Scutching machine good in effect

A kind of cotton cleaning machine, good technology, applied in the field of cotton cleaning machine, can solve the problems of poor impurity removal effect, low efficiency of cotton cleaning machine, etc., and achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

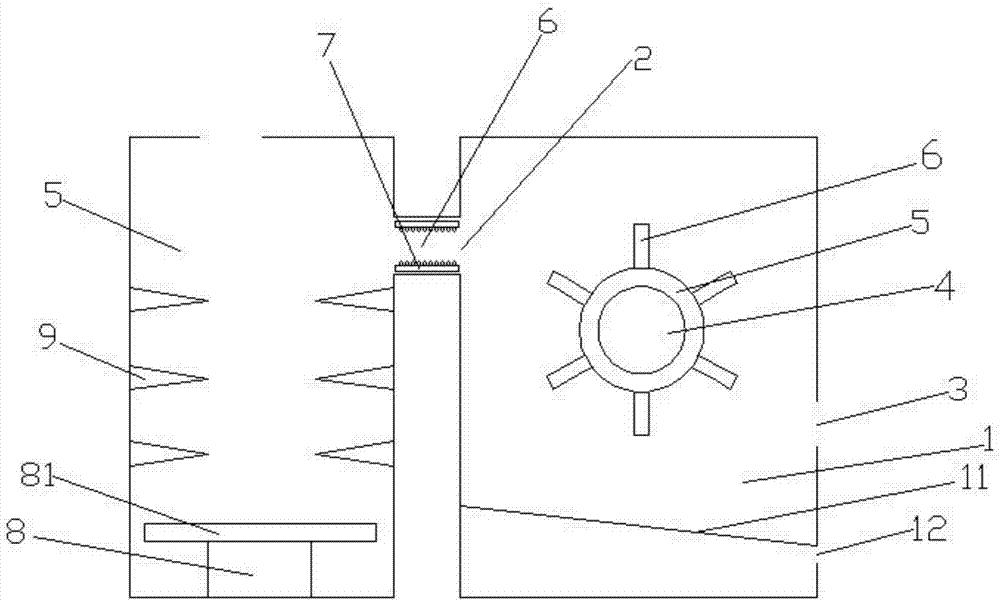

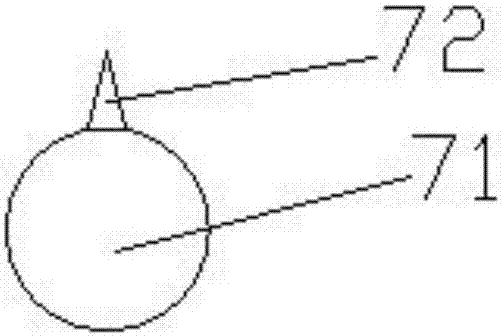

[0020] As shown in the figure, a kind of cotton cleaning machine with good effect of the present invention comprises a cleaning box 1, which is provided with a cotton inlet 2 and a cotton outlet 3, and is provided in the cleaning box 1 There is a beater roller 4, which is driven by a motor (not shown), and also includes a pretreatment box 5, which is connected to the cotton inlet 2 through a passage 6; There is a carding board 7, and the carding board 7 is composed of a body 71 and sawtooth 72 on the surface of the body 71, and a crushing device is arranged in the pretreatment box 5.

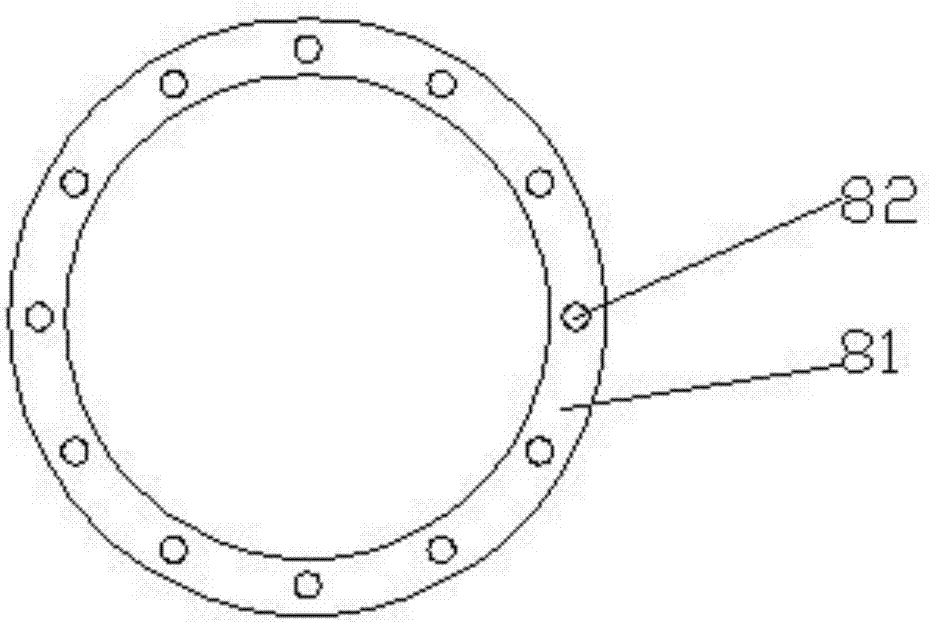

[0021] The crushing device includes a fan 8 located at the bottom of the pretreatment box 5 and a bayonet 9 arranged on the inner wall of the pretreatment box 5 . Through the blower fan 8 at the bottom and the bayonet 9 on the inner wall, the cotton can be crushed, the impurities of large particles can be separated, and the impurity removal pressure in the cleaning box 1 can be reduced. Specifi...

Embodiment 2

[0025] Such as Figure 4 As shown, the body 71 is a cuboid, and the rest of the technical solutions are the same as those in Embodiment 1, and the sawtooth 72 of the body 71 is set in a direction perpendicular to the cotton moving direction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com