Mortar metalevel particle disperser

A disperser and mortar technology, which is applied in the field of high-speed mixer and mortar element-level particle disperser, can solve the problems of general stirring effect, low degree of mortar circulation and long stirring time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

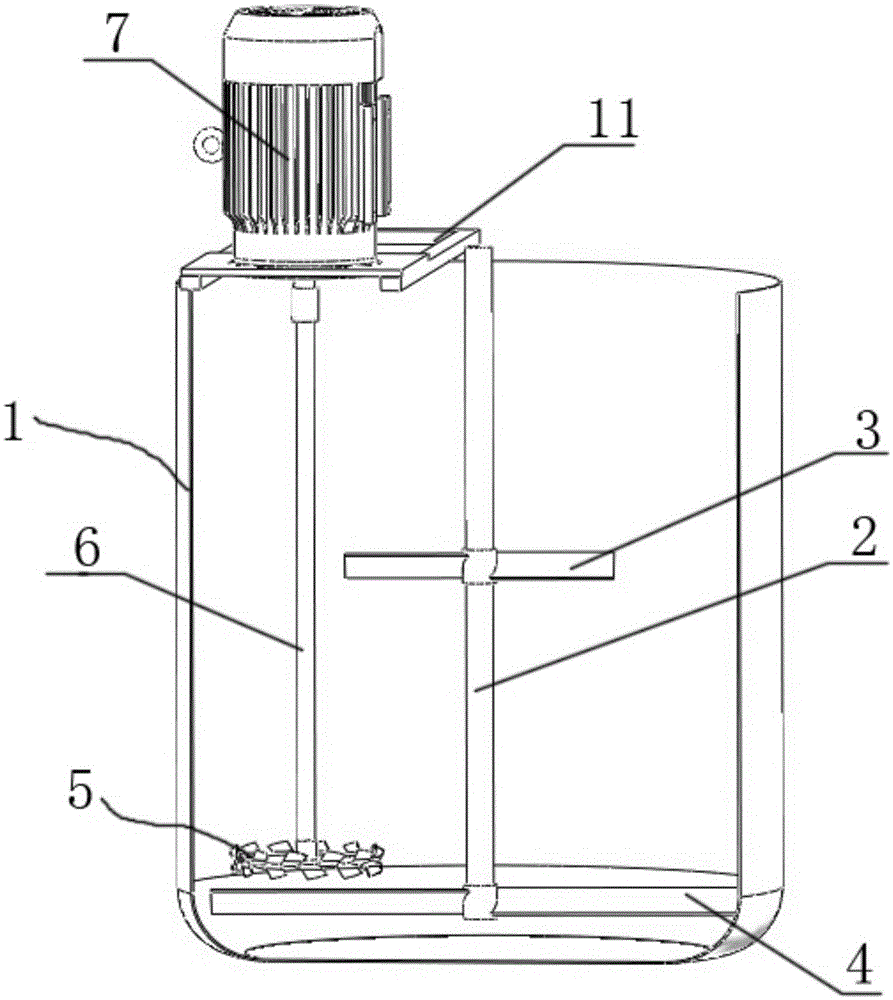

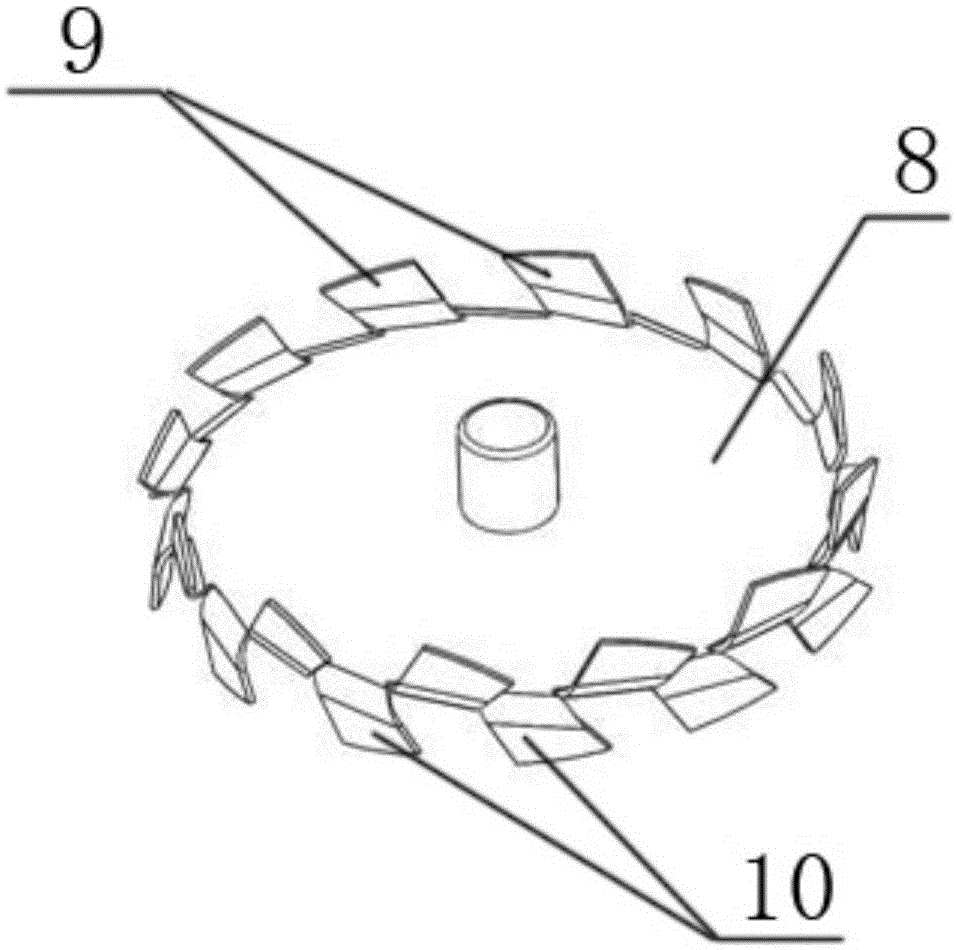

[0028] A kind of mortar element-level particle disperser, see Figure 2 to Figure 5 : It comprises a stirring container 1, the inside of which is provided with a central rotating shaft 2, the central rotating shaft 2 is arranged with an upper paddle 3 and a lower paddle 4, the stirring container 1 is arranged with a high-speed agitator, and the high-speed agitator includes a disc sawtooth Shaped impeller 5, turntable rotating shaft 6, power unit 7, one side of the inside of the mixing container 1 is arranged with a disc-shaped sawtooth impeller 5, the disc-shaped sawtooth impeller 5 includes a turntable 8, an upper sawtooth blade 9, a lower sawtooth blade 10, a turntable The center of 8 is connected with a turntable shaft 6, and the upper end of the turntable shaft 6 is externally connected to a power device 10. The turntable shaft 6 is located on one side of the center of the stirring container 1 and arranged eccentrically. The turntable shaft 6 is arranged vertically. In the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com