Air filter cotton preparation and treatment process

A treatment process and air filtration technology, which is applied in the field of air purification, can solve the problems of inability to disperse fiber cotton, uneven mixing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

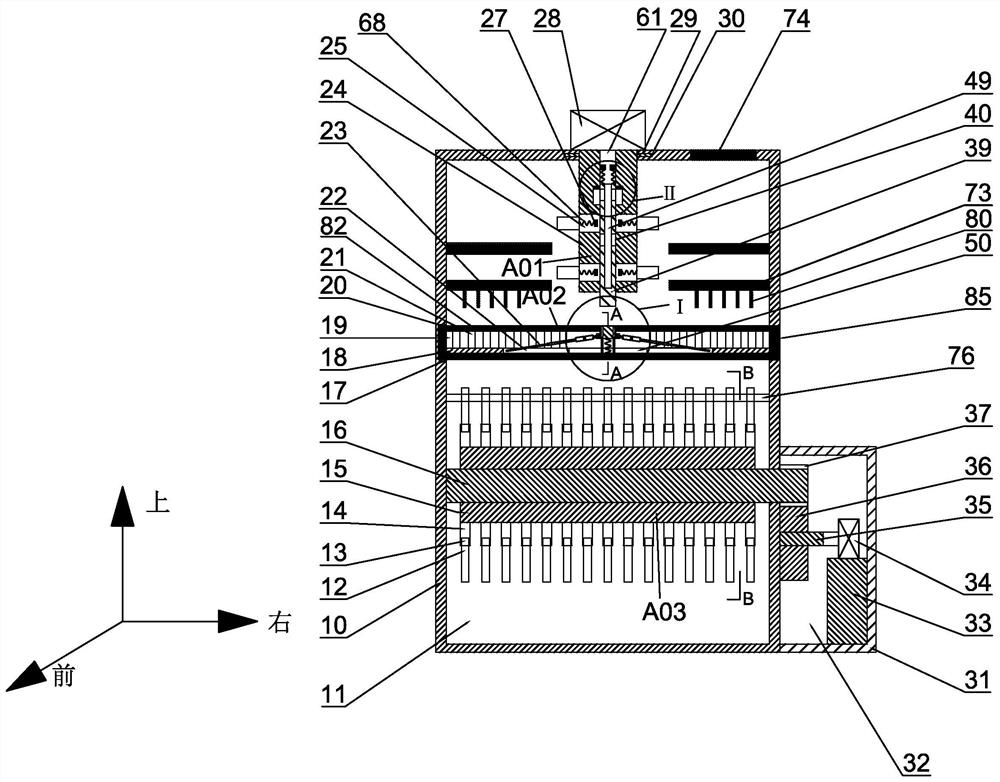

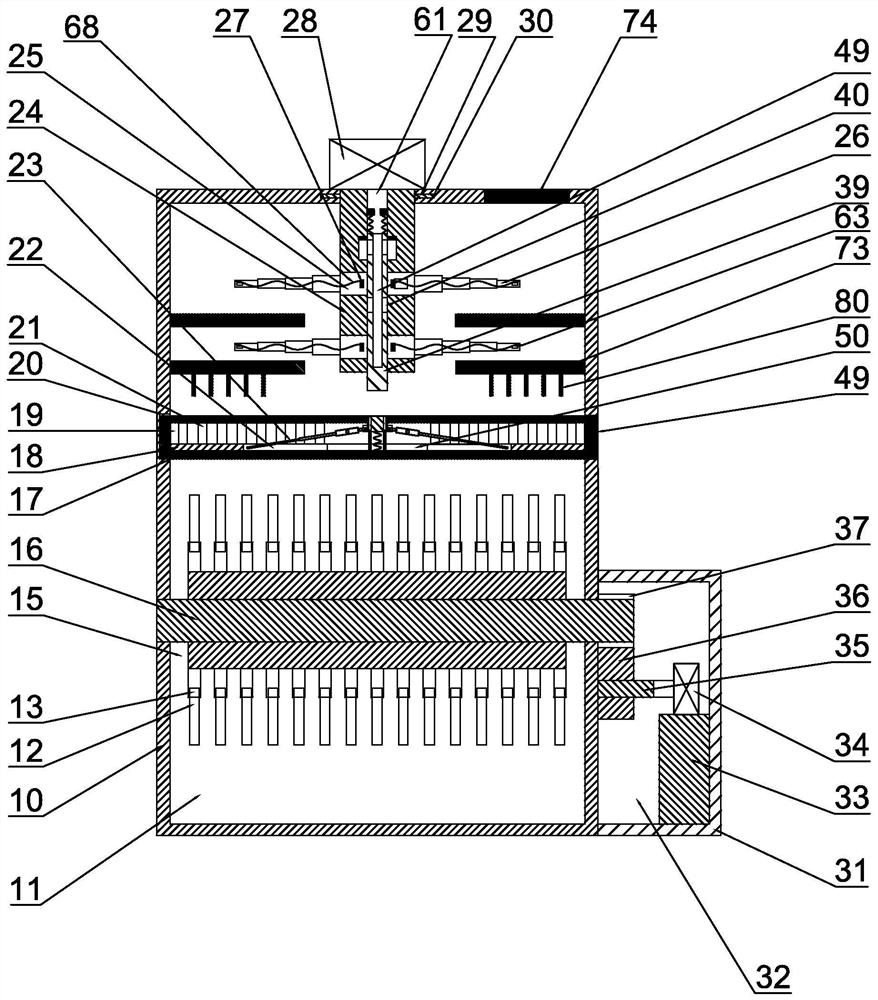

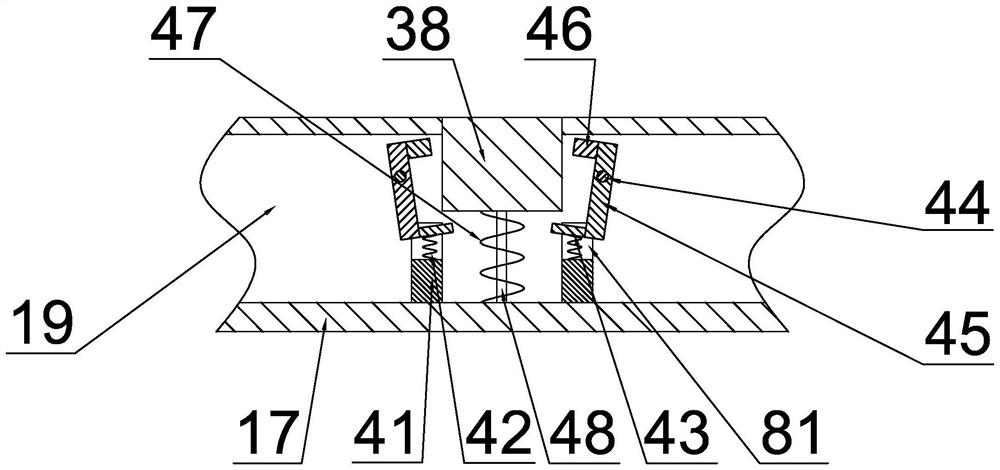

[0022] Such as figure 1 As shown, a kind of air filter cotton preparation treatment process comprises housing 10, and housing 10 is provided with stirring chamber 11, and housing 10 is provided with first groove 20, and first groove 20 is positioned at the middle part of stirring chamber 11 and is connected with stirring chamber 11, the right side wall of the housing 10 is provided with a first fixing block 31, and the first fixing block 31 is provided with a second groove 32;

[0023] The first-level cotton mixing mechanism A01, the first-level cotton mixing mechanism A01 is set in the mixing chamber 11, and the first-level cotton mixing mechanism A01 is used to mix various raw materials evenly;

[0024] The secondary cotton mixing mechanism A02, the secondary cotton mixing mechanism A02 is set in the space formed by the first tank 20 and the housing 10, the secondary cotton mixing mechanism A02 is located below the primary cotton mixing mechanism A01, the secondary cotton mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com