Organic fertilizer rapid drying device

A rapid drying and organic fertilizer technology, applied in drying, drying machine, manure drying, etc., can solve the problems of rough and simple drying equipment, affecting processing quality, and general drying effect, so as to increase the drying effect, The effect of increasing drying quality and increasing drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

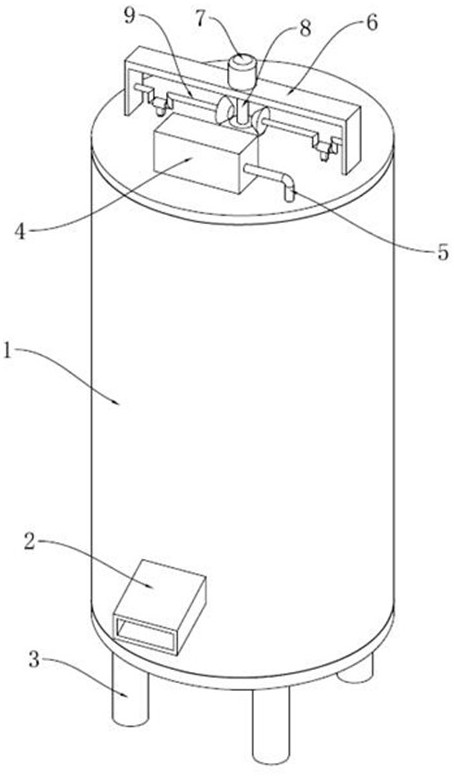

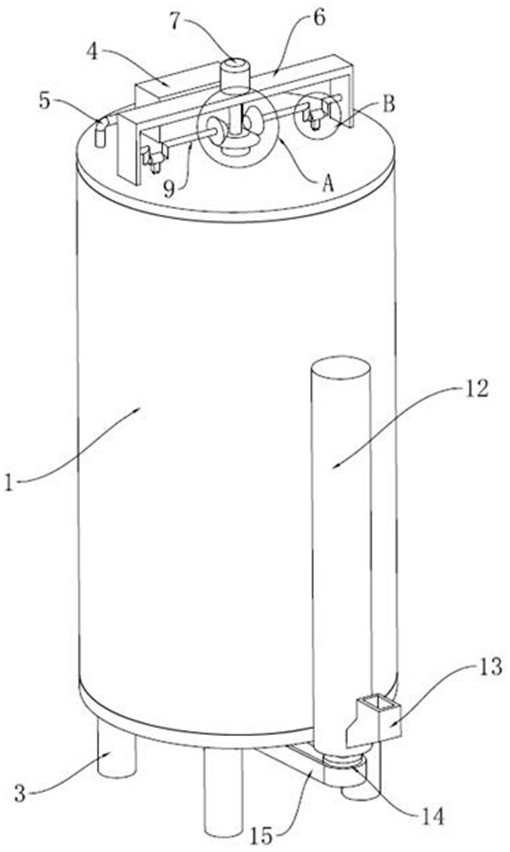

[0041] refer to Figure 1-12 , in an embodiment of the present invention, a quick drying device for organic fertilizers includes a drying box 1, a U-shaped frame 6 is installed on the top of the drying box 1, and a drying motor 7 is installed at the center of the upper end of the U-shaped frame 6. The output shaft 8 of the drying motor 7 is connected with a driving gear 11, and a driven gear 10 is meshed on both sides of the driving gear 11, and the outer center of the driven gear 10 is connected with a rotating shaft 9, and the rotating shaft 9 is provided with a rotating crank 17. The crank 17 is covered with a rotating curved sleeve 18, and a traction connecting rod 19 is installed on the rotating curved sleeve 18. The end of the traction connecting rod 19 away from the rotating curved sleeve 18 is hinged with a lifting connecting rod 20; specifically, the drying motor 7 is rotating At the same time, the output shaft 8 drives the driving gear 11 to rotate, and then meshes w...

Embodiment 2

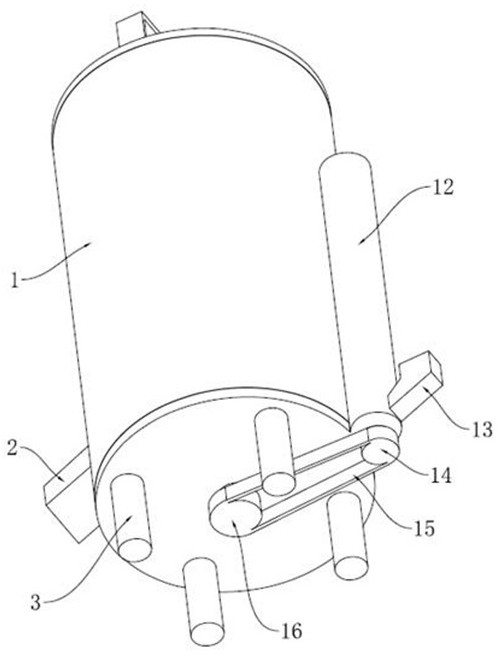

[0052] In another embodiment of the present invention, the difference between this embodiment and the above-mentioned embodiment is that, the bottom of the discharge plate 29 is connected to the bottom center of the drying box 1 through a limit post 31. Limiting cylinder 30, the bottom of limiting cylinder 30 is connected with driving pulley 16, and driving pulley 16 is connected with driven pulley 14 by belt 15, and driven pulley 14 upper end is connected with lifting shaft 34, and lifting shaft 34 wears A number of lifting screws 35 are connected to the lifting cylinder 12 fixed on the outer wall of the drying box 1, the top of the lifting cylinder 12 communicates with the inside of the drying box 1, and the bottom of the lifting cylinder 12 is also equipped with a feed hopper 13, specifically Yes, using the cooperation between the limit column 31 and the limit cylinder 30, the limit cylinder 30 is rotated, and finally under the action between the driving pulley 16, the belt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com