Fiber opening and feeding device and cotton opening, dispersing and mixing mechanism for spinning

A feeding device and fiber technology, applied in the direction of fiber mixing, fiber opening and cleaning machine, fiber treatment, etc., can solve the problems of low control efficiency, inconvenient maintenance, high unit investment cost, etc., to improve opening strength and operation flexibility high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

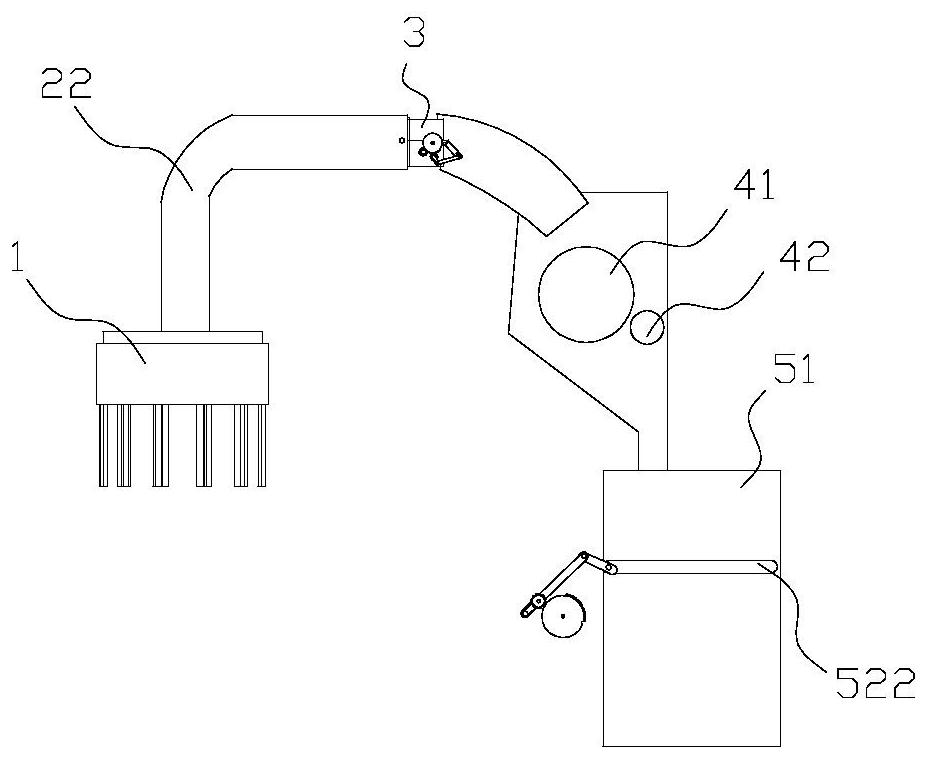

[0069] Such as figure 1 , 2 As shown, this embodiment discloses a fiber opening and feeding device for the production of textile fabrics, including a cotton picking machine 1, and the cotton picking machine 1 includes a fiber placement bin 11, a cotton picking mechanism 12, and a cotton picking mechanism 12 for placing fibers. Fibers in bin 11 are picked up.

[0070] A fiber two-way switching conveying device 3 is also arranged at the rear of the plucking machine 1 , and the fiber two-way switching conveying device 3 is used for conveying the fibers grasped by the plucking machine 1 .

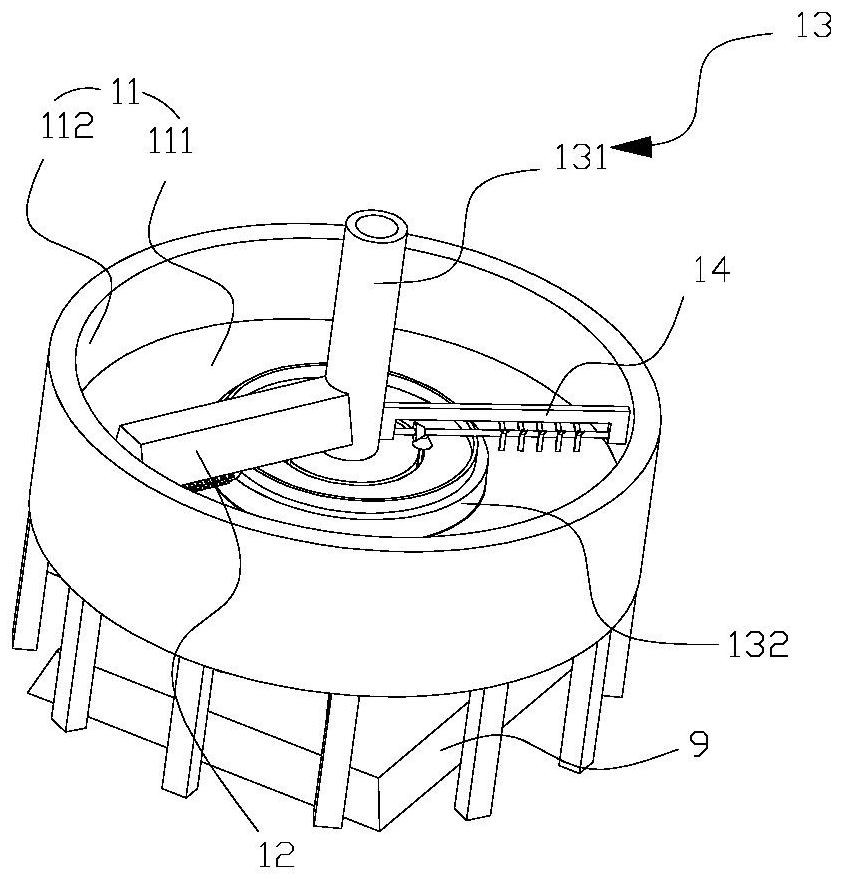

[0071] The catching machine 1 also includes a turret 13, a fiber pre-opening device 14, and the catching mechanism 12 and the fiber pre-opening device 14 are all arranged on the turret 13, and there is a angle. Rotation of the rotating shaft 131 of the turret 13 can drive the cotton grasping mechanism 12 and the fiber pre-opening device 14 to rotate synchronously. The fiber pre-opening devic...

Embodiment 2

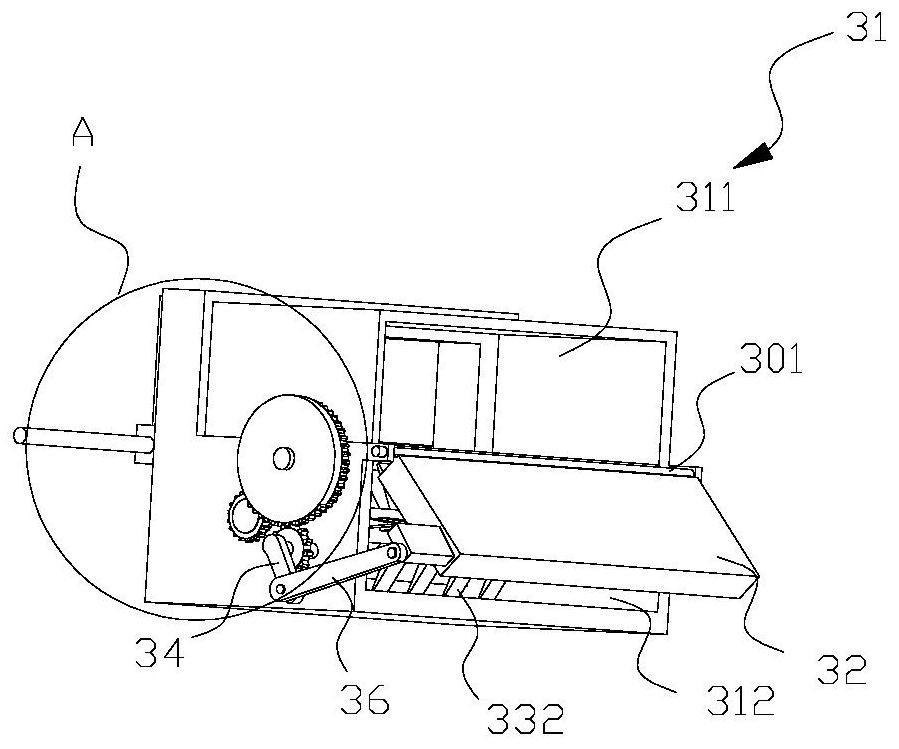

[0103] Such as Figure 9-14 As shown, the difference between this embodiment and the above-mentioned embodiments is that one end of the two-way switching valve plate 37 is a connection end, and the other end is a free end, the connection end is fixed on the switching valve plate rotating shaft 381, and the switching valve plate rotating shaft 381 is connected to the conveying channel. The feeding end of 31 rotates and fits. The end of the switching valve plate rotating shaft 381 is provided with a sub-locking part, and a first female locking part and a second female locking part are arranged on the frame 19 of the plucking machine of the fiber two-way switching conveying device. When the switching valve plate rotating shaft 381 rotates to the two-way switching valve plate 37 closed at the feed port of the first conveying feeding channel 311 or the feeding port of the second conveying feeding channel 312, the child locking part can be locked with the first female lock The lock...

Embodiment 3

[0112] Such as figure 2 , 15 , 16, the difference between this embodiment and the above embodiments is that: the fiber storage bin 11 includes a chassis 111 and a peripheral plate 112, and the peripheral plate 112 surrounds the periphery of the chassis 111.

[0113] The cotton grabbing mechanism 12 includes an installation cover 121 and a cotton grabber 122. The bottom of the installation cover 121 is provided with a fiber inlet 1211 and a linkage opening 1212. The fiber inlet 1211 communicates with the conveying channel 31. The fiber inlet 1211 is rotated and fitted with a cotton catcher 122 , the interlocking port 1212 is isolated from the fiber inlet 1211 , and one end of the cotton grabber 122 extends into the interlocking port 1212 .

[0114] The turret 13 includes a rotating shaft 131 and an annular installation bin 132, and the annular installation bin 132 has a hollow structure. The rotating shaft 131 protrudes from the central hole of the annular installation bin 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com