Method for preparing multi-micropore super-soft yarn

A super-soft yarn and multi-microporous technology, which is applied in the field of fiber spinning, can solve the problems of uneven yarn thickness, insignificant hollowing effect of towels, uneven distribution of soluble fibers, etc., so as to save time and effort and keep soft products Effect, simple effect of preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

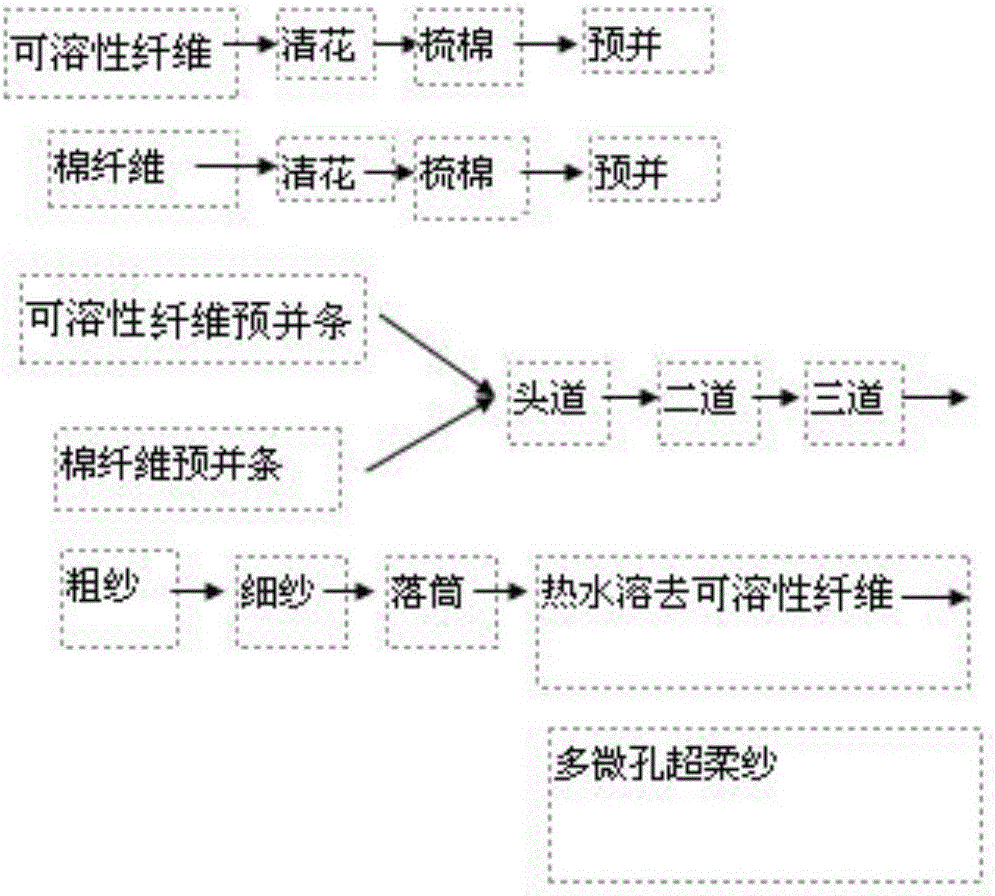

[0054]A kind of preparation method of microporous super soft yarn, its specific steps are:

[0055] (1) Cotton fiber is made pre-drawing of cotton fiber through cleaning, carding and pre-drawing process;

[0056] (2) The soluble vinylon fiber is respectively prepared through the blowing, carding and pre-drawing process of the soluble vinylon fiber;

[0057] (3) The pre-drawing of cotton fiber and the pre-drawing of soluble vinylon fiber are carried out through the feeding device at the same time, and then the second drawing and the third drawing are carried out in sequence, and finally the roving, spun yarn, winding and water-soluble processes are processed. get the final product.

[0058] The length of the cotton fiber is 31.5mm, Micronaire A grade, and the short-staple rate is 8%; the main body length of the soluble vinylon fiber is 38mm, and the water melting temperature is 40°C.

[0059] In the drawing process, the cotton fiber pre-drawing mass percentage is 70%, and the...

Embodiment 2

[0068] A kind of preparation method of microporous super soft yarn, its specific steps are:

[0069] (1) Cotton fiber is made pre-drawing of cotton fiber through cleaning, carding and pre-drawing process;

[0070] (2) The soluble vinylon fiber is respectively prepared through the blowing, carding and pre-drawing process of the soluble vinylon fiber;

[0071] (3) The pre-drawing of cotton fiber and the pre-drawing of soluble vinylon fiber are carried out through the feeding device at the same time, and then the second drawing and the third drawing are carried out in sequence, and finally the roving, spun yarn, winding and water-soluble processes are processed. get the final product.

[0072] The length of the cotton fiber is 29mm, Micronaire A grade, and the short-lint rate is 9%; the main body length of the soluble vinylon fiber is 35mm, and the water melting temperature is 90°C.

[0073] In the drawing process, the cotton fiber pre-drawing mass percentage is 80%, and the so...

Embodiment 3

[0082] A kind of preparation method of microporous super soft yarn, its specific steps are:

[0083] (1) Cotton fiber is made pre-drawing of cotton fiber through cleaning, carding and pre-drawing process;

[0084] (2) making soluble polyester fiber pre-drawing through cleaning, carding and pre-drawing process respectively;

[0085] (3) The pre-drawing of cotton fibers and the pre-drawing of soluble polyester fibers are drawn simultaneously through the feeding device, and then the second drawing and the third drawing are carried out in sequence, and finally the roving, spun yarn, winding and water-soluble processes are processed. get the final product.

[0086] The length of the cotton fiber is 30mm, Micronaire A grade, and the short-staple rate is 10%; the length of the main body of the soluble polyester fiber is 51mm, and the water melting temperature is 95°C.

[0087] In the drawing process, the cotton fiber pre-drawing mass percentage is 90%, and the soluble polyester fib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com