Method for optimizing dummy plate of double-volute type double-suction pump and product produced with same

An optimization method and technology of double-suction pump, which are applied to non-variable-capacity pumps, components of pumping devices for elastic fluids, pumps, etc., can solve the problems of inability to meet the working requirements of the pump, reduction of head and efficiency, etc. Achieve the effect of avoiding liquid energy loss, reducing impeller radial force and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

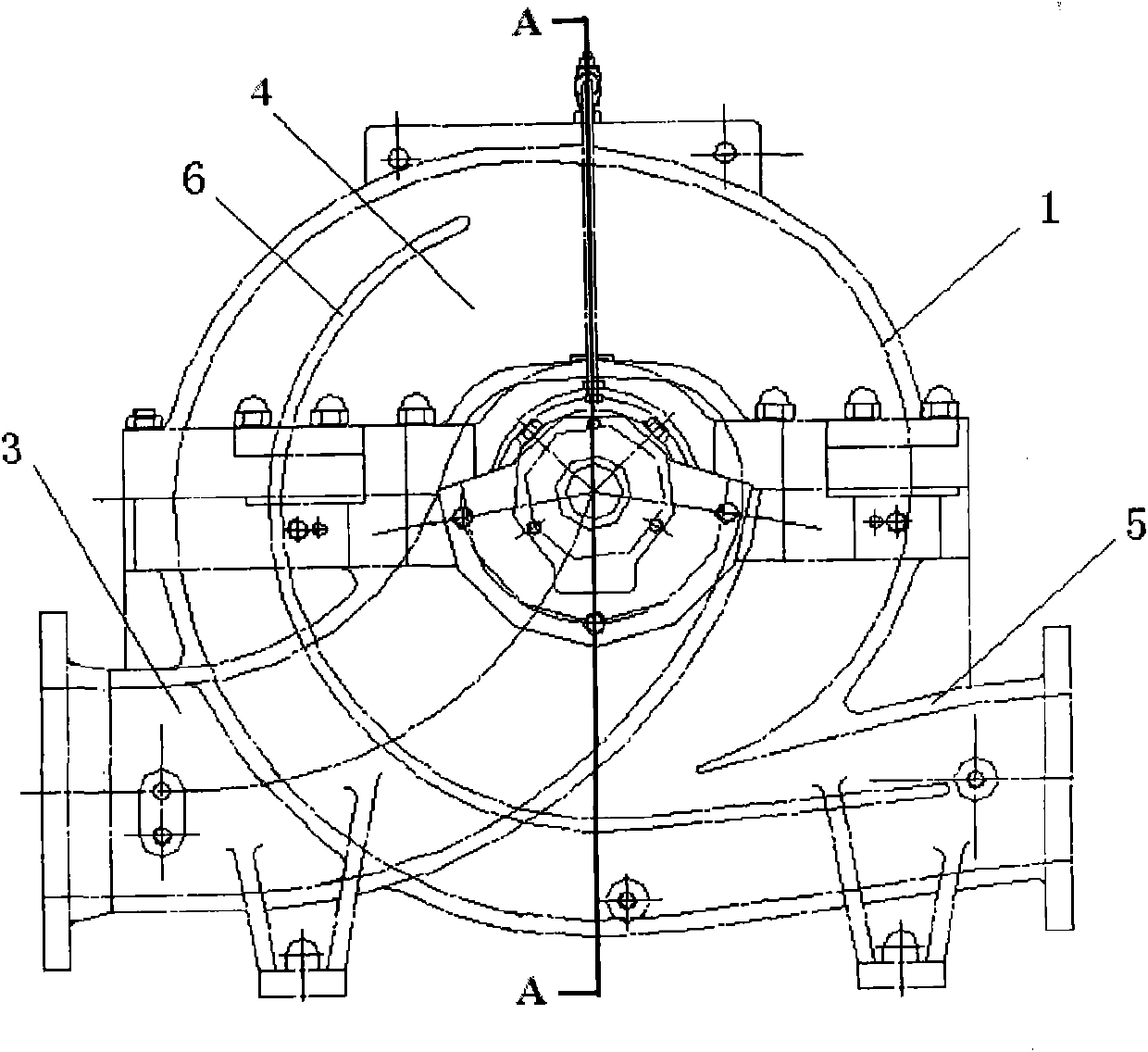

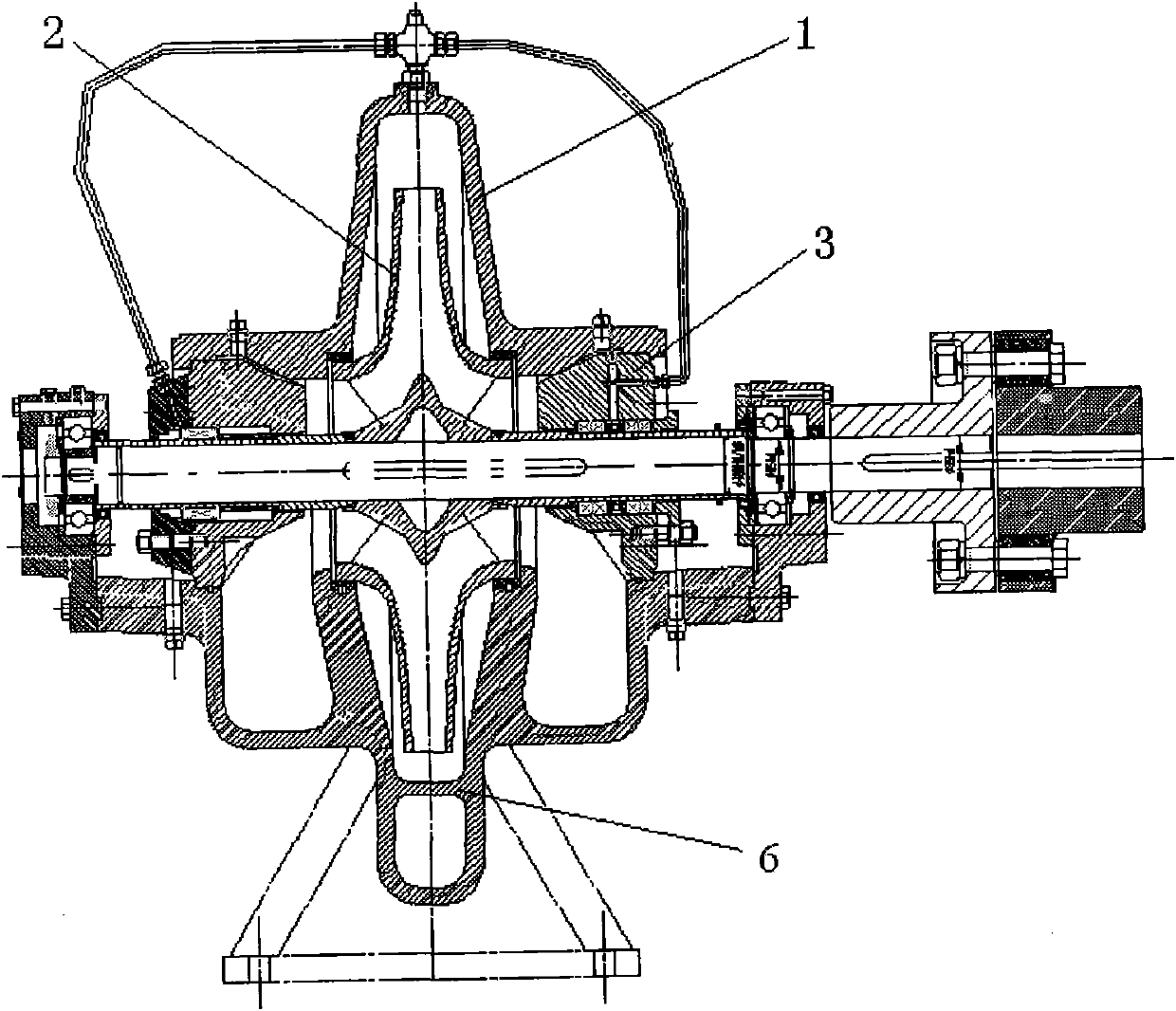

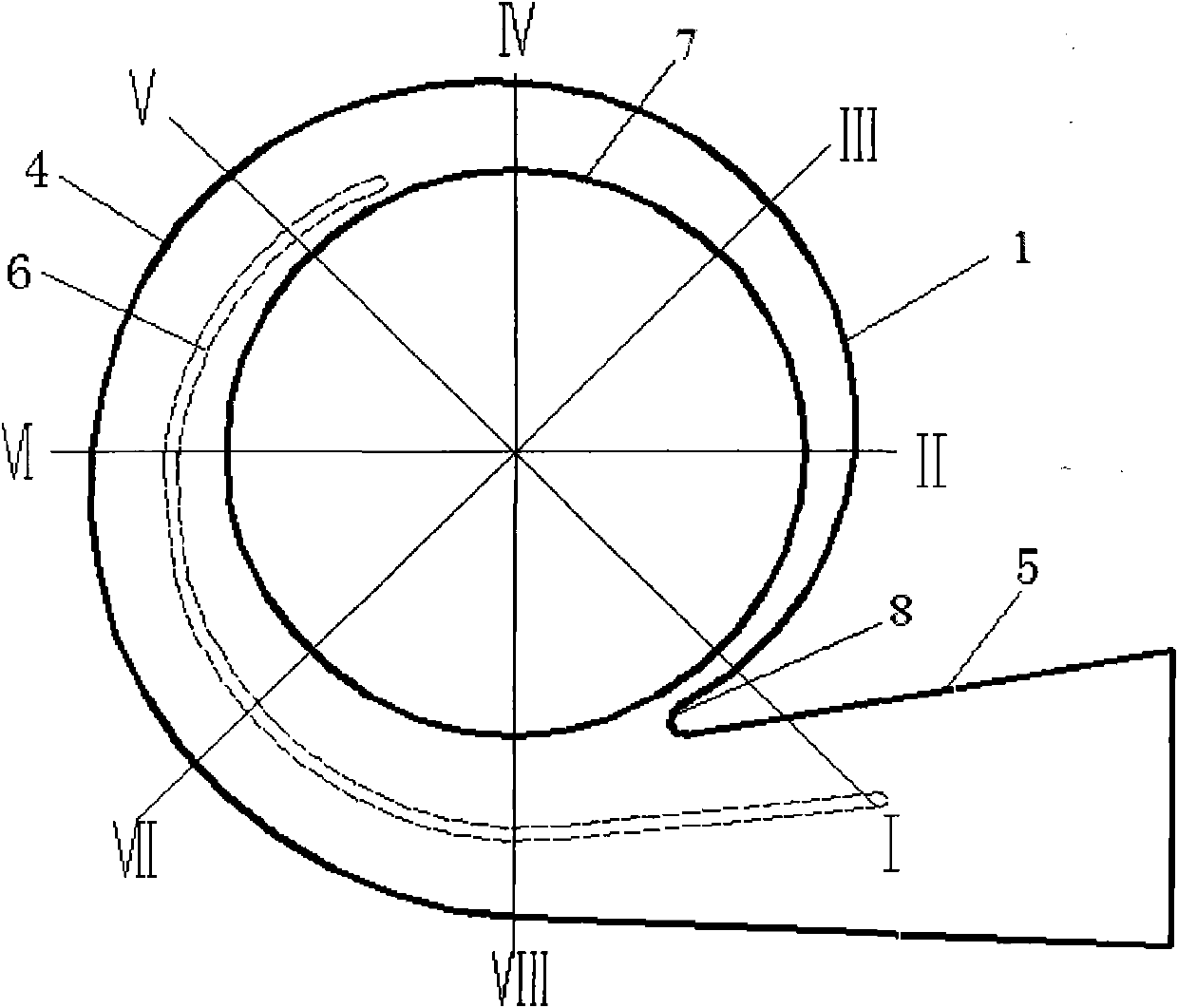

[0023] Such as figure 1 , figure 2 As shown, the double volute type double suction pump includes a volute 1, an impeller 2 is arranged inside the volute 1, and a semi-spiral suction chamber 3 is arranged at the entrance of the impeller 2. The volute 1 includes a volute body 4 and a diffuser pipe 5, along the rotation arc of the volute body 4 and the diffuser section of the diffuser pipe 5, a partition 6 is arranged, and the partition 6 divides the interior of the volute 1 into two flow passages. The water flows into the impeller 2 through the semi-spiral suction chamber 3, and flows into the volute 1 after being driven by the impeller 2 to rotate.

[0024] The purpose of the present invention is to minimize the radial force of the impeller 2 under the premise of maintaining the original hydraulic performance of the double-volute double-suction pump...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com