Opener for fibre in tufts on a carding preparation line, opener fibre, and method for processing fibre dundle

A technology of cotton opener and fiber bundle, which is applied in the field of cotton opener and can solve problems such as confusion and impurities in fiber bundles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

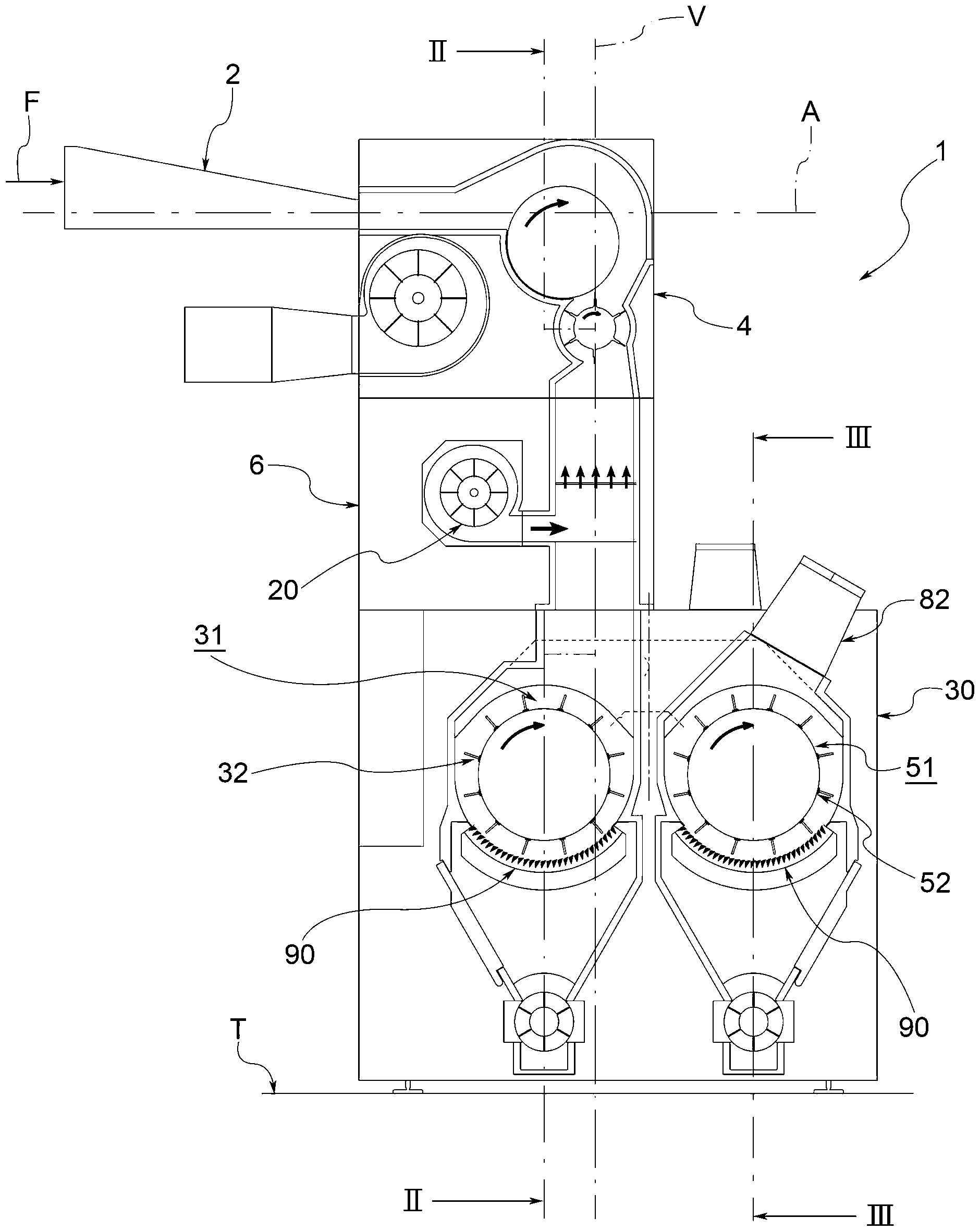

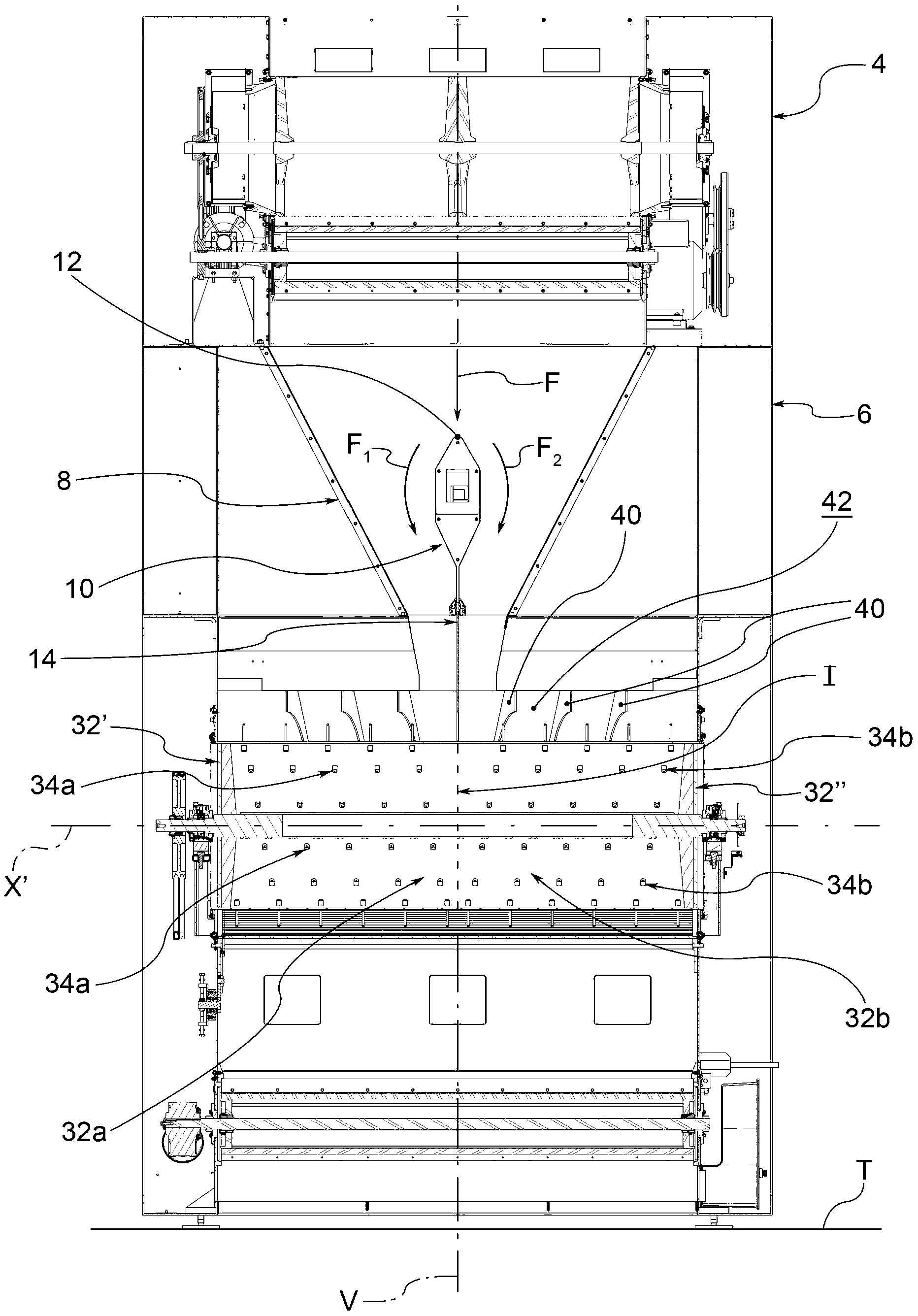

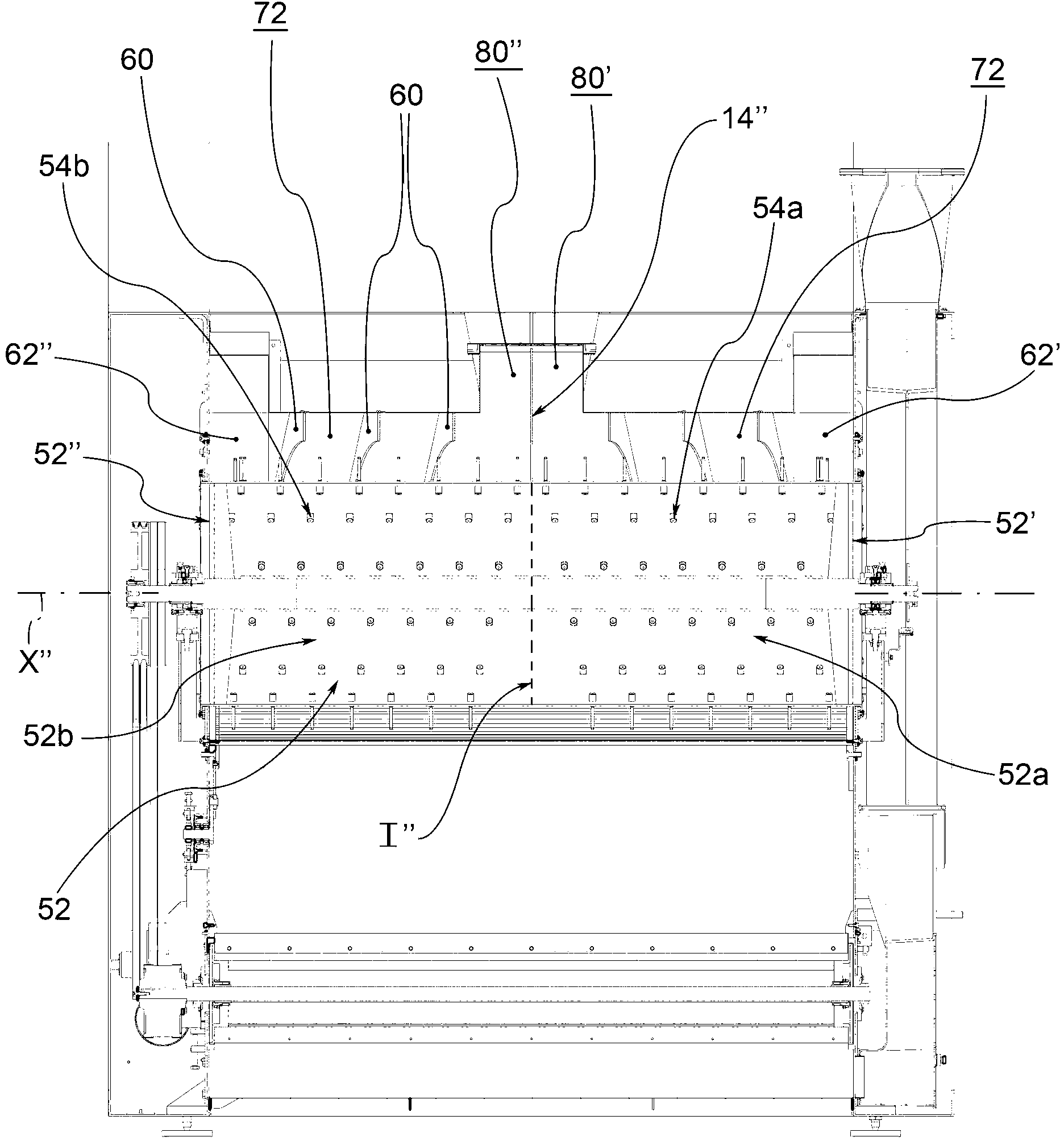

[0021] Referring to the drawings, reference numeral 1 generally indicates an assembly for processing fiber bundles, which forms part of a fiber processing line, in particular a carding preparation line.

[0022] The assembly 1 comprises a feed pipe 2 for conveying fibers F to be processed, for example fibers from a loosening machine.

[0023] The supply pipe 2 is arranged at a predetermined height from the ground plane T, extending along a substantially rectilinear supply axis A, preferably parallel to the ground plane T. As shown in FIG.

[0024] The assembly 1 also comprises feeding means 4 adapted to separate the dust-laden air from the fibers, preferably for feeding fiber bundles downstream. In particular, the feeding device 4 is adapted to deviate the fibers in the feeding direction downstream V, eg vertically and perpendicular to the ground plane T (and thus preferably perpendicular to the feeding axis A).

[0025] Preferably, the module 1 comprises a separator device 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com