Automatic cooling and lubricating device for forging die

A lubricating device and automatic cooling technology, which is applied to forging/pressing/hammer devices, manufacturing tools, forging/pressing/hammering machinery, etc., can solve problems such as low work efficiency and low degree of automation, and achieve improved work efficiency and smooth operation Smooth and labor-saving, low friction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

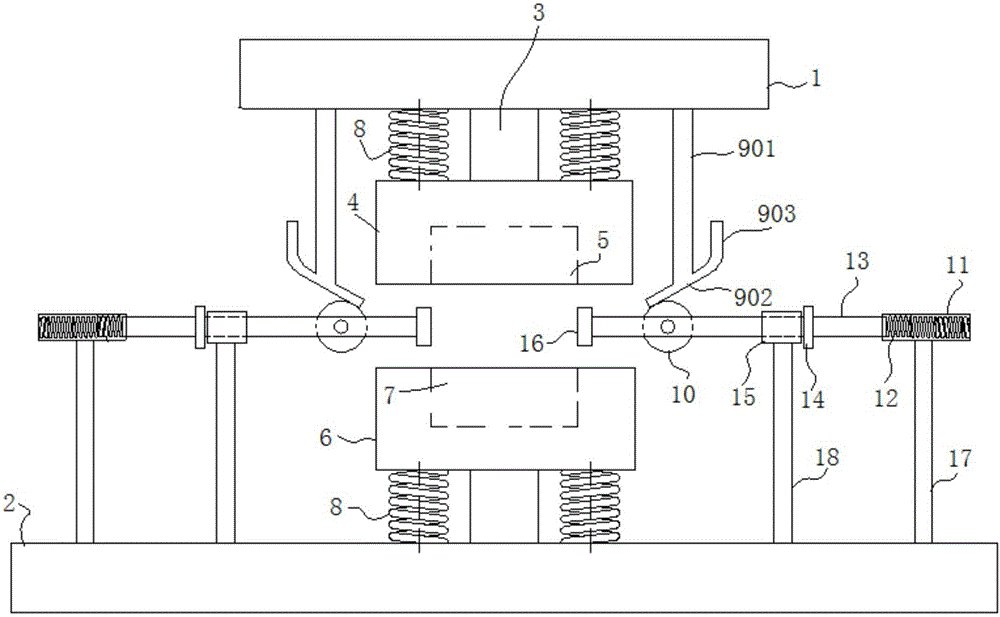

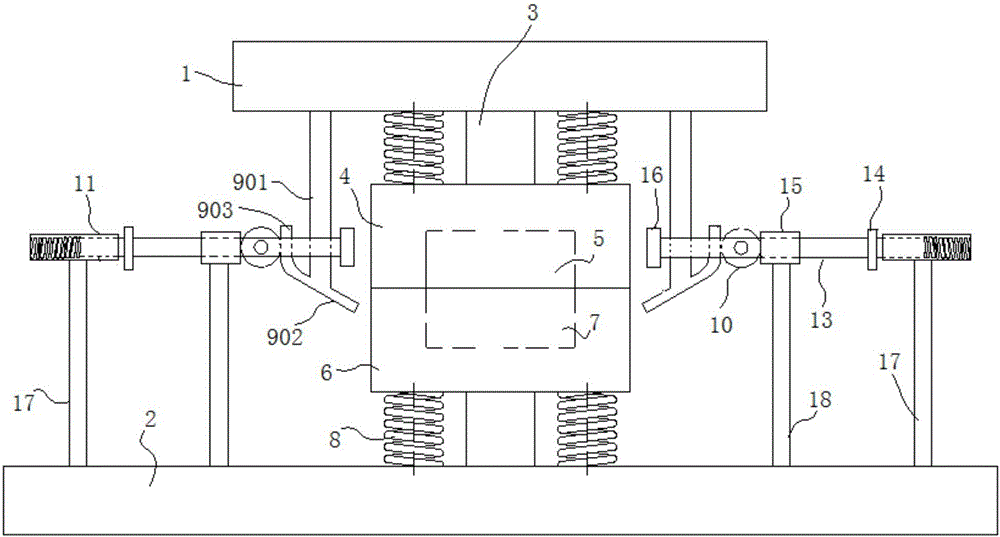

[0041] A kind of automatic cooling lubricating device of forging mold of this embodiment, wherein mold such as figure 1 , figure 2As shown, it includes upper die base 1, lower die base 2, upper die 4, lower die 6 and punch 3, upper die base 1 and upper die 4, lower die base 2 and lower die 6 are connected by spring 8 , the forging is evenly stressed during forging; the upper mold cavity 5 is opened in the upper mold 4, and the lower mold cavity 7 is opened in the lower mold 6. When the mold is closed, the upper mold cavity 5 and the lower mold cavity 7 form a complete mold. cavity. The cooling and lubricating device of this embodiment is provided with two groups symmetrically on both sides of the mould, further ensuring sufficient cooling and lubrication of the upper mold cavity 5 and the lower mold cavity 7, wherein each group of lubricating devices includes a nozzle 16, a pushing device and a fixing device, The nozzle 16 is arranged on the fixing device and extends toward...

Embodiment 2

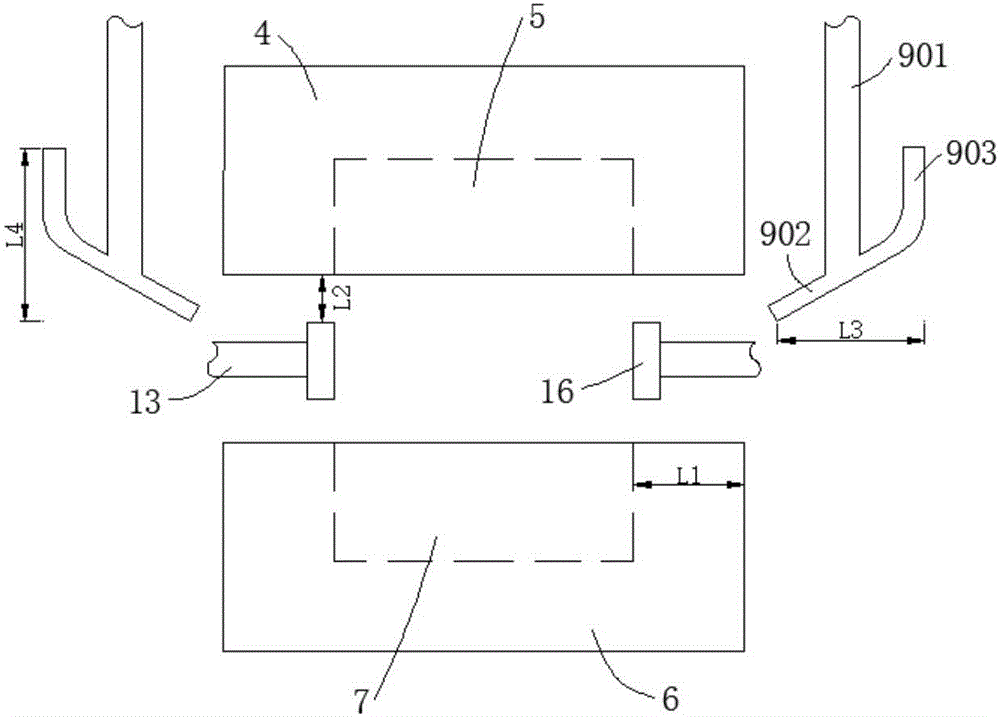

[0058] An automatic cooling and lubricating device for a forging die in this embodiment has the same basic structure as in Embodiment 1. Further, in this embodiment, the inclined push rod 902 includes a transverse extension and a connecting rod 903, such as Figure 7 As shown, the height of the transverse extension section rises gradually along the direction away from the mold, and its highest end is connected with the connecting rod 903 in an arc transition. The connecting rod 903 extends upward and the angle α between the horizontal plane is not greater than 90°. The total length L3 of the horizontal projection of the extension section and the connecting rod 903 is greater than the distance L1 from the outer wall of the lower mold 6 to the inner wall of the lower mold cavity 7, and the total length L4 of the vertical projection of the lateral extension section and the connecting rod 903 is greater than the upper mold in the initial state. 4 The vertical distance L2 from the l...

Embodiment 3

[0060] An automatic cooling and lubricating device for a forging die in this embodiment has the same basic structure as that in Embodiment 2, except that the inclined push rod 902 in this embodiment includes a transverse extension and a connecting rod 903, such as image 3 As shown, the angle α between the connecting rod 903 and the horizontal plane is 90°, that is, the connecting rod 903 is a vertical rod connected to the high end of the horizontal extension section. Correspondingly, the horizontal projection total length L3 of the horizontal extension section is greater than that of the lower mold 6 The distance L1 from the outer wall to the inner wall of the lower mold cavity 7, the sum L4 of the vertical projection length of the lateral extension section and the length of the connecting rod 903 is greater than the vertical distance L2 from the lower end surface of the upper mold 4 to the upper end surface of the nozzle 16 in the initial state, and the vertical distance L2 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com