Process for making bamboo fiberfill and articles thereof

a technology of bamboo fiber and fiber filling, which is applied in the field of process of making bamboo fiber filling and to articles, can solve the problems of easy decomposition, many of these natural fibers, and do not possess the antibacterial and deodorizing properties desirable in household bedding articles, so as to reduce the size of the bamboo fiber tu

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

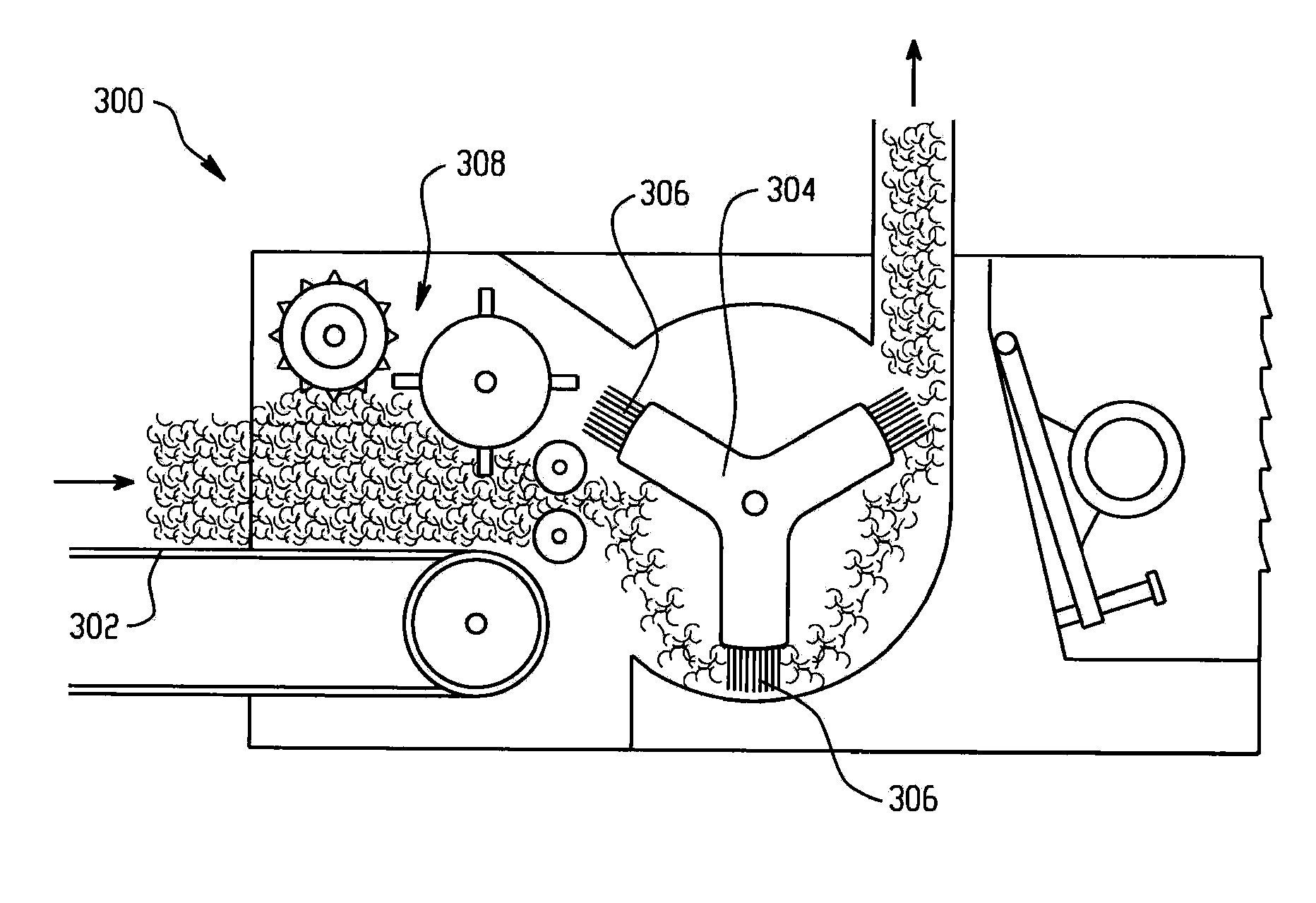

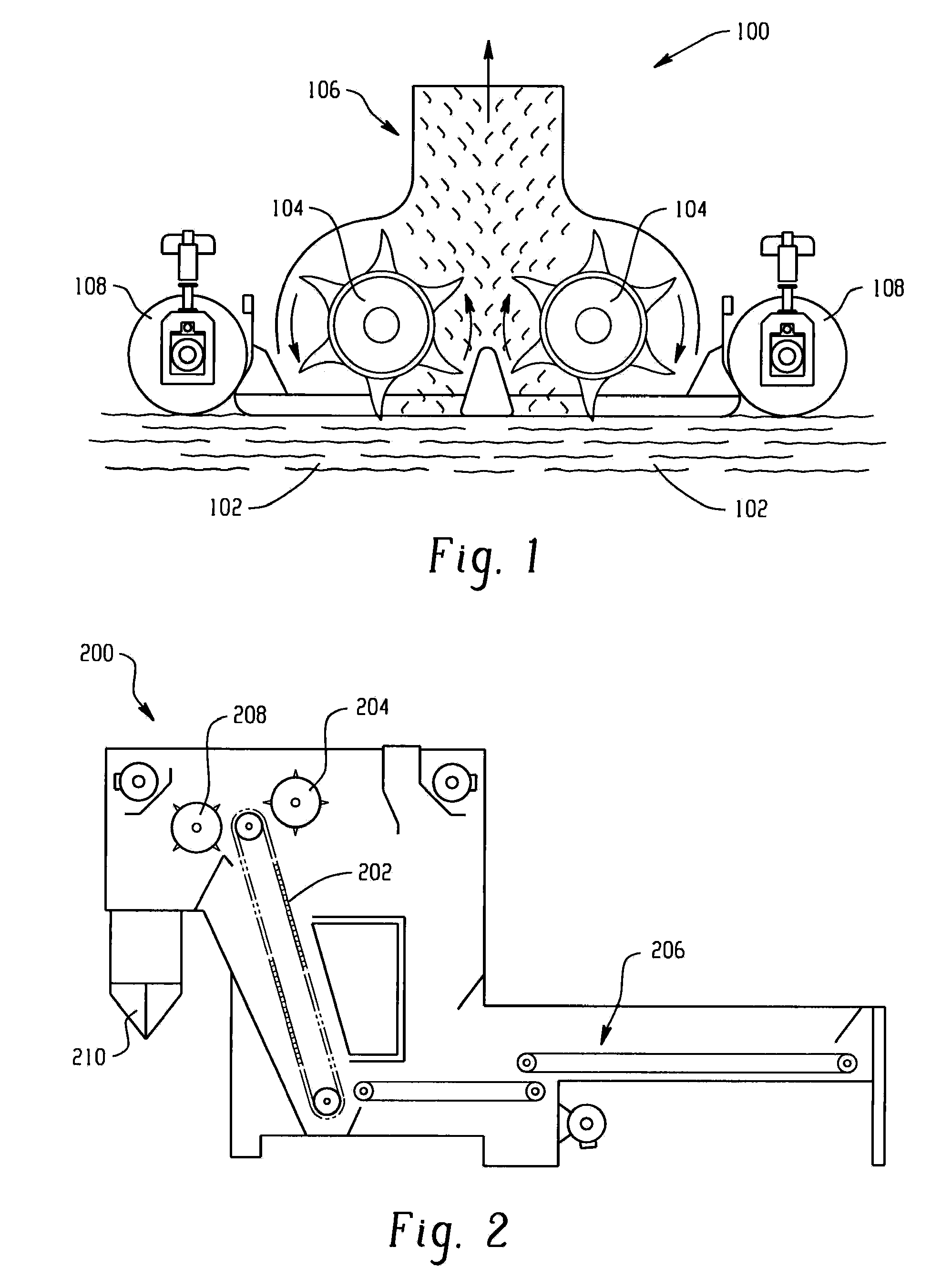

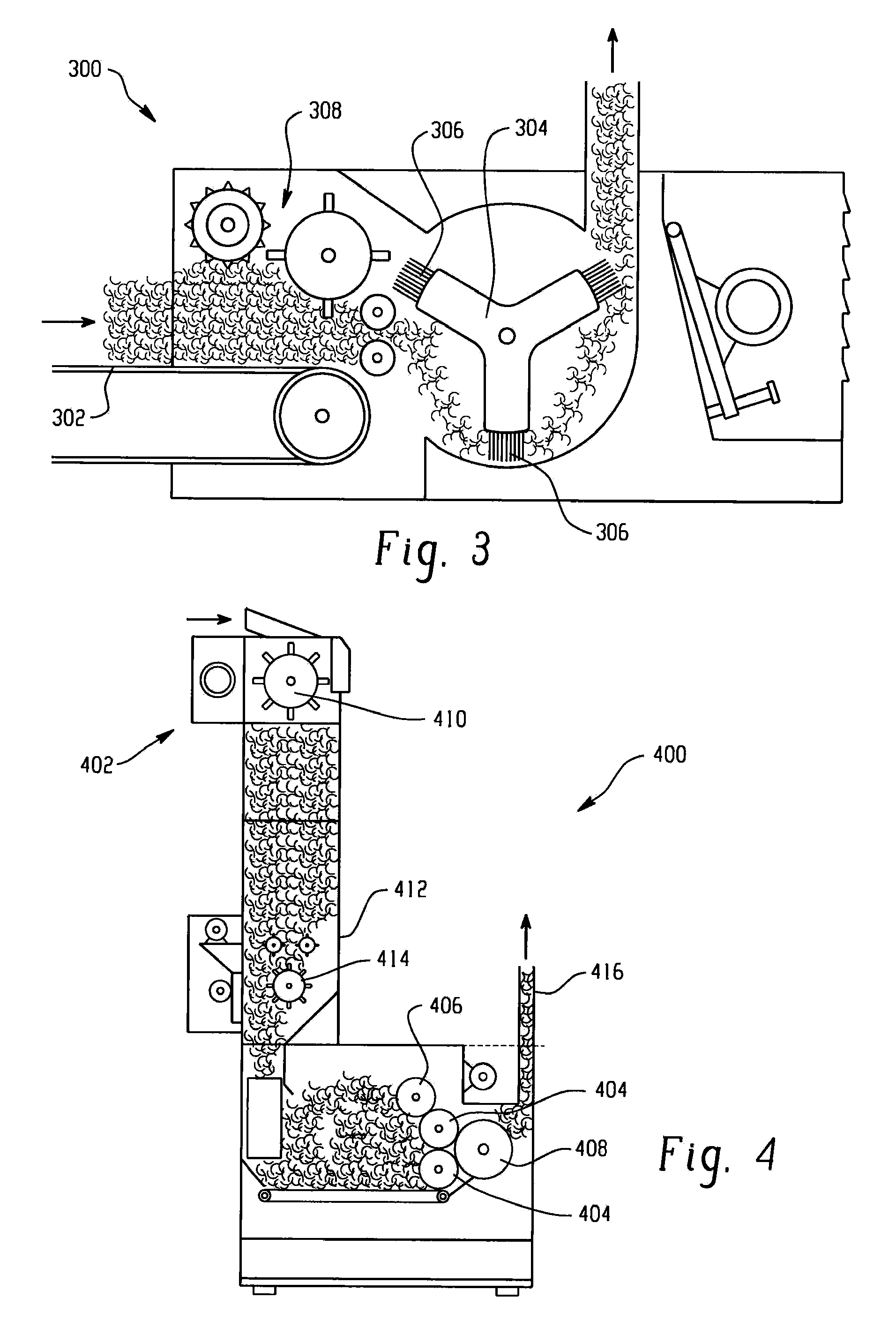

[0017]The inventors hereof have found that bamboo fiber can be processed and formed into a nonwoven web or air blown and used as fiberfill in articles such as bedding, quilting, pillows, comforters, blankets, home furnishing, and the like. The bamboo fiber is derived from the pulp of the bamboo plant. The bamboo plant is naturally anti-bacterial and possesses deodorizing abilities as well. The bamboo fiber retains these characteristics, and therefore, the fibers require no additional manufacturing processes or treatments to exhibit such qualities. As an added benefit, the bamboo plant can be grown without the need for environmentally harmful pesticides or fertilizers. The bamboo pulp can be processed into a fiber through a “green” process, having minimal environmental impact. All of these attributes make bamboo fiberfill a unique choice for household articles in an increasingly environmentally conscious consumer market.

[0018]Disclosed herein is an exemplary process for producing non...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Linear density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com