业合作社

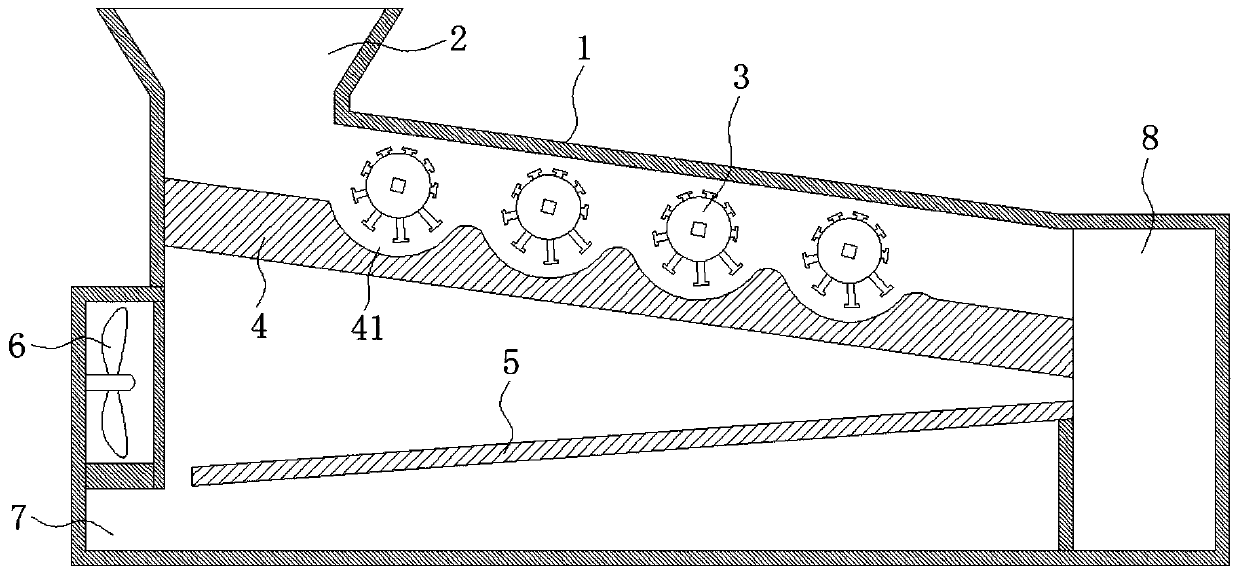

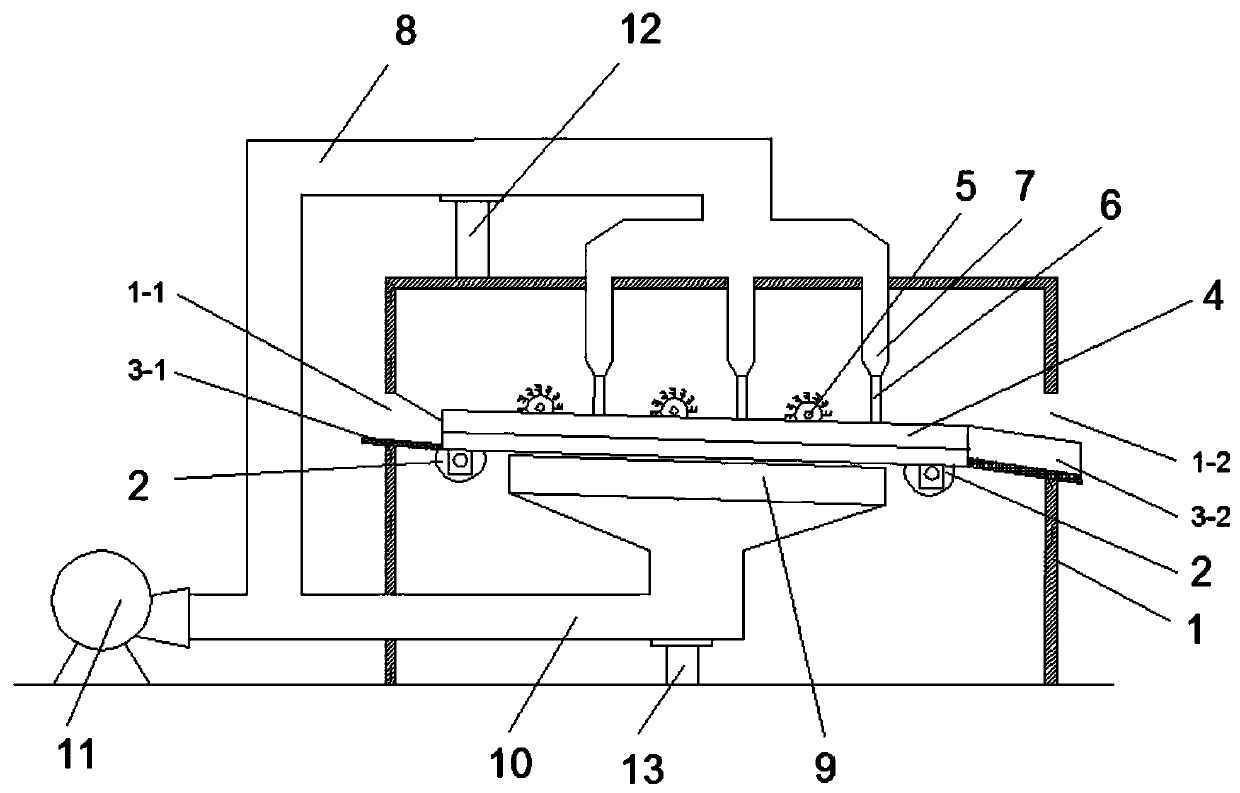

High-efficiency powerful dust cleaner special for cotton textiles

InactiveCN110117844AImprove dust collection efficiencySmooth slidingFibre cleaning/opening by air draught arrangementsFibre cleaning/opening by beater armsFiberSystem structure

Disclosed is a high-efficiency powerful dust cleaner special for cotton textiles. The high-efficiency powerful dust cleaner special for cotton textiles comprises a housing, conveying rollers, a conveying plate, baffles, scattering roller, cylinder air pipes, cylinder air pipe cavities, an upper exhaust pipe, a dust sucking plate, a lower exhaust pipe and a dust sucking fan, wherein the conveying rollers are arranged at both ends inside the housing; the conveying plate is obliquely arranged inside the housing; the baffles are arranged on both sides of the conveying plate; every scattering roller comprises a roller body, scattering rods and scattering lugs; the scattering rollers are arranged on the upper surface of the conveying plate; the cylinder air pipes are arranged on the upper surface of the conveying plate; the cylinder air pipe cavities are arranged at the top ends of the cylinder air pipes; the upper exhaust pipe is vertically communicated with the cylinder air pipe cavities;the dust sucking plate is arranged on the lower surface of the conveying plate; the lower exhaust pipe is arranged at the bottom end of the dust sucking plate, and one end of the lower exhaust pipe isfixedly connected with the dust sucking fan. The high-efficiency powerful dust cleaner special for cotton textiles can achieve repeated multi-angle dust sucking effects on cotton fiber at high efficiency, ensure smooth sliding of the cotton fiber inside the housing and stable operation of the system structure.

Owner:丹阳市永泰纺织有限公司

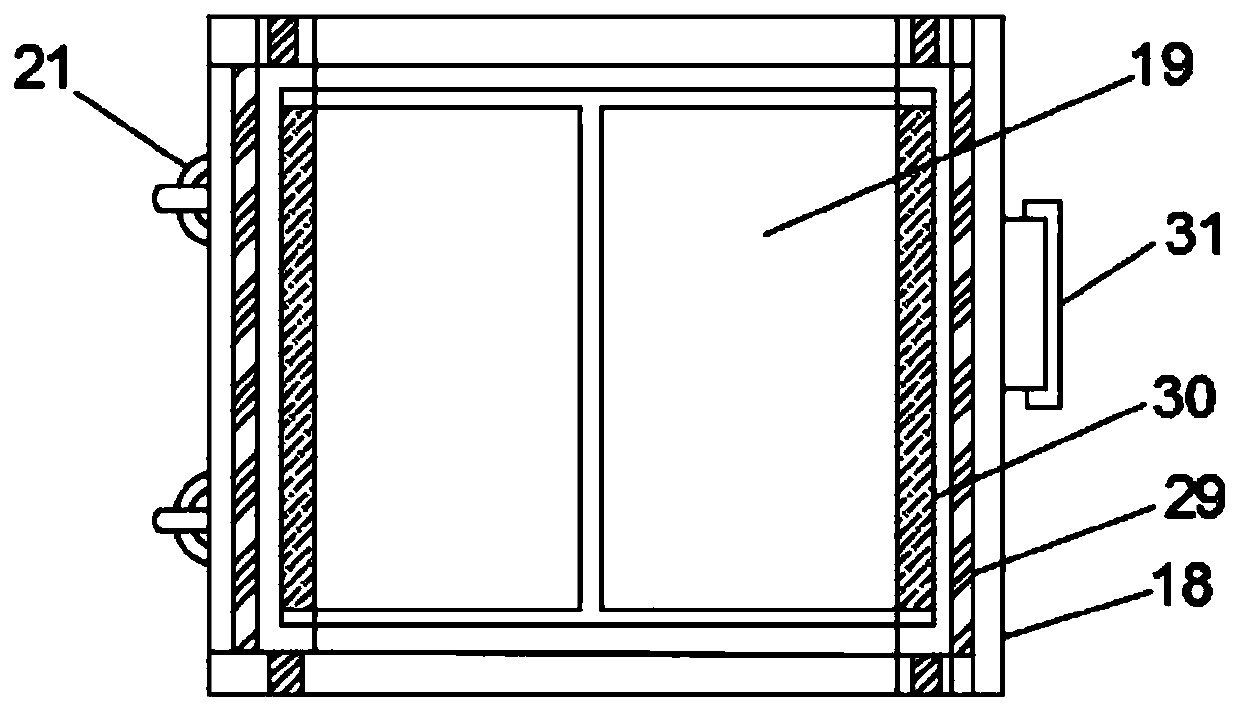

Quantifying device for knitwear raw materials

InactiveCN108441988AReduce the burden onEffective quantitativeFibre cleaning/opening by beater armsFibre separationEngineeringFilter effect

The invention discloses a quantifying device for knitwear raw materials, and relates to the technical field of knitwear. The quantifying device comprises a box body, a top box is fixedly connected tothe top of the box body, a bellows is fixedly connected to the top of the left side of the box body, a partition plate is fixedly connected between the two sides of the inner wall of the box body, a quantifying box is fixedly connected to the position, at the bottom of the partition plate, of the left side of the inner wall of the box body, a collecting box is fixedly connected to the position, atthe bottom of the partition plate, between the inner right side of the box body and the right side of the quantifying box, and a bottom box is fixedly connected between the bottom of the inner wall of the box body and the bottom of the quantifying box. The quantifying device for knitwear raw materials can perform quantifying effectively to ensure the accuracy in later processing and also can perform discharging in time after the quantity is reached; use is quite convenient, the burden of workers is relieved, feeding is facilitated, and bulky raw materials can be dispersed; meanwhile, a certain impurity filtering effect can be achieved, and later processing and using are facilitated.

Owner:安徽弋尚纺织科技有限公司

Scutching machine good in effect

InactiveCN106884229AGuaranteed to workExtended service lifeFibre cleaning and opening machine combinationsFibre cleaning/opening by beater armsEngineeringMechanical engineering

The invention discloses a cotton cleaning machine with good effect. The cleaning machine includes a cleaning box, the cleaning box is provided with a cotton inlet and a cotton outlet, and a beating roller is arranged in the cleaning box, and the beating roller is driven by a motor, and also includes a pretreatment box, The pretreatment box is connected with the cotton inlet through a channel; a carding plate is arranged at the channel, and the carding plate is composed of a body and sawtooth on the surface of the body, and a crushing device is arranged in the pretreatment box. The cotton cleaning machine of the present invention sets a pretreatment box before the cotton cleaning box, and carries out a preliminary impurity removal to the cotton through the crushing device in the pretreatment box, and at the same time, the cotton is combed by the carding board and then enters the cotton cleaning box. This enables the cleaning box to work efficiently and prolongs the service life of the beating roller in the cleaning box.

Owner:苏州市朗润纺织科技有限公司

Device for cleaning fibrous material

InactiveCN109137147ASatisfied and fast deliveryAvoid cloggingFibre cleaning/opening by air draught arrangementsFibre cleaning/opening by beater armsFiberEngineering

Owner:MASCHINENFABRIK RIETER AG

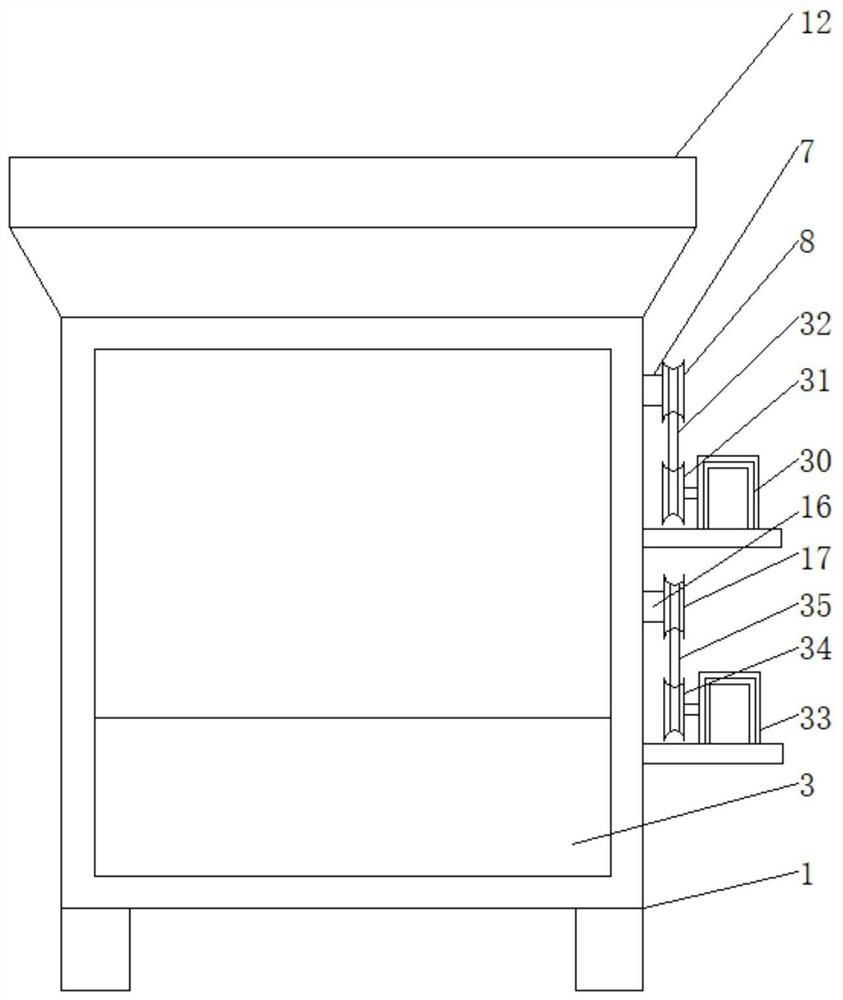

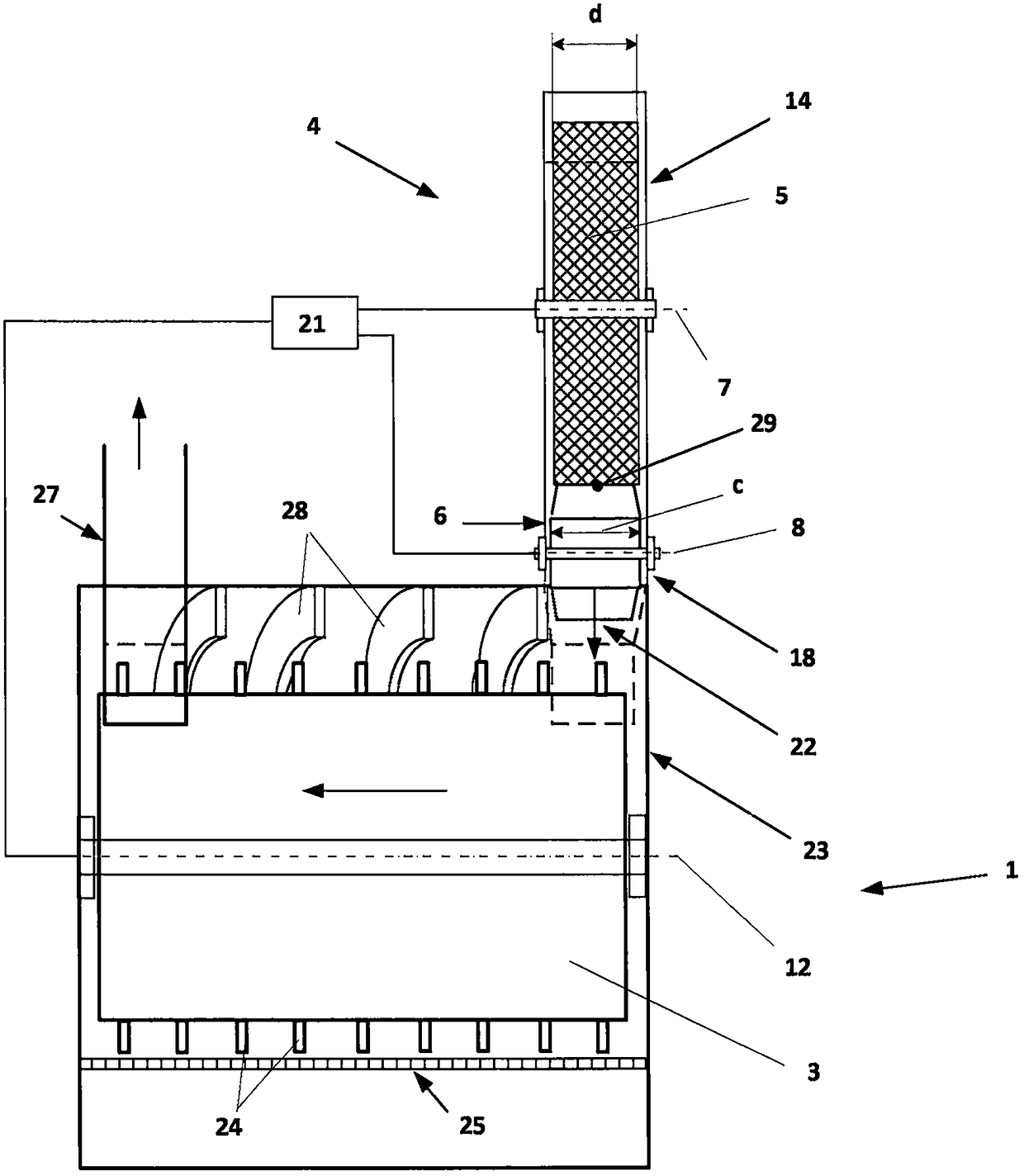

Axial opener for the treatment of fiber tufts

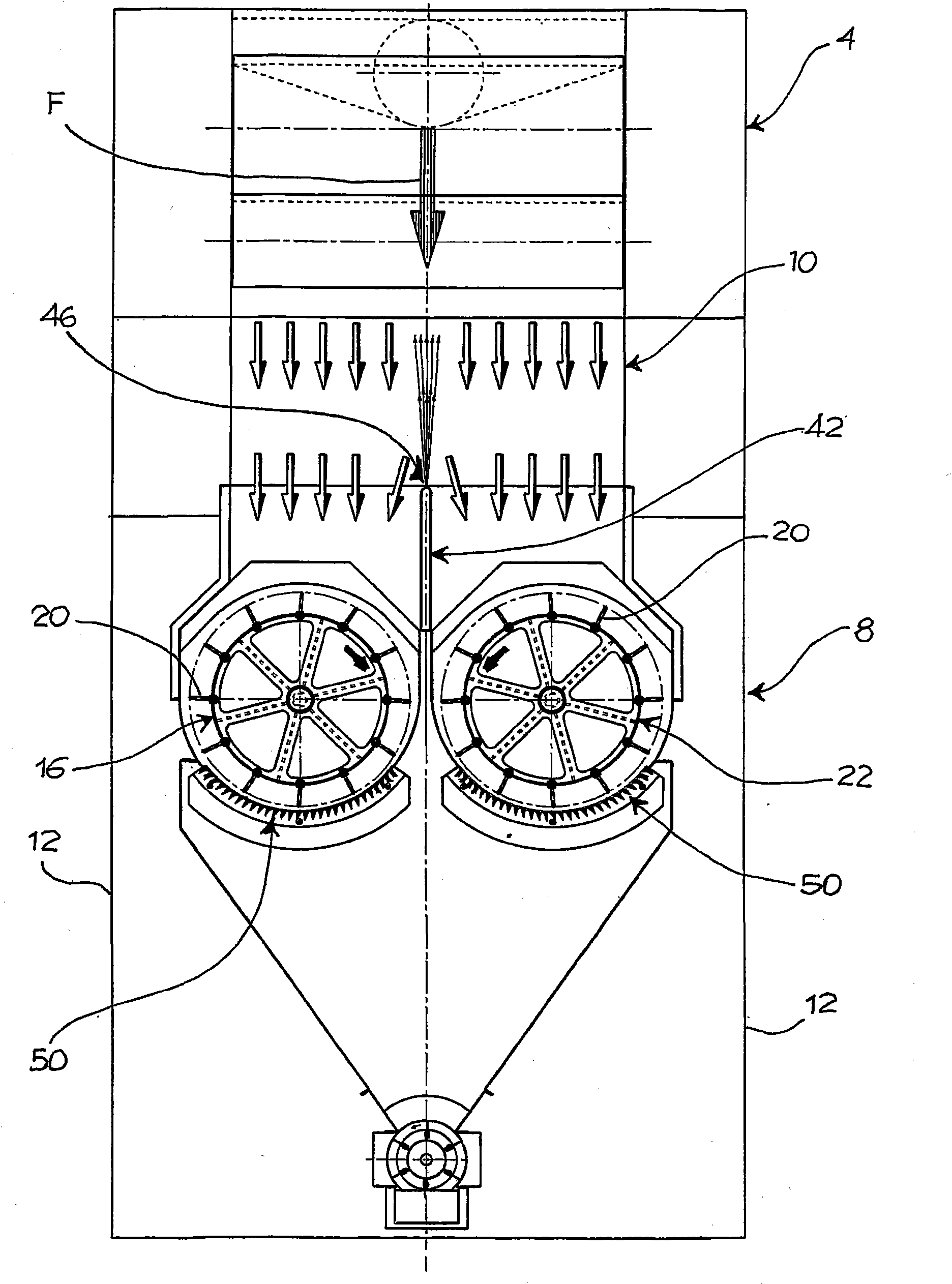

InactiveCN101842527AFibre cleaning and opening machine combinationsFibre cleaning/opening by beater armsFiberBiomedical engineering

An axial opener (8) for fibers in tufts comprising an input pipe (10), opener rollers (16,22) and a separation 5wall (42) upline of the cleaner rollers, to separate the compartments where the rollers are lodged and channel the fibers to be processed in part towards the first compartment and in part towards the second compartment of the opener.

Owner:MARZOLI SPA

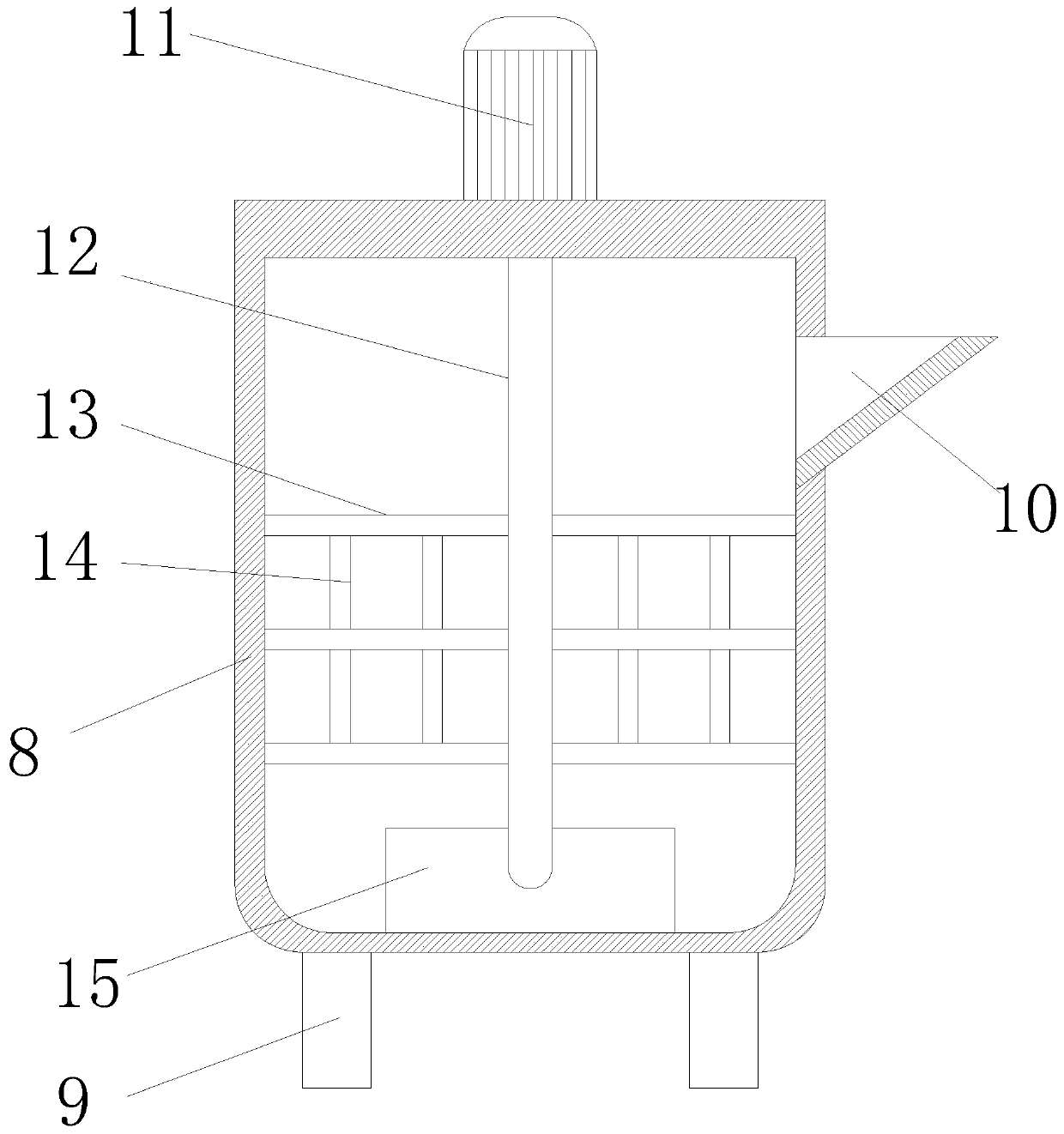

Rotary drum-type fiber opening device

ActiveCN107090613AFull spraySimple structureLubricating devicesFibre cleaning/opening by beater armsFiberEngineering

The invention relates to a fiber opening device, in particular to a rotary drum-type fiber opening device. The rotary drum-type fiber opening device comprises a rack body, two automatic fiber sucking devices, a plurality of fiber conveying pipes, an opening machine, a fiber bin and an automatic oil spraying mechanism, wherein the automatic oil spraying mechanism comprises a feeding hopper, a sliding sleeve, a shell, an overturning inner drum, a stirring shaft and a planetary gear set, the feeding hopper is communicated with the fiber conveying pipes, one end of the sliding sleeve is communicated with the feeding hopper and is in rotary connection with the feeding hopper, the other end of the sliding sleeve is communicated with the overturning inner drum and is in rotary connection with the overturning inner drum, the shell is fixed to the rack body, oil spraying heads are arranged on the inner wall of the shell, the overturning inner drum is arranged in the shell, an oil inlet hole is formed in the overturning inner drum, the overturning inner drum is fixedly connected with a planetary carrier of the planetary gear set, the overturning inner drum is communicated with the fiber conveying pipes, and the stirring shaft is arranged in the overturning inner drum. For solving the problem of uneven fiber and oil spraying, the device can uniformly spray fiber and oil.

Owner:CHONGQING TIANYUN AUTO PARTS

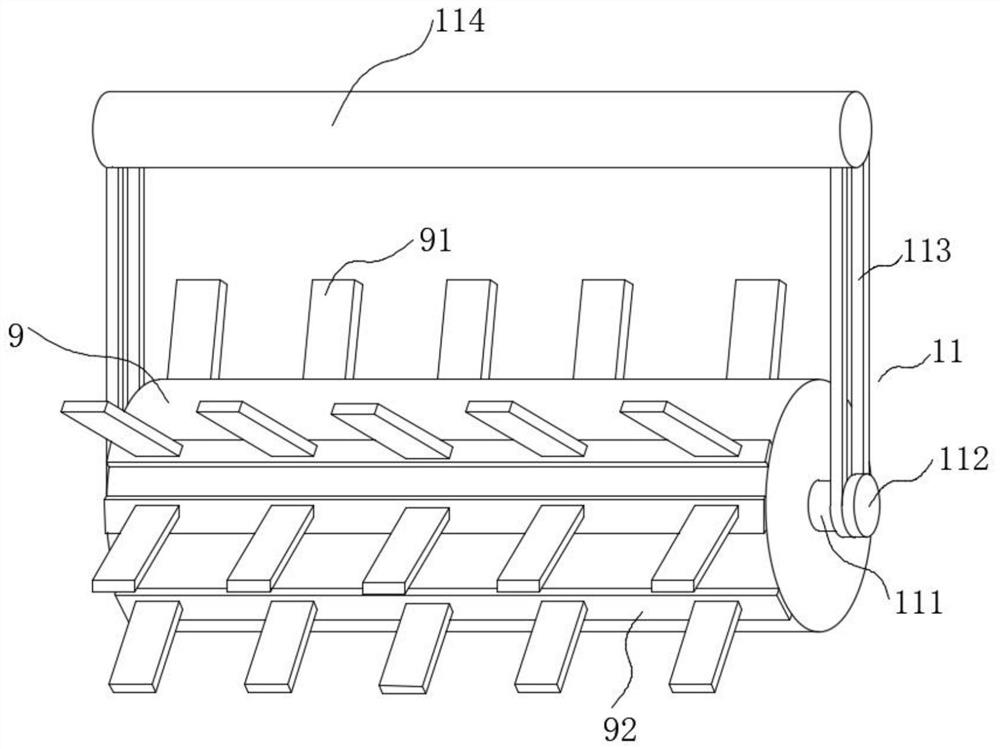

Mini bale plucker

InactiveCN1733987AOptimize structural configurationAchieve mixingFibre cleaning/opening by beater armsFibre breaking by beater armsFiberSmall footprint

A mini gripping wrap machine includes a frame, wherein a gripping arms is mounted on the frame, which is driven by the gearings; a rib is mounted on the frame, which has a plurality of ribs, between the ribs there some distance for the gripping tooth of the gripping arms to hold out; a fiber wrap baffle plate is mounted on the frame; a regulator is mounted between the rib frame and the frame. This mini grasping wrap machine uses each grasping wrap arms that runs synchronously as the running part to do single wrap grasping, which occupies fewer areas, and because it processes only one kind of the fiber, so it can realize pluralities of fiber mixing.

Owner:吕恒正 +1

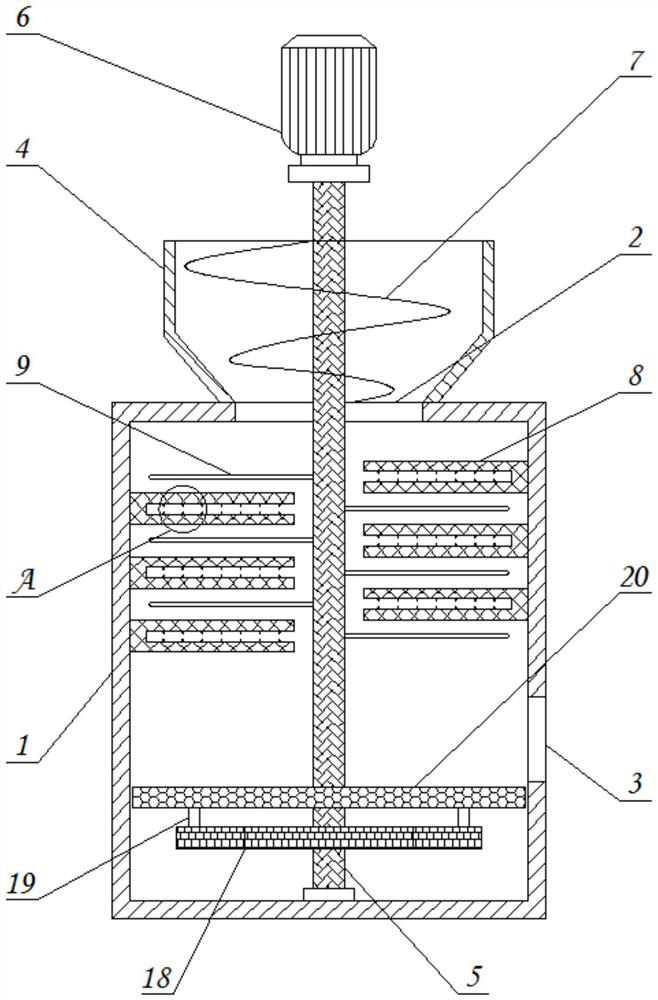

High-opening-efficiency fiber raw material opening equipment for spinning

ActiveCN111876854AImprove opening efficiencyAvoid blockingFibre cleaning/opening by beater armsFibre cleaning/opening machinesFiberSpinning

The invention relates to the technical field of spinning, and discloses high-opening-efficiency fiber raw material opening equipment for spinning. The high-opening-efficiency fiber raw material opening equipment comprises a box body, a feeding port is formed in the top of the box body, a funnel barrel is fixedly connected to the top of the box body, a rotating shaft is rotatably connected to the inner bottom wall of the box body, and a motor is fixedly connected to the top of the rotating shaft. A spiral blade is arranged outside the rotating shaft, a fixed rod is fixedly connected to the inner wall of the box body, a rotating strip is fixedly connected to the exterior of the rotating shaft, two first grooves and two second grooves are formed in the fixed rod, and reset springs are fixedlyconnected to the sides, opposite to each other, of the two first grooves correspondingly; and second ejector pins are fixedly connected to the opposite sides of the two reset springs correspondingly.The spiral blade is arranged in the funnel barrel and drives fiber raw materials to enter the box body from the feeding port when rotating, so that the effect of preventing the fiber raw materials from being accumulated in the funnel barrel to block the feeding port is achieved.

Owner:海宁市米奥服饰有限公司

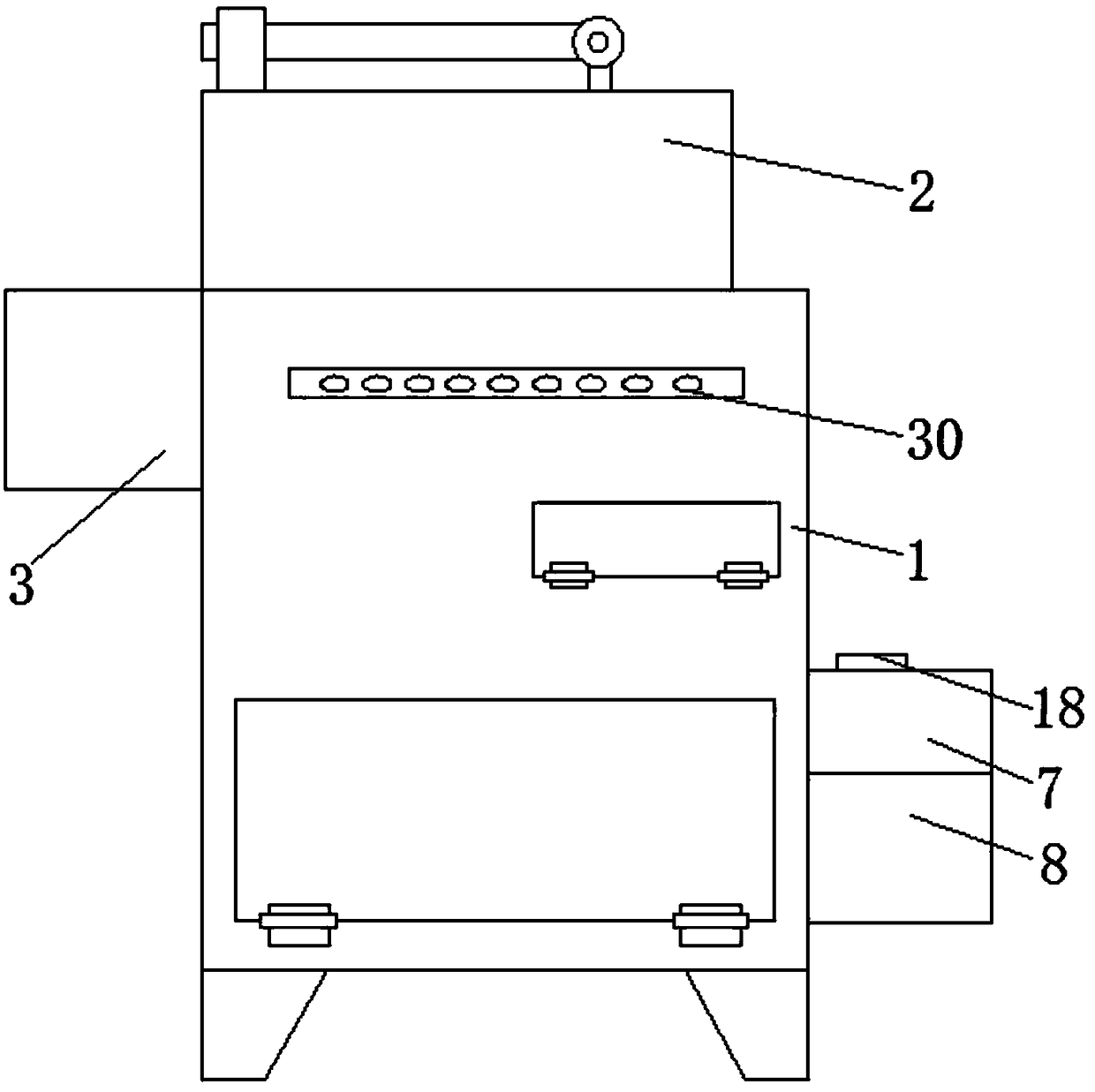

Impurity removing opener for non-woven fabric production

InactiveCN110983497AAvoid secondary pollutionSolve manual handlingFibre cleaning/opening by beater armsFibre cleaning/opening machinesProcess engineeringNonwoven fabric

The invention discloses an impurity removing opener for non-woven fabric production. The opener comprises a machine shell; a feeding hole is formed in the upper surface of the machine shell; and a first vibration structure, a cotton condenser and a cotton storage column are arranged at the position, close to the upper part, of the interior of the machine shell. Through the cooperative use of a second lifting support arm, a limiting sliding rail and a limiting pulley, a storage and transportation box is slowly tilted until the storage and transportation box is upside down on the feeding hole, and raw materials push a protective cover to be opened and enter the machine shell from the storage and transportation box and the feeding hole, so that the problem that the raw materials need to be carried and poured manually in the past is solved, time and labor are saved, and secondary pollution of the raw materials can be avoided; the problem of low cleaning efficiency of dust in the raw materials after cotton opening is solved through the cooperative use of arranged air conveying pipe, first dust grid and second dust grid; and the dust in the raw materials can be effectively separated fromthe raw materials under the double action of gravity and wind force in a process that the raw materials fall from top to bottom after being subjected to cotton opening.

Owner:安徽绿源高分子材料科技有限公司

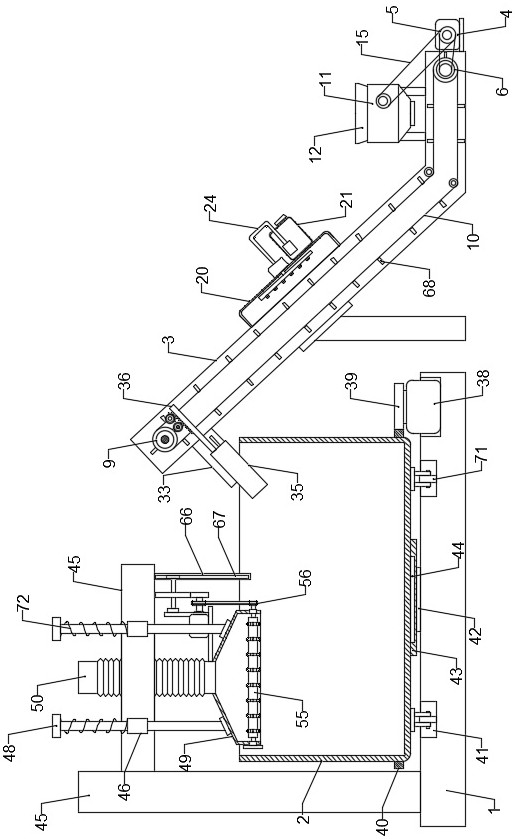

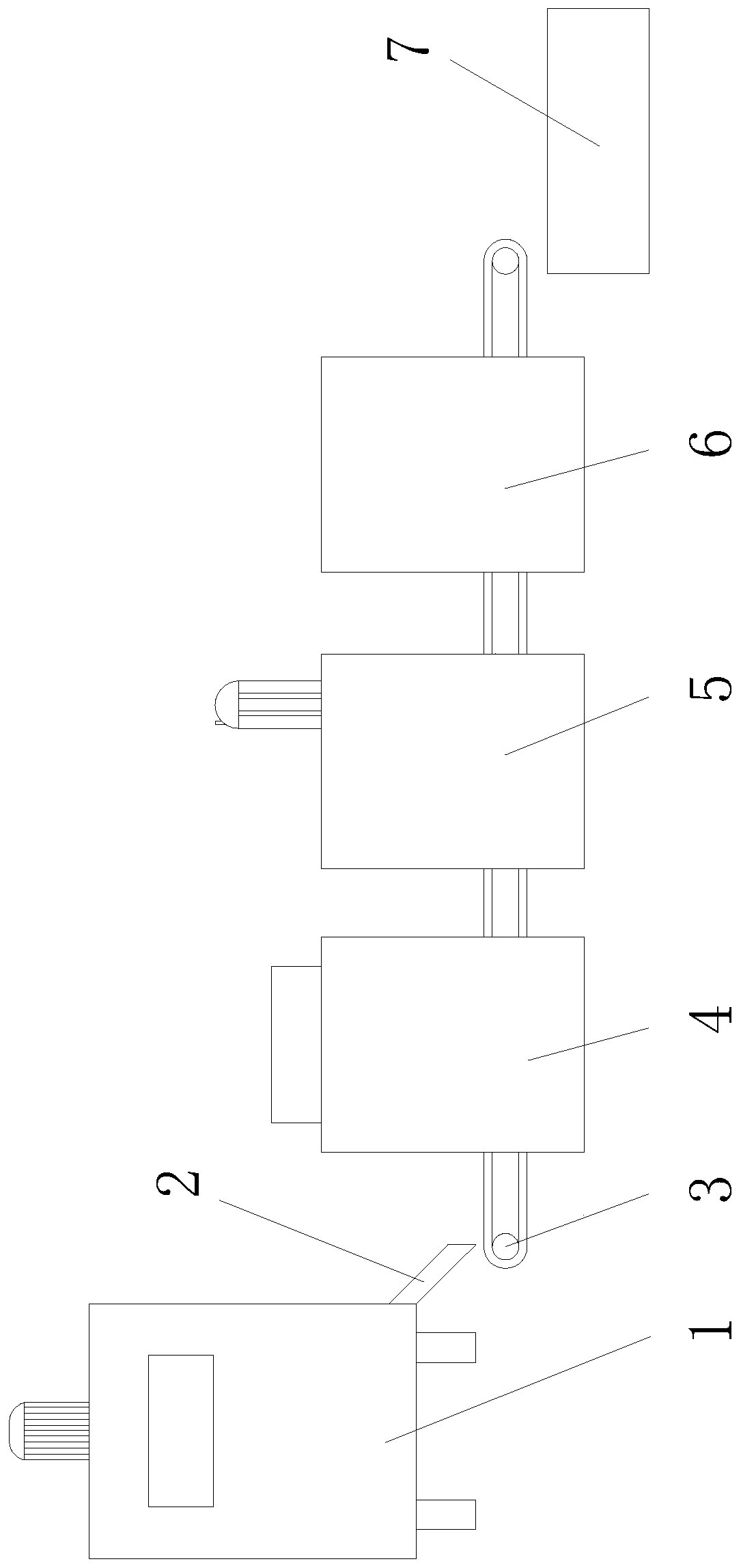

Fully cured felt production line

InactiveCN109736017AAvoid product qualityQuality improvementFibre cleaning/opening by beater armsLiquid/gas/vapor removal by gas jetsPower addedFiber

The invention discloses a fully cured felt production line which comprises a loosening mechanism, a disinfecting mechanism, a drying mechanism, a powder scattering mechanism and a roll pressing forming machine. A guide slot is fixedly formed in the lower end of the right side wall of the loosening mechanism, and a conveyor belt is arranged on the lower right side of the guide slot. The invention relates to the fully cured felt production line. By arranging a steam spray nozzle, a hot blower, a powder scattering barrel and the like, waste fibers and a cotton raw material are disinfected, driedand processed, so that the quality of the raw material is improved. An adhesive is paved uniformly, so that the product quality of the felt is improved and the like. The problems that the human cost is increased as most adhesives are paved in a power adding groove manually, the follow-up felt forming effect is affected as the powder adding effect is not uniform, and the product quality of the feltis affected as processing raw materials which are commonly blended with recovered waste fiber raw materials are directly processed are solved.

Owner:HUBEI TIANYUN NOISE REDUCTION & ANTIVIBRATION NEW MATERIAL

Air filter cotton preparation and treatment process

PendingCN112535922AEffectively break upStir wellDispersed particle filtrationFibre cleaning/opening by beater armsFiberAir filter

The invention discloses an air filter cotton preparation and treatment process which comprises a shell. A stirring cavity is formed in the shell, a first groove is formed in the shell, the first groove is located in the middle of the stirring cavity and communicates with the stirring cavity, a first fixing block is arranged on the right side wall of the shell, and a second groove is formed in thefirst fixing block. Fiber cotton with fibers proportioned according to different proportions can be uniformly stirred, moisture in the fiber cotton can be blow-dried while a stirring rod is driven bya hot-air blower to rotate, and the fiber cotton which is stirred into balls can be opened.

Owner:WENZHOU BINGXI ENVIRONMENTAL PROTECTION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com