Device for cleaning fibrous material

A fibrous material and cleaning technology, which is applied in the direction of cleaning with suction device, fiber cleaning machine, stirring arm cleaning, etc., can solve the problems of high wear and tear of feed roller and screen drum, peeling grains, etc., and achieve fast transmission Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

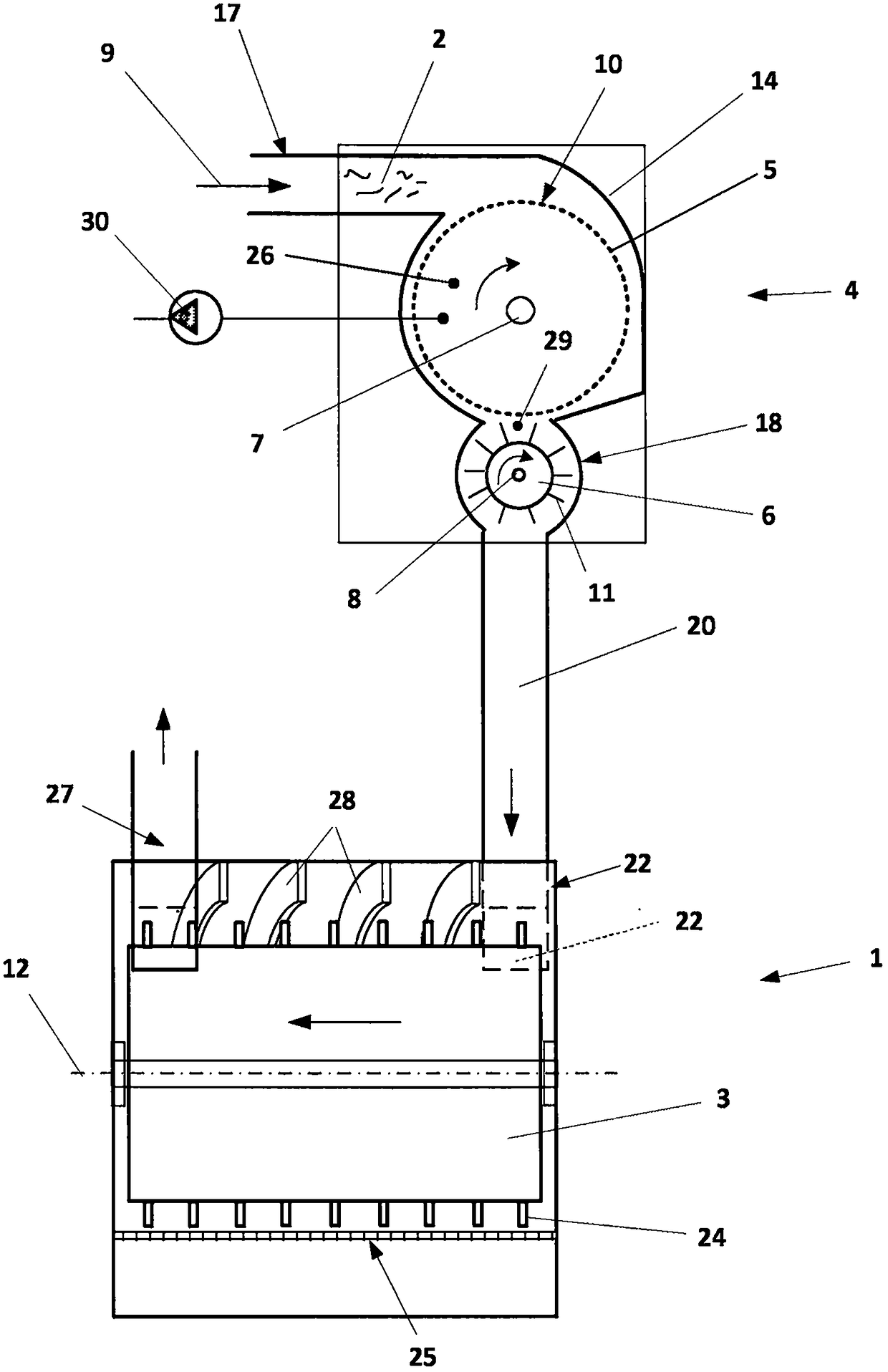

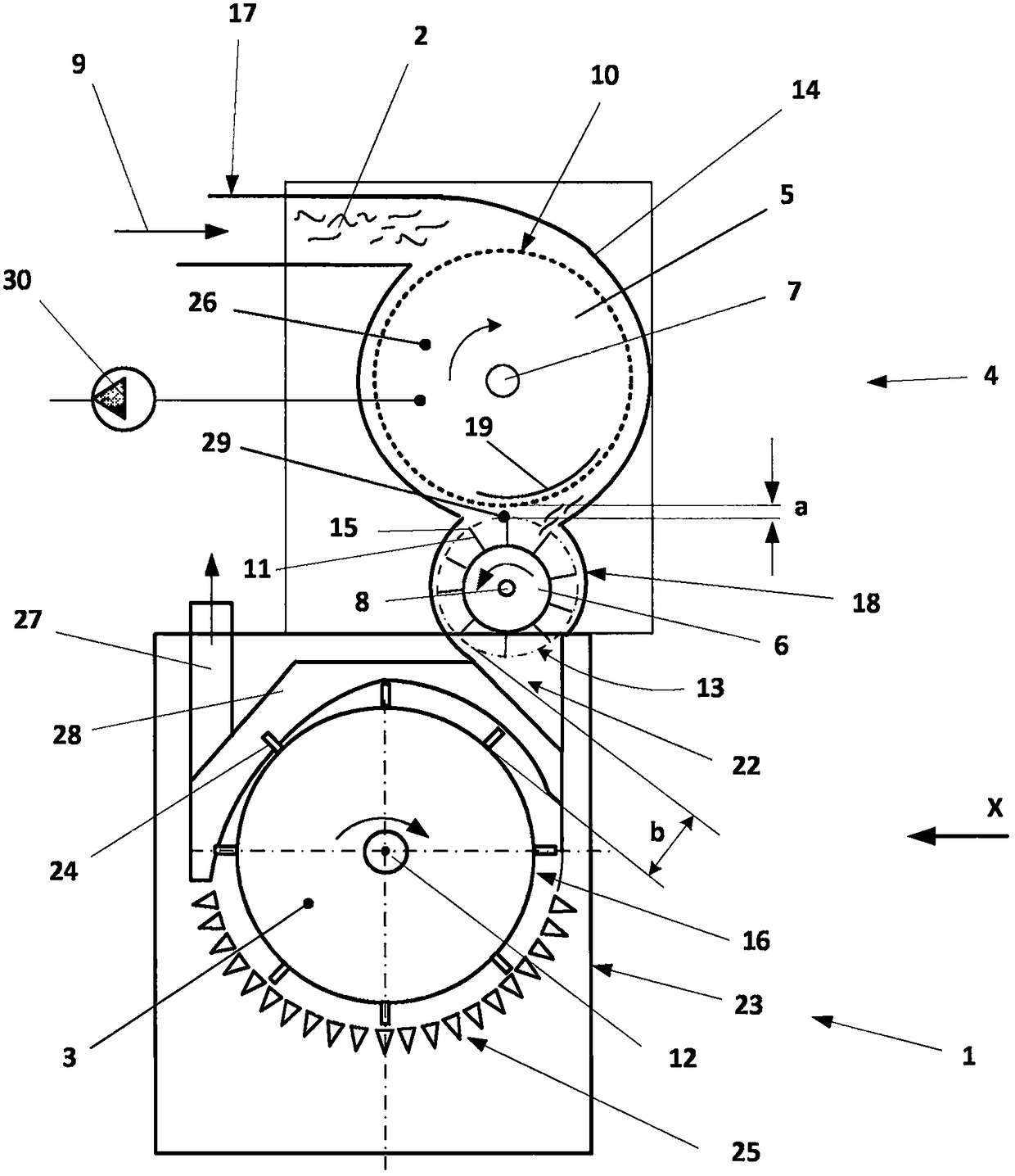

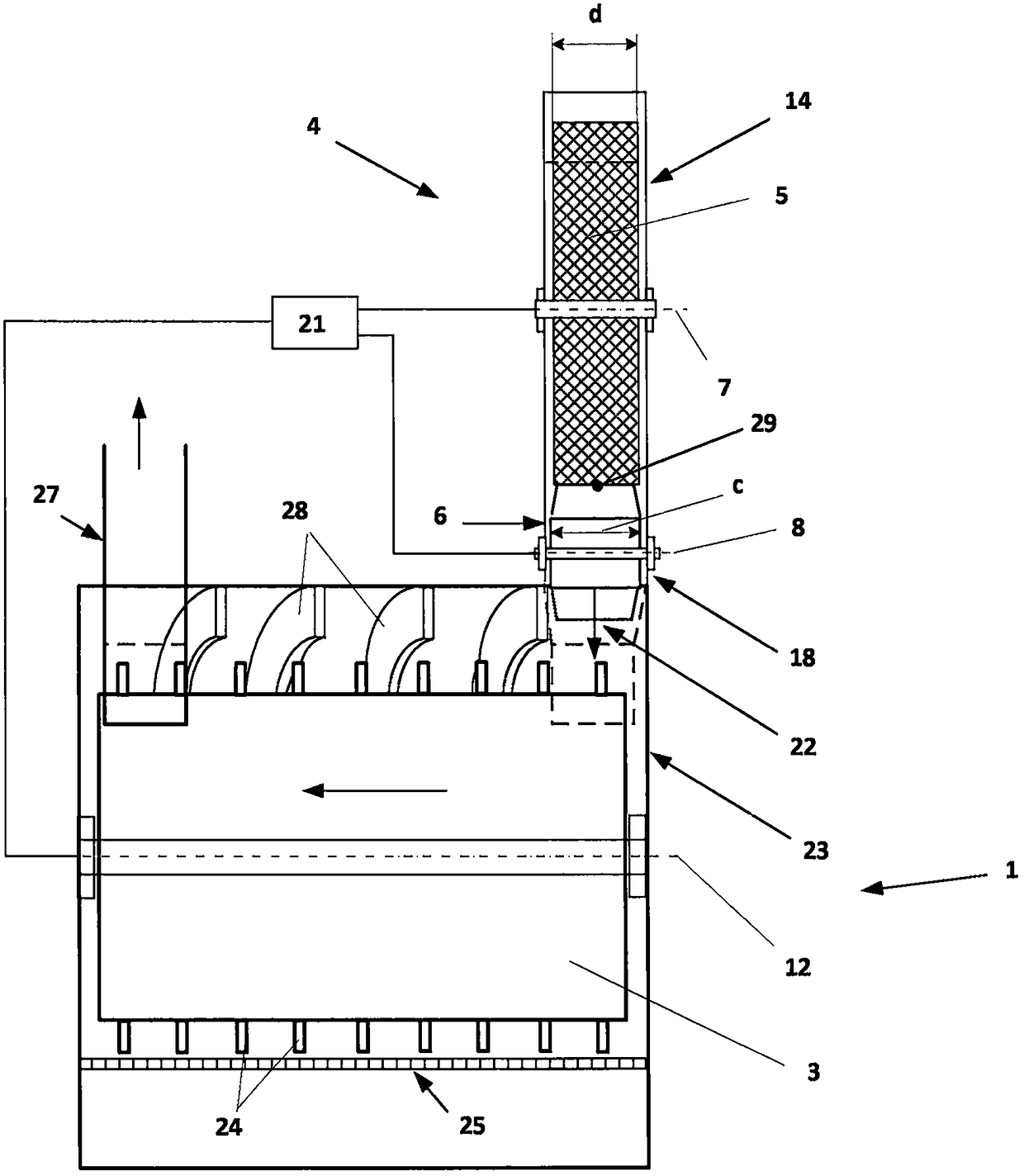

[0020] figure 1 Shows a schematic diagram of an embodiment of a cleaning device according to the prior art, comprising a condenser 4 and a cleaner 1 arranged below the condenser 4 and having a rotatably mounted cleaning roller 3 . The condenser 4 has a screen drum 5 mounted for rotation about a longitudinal axis 7 in a screen drum housing 14 , which is filled with fiber material 2 through channels 17 ; the condenser also has a feed roller 6 (also known as a flap drum), which is mounted for rotation about the longitudinal axis 8 in the feed roller housing 18 .

[0021] The fibrous material 2 is fed to the screen drum 5 by means of conveying air. A vacuum is applied in the interior 26 of the screen drum 5 by a vacuum source 30 . The fibrous material 2 fed in this way is sucked onto the surface 10 of the screen drum 5 and separated from the conveying air 9 by the air-permeable surface 10 of the screen drum 5; was removed. In this process, a web of fibrous material is formed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com