Mini bale plucker

A kind of bag grabbing machine and micro technology, which is applied in the directions of opening the bag with a beater and opening and cleaning with a stirring arm, to achieve the effect of strong flexibility, simple structure and small footprint.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

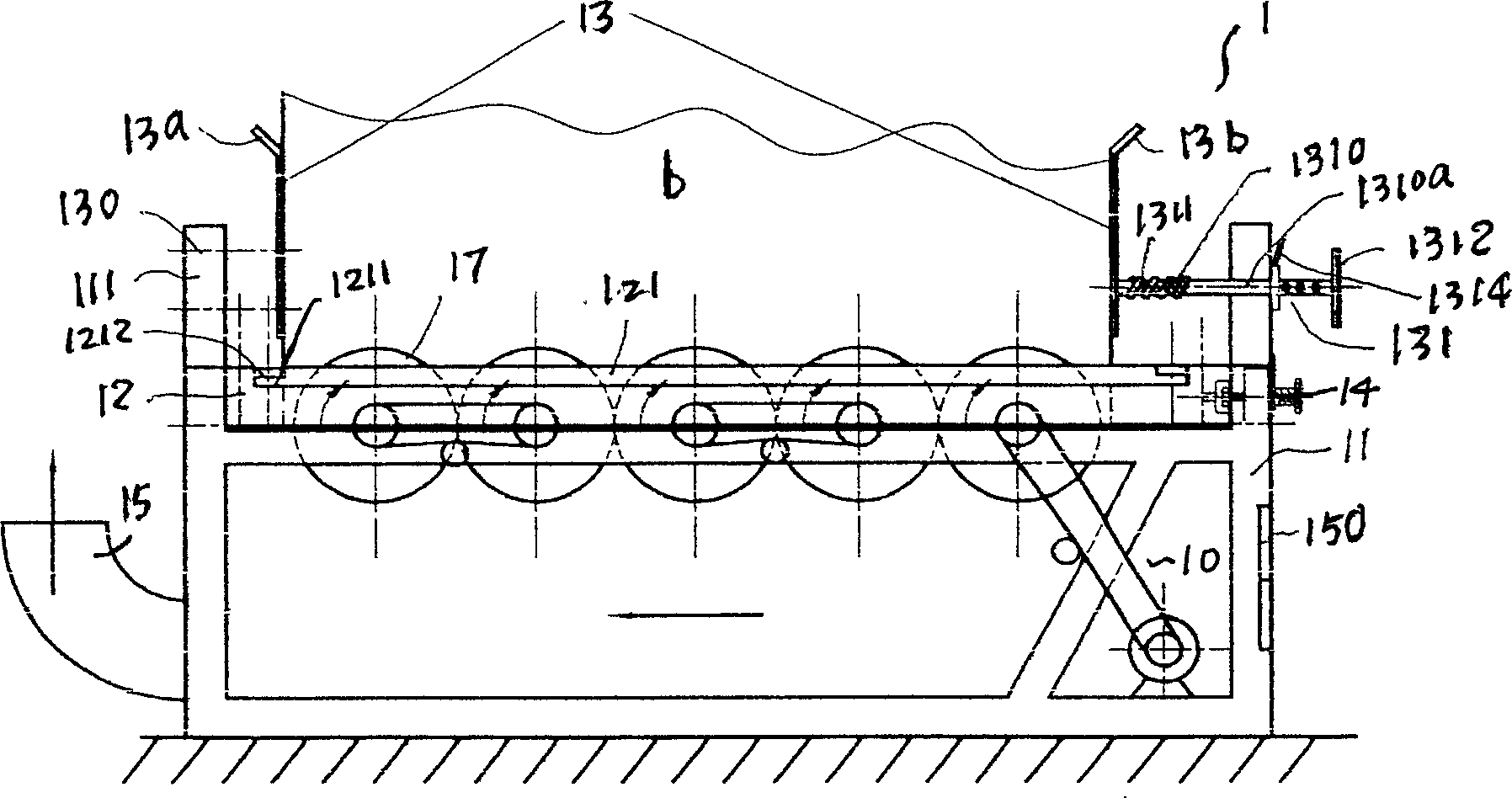

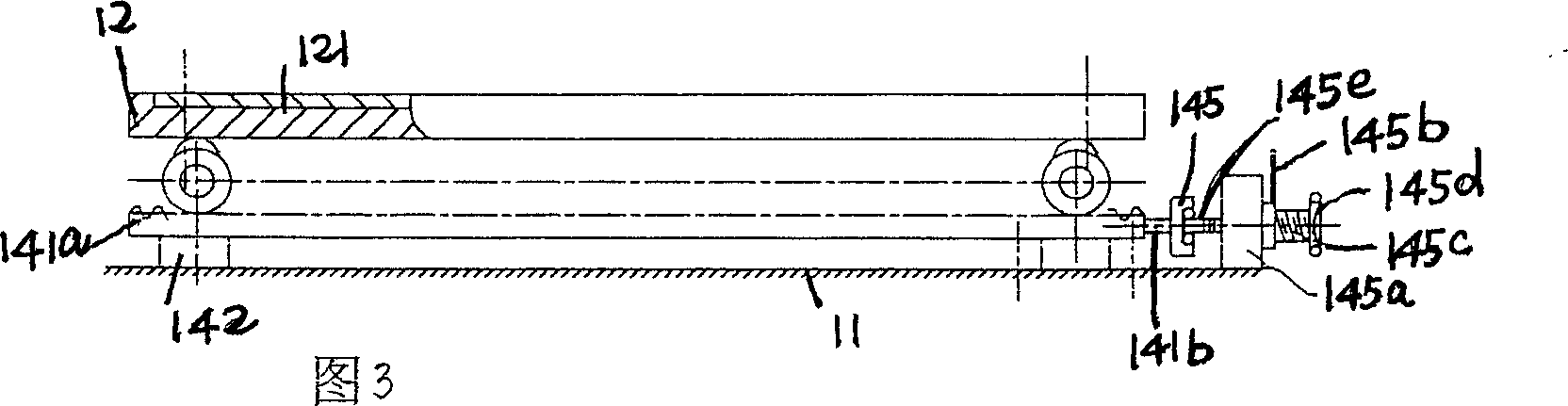

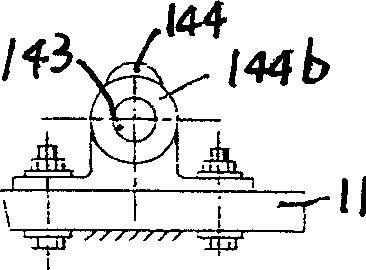

[0028] The specific implementation, structure, features and effects provided by the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0029] See figure 1 As shown in -3, a miniature bale grabbing machine 1 includes a frame 11, wherein frame sides 111 are provided on both sides of the frame; a rib frame 12 is placed in the frame side of the frame to support the fiber bag, and the rib Several ribs 121 are arranged on the frame, and there are gaps between the ribs to allow the grabbing teeth of the bag grabbers to protrude. There are assembly tenons 1211 at both ends of the ribs, which are embedded on the rib frame in conjunction with the assembly pressure plate 1212, so that the rib frame Form an overall plane, forming a solid rib frame with ribs and a gap that allows the grabbing teeth to protrude, which is convenient for the safe placement of fiber bales;

[0030] The aforementioned rib spacing shoul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com