Flock grabbing device for cotton yarn production

A technology of cotton yarn and cotton catcher, which is applied in the direction of lubrication device, opening and cleaning with stirring arm, fiber treatment, etc., can solve the problems of cotton yarn production, achieve the effect of uniform feeding, convenient feeding, and reduce labor force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

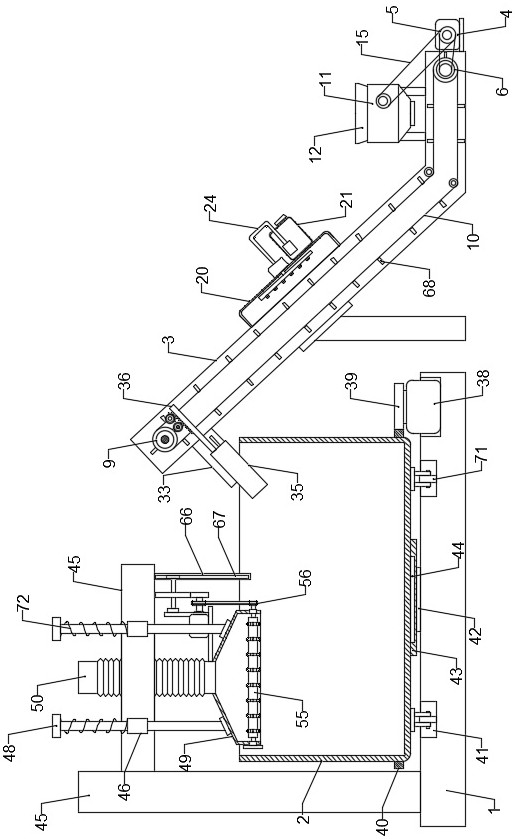

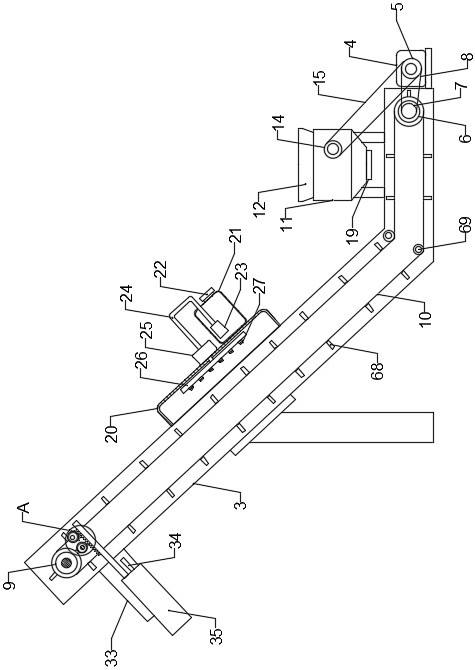

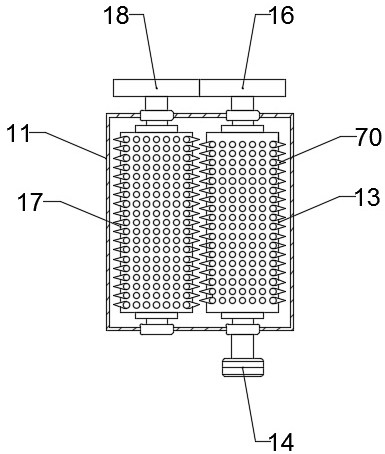

[0031] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-10Shown: a cotton grasping device for cotton yarn production, comprising a mounting base 1 and a rotating bin 2 movably installed on the mounting base 1, one side of the rotating bin 2 is provided with a feeding mechanism, and the rotating bin 2 The bottom is provided with a rotating mechanism, and the rotating material bin 2 is provided with a gripping mechanism; the feeding mechanism includes a conveyor frame 3, a drive motor 4, a double-axis pulley 5, a driving roller 6, a pulley 7, a transmission belt 8, Driven roller 9, conveyor belt 10, drop box 11, tapered drop opening 12, driving cotton roller 13, pulley two 14, transmission belt two 15, driving gear one 16, driven cotton roller 17, driven gear one 18 , feeding port 19, spray installation shell 20, small water tank 21, water inlet 22, water pump 23, water delivery pipe 24, atomizer 25, spray pipe 26, seve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com