Spraying, dust-settling and cooling device for construction

A technology of building construction and cooling device, which is applied in the directions of using liquid separation agent, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of poor dust reduction and cooling effect, insufficient spraying, etc., and achieves the best spraying effect. The effect of spraying a large area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

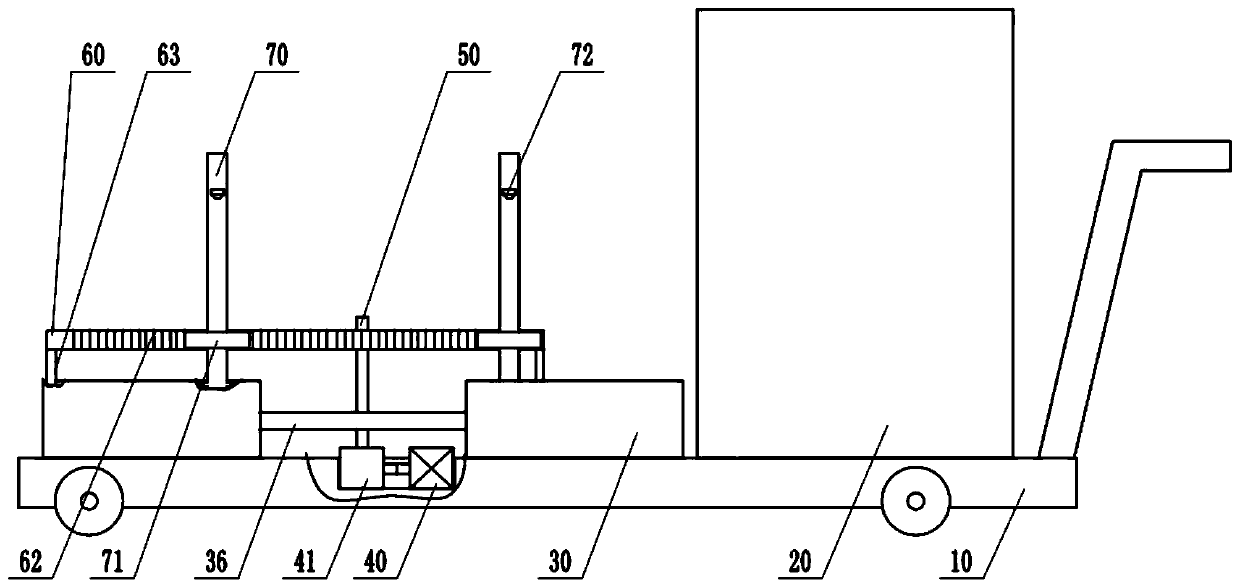

[0028] This embodiment is basically as figure 1 Shown: the spray dust reduction and cooling device for building construction includes a moving vehicle body 10, a power mechanism, a spray mechanism and a water storage tank 20 fixed on the moving vehicle body 10. By pushing the moving vehicle body 10, the device can be moved to the A place that needs dust and cooling.

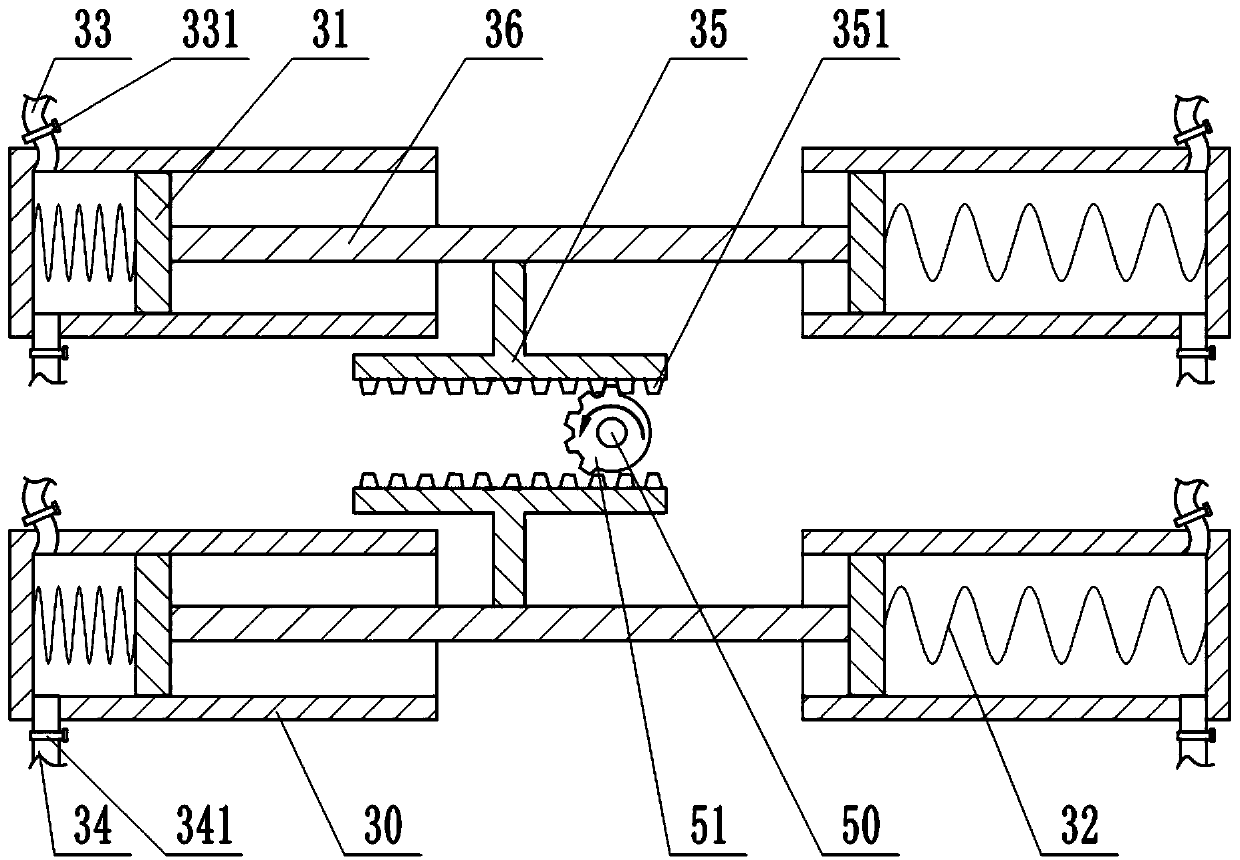

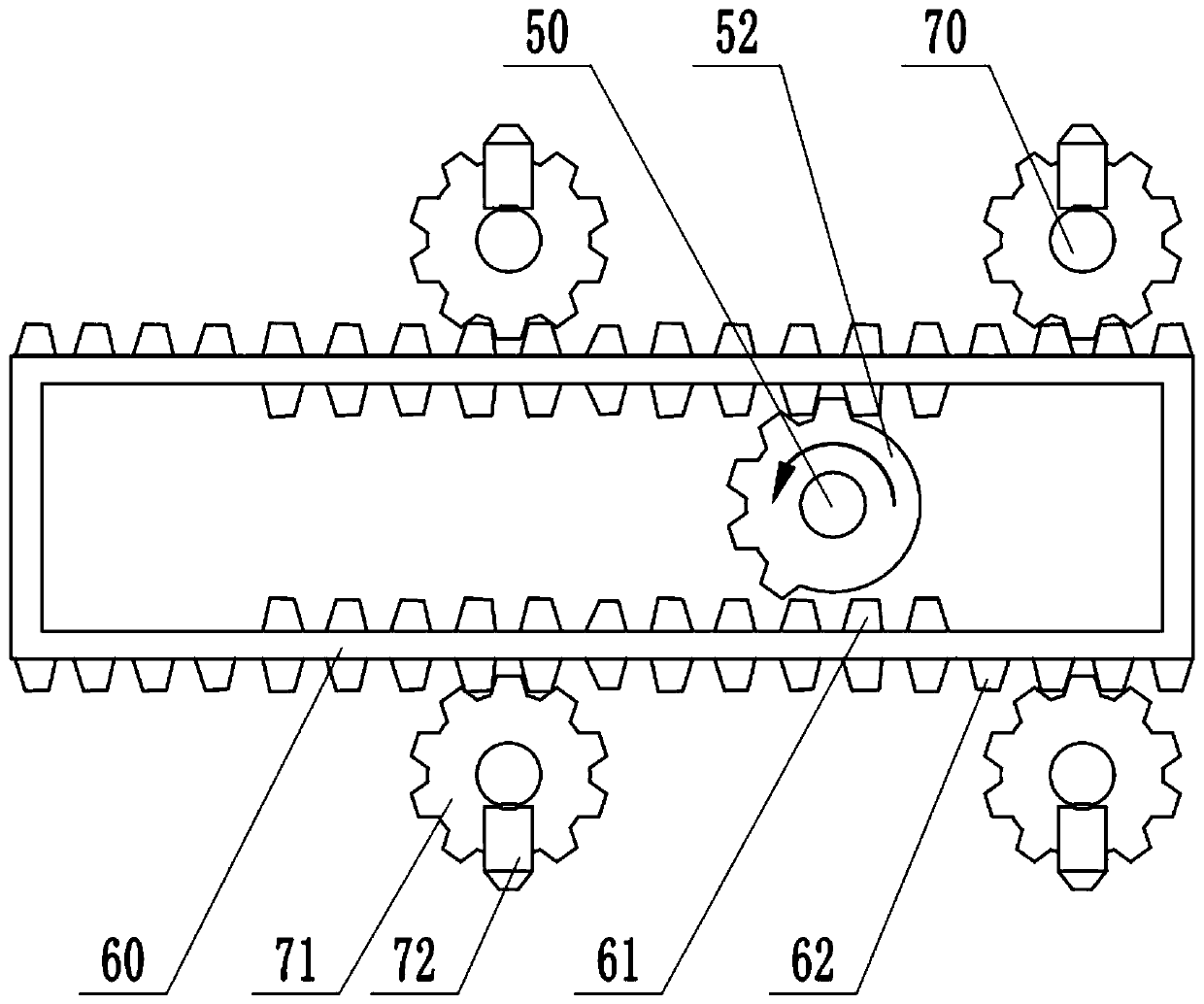

[0029] combine figure 2As shown, the power mechanism includes a driving part and two moving parts, and the moving part includes two oppositely arranged piston cylinders 30 , both of which are welded to the moving vehicle body 10 . The opposite side of the piston cylinder 30 is open, the piston cylinder 30 is slidably connected with the piston 31, and the piston cylinder 30 is provided with a reset member 32 for resetting the piston 31. In this embodiment, the reset member 32 is a spring. One end is connected to the piston 31, and the other end is connected to the side wall of the piston cylinder 30. A connect...

Embodiment 2

[0036] The difference between this embodiment and the first embodiment is that the spray mechanism in this embodiment is different from that in the first embodiment. Figure 4 As shown, the spraying mechanism includes two moving racks 80 and four rotating shafts 90 rotatably connected to the moving vehicle body 10 . The method is similar and will not be repeated here. The two moving racks 80 are respectively fixed on different connecting rods 36 by connecting rods, and the four rotating shafts 90 are symmetrically distributed on one side of the two moving gears. A transmission gear 91 meshing with the moving rack 80 is fixed on the rotating shaft 90, and a nozzle 92 is fixedly installed on the rotating shaft 90. The nozzles 92 on the rotating shaft 90 are symmetrically distributed with two moving gears as symmetrical lines. The water spray pipe 34 on a piston cylinder 30 is connected with a nozzle 92, and by controlling the connection between the water spray pipe 34 on the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com