Rotary drum-type fiber opening device

A drum type, equipment technology, applied in textile and paper making, cleaning with stirring arm, fiber cleaning machine, etc., can solve problems such as uneven spraying of crude oil, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below by means of specific embodiments:

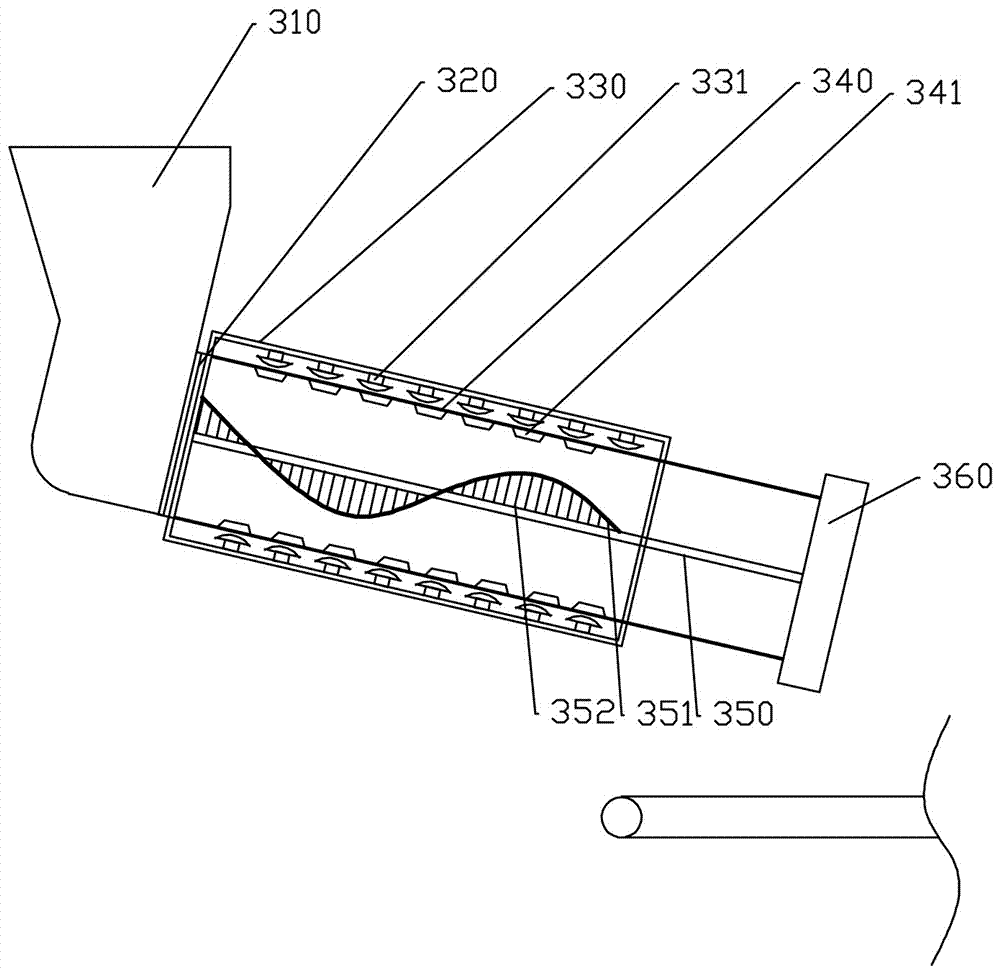

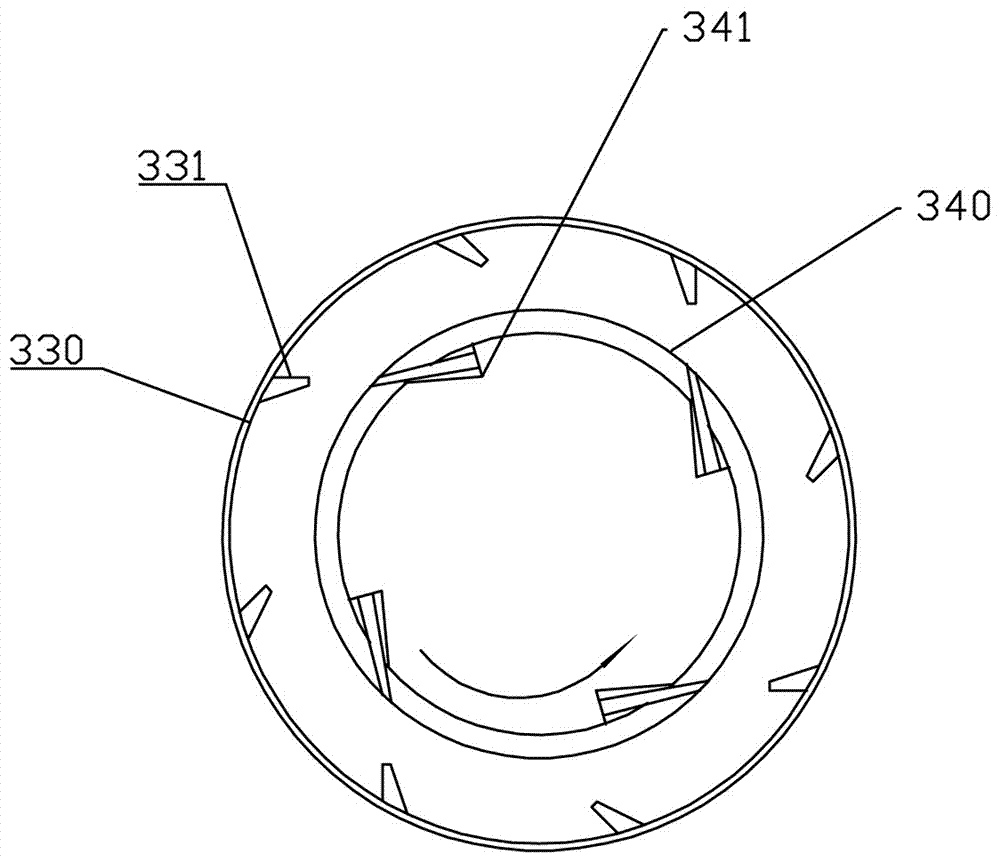

[0019] The reference signs in the drawings of the description include: automatic hair suction device 100, opener 200, automatic oil injection mechanism 300, feeding hopper 310, sliding sleeve 320, housing 330, oil injection head 331, turning inner cylinder 340, Overturn protrusion 341, stirring shaft 350, stirring frame 351, steel wire 352, planetary gear set 360, capillary tube 400, hair bin 500.

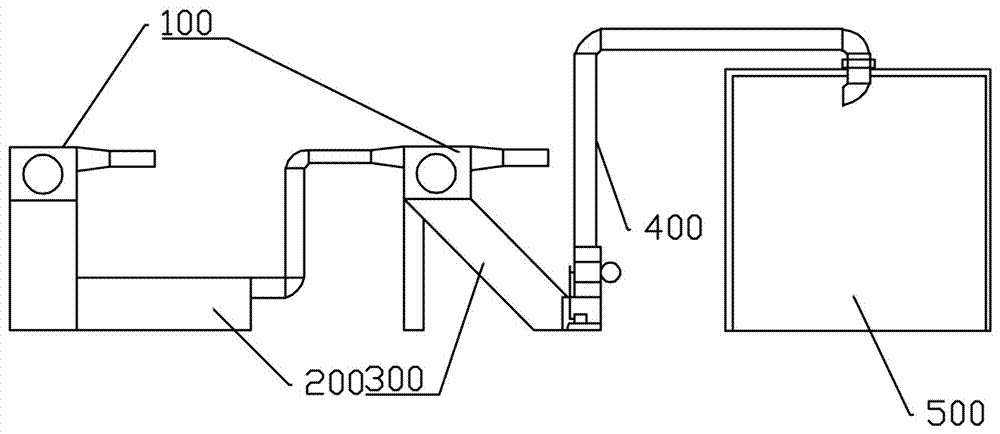

[0020] like figure 1 A drum type and hair opening equipment shown includes a frame body, two automatic hair suction devices 100, a hair feeding tube 400, an opener 200, a hair bin 500, an automatic oil injection mechanism 300, an automatic hair suction device 100, and a hair opener 200. , the automatic hair suction device 100, the automatic oil injection mechanism 300, and the hair bin 500 are communicated through the capillary tube 400 in turn. hopper, such as figure 2 As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com