Feeding device of a fibre preparation line for carding

A fiber and feeding technology, applied in the field of feeding devices, can solve the problems of unsatisfactory good efficiency, contamination of fiber bundles by impurities, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

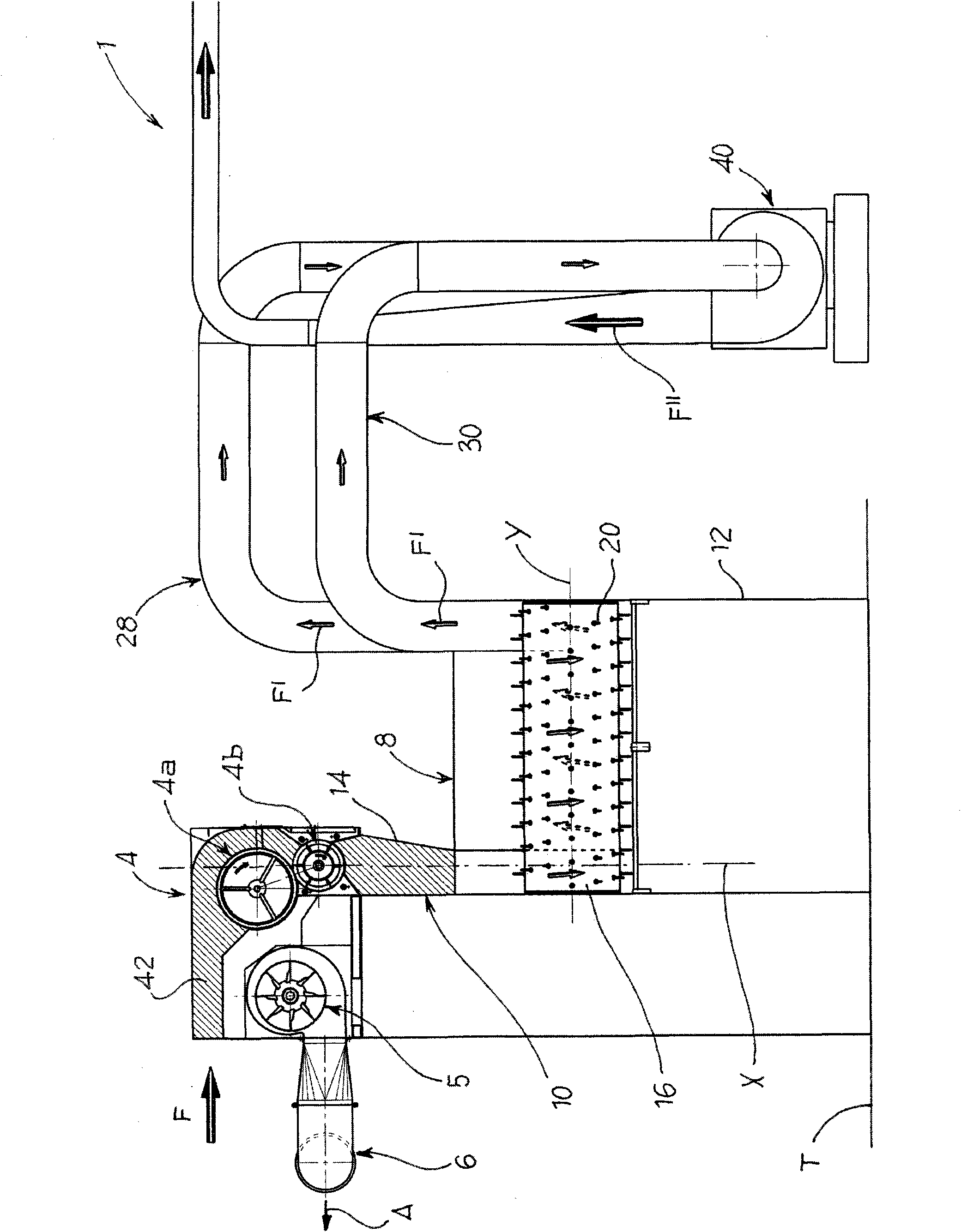

[0023] Referring to the drawings, reference numeral 1 generally designates an apparatus with an axial flow opener for processing bundled fibres, which apparatus forms part of a fiber processing line.

[0024] According to one embodiment, the device comprises a single input duct 2 with two or more branches 2', 2" to convey the fibers to be processed, e.g. from a pick-up unit ( Figure 4 ).

[0025] According to another embodiment, the device comprises suitably separated input ducts 2a, 2b for the transport of the fibers to be processed ( Figure 5 ).

[0026] It should be noted that in Figure 4 and Figure 5 In , the ducts are shown vertically for illustrative purposes; whereas in reality, it is apparent that the ducts extend along a horizontal axis.

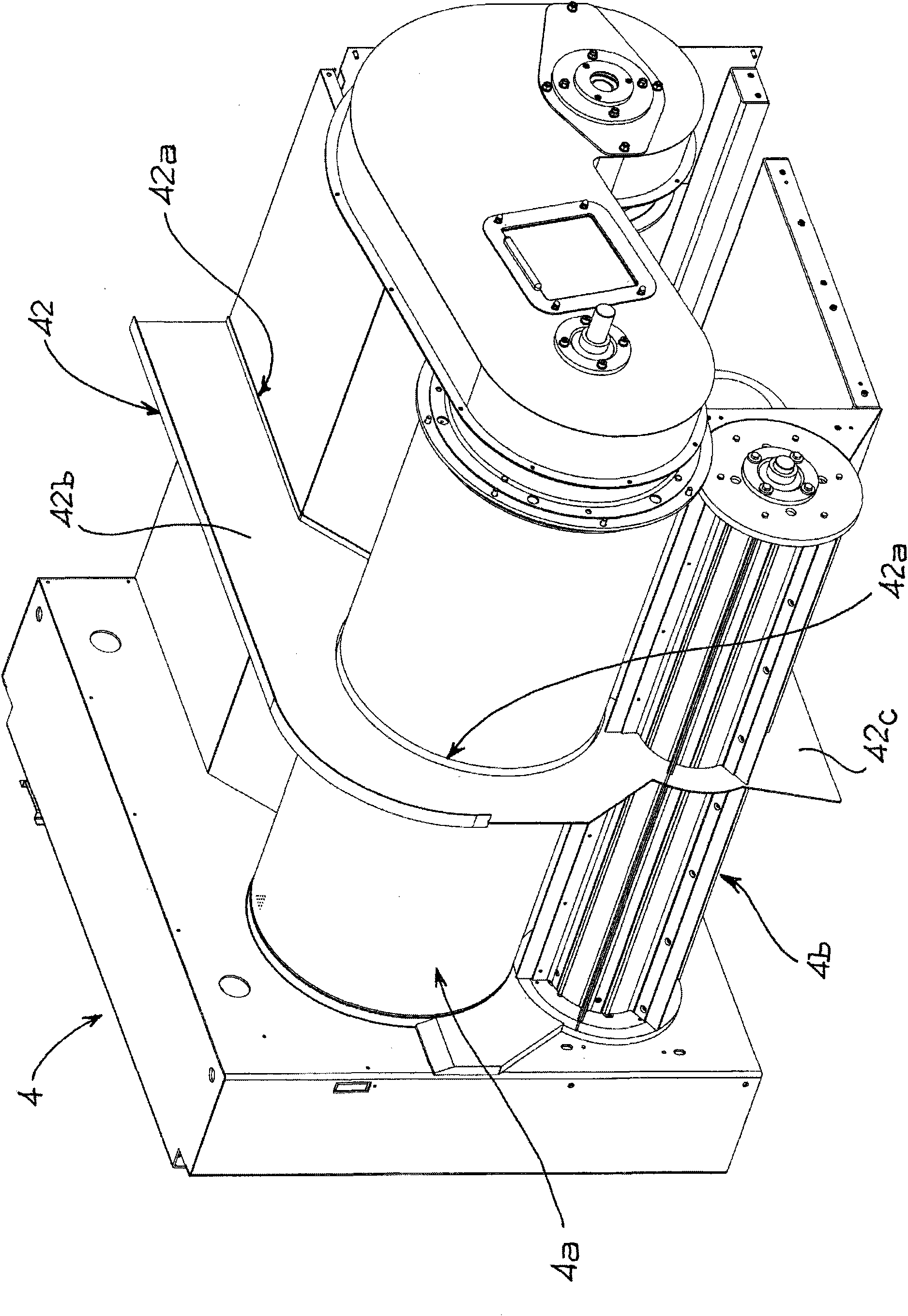

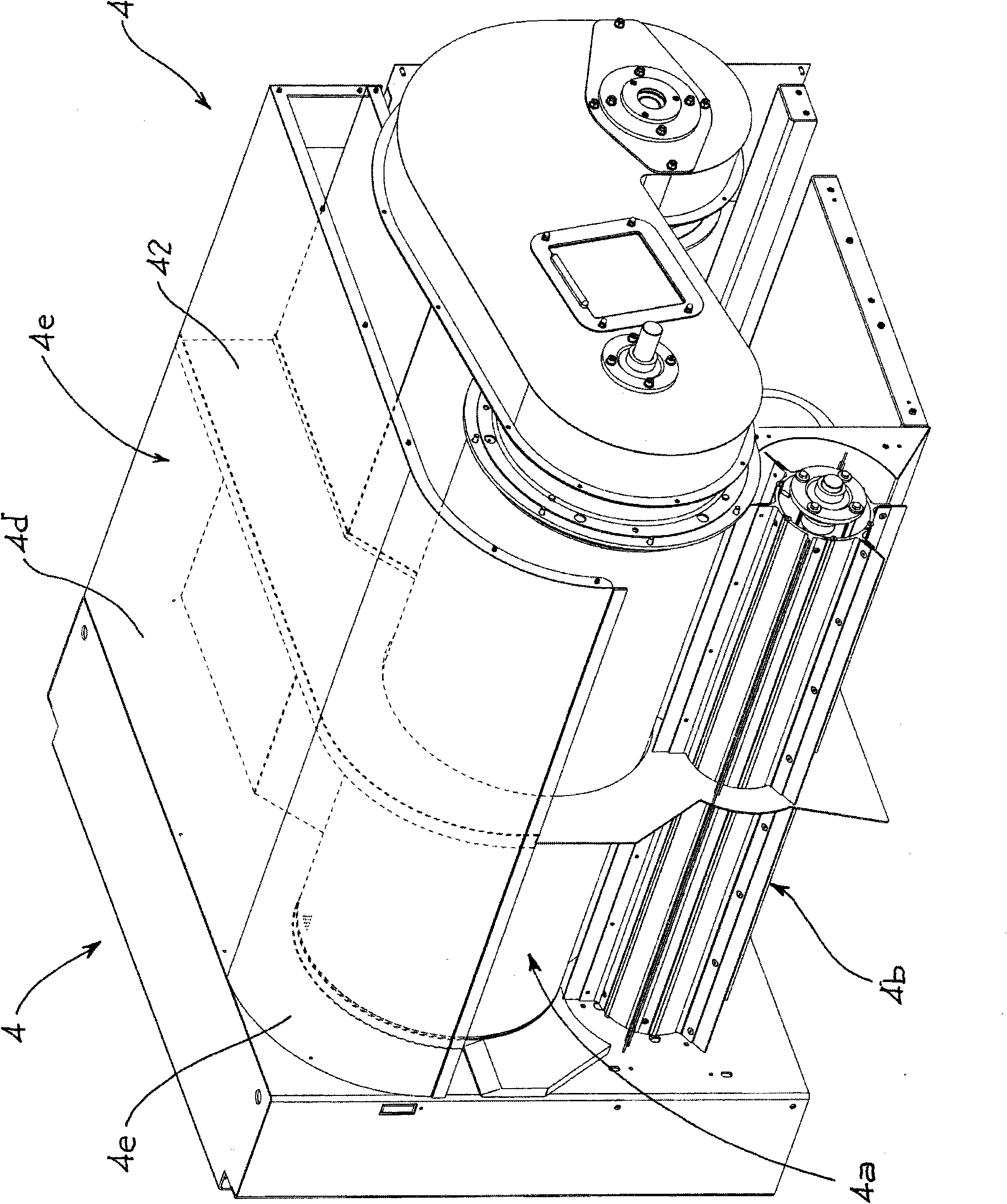

[0027] The plant comprises feeding means 4 for feeding the fibers to downstream machines, in particular also adapted for separating the dust-laden air from the fibers.

[0028] For example, the fibers to be processed are co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com