Impurity removing opener for non-woven fabric production

A technology of non-woven fabric and cotton opener, which is applied to the direction of opening and cleaning with stirring arms, fiber opening and cleaning machines, etc., which can solve the problem of low dust cleaning efficiency and achieve the effect of eliminating secondary pollution and preventing secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

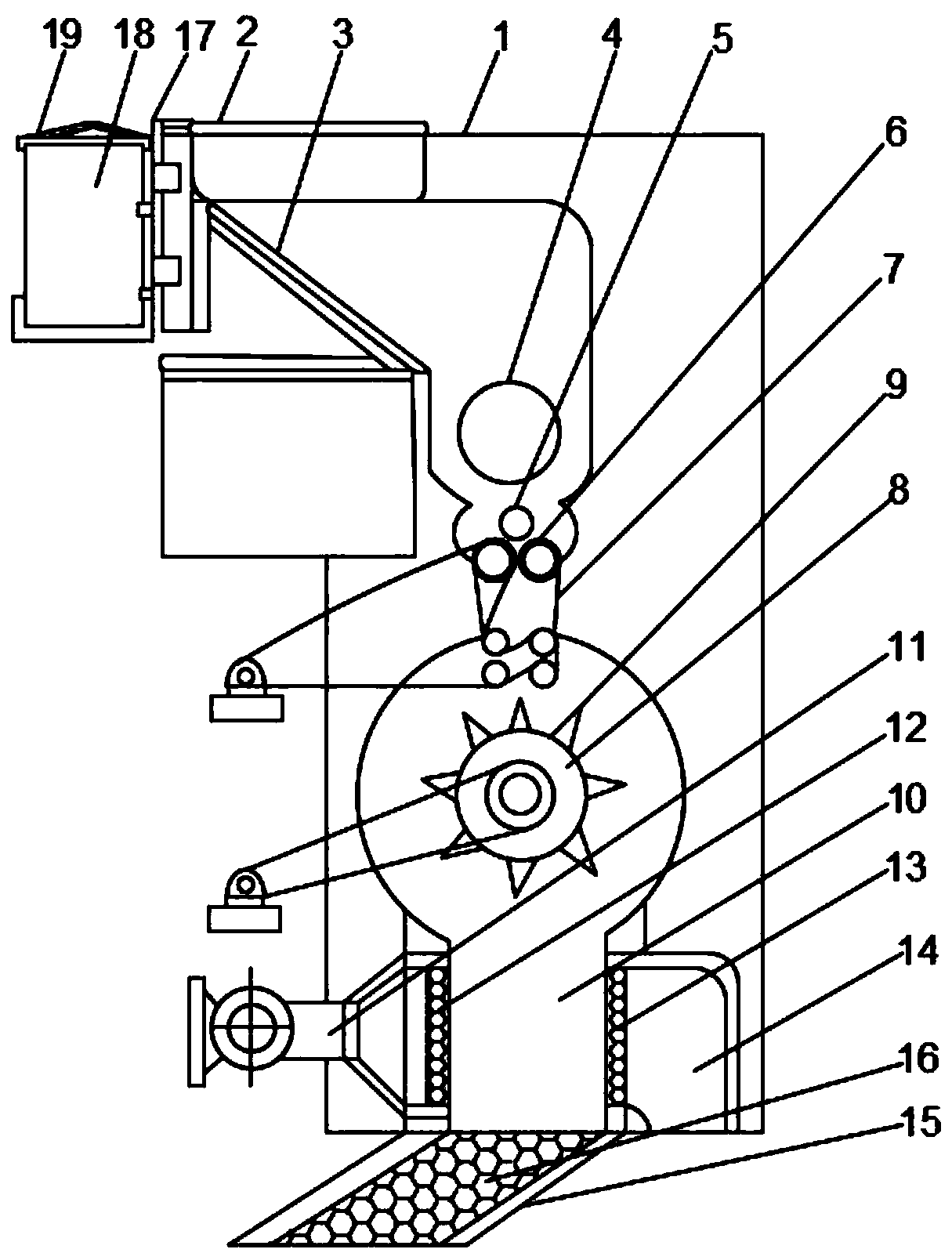

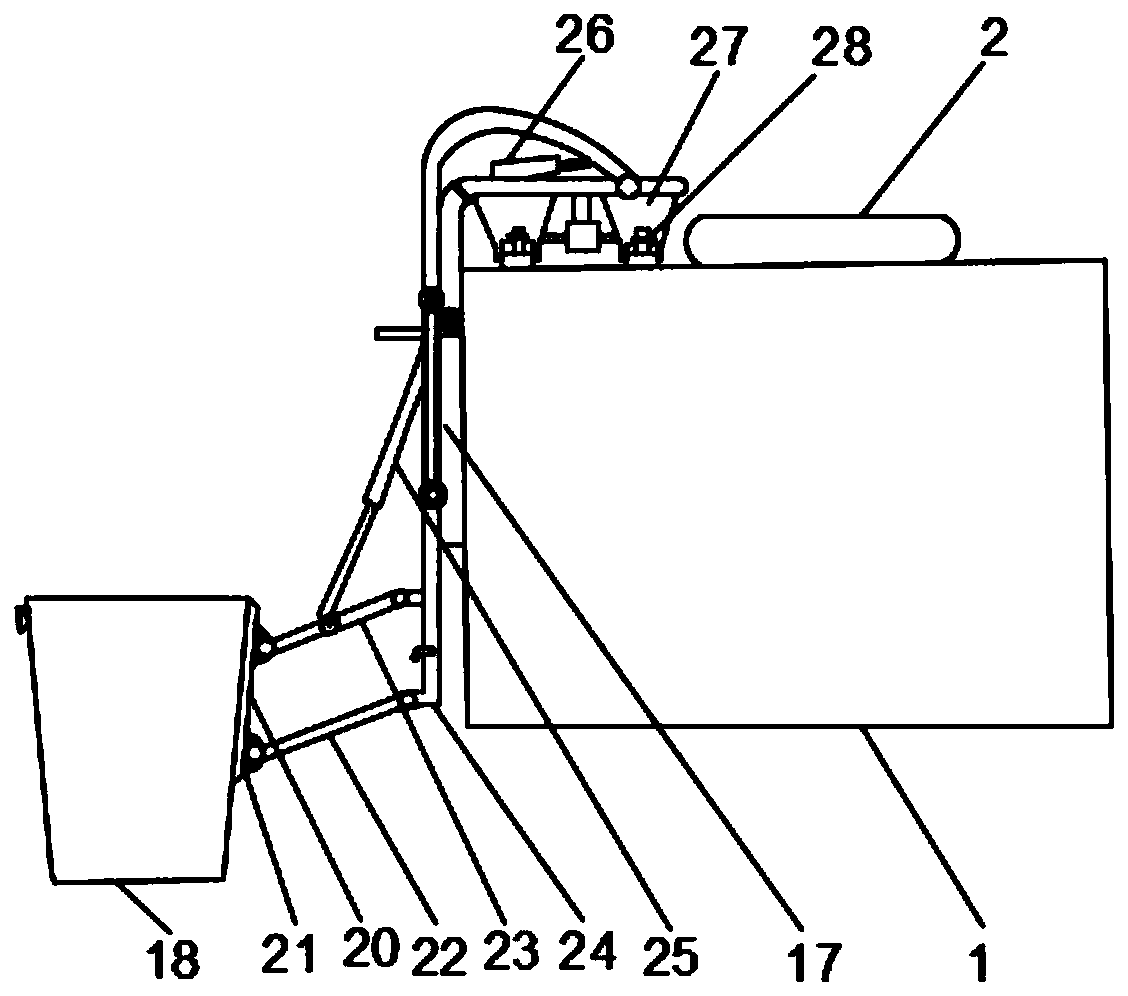

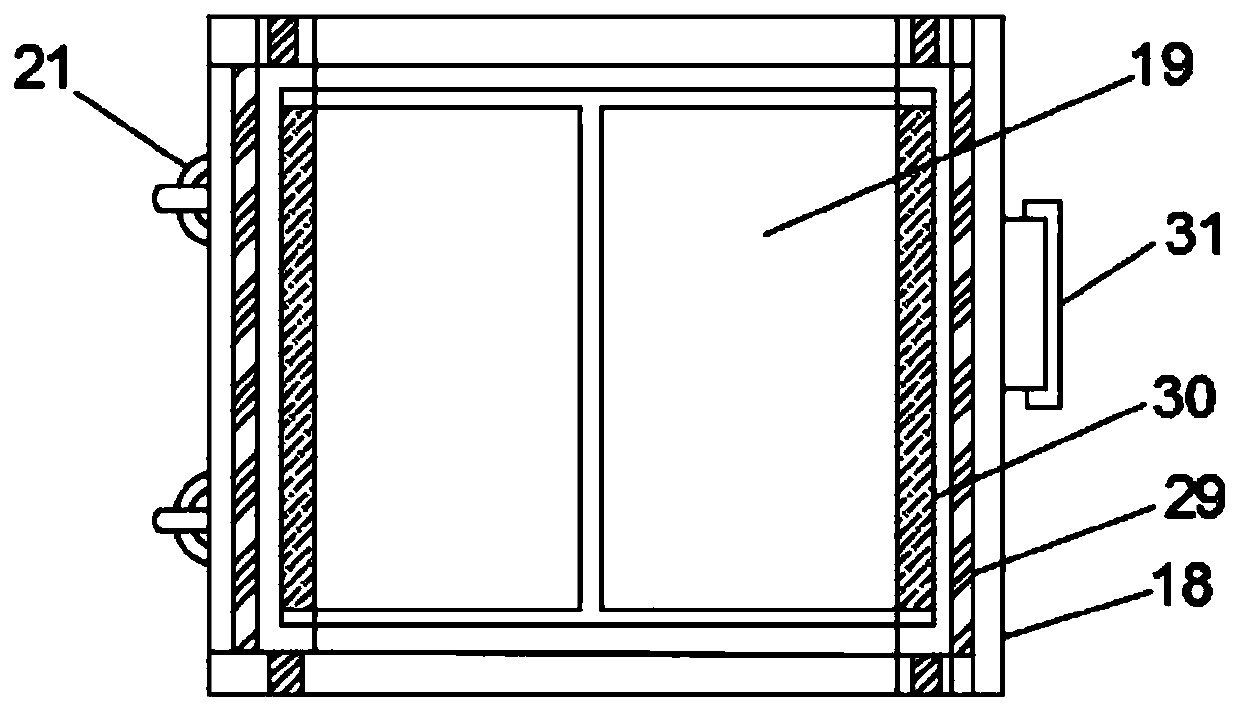

[0032] Such as Figure 1-5As shown, a cotton opener for non-woven fabric production includes a casing 1, the upper surface of the casing 1 is provided with a feed port 2, and the inside of the casing 1 is provided with a second A vibration structure 3, a cotton condenser 4 and a cotton storage column 5, the cotton condenser 4 and the cotton storage column 5 are located at a position close to the bottom of the first vibration structure 3, the cotton condenser 4 is located above the cotton storage column 5, the The inside of the casing 1 is provided with a feeding roller 6 and a rotating shaft 8 near the middle, the feeding roller 6 is located above the rotating shaft 8, and the outer surface of the feeding roller 6 is provided with a transmission belt 7, and the rotating shaft 8 The outer surface of the casing 1 is provided with a porcupine beater 9, and the inside of the casing 1 is provided with a discharge port 10 and an air delivery pipe 11 near the bottom, and the air deli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com