Patents

Literature

32results about How to "Improve productivity per unit time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

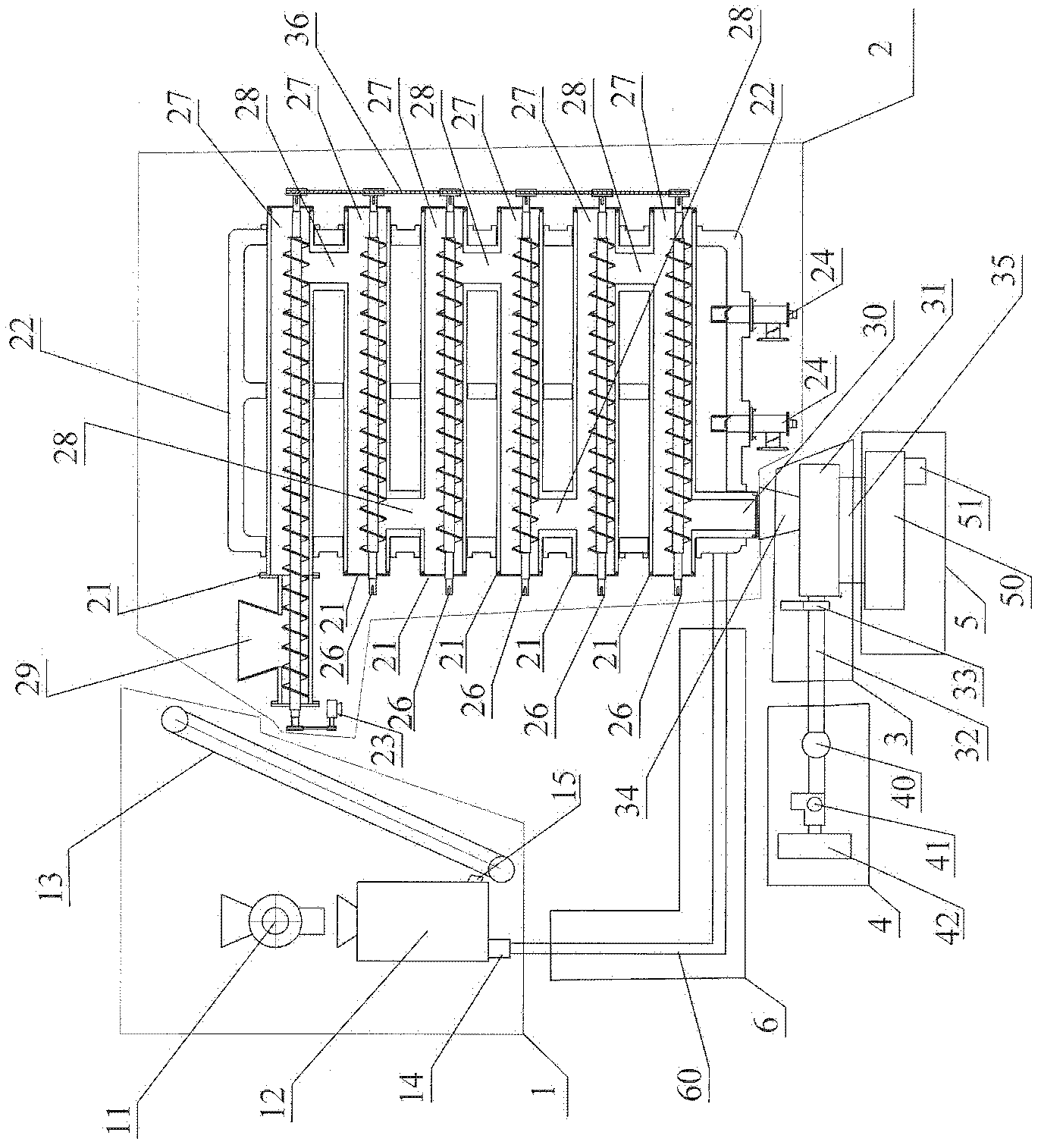

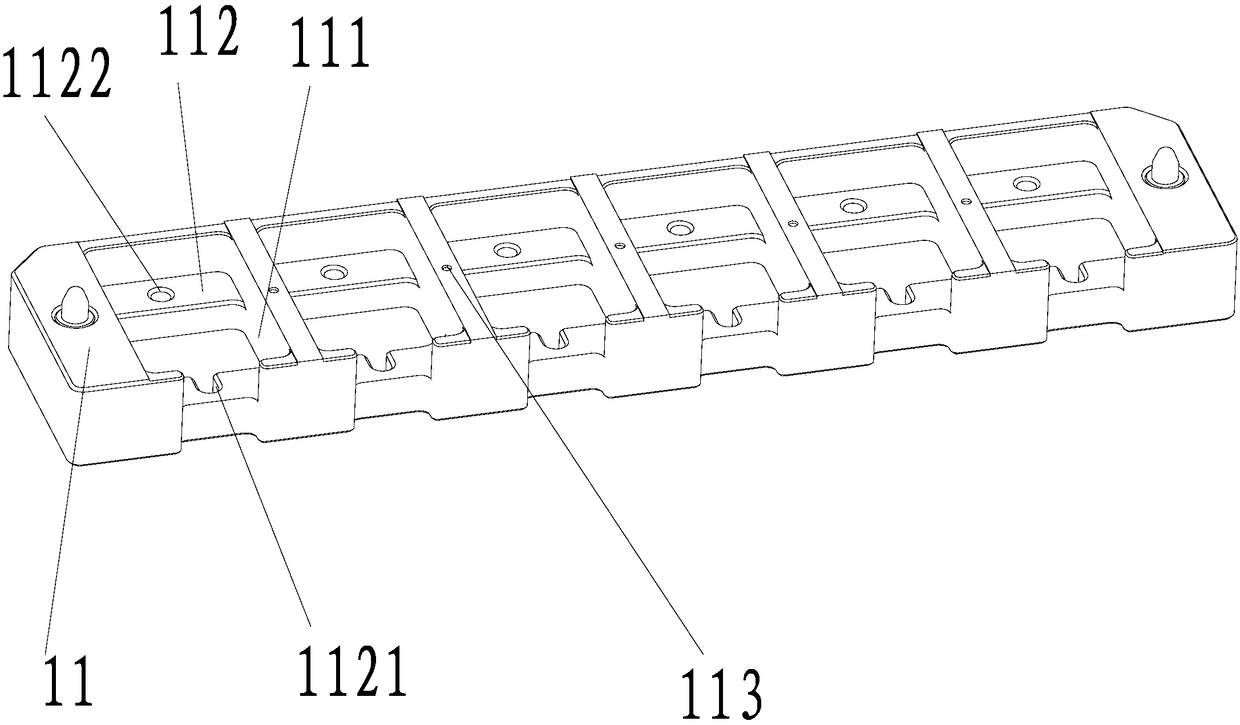

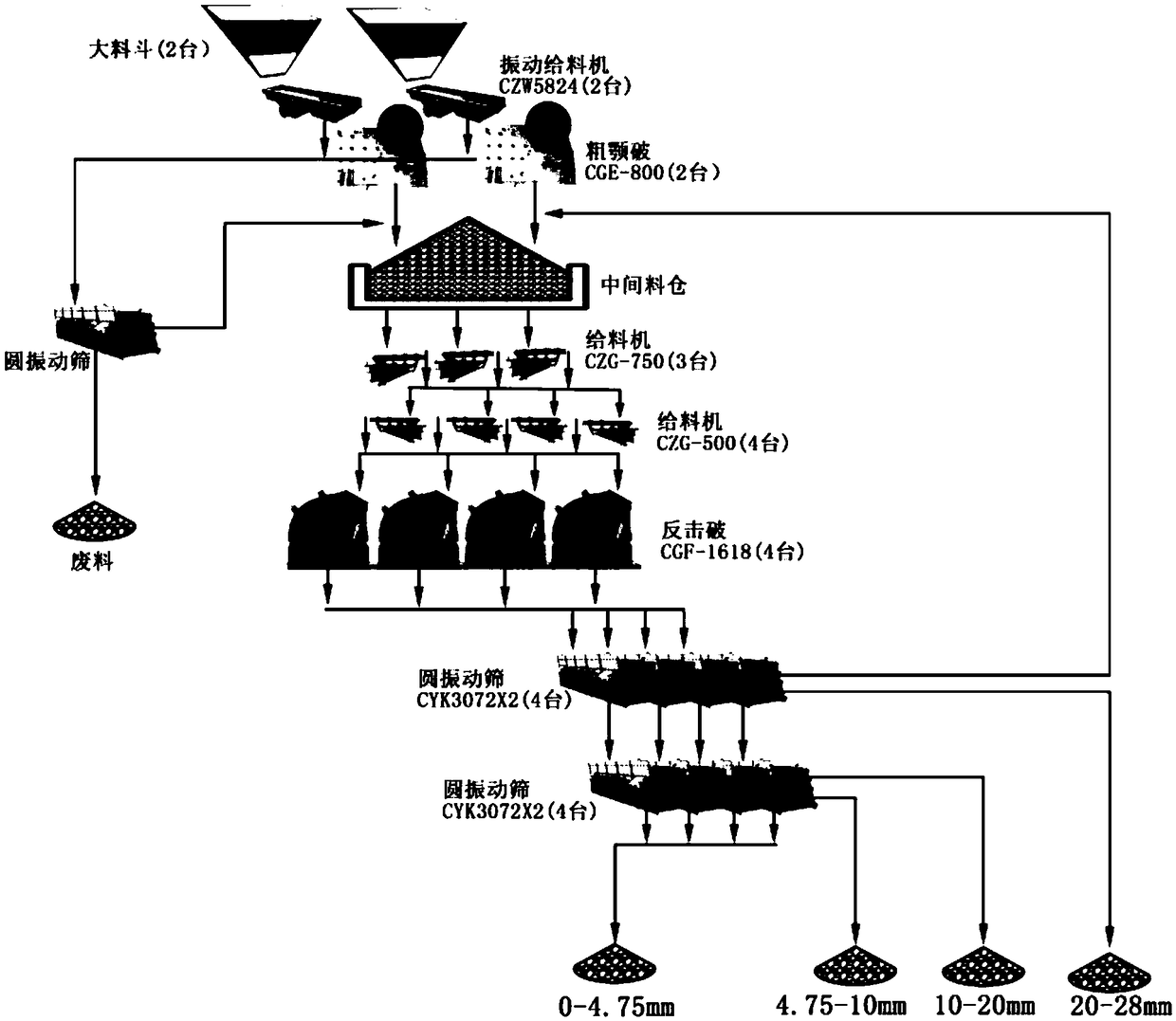

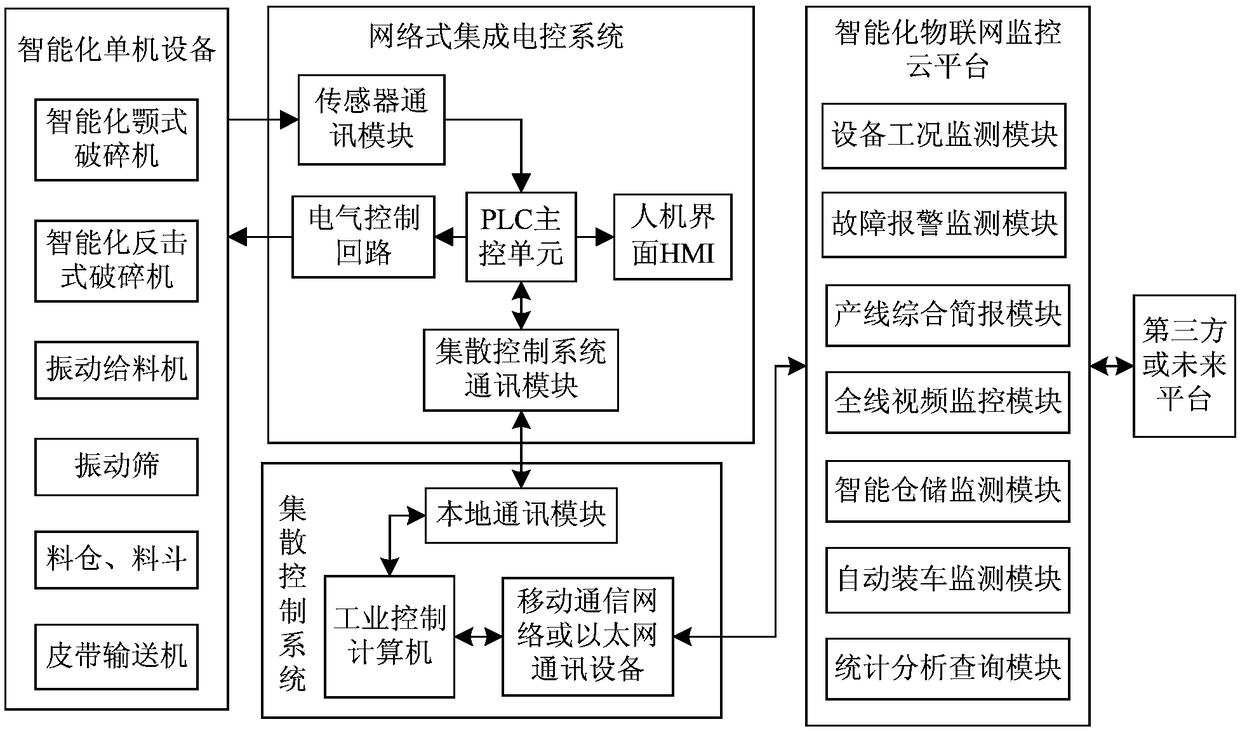

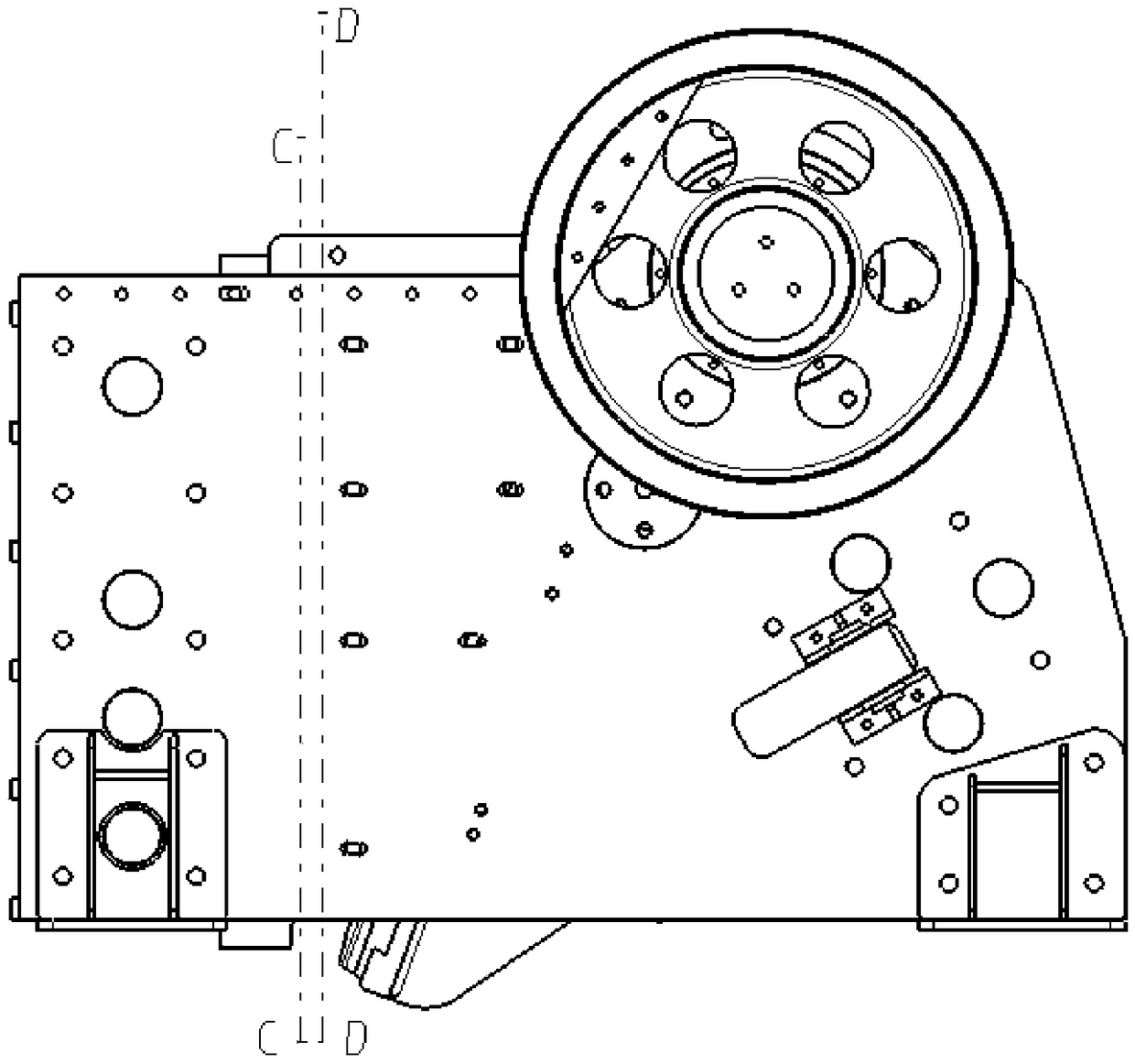

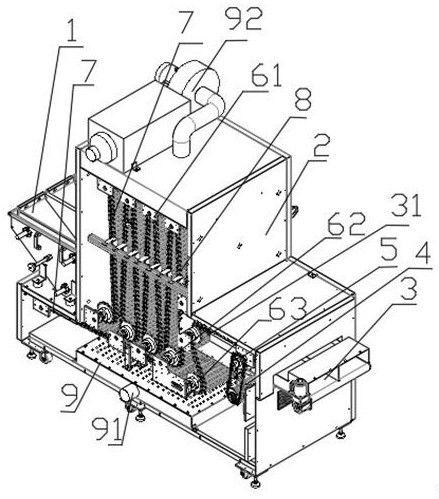

Intelligent gravel aggregate production line

ActiveCN107153410AIncrease the level of automationReduce work intensityTotal factory controlProgramme total factory controlProduction lineDowntime

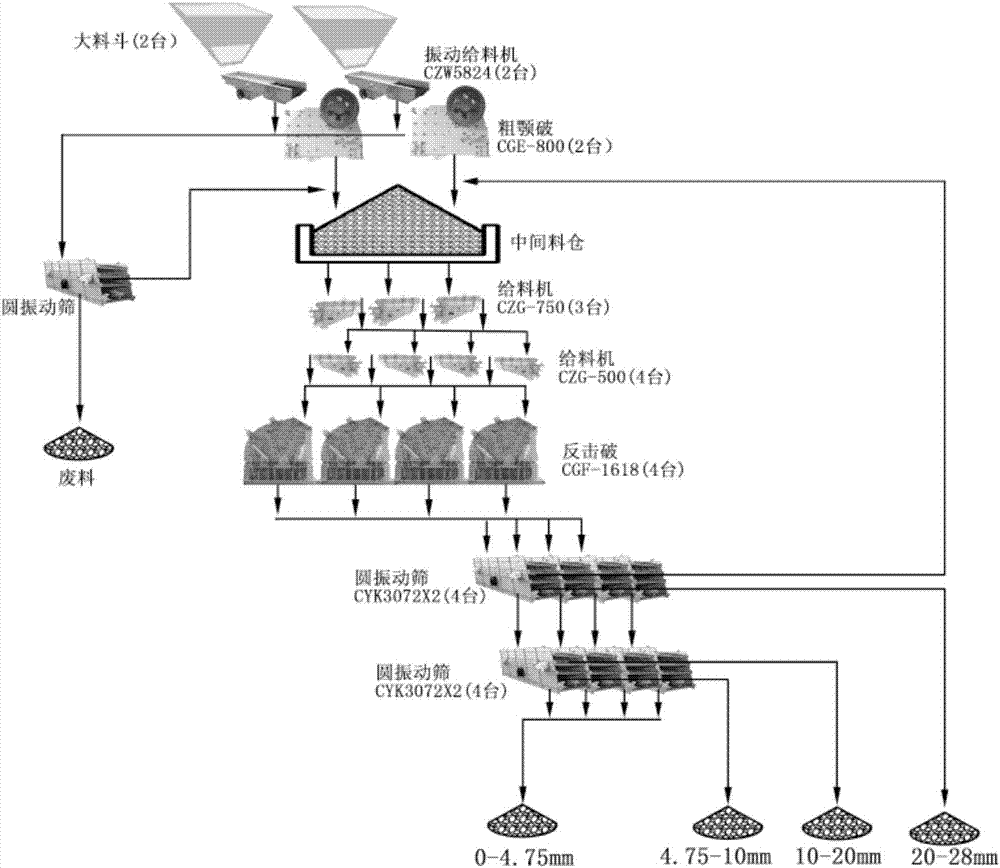

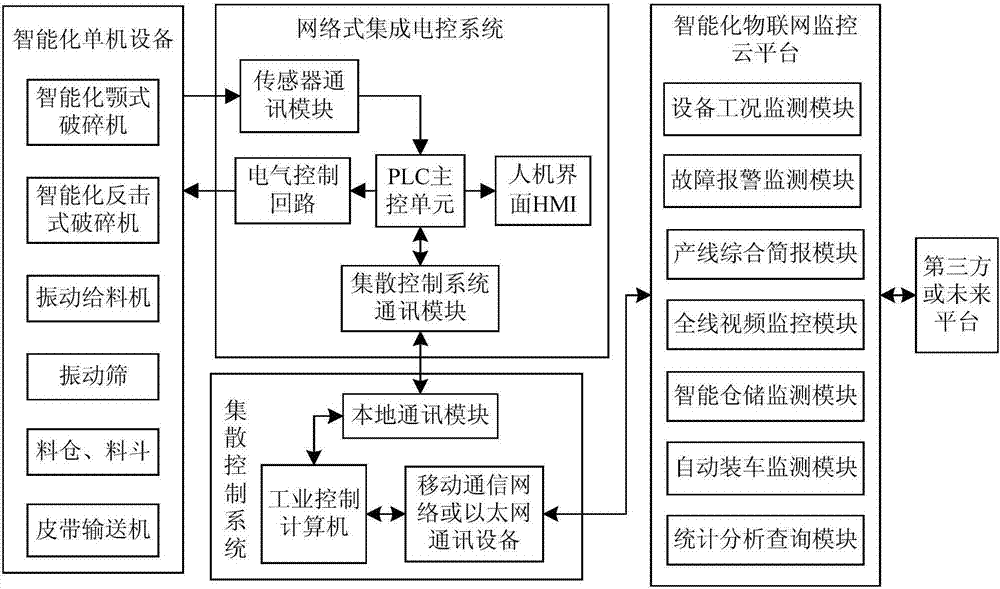

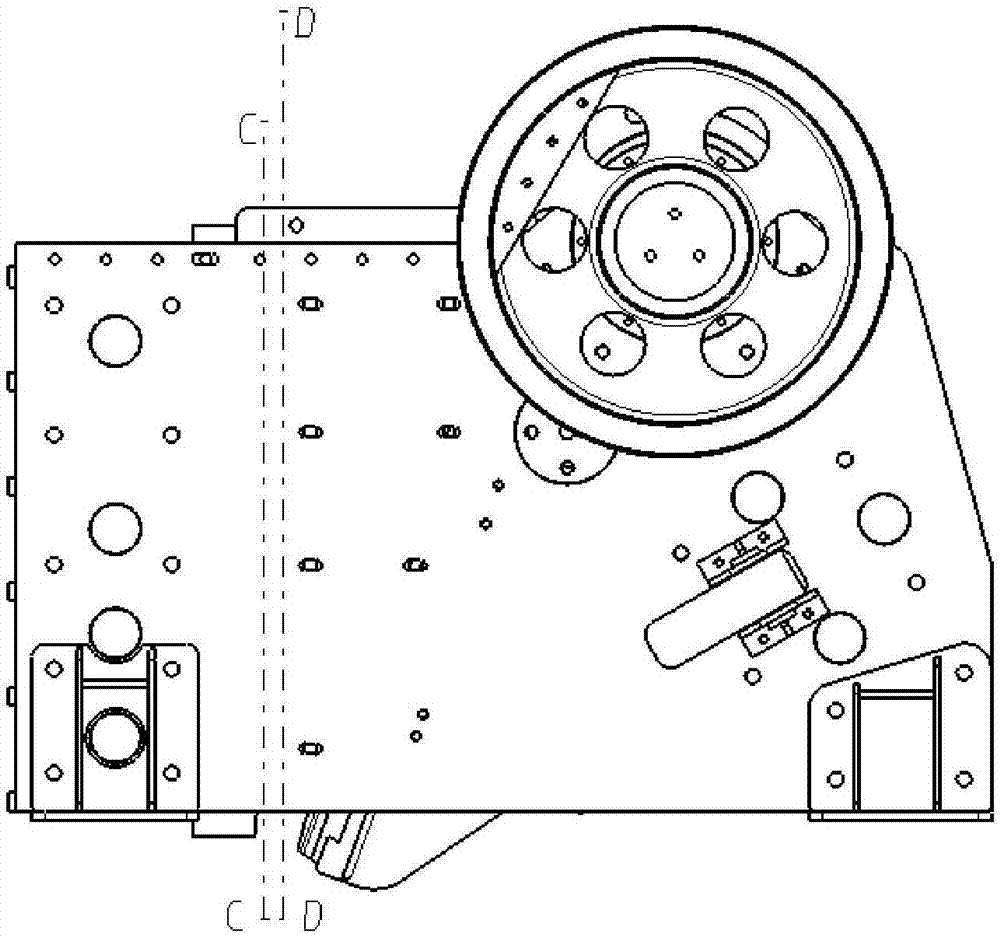

The invention provides an intelligent gravel aggregate production line, and relates to the technical field of gravel aggregate production. The intelligent gravel aggregate production line comprises an intelligent jaw type crusher, an intelligent impact type crusher, a vibrating screen, a vibrating feeder, a material bin, a hopper, a belt conveyor, a control-related network type integrated electric control system, a distributed control system and an intelligent internet of things monitoring cloud platform, wherein various sensors are additionally arranged on the basis of an original crushing screening production line; sensor information is transmitted to the distributed control system through the network type integrated electric control system, so that automatic regulation and control on the production process is realized, and therefore, the sensor information is transmitted to the intelligent internet of things monitoring cloud platform; and production data storage and safety are managed in a unified mode on the basis of classifying and combing through cloud computation. The intelligent gravel aggregate production line has a fault early-warning function and a real-time alarm function, and quickly increases response speed; internet of things intelligent control and remote monitoring are introduced, the production process is automatically regulated and control, operation is performed with optimal load, the yield is increased, and downtime maintenance is reduced.

Owner:SHANGHAI UNITRUSTON INTELLIGENT TECH CO LTD

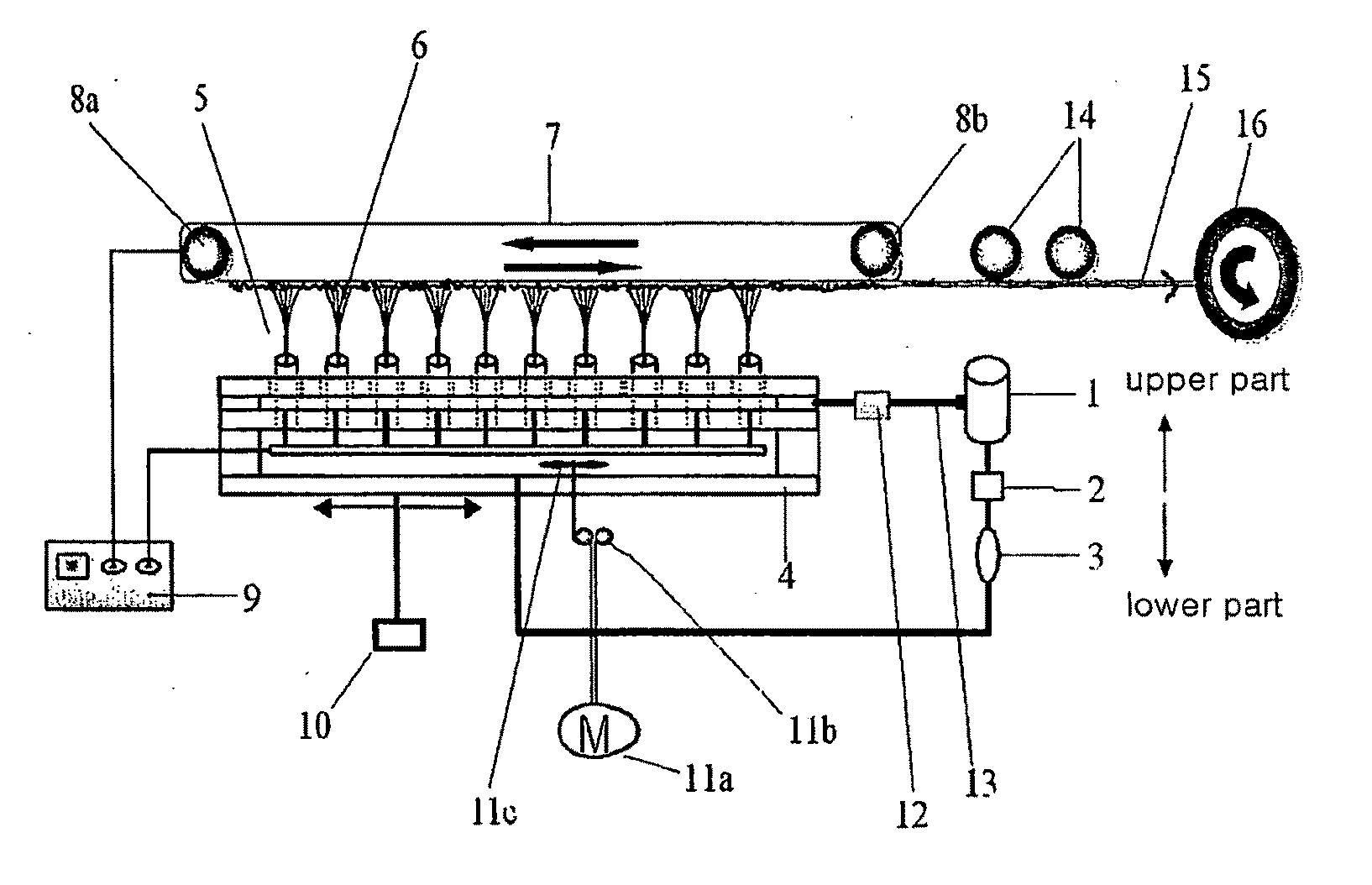

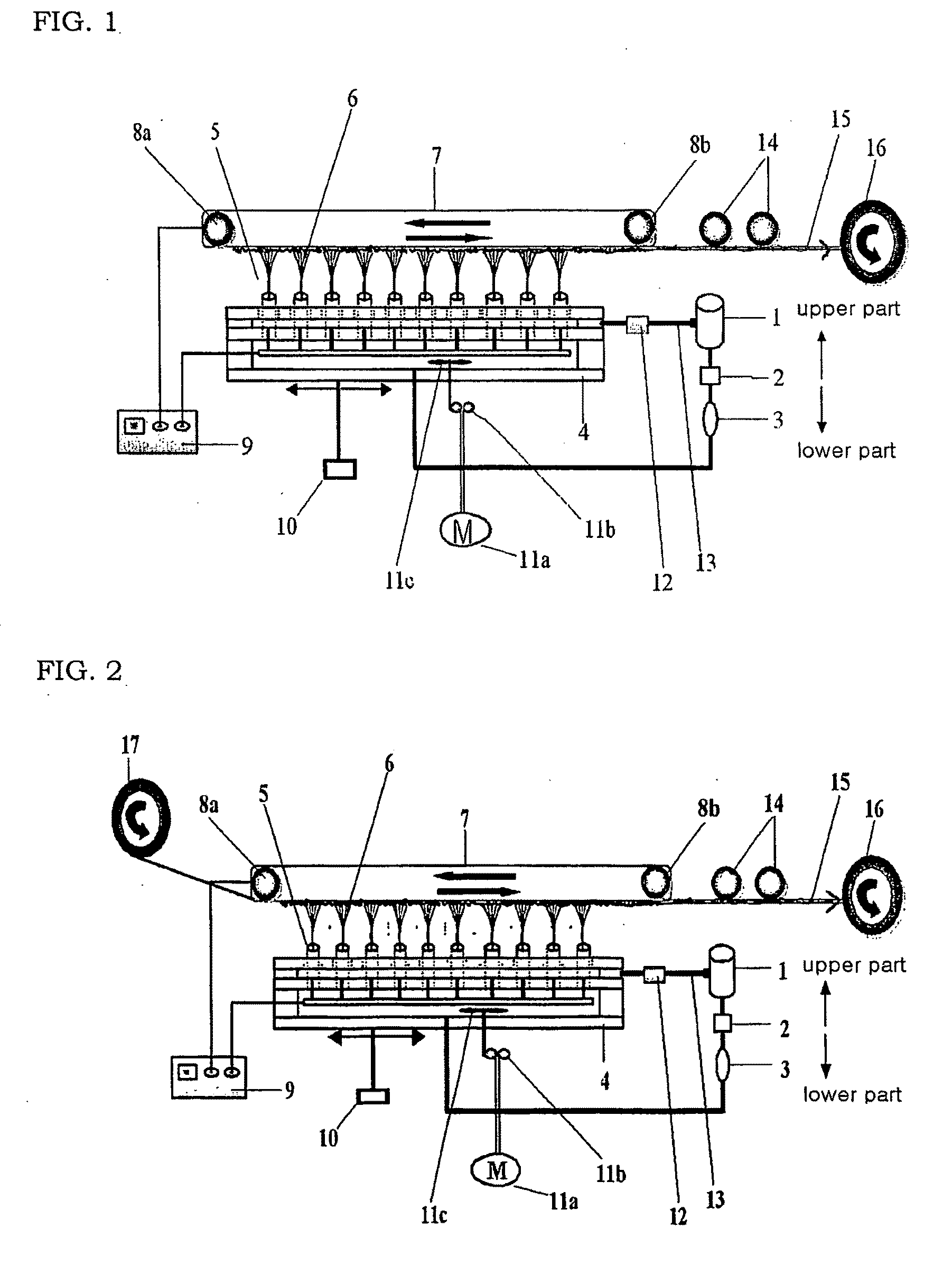

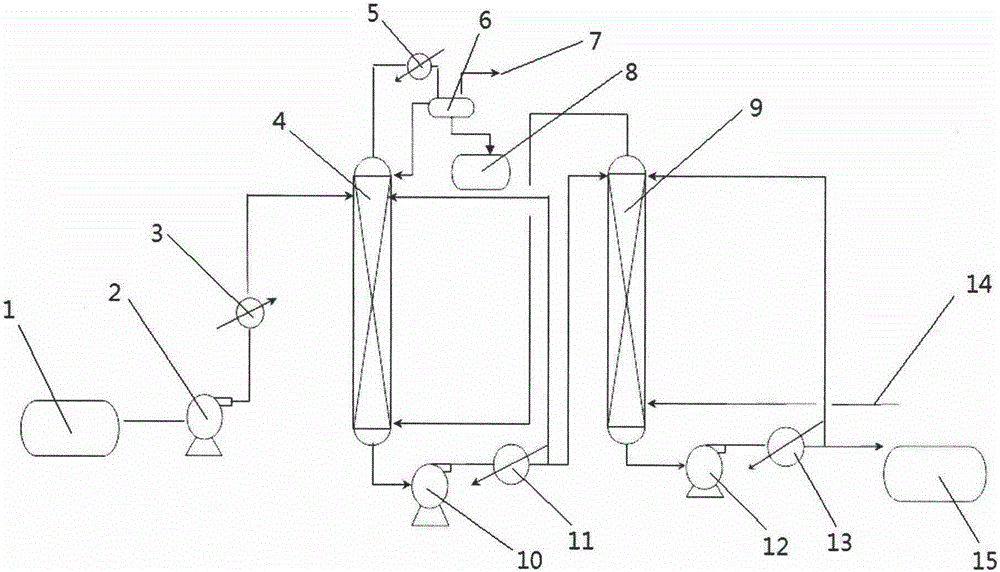

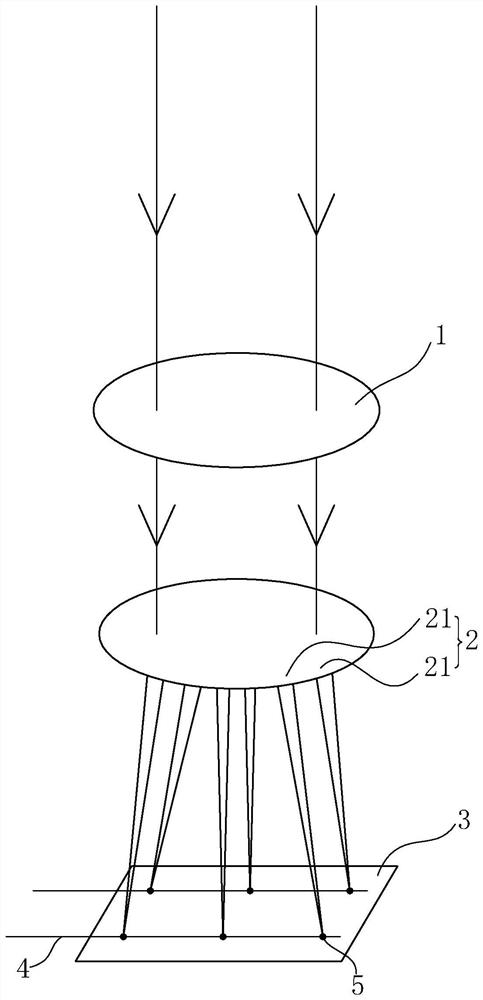

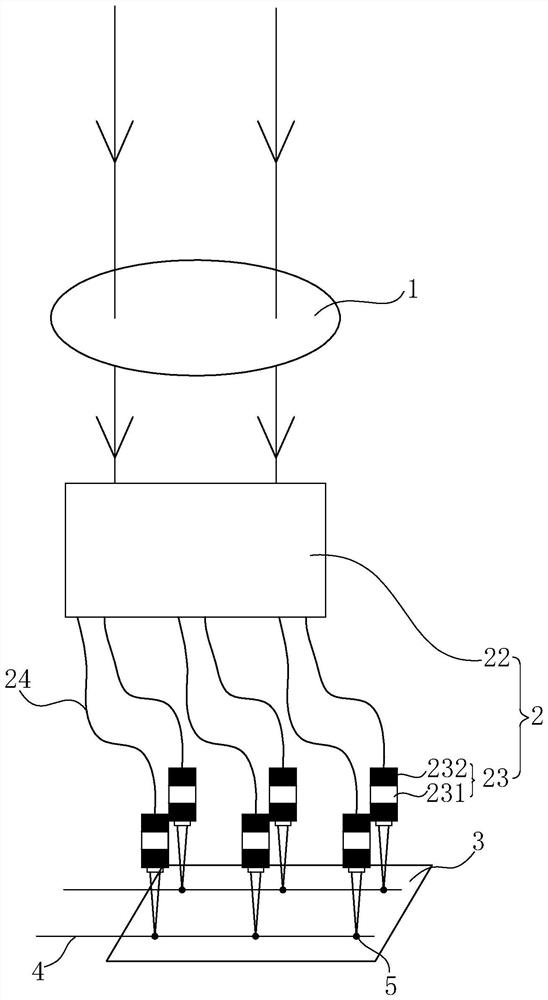

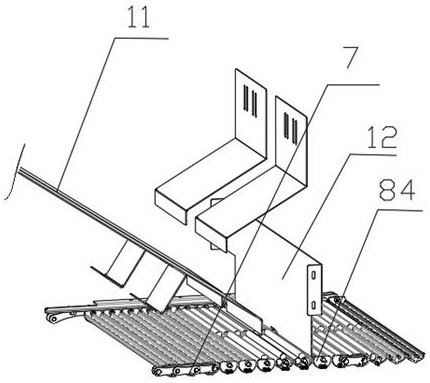

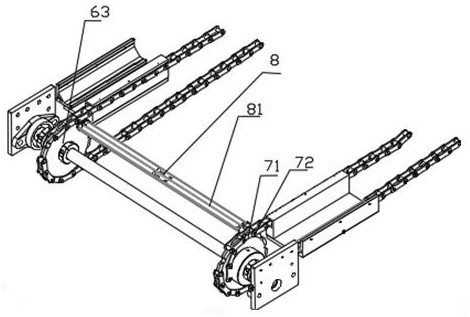

Bottom-up electrospinning devices, and nanofibers prepared by using the same

InactiveUS20090189318A1Improve productivity per unit timeGood fibrillationSpinnerette packsElectric discharge heatingElectrospinningProduction rate

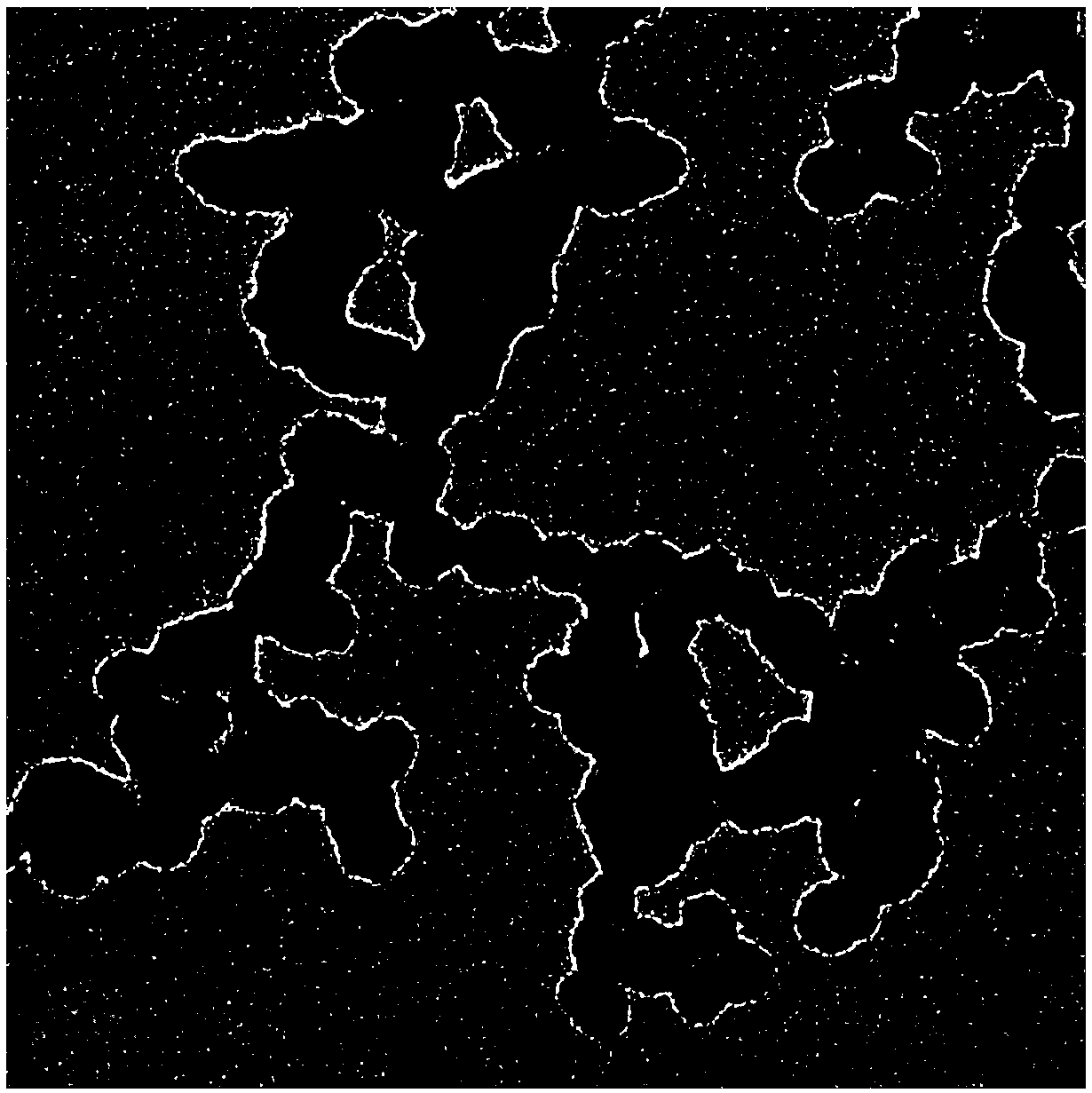

A conventional electrospinning devices is problematic in that the productivity is low and a droplet, by which a spinning liquid is not formed into fiber but dropped in a drop shape, occurs, to thereby deteriorate the quality of a nonwoven fabric. To solve the above problem, the present invention provides an bottom-up electrospinning devices, comprising: a spinning liquid main tank 1; a metering pump 2; a nozzle block 4; nozzles 5 installed on the nozzle block; a collector 7 for collecting fibers being spun from the nozzle block; and a voltage generator 9 for applying a voltage to the nozzle block 4 and the collector 7, wherein [A] the outlets of nozzles 5 installed on a nozzle block are formed in an upper direction; [B] a collector 7 is located on the top part of the nozzle block; and [C] a spinning liquid discharge device 12 is connected to the uppermost part of the nozzle block 4.

Owner:FINETEX TECH GLOBAL +1

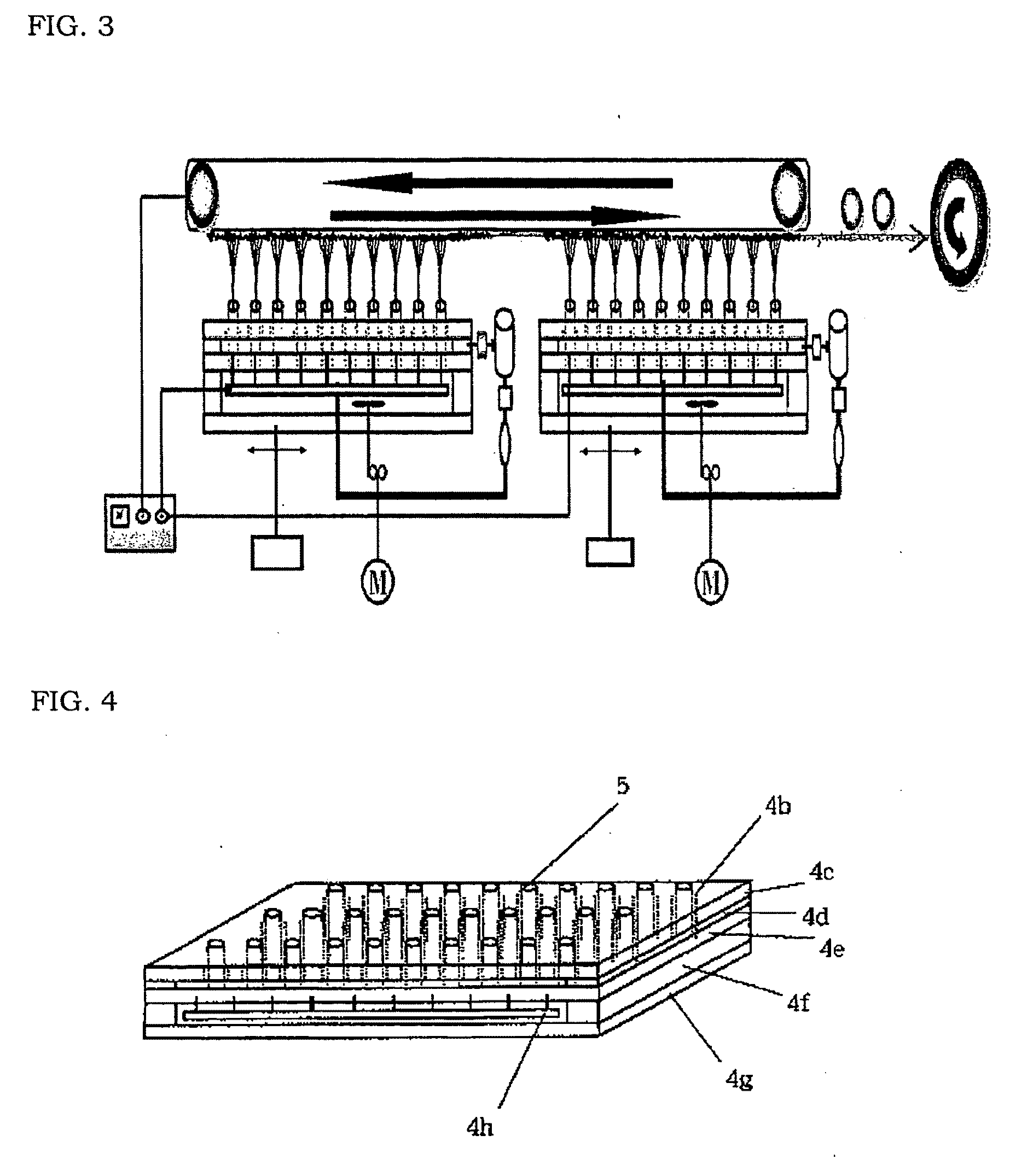

High-speed hot press and its application method

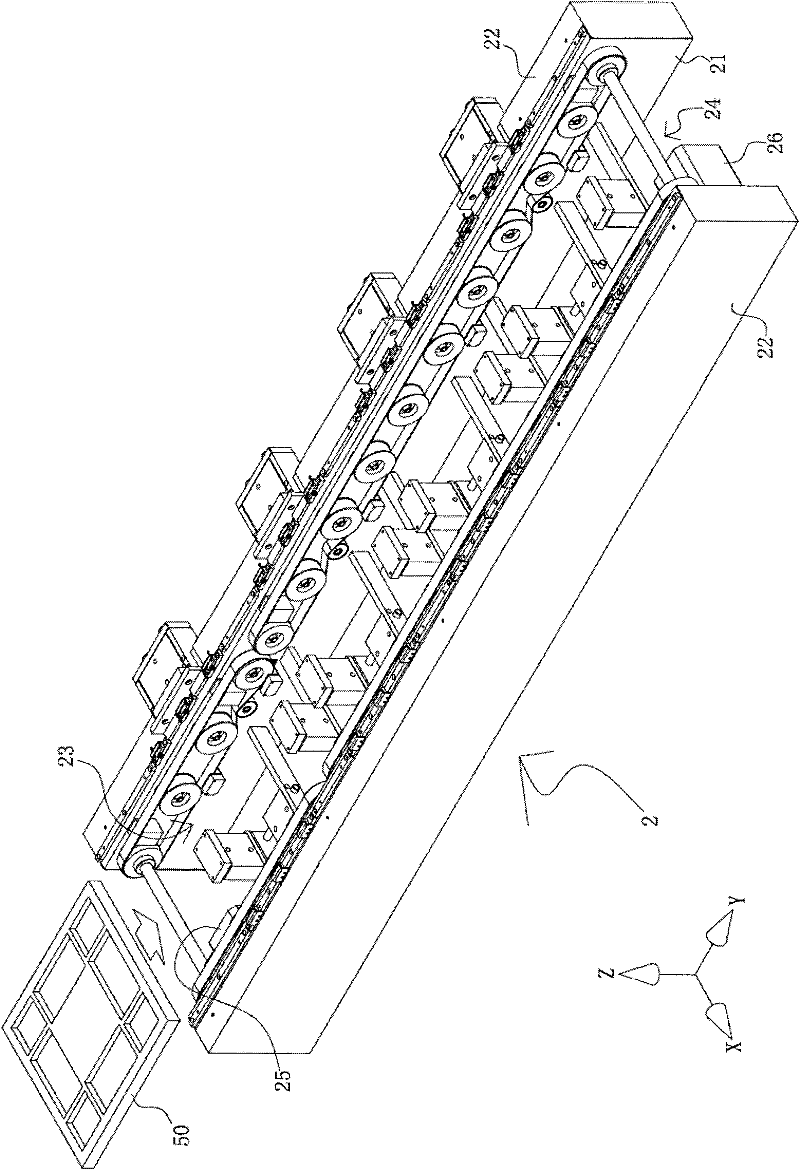

InactiveCN102275038ALow costReduce the burden onNon-electric welding apparatusEngineeringConveyor belt

The invention aims to provide a high-speed hot press which can be matched with a movable pulse hot-pressing module to improve the process operation mode and enhance the productivity per unit time, and the application method of the high-speed hot press as well. The high-speed hot press comprises a machine station, a conveyor belt mechanism, a hot-pressing module, a moving mechanism and an operation system. The high-speed hot press is characterized in that the hot-pressing module is composed of a pulse hot-pressing electrode, a heat-dissipating module, a horizontal adjusting module, an actuating module and a transformer module which are orderly stacked from bottom to top; and the moving mechanism consists of two parallel opposite longitudinal bearing rails, a plurality of horizontal moving rails, a plurality of horizontal moving apparatuses and a plurality of longitudinal moving apparatuses, wherein the longitudinal bearing rails are respectively arranged at one side of the top end of the machine station, the horizontal moving rails are respectively corresponding to the hot-pressing modules and are arranged between the longitudinal bearing rails, the horizontal moving apparatuses are respectively disposed at positions where the horizontal moving rails and the longitudinal bearing rails are connected, and the longitudinal moving apparatuses are respectively disposed at positions where the hot-pressing modules and the horizontal moving rails are connected and enable the hot-pressing modules to be suspended below the horizontal moving rails.

Owner:PROGRESS Y&Y

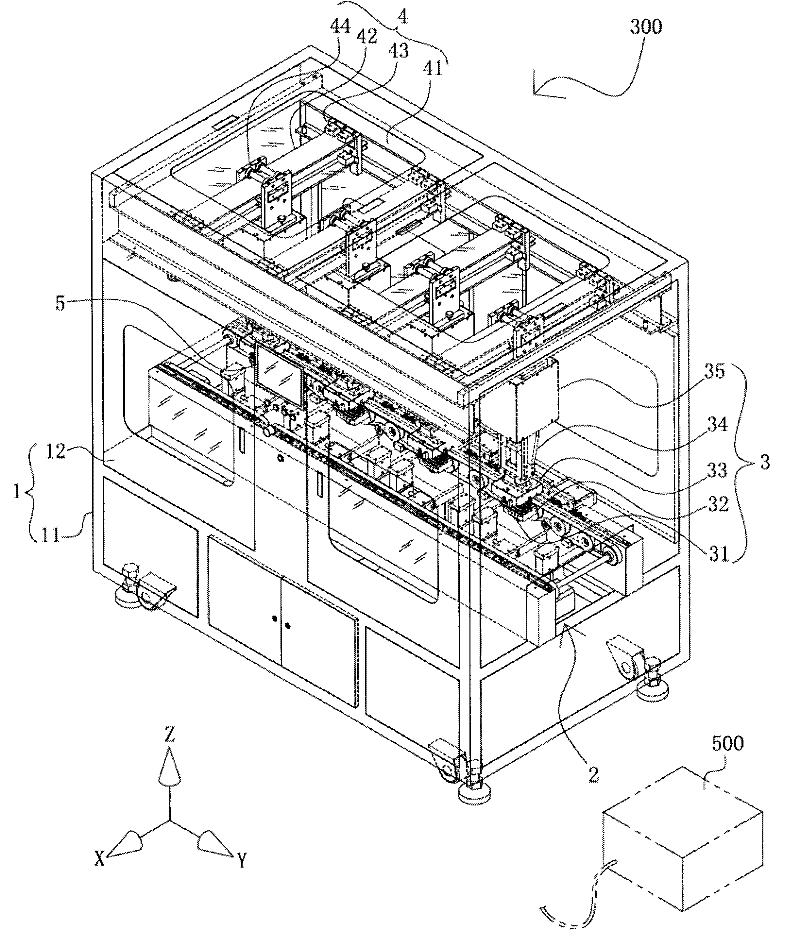

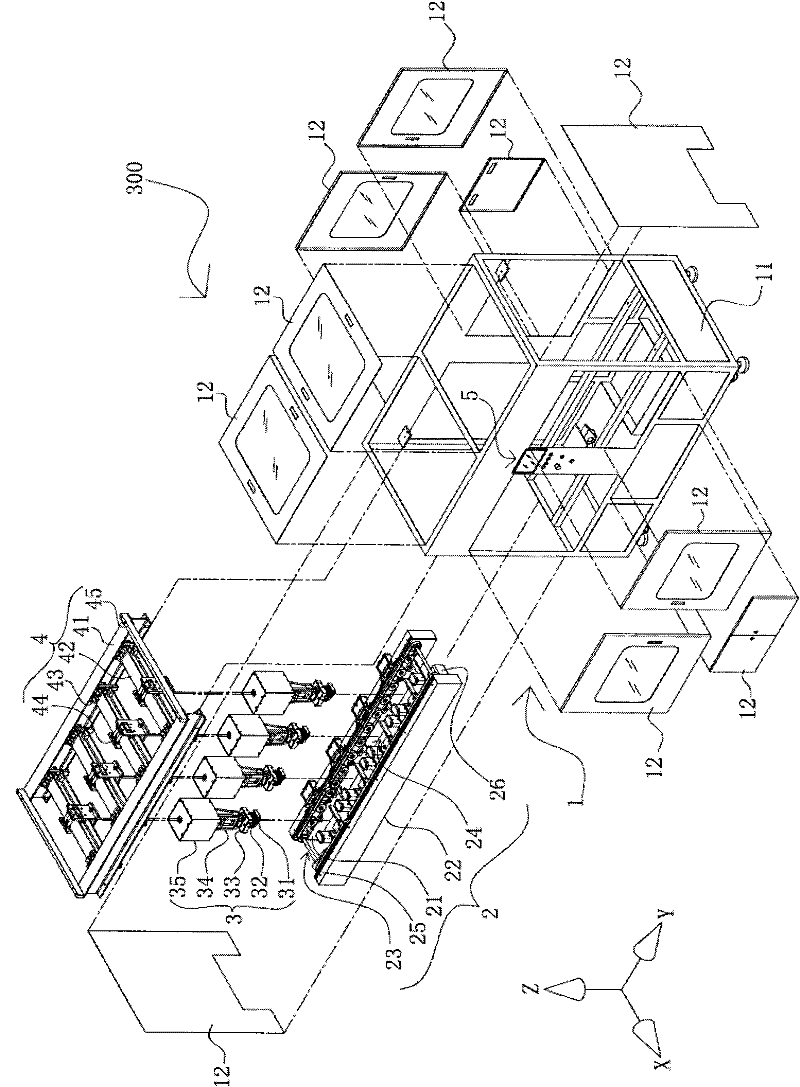

Light emitting diode, manufacturing method thereof, light emitting diode module, and manufacturing method thereof

ActiveUS8785953B2Reduce unevennessUniform characteristicsSolid-state devicesSemiconductor/solid-state device manufacturingPhosphorAdhesive

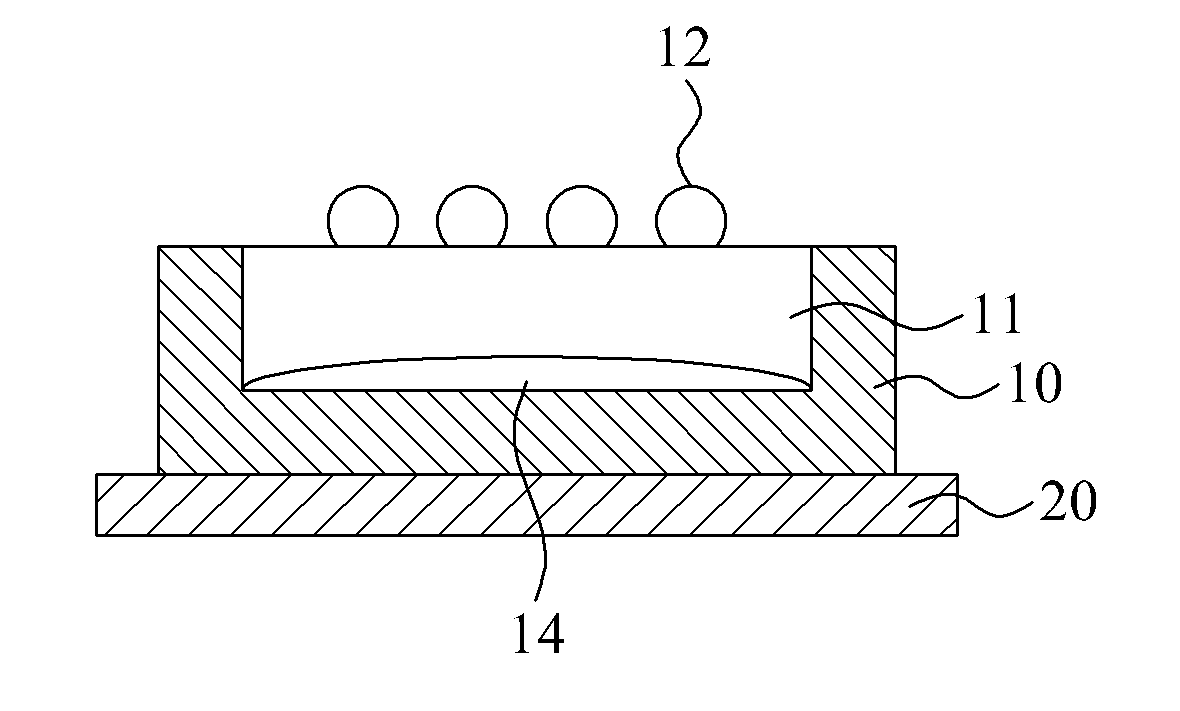

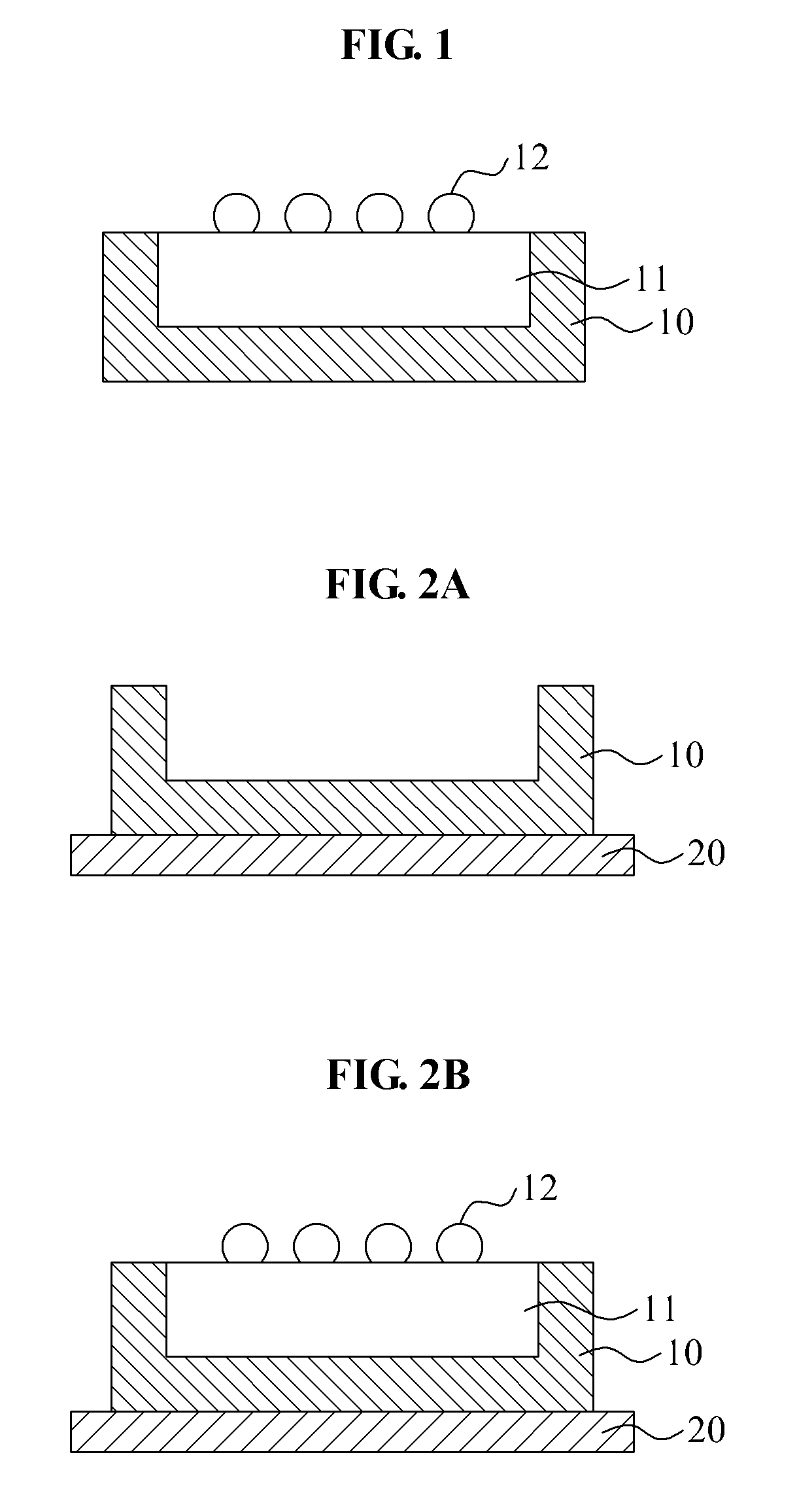

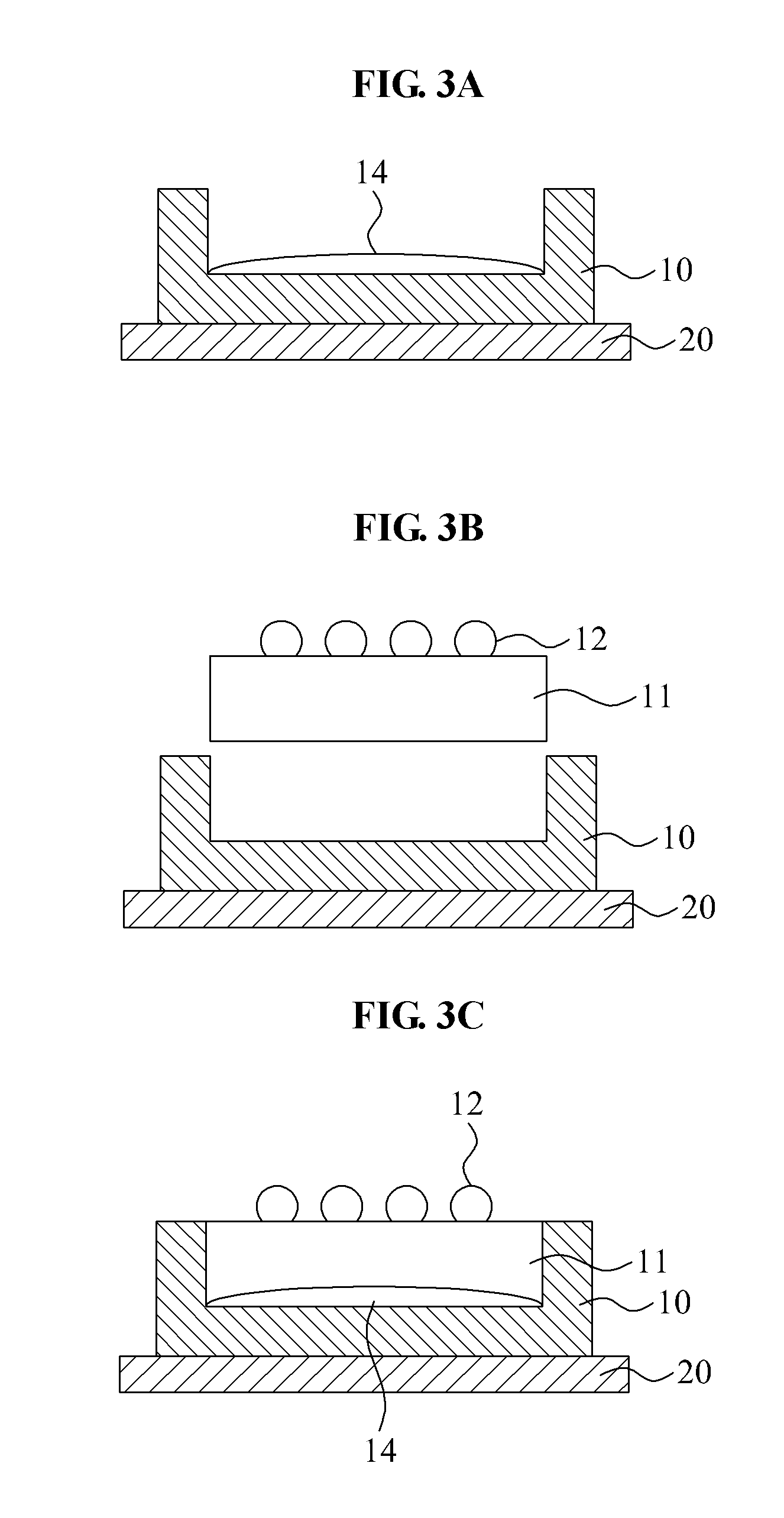

A manufacturing method of a light emitting diode (LED) and a manufacturing method of an LED module are provided. The manufacturing method of the LED may include manufacturing a plurality of LED chips, manufacturing a phosphor pre-form including a plurality of mounting areas for mounting the plurality of LED chips, applying an adhesive inside the phosphor pre-form, mounting each of the plurality of LED chips in each of the plurality of mounting areas, and cutting the phosphor pre-form to which the plurality of LED chips are mounted, into units including individual LED chips.

Owner:SAMSUNG ELECTRONICS CO LTD

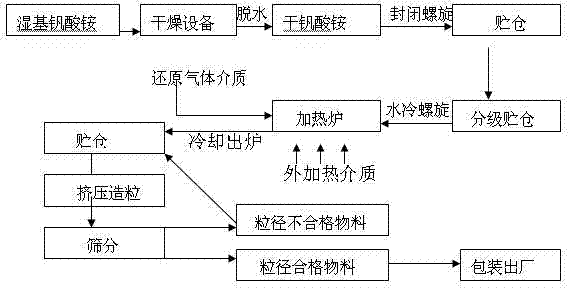

Production method of high-bulk density and high-stability vanadium trioxide

InactiveCN103588248AAlleviate the problem of inaccurate total vanadium contentSolve the problem of inaccurate total vanadium contentVanadium oxidesPelletizingSpecific gravity

The invention discloses a production method of high-bulk density and high-stability vanadium trioxide, which is characterized by comprising the following steps of reducing dry ammonium vanadate with reducing gas to obtain powdery vanadium trioxide; extruding the powdery vanadium trioxide by a feeder and a roller press to form strip vanadium trioxide; performing granulation and screening to form granular vanadium trioxide. The method is simple in production process, low in cost and suitable for large-scale industrial production. By adopting the method, the bulk density of the granulated vanadium trioxide is increased from 0.9-1.0g / cm<3> to 2.0-3.0kg / m<3>, the internal gas content is reduced, the oxidation is slowed down, the problem of inaccurate total vanadium content caused by natural oxidation of raw materials in the fields of ferrovanadium smelting and nitralloy production is solved, the loss of flying materials is greatly reduced, the vanadium yield of the system is improved, and the unit-time output of vanadium nitride or ferrovanadium also can be remarkably increased.

Owner:HEBEI IRON AND STEEL

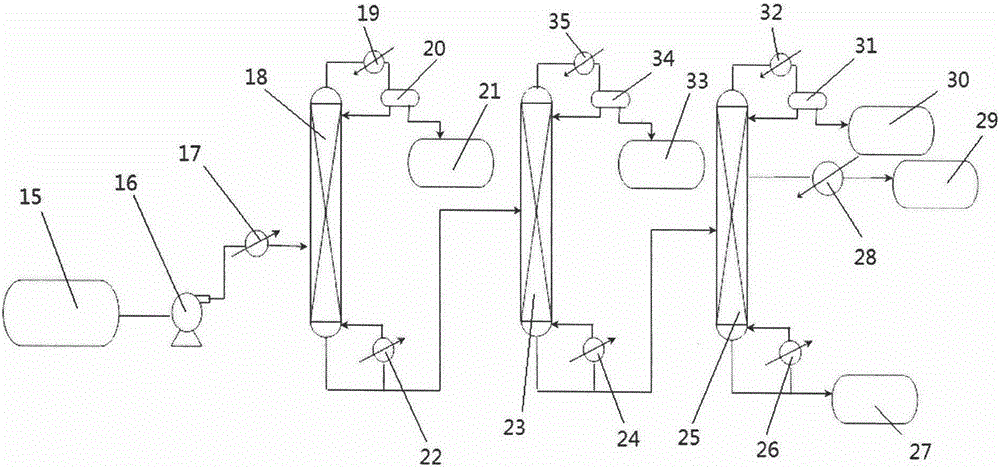

A process for continuously producing m-toluic acid

InactiveCN105061187AImprove reaction efficiencyIncrease production capacityOrganic compound preparationCarboxylic compound separation/purificationM-tolualdehydeWork flow

The invention discloses a process for continuously producing m-toluic acid. The process comprises a synthesizing production process corresponding to a synthesizing workshop section and a rectifying production process corresponding to a rectifying workshop section. The process for continuously producing m-toluic acid comprises a work flow of (1) synthesizing process, namely synthesizing by adopting a multi-level outer-loop serial connection process; and (2) rectifying process, namely rectifying by utilizing an m-xylene recovery tower, a m-tolualdehyde recovery tower and a m-toluic acid rectifying tower. The process has the advantages of reasonable structural design and continuous operation, a gaseous phase and a liquid phase are sufficiently contacted by means of countercurrent to react, so that the reaction efficiency can be greatly improved, the product production capacity in unit interval can be improved, and operation energy consumption can be reduced. Furthermore, the continuous rectification process can be used for greatly shortening the time for heating a to-be-separated mixture and remarkably inhibiting generation of deep byproducts, so that the once through yield can be greatly improved, and the production benefit can be remarkably increased.

Owner:JIANGSU PANOXI CHEM

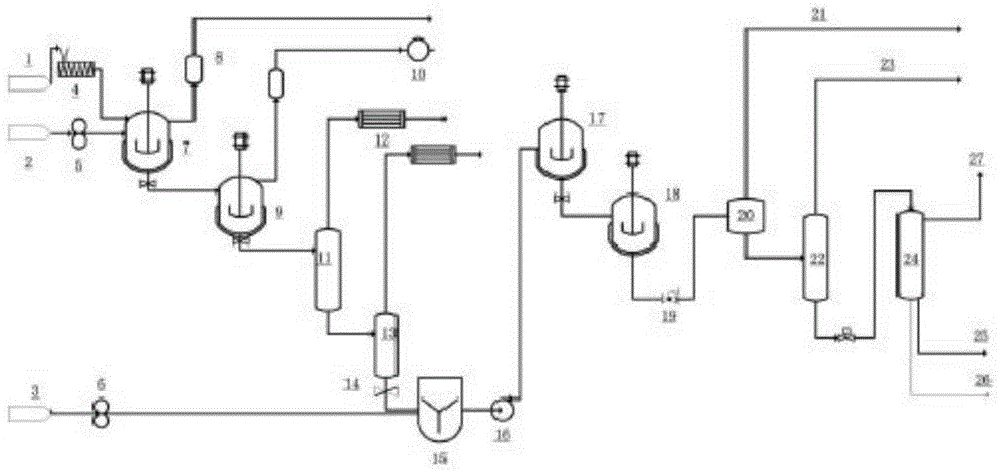

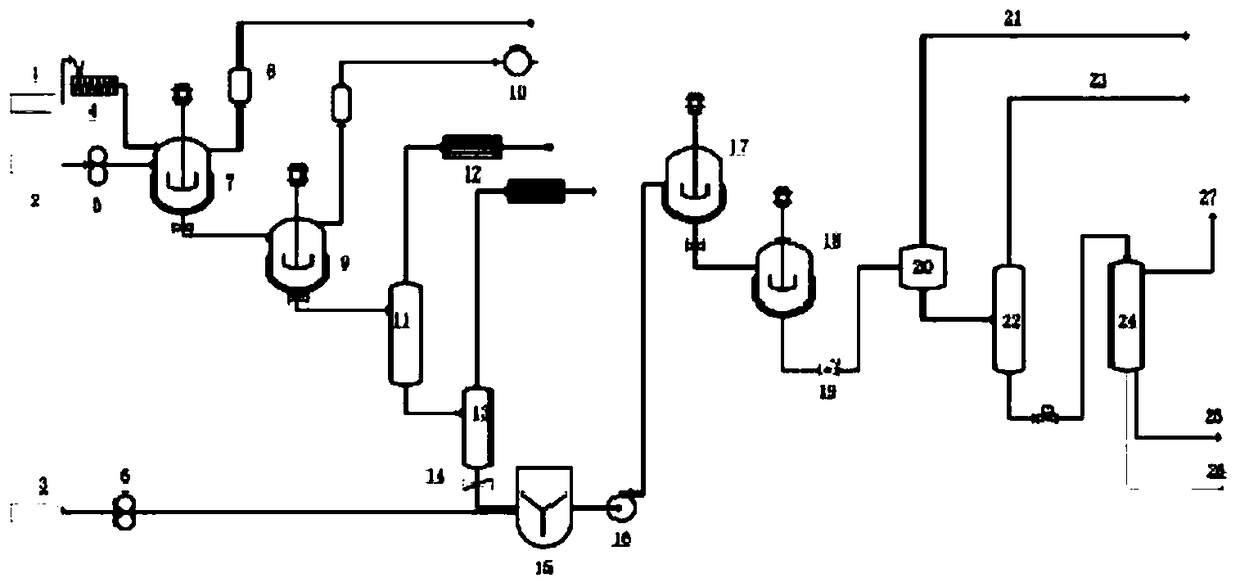

Preparation method of methylphenylcarbamate

ActiveCN106146353ARealize comprehensive applicationSolutionCarbamic acid derivatives preparationOrganic compound preparationCarbamateDistillation

The invention relates to a preparation method of methylphenylcarbamate. The preparation method comprises 1, adding urea and aniline into a pre-reactor and a diphenyl urea synthesis reactor and synthesizing diphenyl urea, 2, conveying the reaction liquid into a falling film evaporator and an evaporating crystallizer through a feeding pump, separating aniline, mixing the aniline and methanol, feeding the mixture into an alcoholysis reactor, carrying out a reaction process, feeding the reaction materials into a flash evaporation pot, separating a part of methanol and aniline and separating residual methanol and most of aniline through the falling film evaporator to obtain a methylphenylcarbamate crude product, and 3, feeding the methylphenylcarbamate crude product into a scraped film type molecule distillation device and further separating the residual microscale aniline and high-boiling residues so that high purity methylphenylcarbamate is obtained and has purity greater than or equal to 99.9%. The preparation method effectively improves methylphenylcarbamate synthesis efficiency and has a product yield greater than or equal to 98.0%. The preparation method is simple and easy and provides an effective synthesis and separation method of a phenyl carbamate intermediate used in preparation of diphenylmethane diisocyanate through the non-phosgene way.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Crystallization method for continuous desolvation production of glyphosate by using glycocoll method

ActiveCN101704840BHigh yieldLarge crystal grainsGroup 5/15 element organic compoundsSolution crystallizationPolymer scienceDesolvation

The invention relates to a crystallization method for continuous desolvation production of glyphosate by a using glycocoll method, comprising the following steps of: adding glyphosate crystalline liquid in a crystallization kettle, rising the temperature of the crystallization kettle to 95-100 DEG C within 20-40 min; controlling the stirring speed at 20-25 rpm and the temperature of the crystallization kettle at 100-110 DEG C and reacting for 3-4 h; adjusting the stirring speed to 30-40 rpm, stirring for 30-40 min, and rising the temperature of the crystallization kettle to 110-115 DEG C; then controlling the temperature of the crystallization kettle at 115-117 DEG C and reacting for 2-3 h; adding deionized water and alkali in the crystalline liquid, controlling the stirring speed at 20-25 rpm, stirring for 6-8 h and reducing the temperature of the crystallization kettle to 20-30 DEG C . The glyphosate obtained in the invention has the dry powder content of 96-98 percent and stable quality; the solid glyphosate has high yield, large crystal grain, even particle size distribution, shorter crystallization time and is beneficial to improving the output in unit time.

Owner:CAC NANTONG CHEM

Shell machining technology for electronic product and surface hardening technology for electronic product

InactiveCN106140583AGood effectChange the serious problem of loss and wastePretreated surfacesCoatingsEngineeringMachining

The invention discloses a shell machining technology for an electronic product and a surface hardening technology for the electronic product. The shell machining technology includes the steps that a plastic part treated through a back face technology is subjected to plastic part cleaning, plastic part drying, plastic part surface hardening liquid spraying, normal-temperature leveling and heating leveling in sequence. When the surface energy of the plastic part is low, a plastic part surface ionizing manner is adopted, and a better product effect can be achieved. The plastic part sequentially passes through all functional sections from the first section to the seventh section of an integrated device, a needed hardened coating is obtained on the surface of the plastic part, and finally an electronic product plastic shell high in performance requirement is obtained through appearance size cutting.

Owner:东莞市汇诚塑胶金属制品有限公司

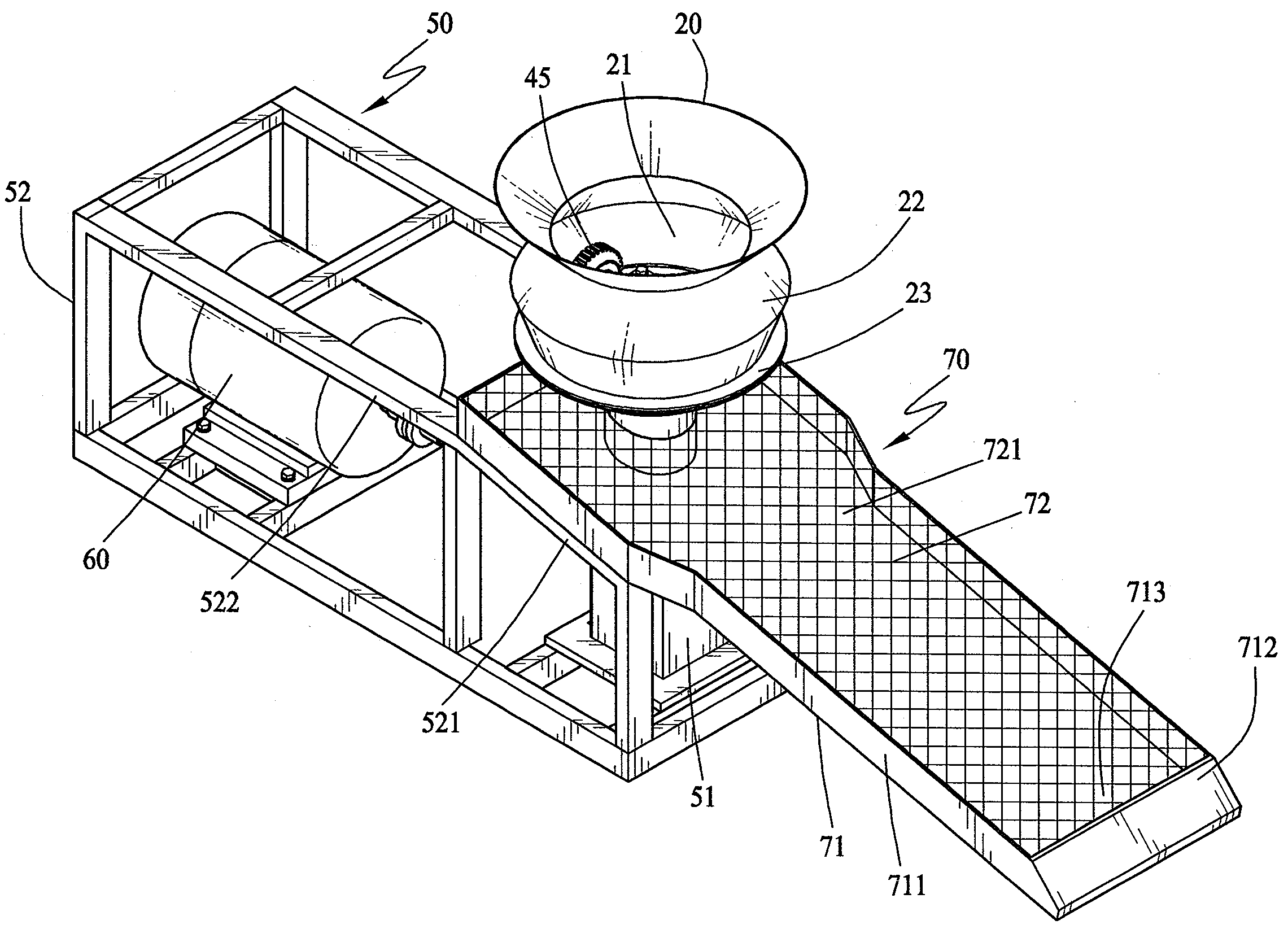

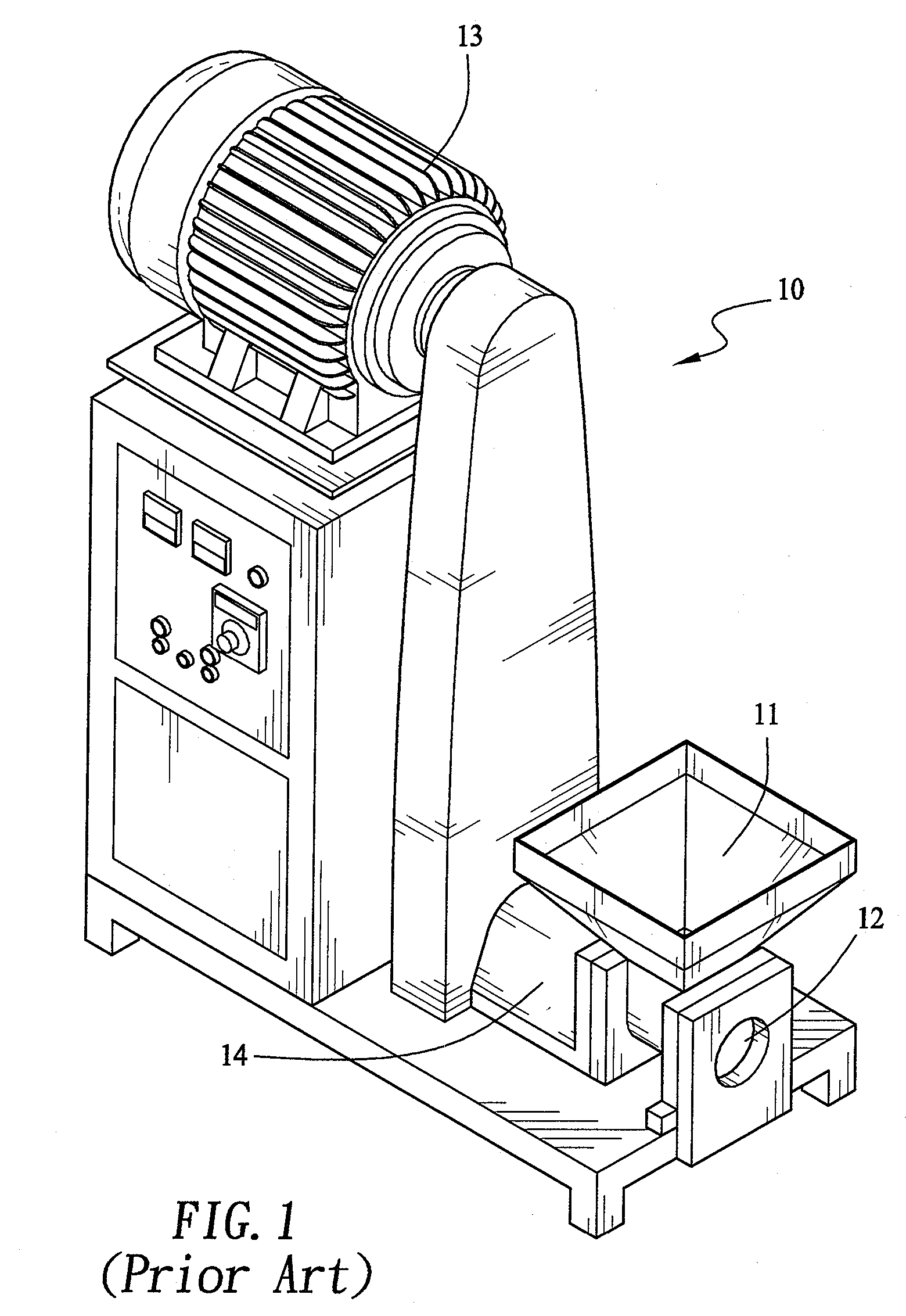

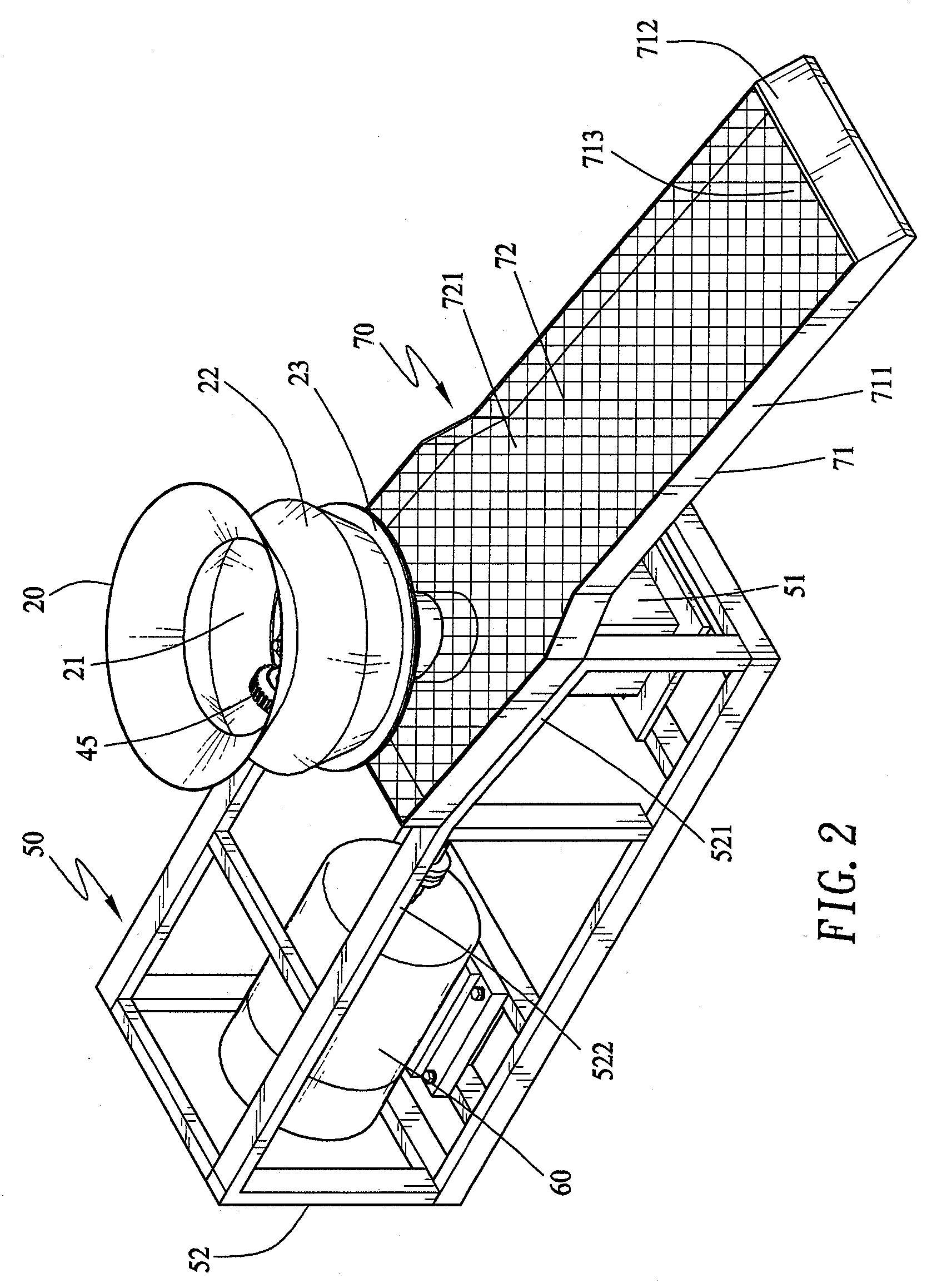

Plodder machine

InactiveUS20100310692A1Improve productivity per unit timeLabor savingTailstocks/centresConfectioneryEngineeringTime cost

A plodder machine includes a raw material receiving member, a forming member mounted to a bottom of the receiving member to define a receiving space therebetween, a rolling device mounted in the receiving space, and a mounting base supporting the forming member and a power transmission device thereon. The rolling device is driven by the power transmission device to rotate horizontally and thereby press a raw material into a plurality of forming holes circularly arrayed on the forming member to form bar-shaped products. A screening discharging device is connected to the mounting base and located below the forming member to catch and separate the bar-shaped products from recyclable raw material fragments at reduced labor and time costs. Forming sleeves each having a bore of different cross sectional shape and size can be selectively fitted in the forming holes to change the cross-sectional shapes and sizes of the bar-shaped products.

Owner:LAI KUEI TSAI

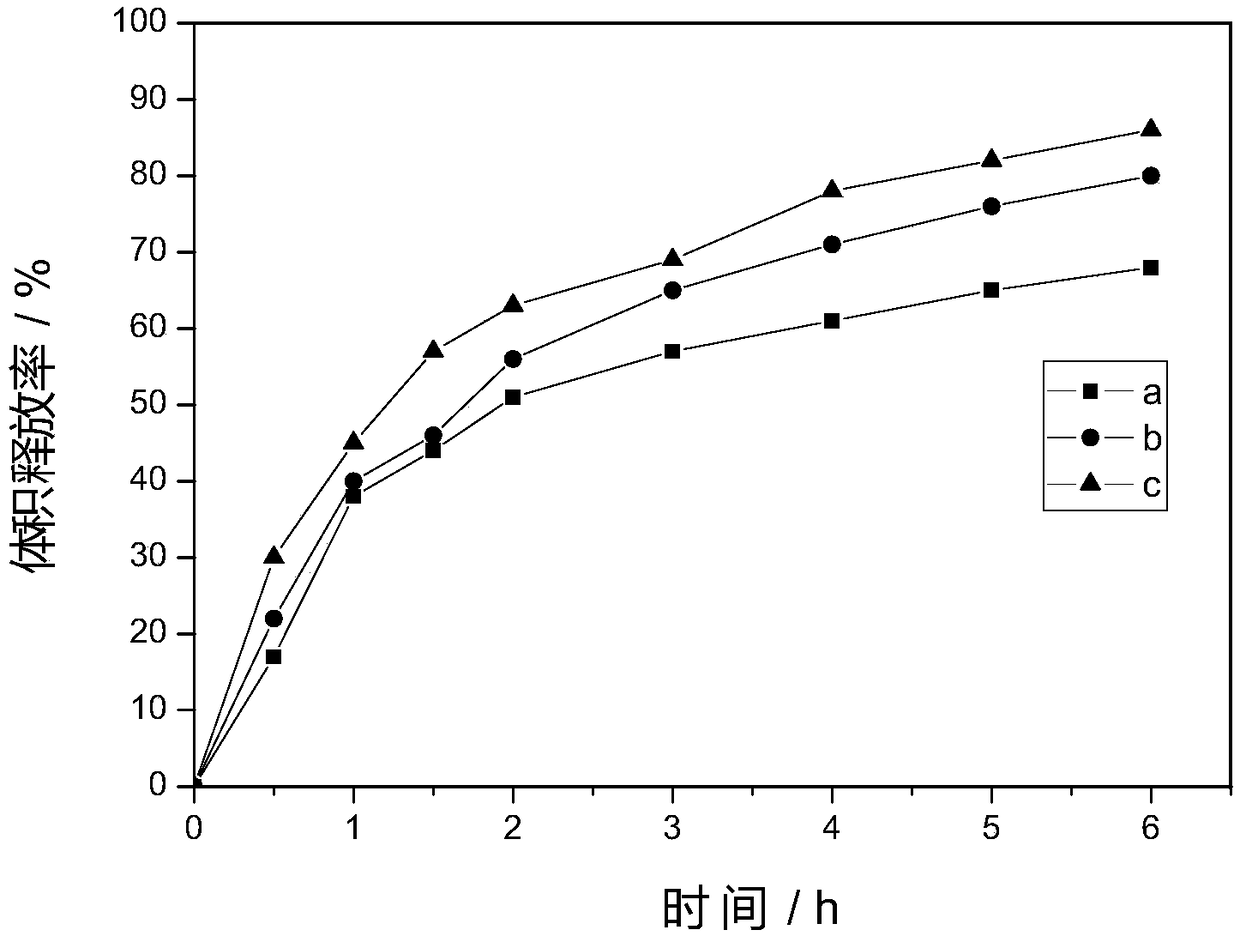

Composite nanometer particle obtained by coating curcumin eutectic crystal/piperine with polymers, and preparation of composite nanometer particle and application thereof to slow release pharmaceutical preparation

ActiveCN109432055AImprove physical and chemical propertiesImprove bioavailabilityAntibacterial agentsAntipyreticSupercritical anti solventAnti solvent

The invention belongs to the field of medicines, and particularly relates to a composite nanometer particle obtained by coating curcumin eutectic crystal / piperine with polymers. The composite nanometer particle comprises a core and a shell coating the core, wherein the core is a mixture of the curcumin eutectic crystal and the piperine; the shell is a hydrophilic polymer. The invention further discloses a preparation method and application of the composite nanometer particle. According to the preparation method provided by the invention, the composite nanometer particle with an in-situ coatingstructure is successfully prepared by creatively utilizing a curcumin eutectic crystal compound through a supercritical fluid anti-solvent technology (SAS). The invention provides the composite nanometer particle with the advantages of better dissolution performance, stability and bioavailability.

Owner:MEDONCARE PHARMA CO LTD

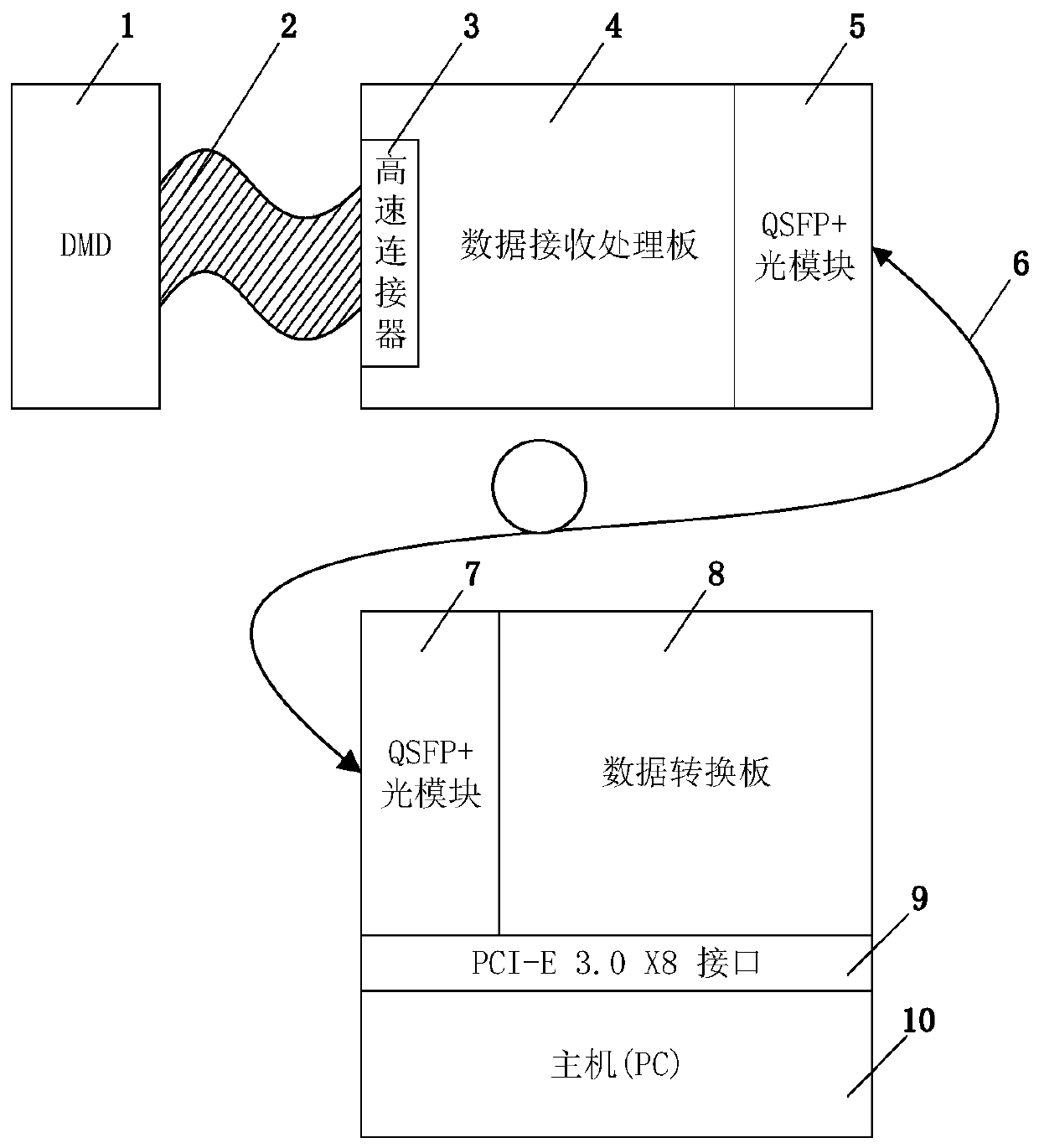

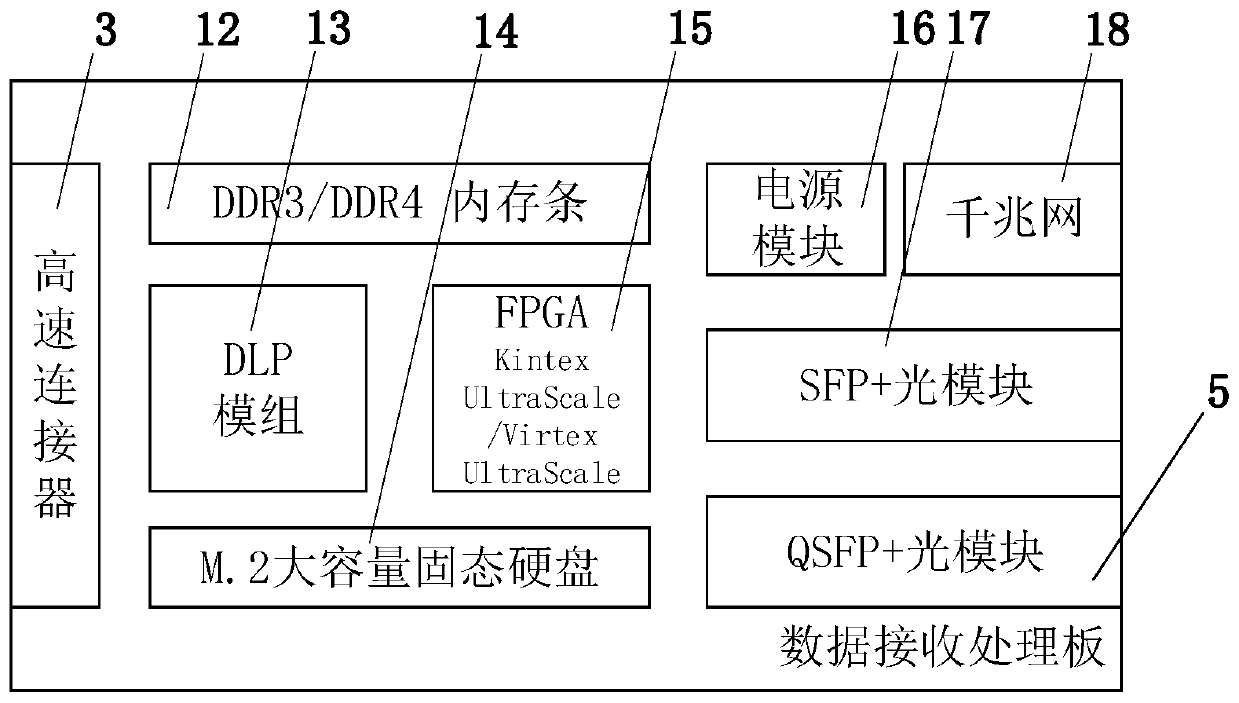

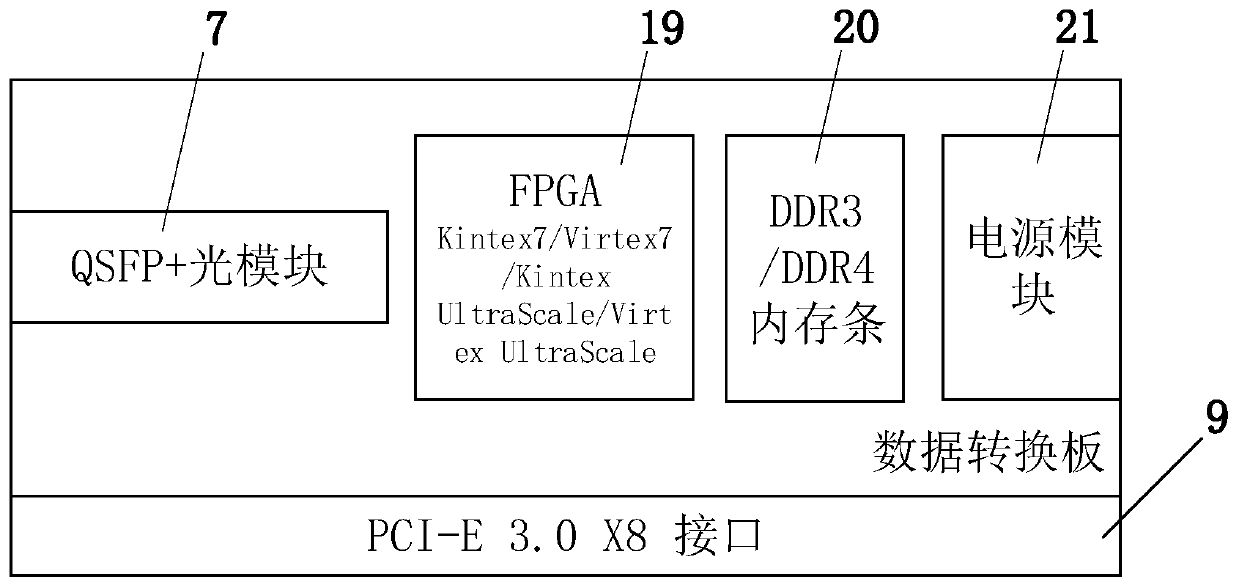

Graphic data high-speed transmission device of direct-writing photoetching equipment and transmission method thereof

PendingCN110824862AImprove productivity per unit timeAccurate exposureFibre transmissionPhotomechanical exposure apparatusComputer hardwareGraphics

The invention relates to a graphic data high-speed transmission device of direct-writing photoetching equipment. The device comprises a graphic display device, a data receiving and processing board connected with the graphic display device through a rigid-flex board, a data conversion board connected with the data receiving and processing board through a multimode optical fiber, and a host connected with the data conversion board. The data receiving and processing board comprises a first FPGA chip, a high-speed connector, a DLP module, an SFP+ optical module and a first QSFP+ optical module, wherein the high-speed connector, the DLP module, the SFP+ optical module and the first QSFP+ optical module are connected with the first FPGA chip. The high-speed connector is connected with one end of the rigid-flex board. The data conversion board comprises a second FPGA chip, a second QSFP+ optical module and a PCI-E 3.0 X8 interface. The second FPGA chip is connected with the second QSFP+ optical module and the PCI-E 3.0 X8 interface. The first QSFP+ optical module is connected with the second QSFP+ optical module through a multimode optical fiber. According to the invention, the transmission rate of the graphic data of the direct-writing photoetching equipment can be effectively improved; rapid and accurate exposure of a graph is realized; and the unit time productivity of the direct-writing photoetching equipment is greatly improved.

Owner:HEFEI CHIP FOUND MICROELECTRONICS EQUIP CO LTD

Novel welding equipment and welding method for photovoltaic cell

InactiveCN114883445AMelting fastIncrease energy densityFinal product manufactureHeating appliancesLight beamEngineering

The invention relates to novel photovoltaic cell welding equipment and a welding method, and belongs to the field of cell welding, the novel photovoltaic cell welding equipment comprises a welding frame, a light homogenizing mirror module is arranged on the welding frame, the light homogenizing mirror module is used for converting a laser beam into a uniform light beam and projecting the uniform light beam, a light beam gathering assembly is arranged at the bottom of the light homogenizing mirror module, and the light beam gathering assembly is used for gathering the light beam. The light beam gathering assembly is arranged on the welding frame, the photovoltaic battery piece is arranged at the bottom of the light beam gathering assembly, a welding strip is laid at the position of a main grid line on the front face of the photovoltaic battery piece, and the light beam gathering assembly is used for projecting uniform light beams to the photovoltaic battery piece to complete welding of the welding strip and the photovoltaic battery piece. The laser welding device has the advantages that the laser beams are converted into the uniform light beams with the same energy, the uniform light beams are focused on the bonding pad, the energy density is high after laser focusing, tin at a welding spot can be rapidly melted, and the effect of precise welding is achieved.

Owner:SUZHOU HUIBANG AUTOMATION SYST

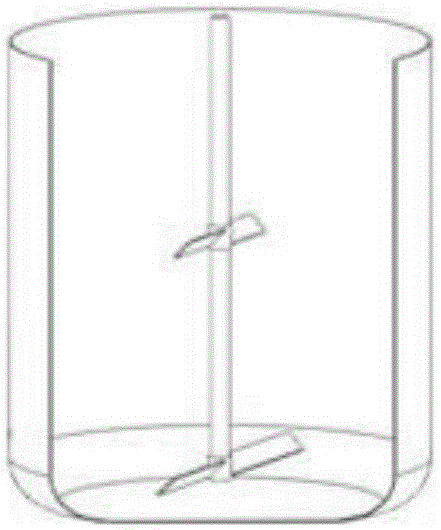

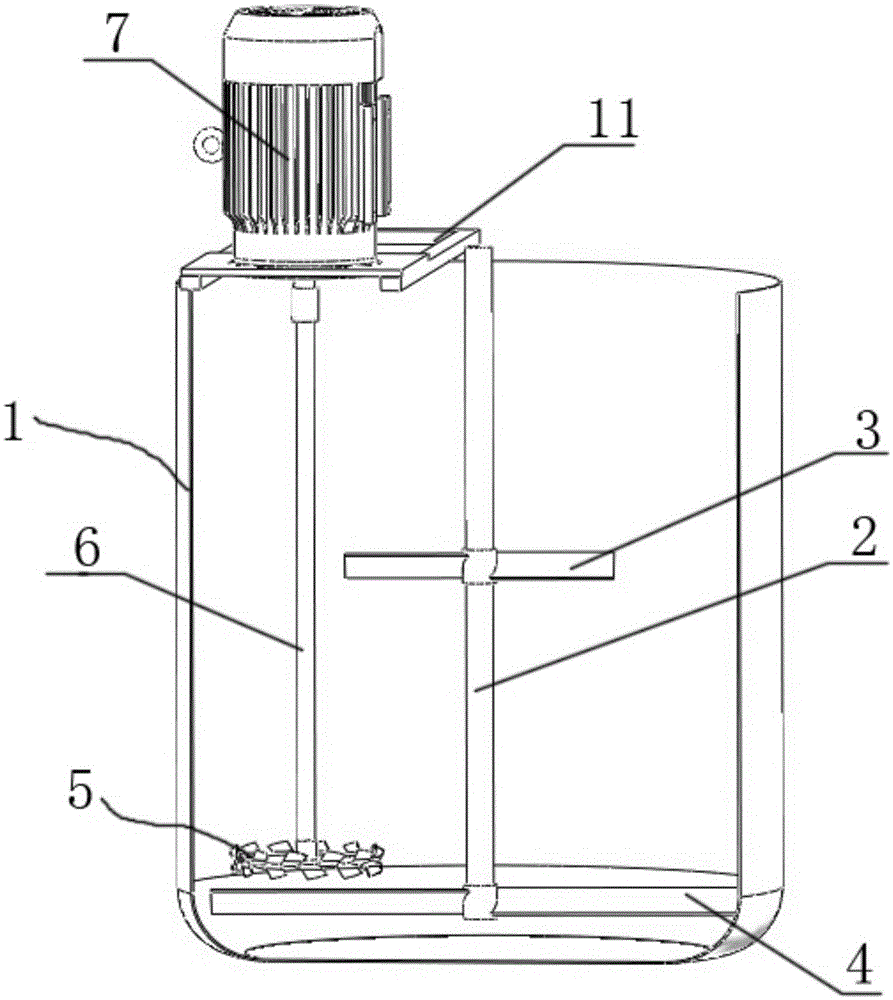

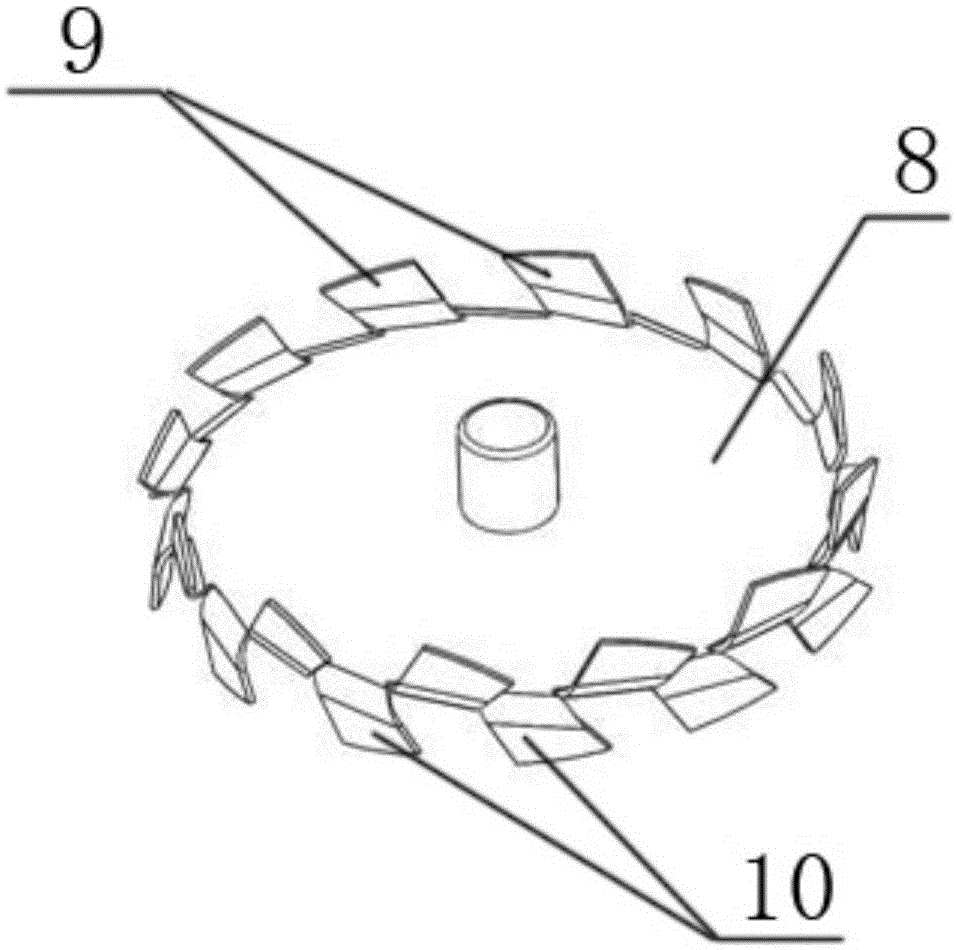

Mortar metalevel particle disperser

InactiveCN105056788AEffectively break upImprove the mixing effectRotary stirring mixersImpellerMaterials science

The invention provides a mortar metalevel particle disperser. The mortar metalevel particle disperser has good stirring effect, good mixing and dispersion effect and higher impact force and shear force, huddle silicon carbide particles can be effectively dispersed, the stirring time is short, and the unit time capacity can be improved. The mortar metalevel particle disperser comprises a stirring container, wherein a central rotating shaft is arranged inside the stirring container, and an upper paddle and a lower paddle are arranged on the central rotating shaft. The mortar metalevel particle disperser is characterized in that a high-speed stirrer is arranged in the stirring container; the high-speed stirrer comprises a disc-type zigzag impeller, a rotary table rotating shaft and a power device; the disc-type zigzag impeller is arranged on the internal side of the stirring container; the disc-type zigzag impeller comprises a rotary table, an upper zigzag plate and a lower zigzag plate; the center of the rotary table is connected with the rotary table rotating shaft; the upper end of the rotary table rotating shaft is externally connected with the power device; and the rotary table rotating shaft is positioned on one side of the central position of the stirring container and is eccentrically arranged.

Owner:HAREON SOLAR TECHNOLOGY CO LTD

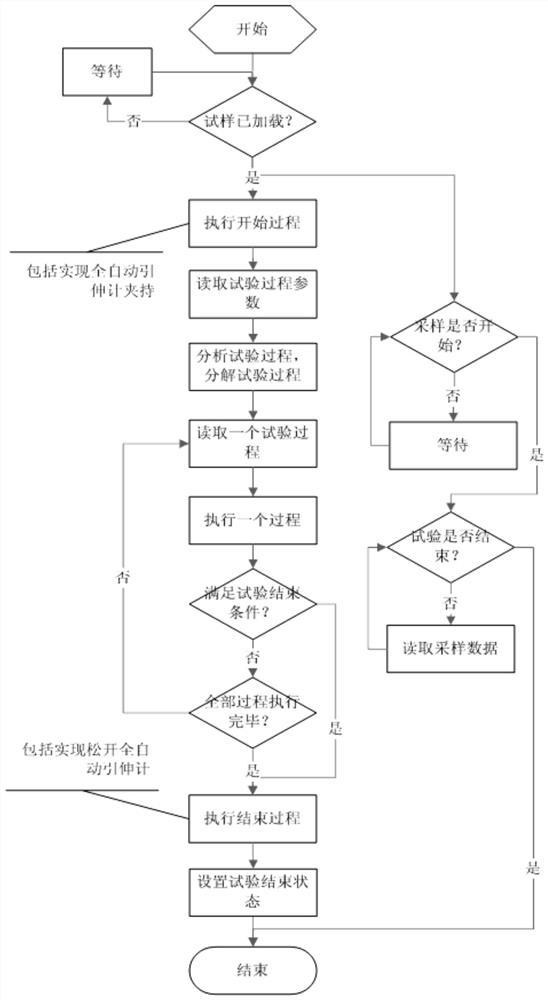

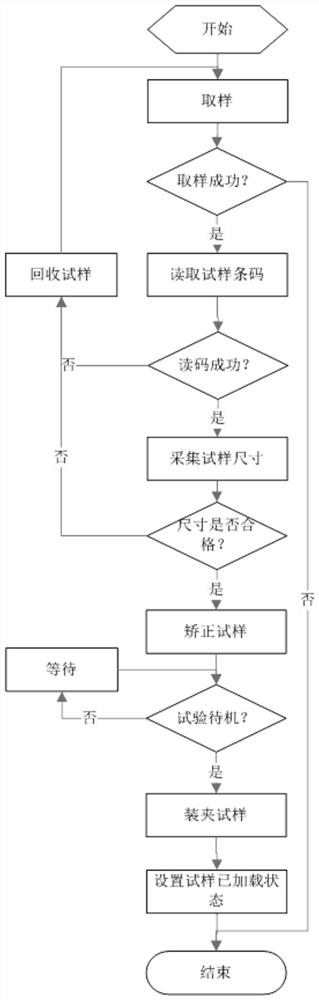

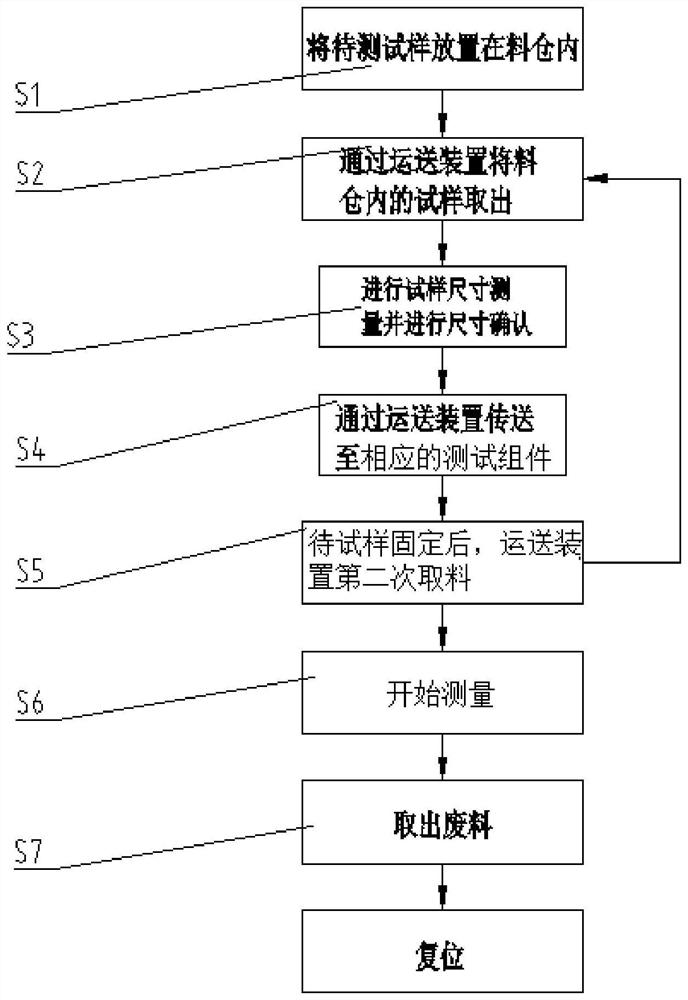

Test method and test system for mechanical properties of material

PendingCN111948414AImprove accuracyImprove productivity per unit timeMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesTest efficiencyTest sample

In order to solve the problem of low working efficiency caused by excessively depending on manual feeding in the prior art, the invention provides the testing method and the testing system for the mechanical properties of the material, a conveying device is controlled by a control center to convey a to-be-tested sample to a testing station, and a tensile test or a bending test is carried out; after the work is completed, the waste is taken out through the waste taking-out device; in addition, when a tensile test or a bending test is carried out, scheduling optimization is carried out on the conveying device by adopting a chicken swarm algorithm and a genetic second-generation hybrid algorithm, so that the productivity in unit time is improved. According to the method, a conveying device iscontrolled by a control center to convey a to-be-tested sample to a test station, a tensile test or a bending test is carried out, and after the above work is completed, waste is taken out through awaste taking-out device; and when a tensile test or a bending test is carried out, scheduling optimization is carried out on the conveying device, so that the productivity in unit time is improved, and the test efficiency is improved.

Owner:NAT POLYMER MATERIALS IND INNOVATION CENT CO LTD

Low-post-acid yoghourt beverage containing active lactic acid bacteria and preparation method of low-post-acid yoghourt beverage

PendingCN112841303AIncrease productivityImprove productivity per unit timeMilk preparationLactobacillusLeavening agentRaw milk

The invention discloses a low-post-acid yoghourt beverage containing active lactic acid bacteria and a preparation method of the low-post-acid yoghourt beverage. Based on the total weight of the yoghurt beverage, the yoghurt beverage comprises the following raw materials: 30-60 w / w% of a fermentation base material, 2-8 w / w% of a sweetening agent and 0.1-0.5 w / w% of a stabilizer, with the balance being water, wherein on the basis of the total weight of the fermentation base material, the fermentation base material comprises 90 w / w%-98 w / w% of raw milk, 1 w / w%-3 w / w% of white granulated sugar A, 1 w / w%-3 w / w% of dietary fibers, 0.1 w / w permillage-0.6 w / w permillage of a protein raw material and 0.2 w / w permillage-1 w / w permillage of a leavening agent, and the leavening agent comprises active lactic acid bacteria. The invention also provides a preparation method of the yoghourt beverage. The pH value and acidity of the yoghourt beverage provided by the invention are kept stable in the shelf life, and a sour-sweet ratio does not need to be adjusted by adding a large number of sweeteners.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

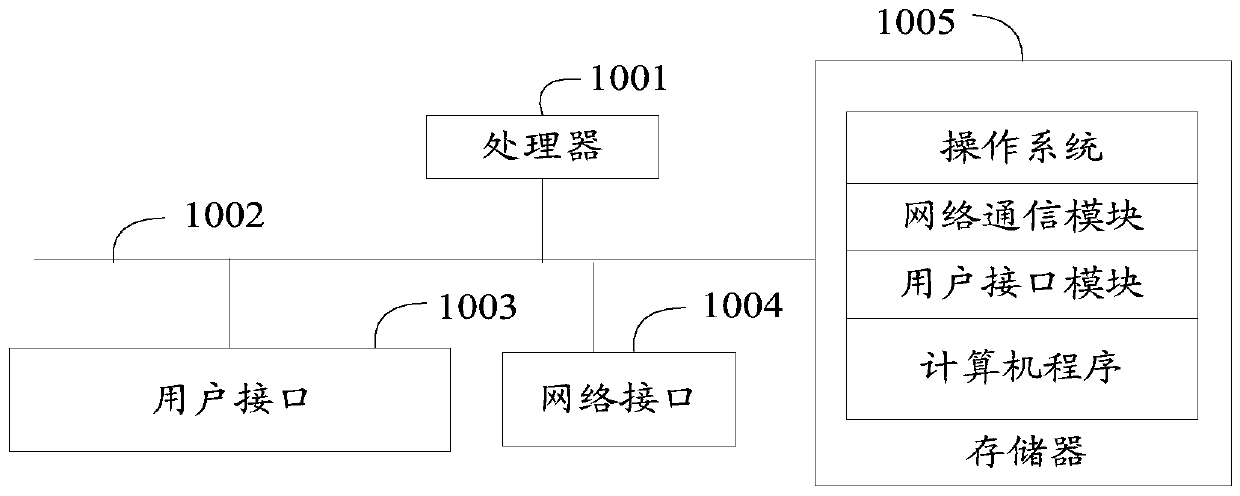

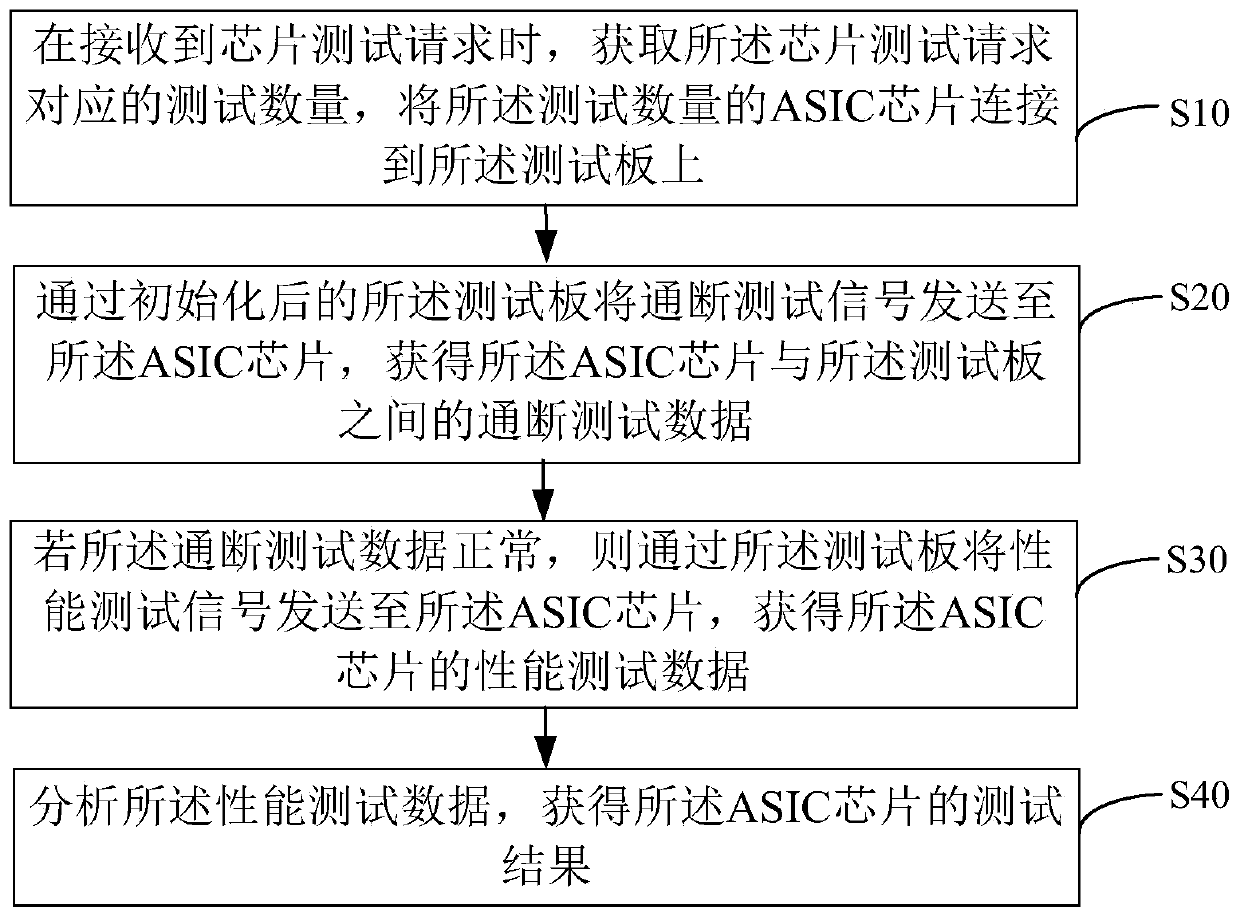

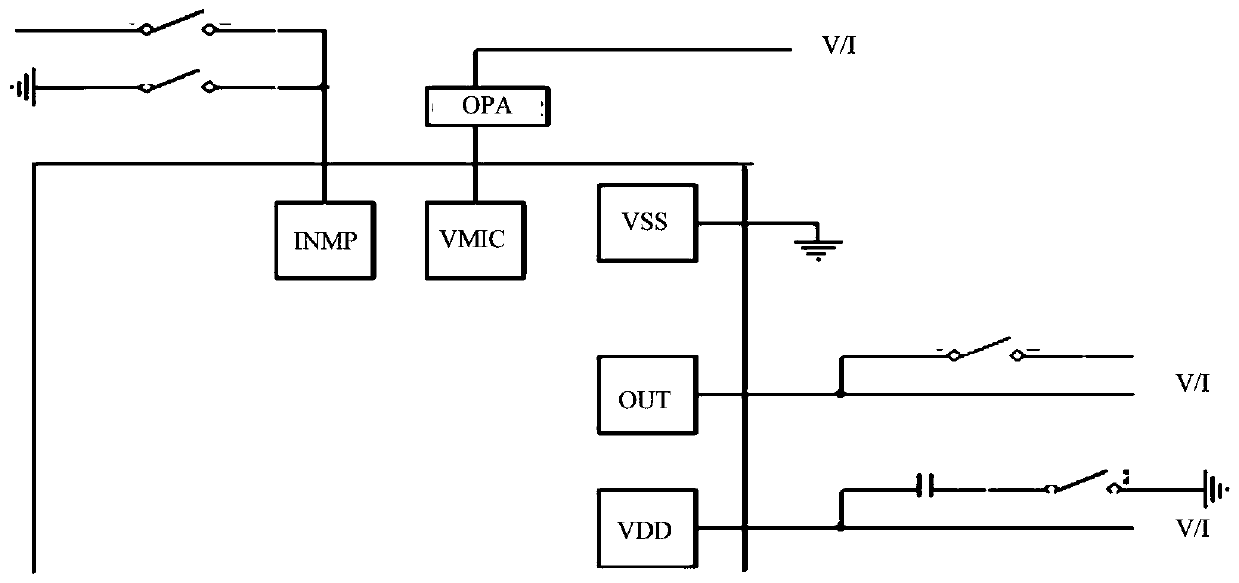

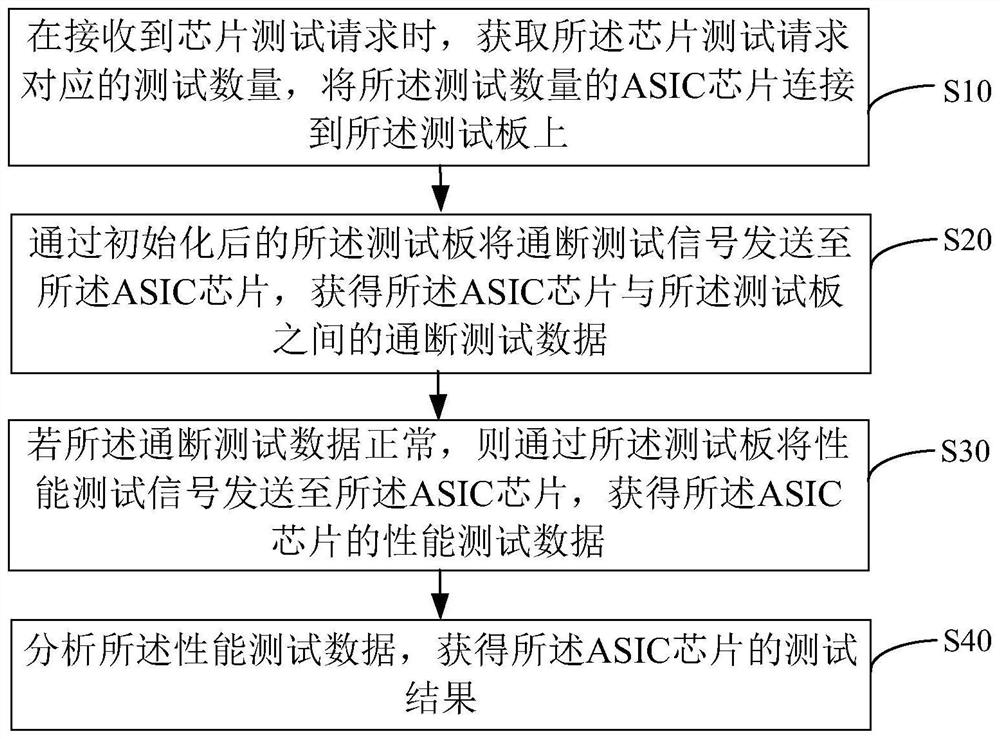

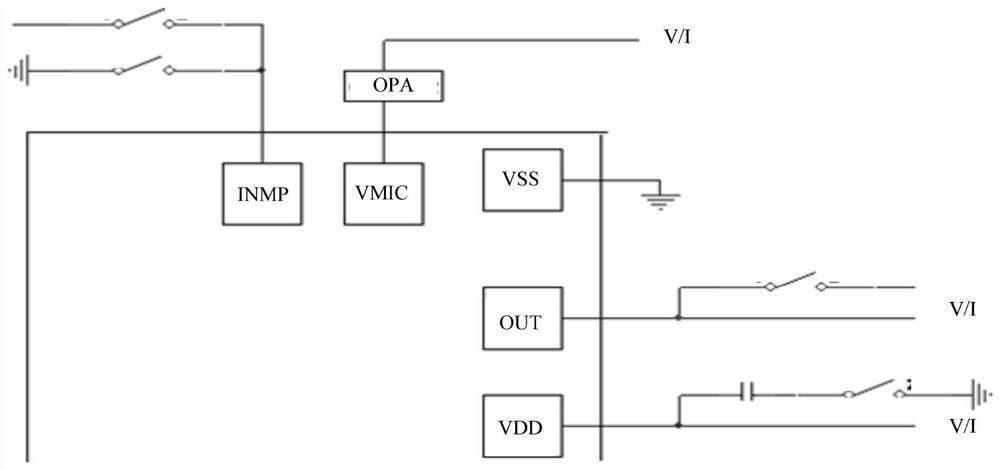

Test method and equipment of ASIC chip wafer and computer storage medium

The invention discloses a test method of an ASIC chip wafer. The test method of the ASIC chip wafer is applied to test equipment, and the test equipment is in communication connection with a test board. The test method comprises the following steps: when a chip test request is received, obtaining the test quantity corresponding to the chip test request, and connecting the ASIC chips of the test quantity to the test board; sending the on-off test signal to the ASIC chip through the initialized test board to obtain the on-off test data between the ASIC chip and the test board; if the on-off testdata is normal, sending the performance test signal to the ASIC chip through the test board to obtain performance test data of the ASIC chip; and analyzing the performance test data to obtain a testresult of the ASIC chip. The invention also discloses the test equipment of the ASIC chip wafer and a computer storage medium. The test efficiency of batch ASIC chips is improved.

Owner:QINGDAO GOERTEK MICROELECTRONICS RES INST CO LTD

A kind of curcumin composite nanoparticle and preparation method thereof

ActiveCN109350610BWell mixedEffective dispersionNervous disorderAntipyreticOrganosolvComposite nanoparticles

The invention belongs to the field of curcumin preparation, and in particular relates to a curcumin composite nano particle and a preparation method thereof. Wherein, the following substances are included in parts by weight: 40-100 parts of curcumin, 1 part of piperine, and 400-5000 parts of plant polysaccharides. The preparation method comprises the following steps: S1, adding curcumin and piperine to liquefied CO2, and dispersing them uniformly to obtain a mixture; S2, pumping the mixture obtained in step S1 into a high-pressure crystallization kettle, and adjusting the temperature and pressure to preset values Finally, pump the plant polysaccharide aqueous solution into the high-pressure crystallization kettle; S3, pass CO2 into the high-pressure crystallization kettle, and maintain the temperature and pressure in the high-pressure reaction kettle until the water is dried, and stop pumping CO 2 , and the dry sample was obtained after the pressure was reduced to normal pressure. In the whole preparation process, the process time is short, no organic solvent is used, and the prepared product has better bioavailability and curative effect.

Owner:MEDONCARE PHARMA CO LTD

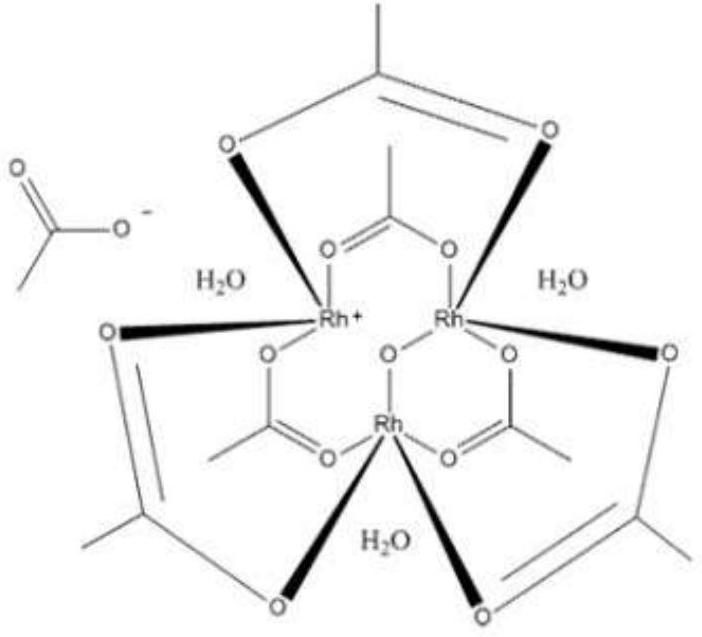

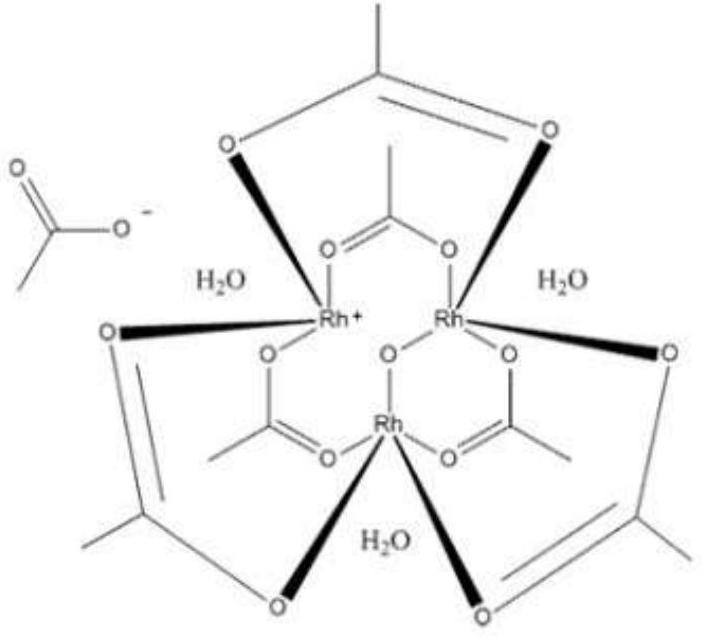

A kind of preparation method of trivalent rhodium acetate trimer

The invention relates to the technical field of inorganic synthesis and discloses a preparation method of rhodium trivalent acetate trimer, which includes the following steps: (1) After mixing rhodium powder and potassium chloride, chlorine gas is introduced for reaction; (2) The product obtained in step (1) is dissolved in water, filtered, potassium hydroxide is added to the filtrate for reaction, and rhodium hydroxide is obtained after filtering and washing; (3) water, nitric acid and glacial acetic acid are added to the rhodium hydroxide. The reaction is carried out. After the reaction is completed, the solution is evaporated to dryness. After the nitrate is driven out with glacial acetic acid, the acid is driven out with water to obtain rhodium trivalent acetate trimer. The present invention uses nitric acid and glacial acetic acid to dissolve rhodium hydroxide, and then uses glacial acetic acid to drive out the nitrate, which can significantly speed up the reaction and thereby increase the yield of rhodium trivalent acetate trimer.

Owner:浙江微通催化新材料有限公司

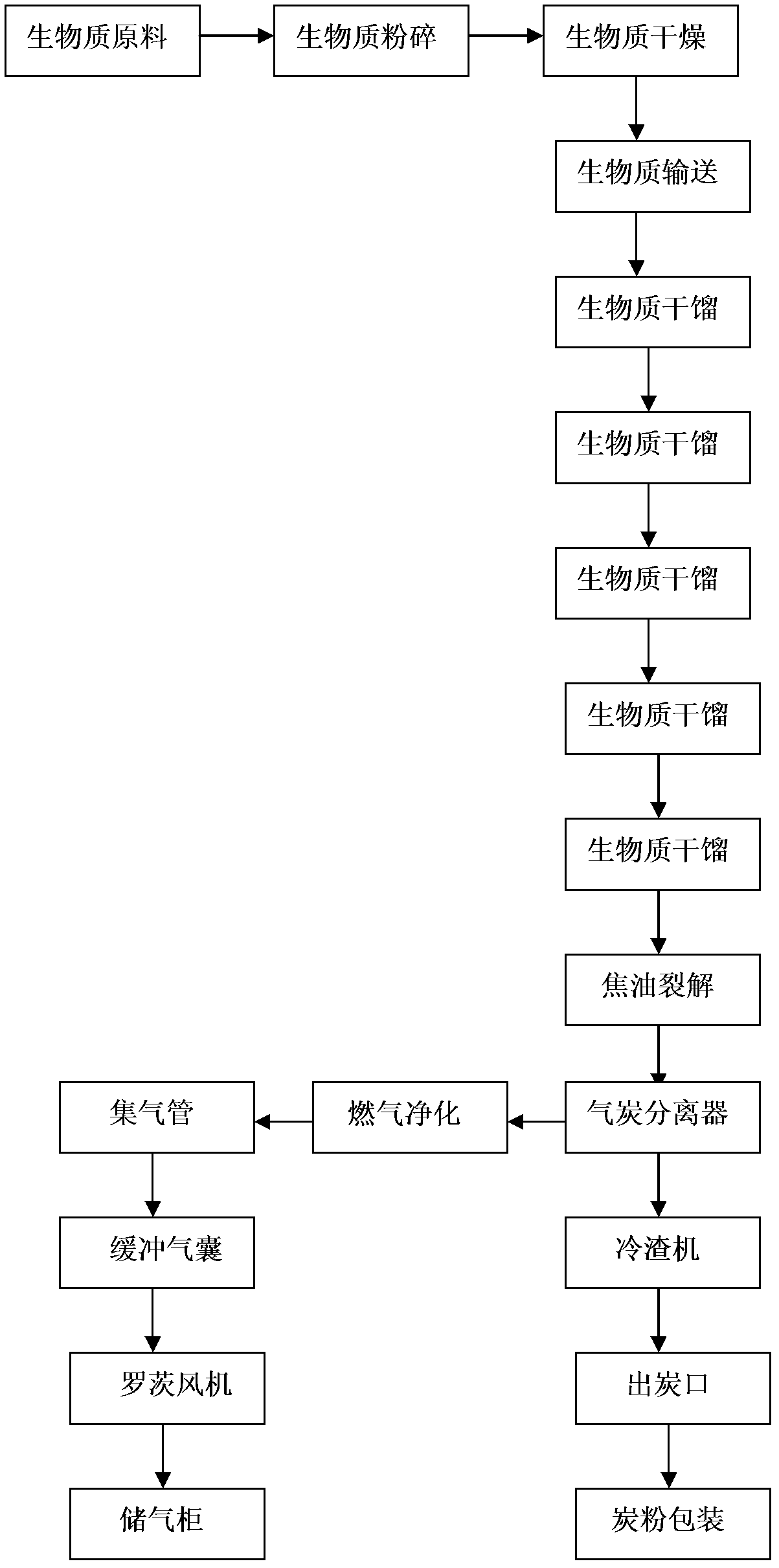

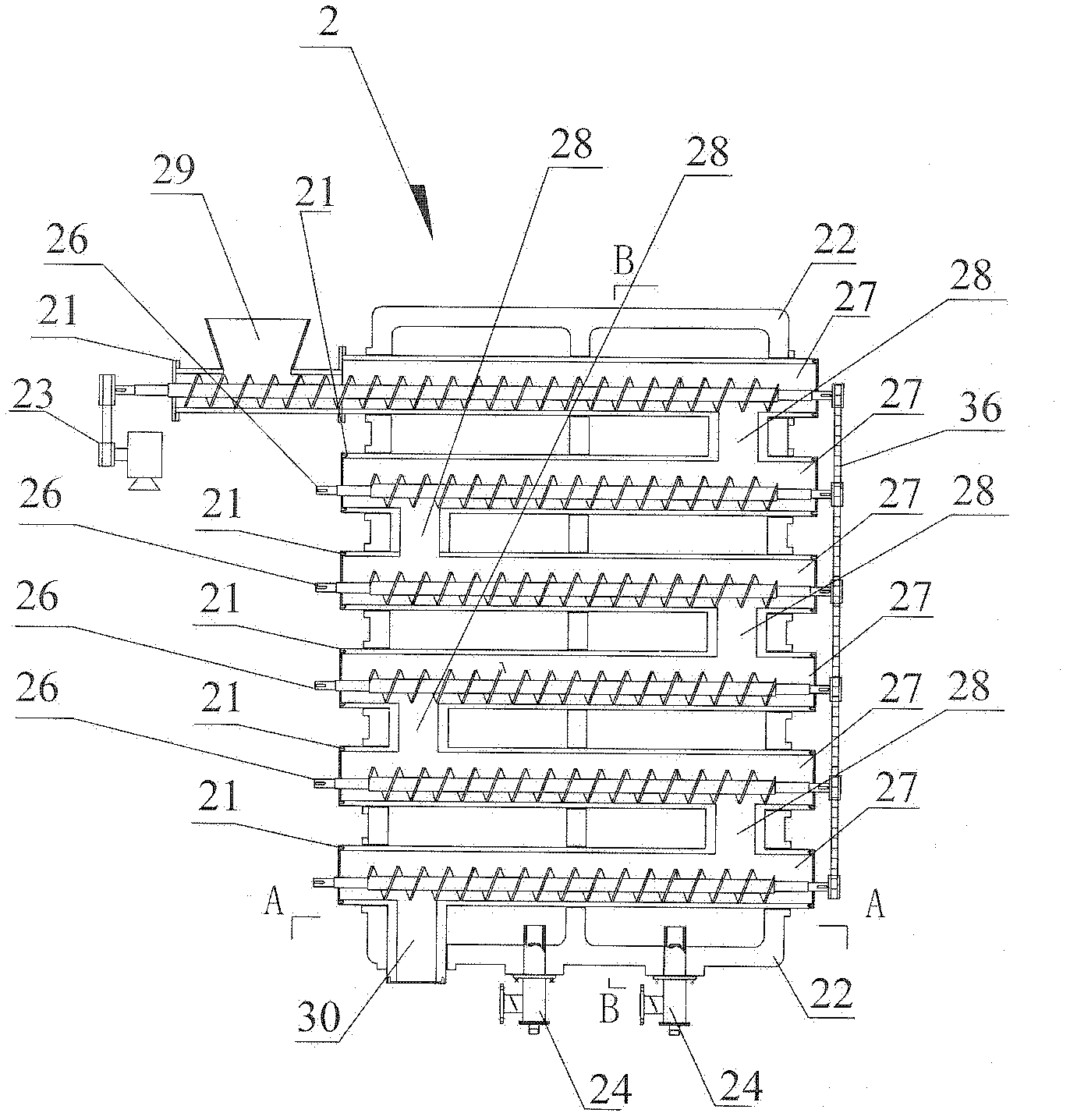

Air-passage multi-tube spiral device for preparing gas through dry distillation and pyrolysis on biomass and process therefor

InactiveCN102533294BEfficient dischargeNo air lock expansionBiofuelsEnergy inputPre treatmentFuel gas

The invention discloses an air-passage multi-tube spiral device and process for preparing gas through dry distillation and pyrolysis on biomass. The device consists of a biomass raw material pre-treatment system, a biomass dry distillation and pyrolysis system, a gas and carbon powder separating and purifying system, a gas conveying and storing system, a carbon powder cooling and collecting system and an afterheat recycling system, wherein the biomass dry distillation and pyrolysis system is provided with a plurality of rows of dry distillation and pyrolysis sleeves; spiral material conveyingdevices and exhaust passages are arranged in each row of dry distillation and pyrolysis sleeves; and a communication pipe is arranged between adjacent dry distillation and pyrolysis sleeves, so the rows of dry distillation and pyrolysis sleeves are connected into an S-shaped pipe in series. The process comprises the following steps of: 1, crushing, drying and conveying a biomass raw material; 2, performing dry distillation and pyrolysis on the biomass; 3, separating and purifying gas and carbon powder; and 4, storing and conveying the gas. The device and the process have the beneficial effects that: the condition the gas flies around to affect the normal production is not caused, mass industrial production can be realized, the production cost is reduced, and low energy consumption is realized.

Owner:王士元

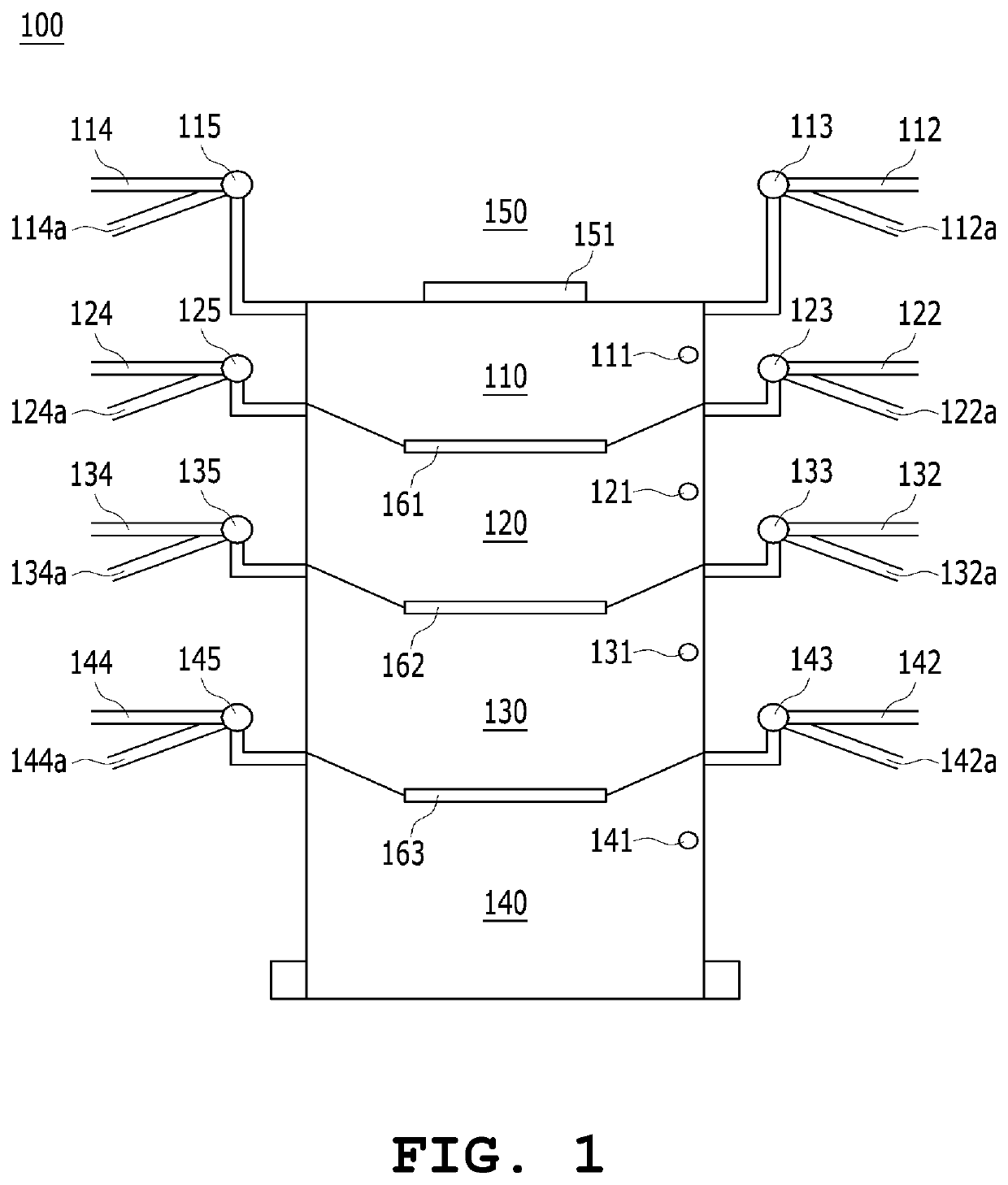

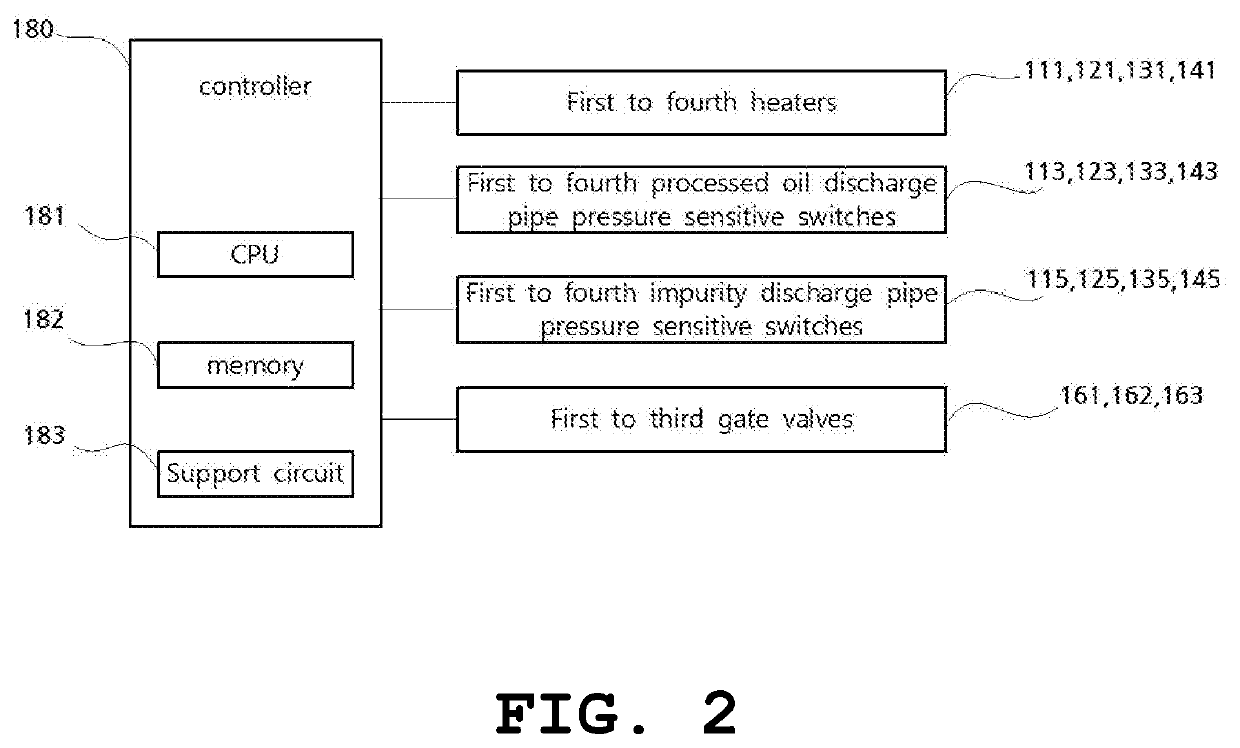

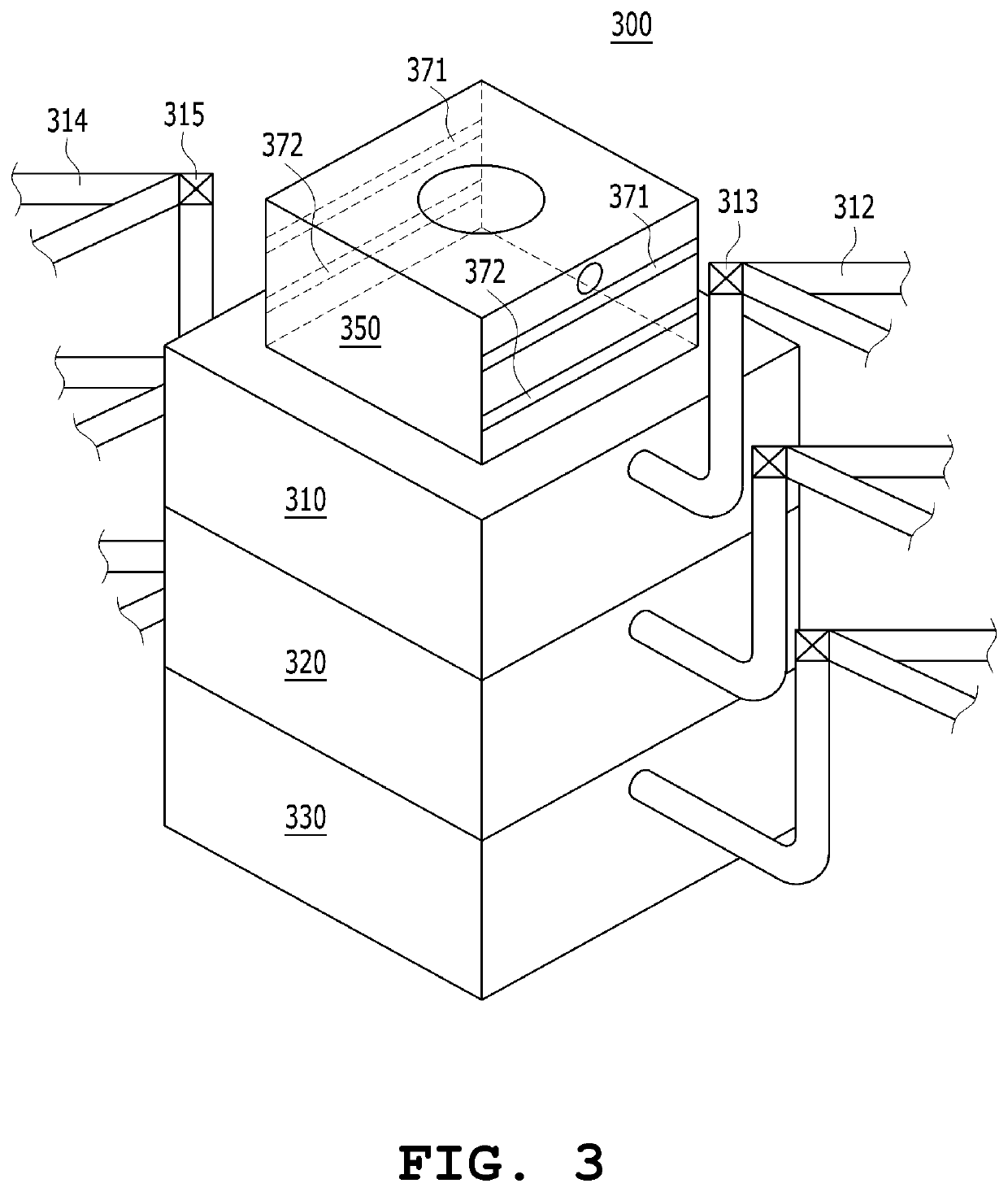

Multistory crude oil refining apparatus

ActiveUS10982154B2Reduced footprintImprove productivity per unit timeHydrocarbon distillationRefining by heating/coolingThermodynamicsPetroleum engineering

The multistory crude oil refining apparatus includes: a crude oil receiving part; a first refining tank, wherein a first heater is mounted in the first refining tank; at least one first processed oil discharge pipe connected to one side of the first refining tank; a first processed oil discharge pipe pressure sensitive switch; at least one first impurity discharge pipe connected to the other side of the first refining tank; a first impurity discharge pipe pressure sensitive switch; a second refining tank, wherein a second heater is mounted in the second refining tank; at least one second processed oil discharge pipe connected to one side of the second refining tank; a second processed oil discharge pipe pressure sensitive switch; at least one second impurity discharge pipe connected to the other side of the second refining tank; and a second impurity discharge pipe pressure sensitive switch.

Owner:PARK YONGIL

Preparation method of trivalent rhodium acetate tripolymer

The invention relates to the technical field of inorganic synthesis, and discloses a preparation method of a trivalent rhodium acetate tripolymer, which comprises the following steps: (1) mixing rhodium powder and potassium chloride, and introducing chlorine for reaction; (2) dissolving the product obtained in the step (1) in water, filtering, adding potassium hydroxide into the filtrate for reaction, filtering and washing to obtain rhodium hydroxide; and (3) adding water, nitric acid and glacial acetic acid into rhodium hydroxide for reaction, after the reaction is completed, evaporating the solution to dryness, performing nitrate removal with glacial acetic acid, and performing acid removal with water to obtain the trivalent rhodium acetate tripolymer. The nitric acid and the glacial acetic acid are adopted to dissolve rhodium hydroxide, and then the glacial acetic acid is used for removing nitrate, so that the reaction can be obviously accelerated, and the yield of the trivalent rhodium acetate tripolymer is improved.

Owner:浙江微通催化新材料有限公司

A kind of preparation method of methyl phenylcarbamate

ActiveCN106146353BImprove removal rateBreak the limitCarbamic acid derivatives preparationOrganic compound preparationCarbamateDistillation

The invention relates to a preparation method of methylphenylcarbamate. The preparation method comprises 1, adding urea and aniline into a pre-reactor and a diphenyl urea synthesis reactor and synthesizing diphenyl urea, 2, conveying the reaction liquid into a falling film evaporator and an evaporating crystallizer through a feeding pump, separating aniline, mixing the aniline and methanol, feeding the mixture into an alcoholysis reactor, carrying out a reaction process, feeding the reaction materials into a flash evaporation pot, separating a part of methanol and aniline and separating residual methanol and most of aniline through the falling film evaporator to obtain a methylphenylcarbamate crude product, and 3, feeding the methylphenylcarbamate crude product into a scraped film type molecule distillation device and further separating the residual microscale aniline and high-boiling residues so that high purity methylphenylcarbamate is obtained and has purity greater than or equal to 99.9%. The preparation method effectively improves methylphenylcarbamate synthesis efficiency and has a product yield greater than or equal to 98.0%. The preparation method is simple and easy and provides an effective synthesis and separation method of a phenyl carbamate intermediate used in preparation of diphenylmethane diisocyanate through the non-phosgene way.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

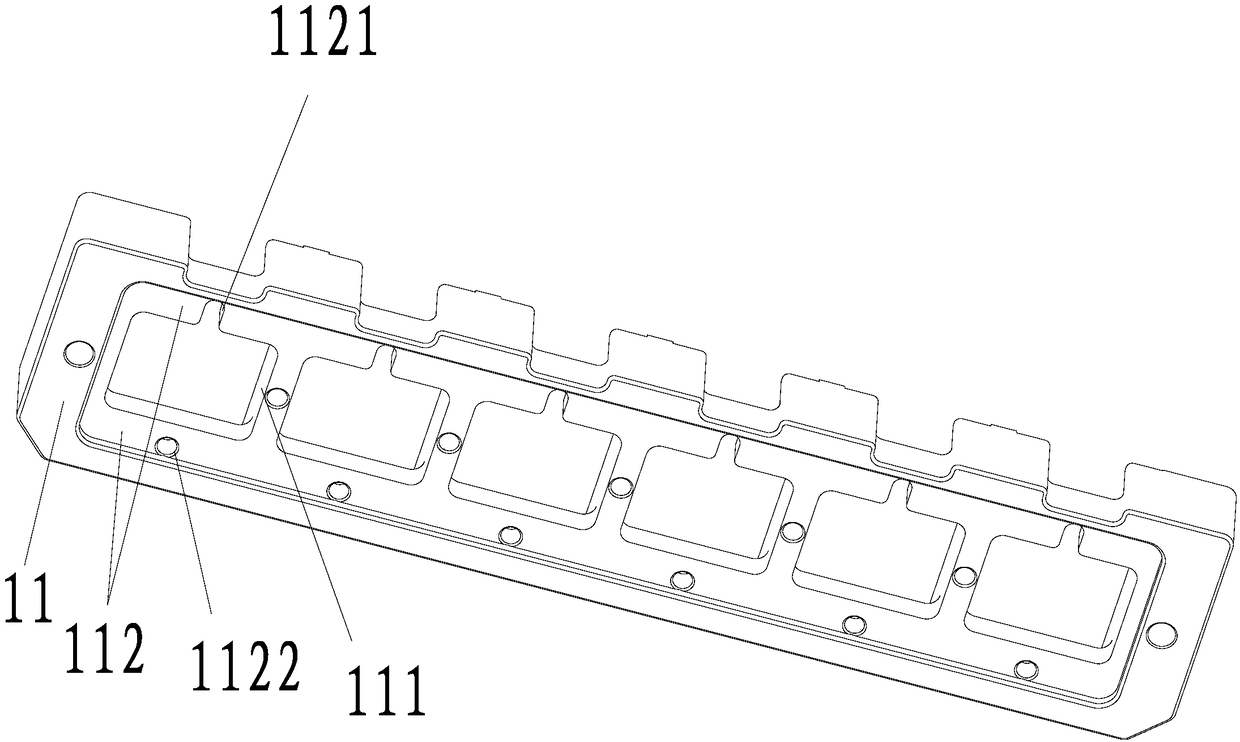

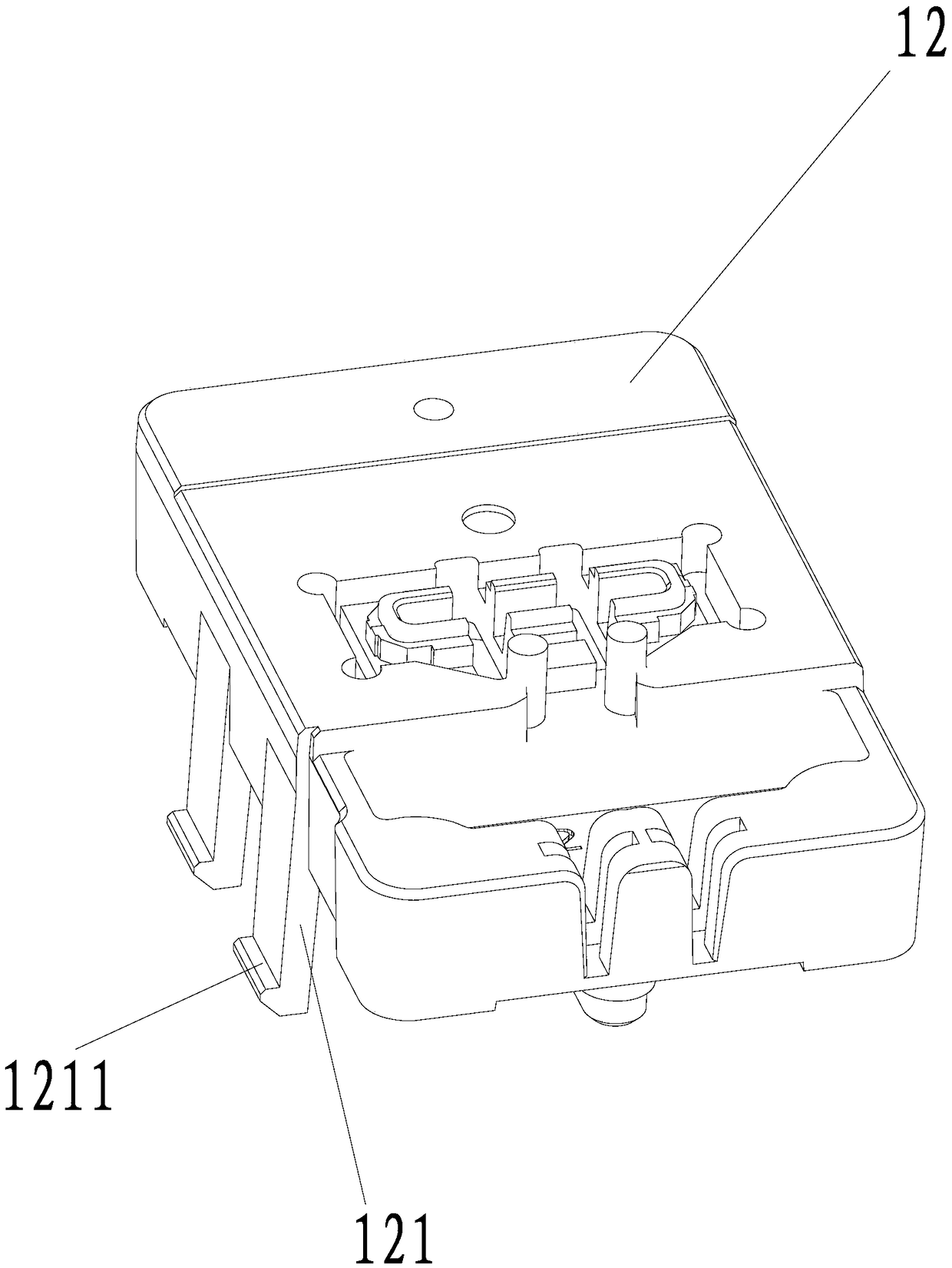

Multipurpose tooling assembly and assembling tooling for loudspeaker

PendingCN108566613AImprove practicalityImprove versatilityElectrical transducersEconomic benefitsEngineering

The invention provides a multipurpose tooling assembly and an assembling tooling for a loudspeaker. The multipurpose tooling assembly comprises an upper die and a lower die; the upper die is formed byassembling an upper base and an upper tooling, and the lower die is formed by a lower base and a lower tooling; the upper base and the lower base are respectively provided with accommodation cavitieswhich are respectively used for accommodating the upper tooling and the lower tooling; the upper tooling and the lower tooling are respectively provided with connection components; the upper base andthe lower base are provided with connection matching components along an assembling direction; the connection components are in assembling connection with the connection matching components; the upper tooling and the lower tooling and the upper base and the lower base are respectively mutually limited; and the upper tooling specifically is a base frame tooling for the loudspeaker, and the lower tooling specifically is a front cover tooling for the loudspeaker. By applying the technical scheme, recovery and reuse of a tooling base can be implemented, and economic benefits of the product are effectively improved.

Owner:XIAMEN SENNER TECH CO LTD

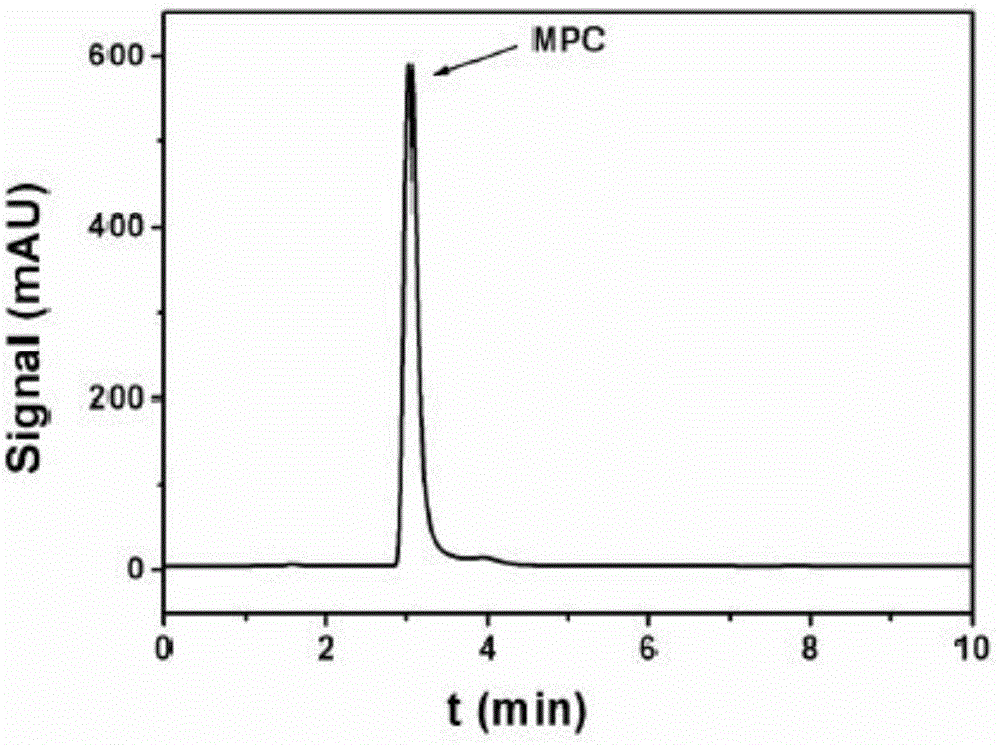

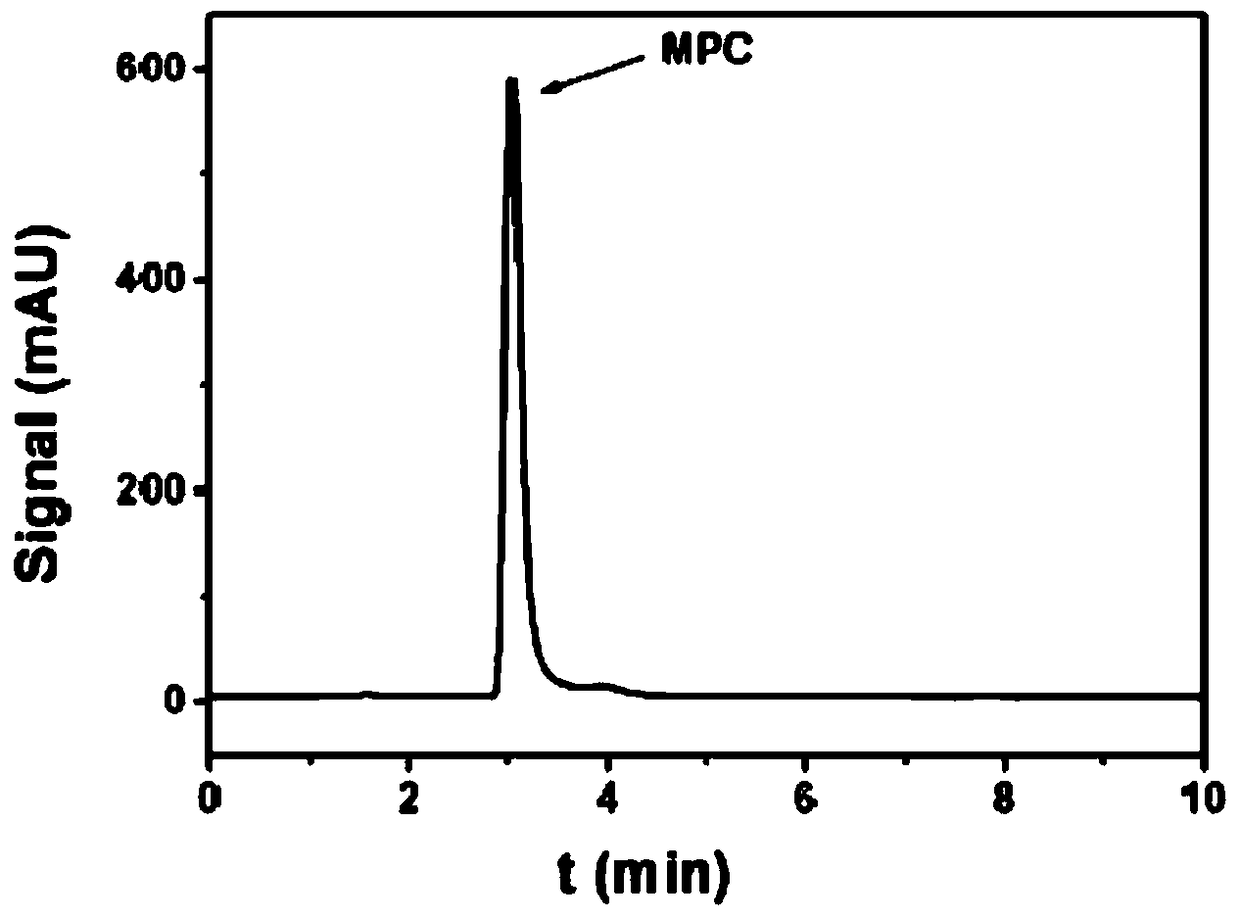

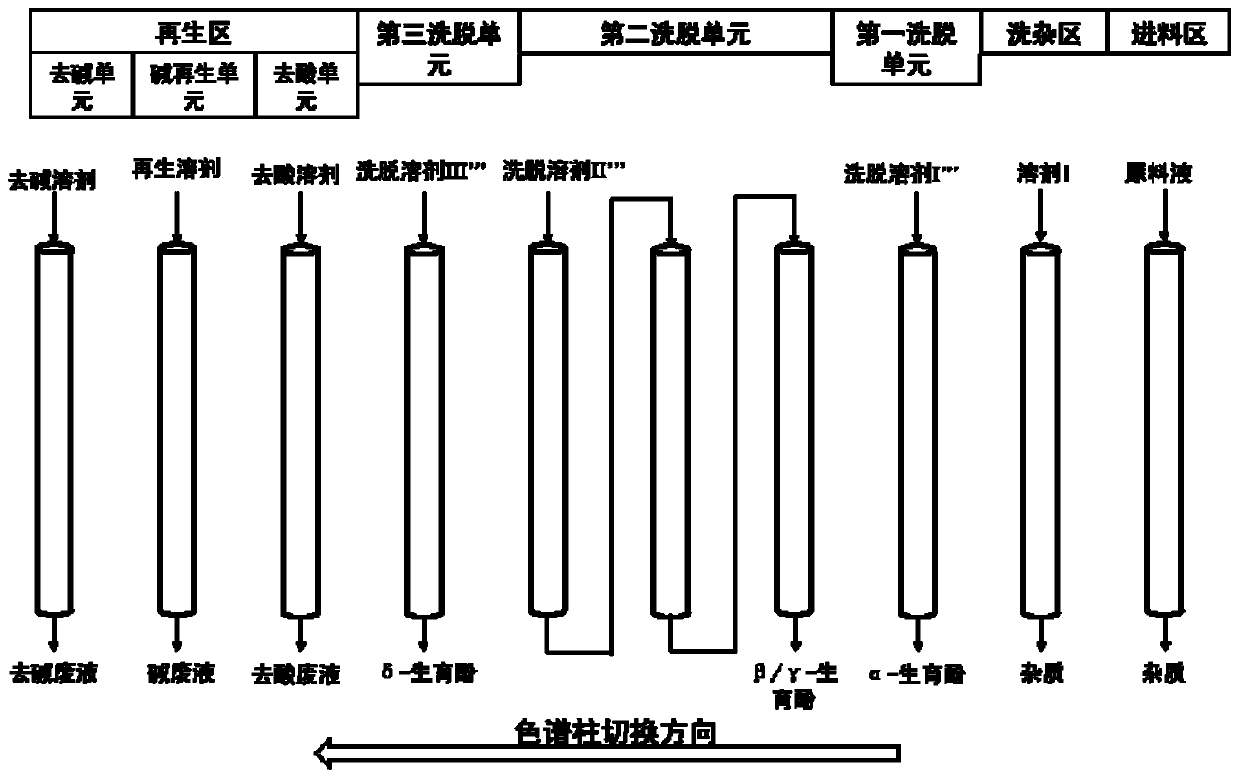

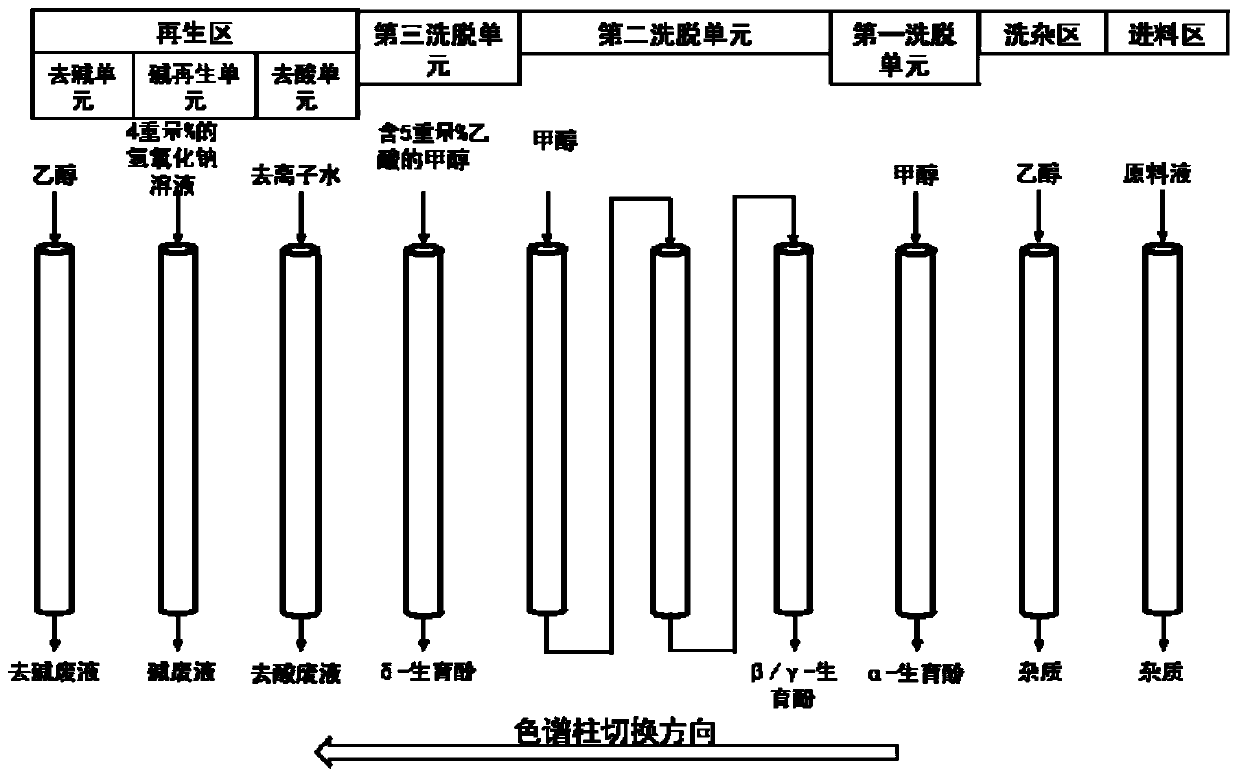

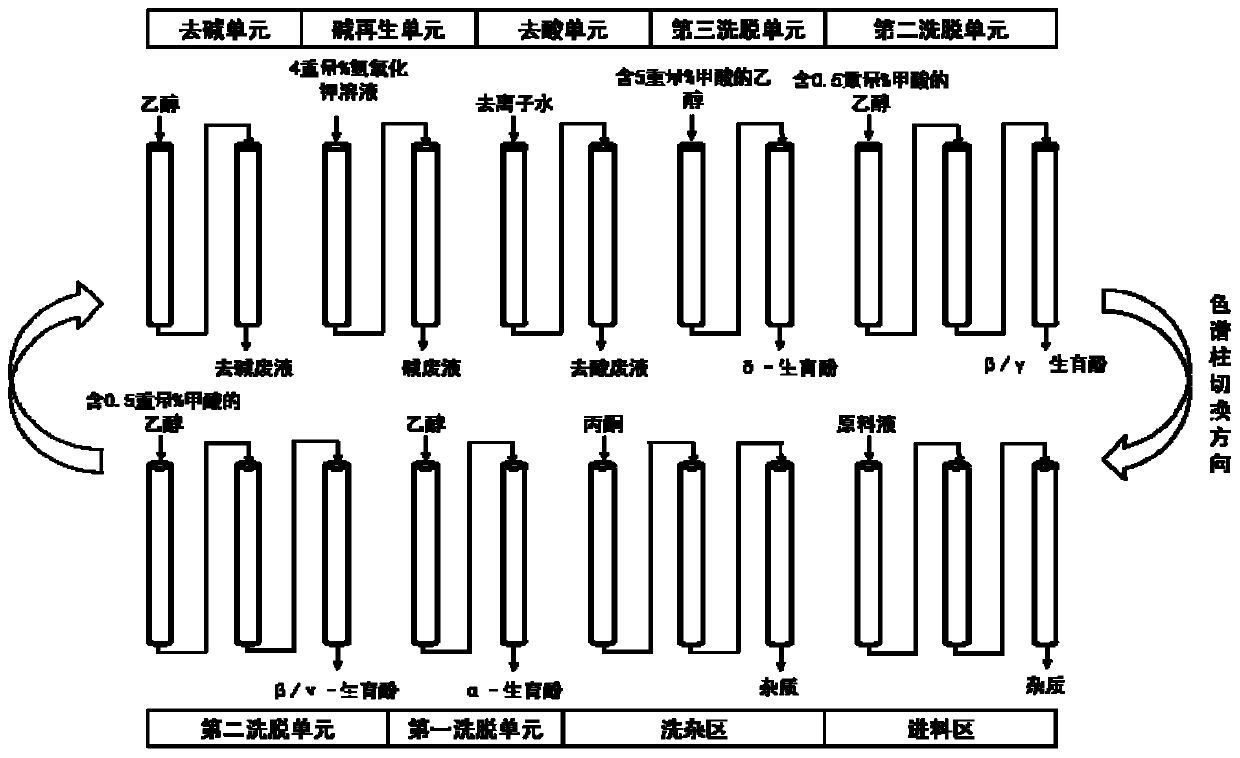

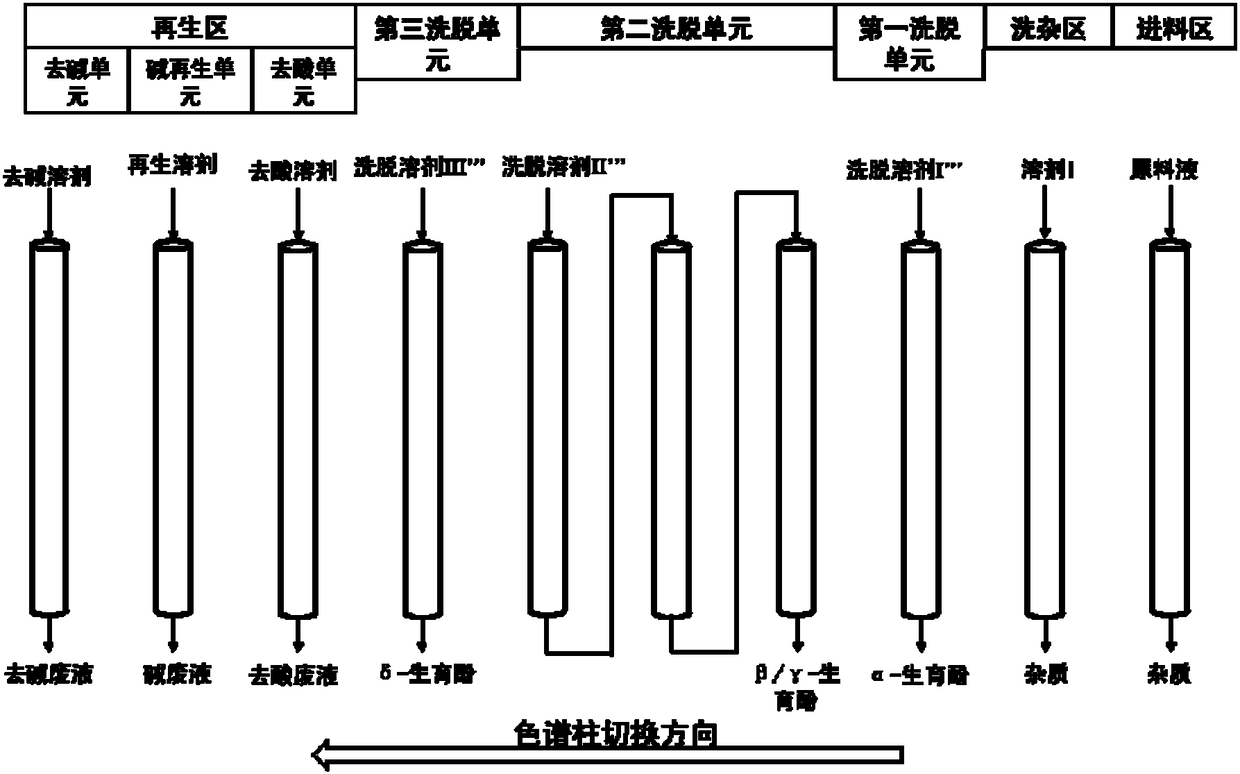

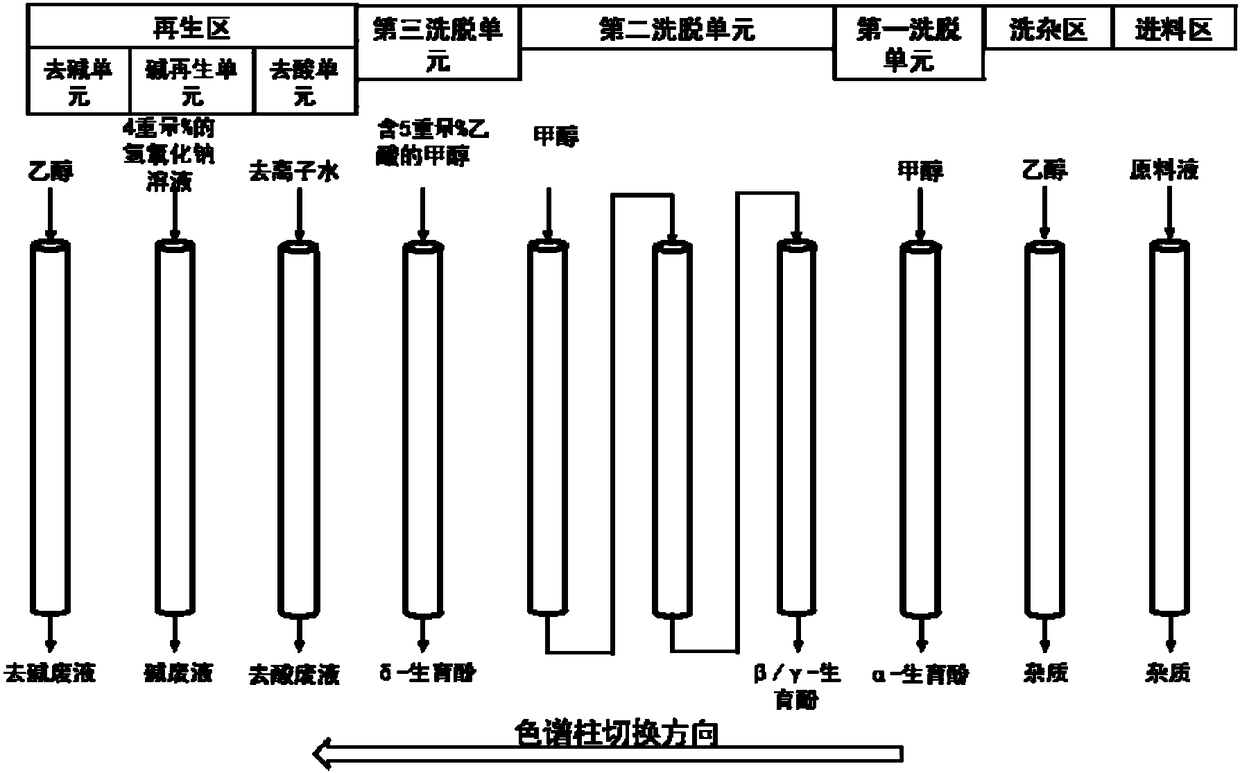

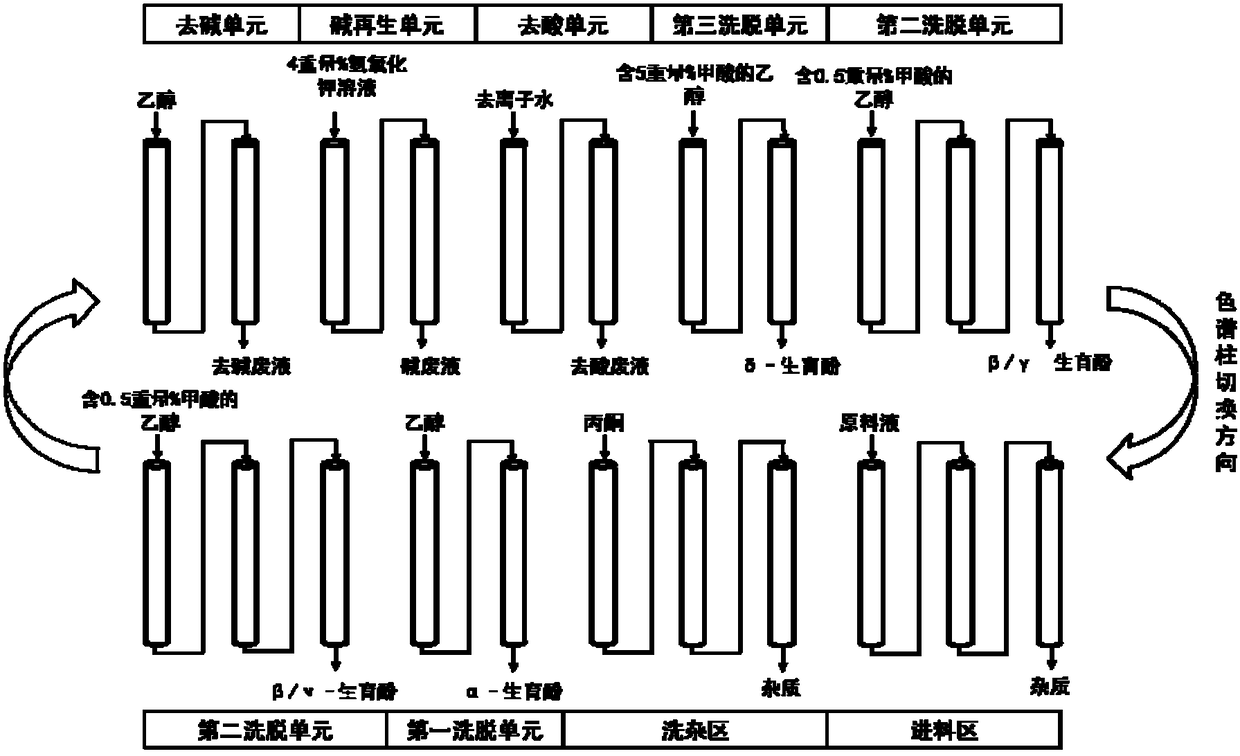

A method for continuous chromatographic separation of tocopherol monomers

ActiveCN108101877BHigh purityHigh recovery rateOrganic chemistrySolid sorbent liquid separationChromatographic separationElution

The invention relates to the field of tocopherol and discloses a method for separating tocopherol monomers with a continuous chromatograph. The continuous chromatograph comprises a feeding area and aneluting area, and multiple eluting units are contained in the eluting area. The method comprises steps as follows: a raw material solution mixed with a crude tocopherol product is injected into the continuous chromatograph through an inlet of the feeding area and is eluted in the multiple eluting units respectively by an elution solvent, and each eluting unit is only used for eluting one kind oftocopherol monomer. With adoption of the technical scheme, alpha-tocopherol, beta / gamma-tocopherol and delta-tocopherol with high purity and high recovery rate can be obtained through continuous separation based on the continuous chromatograph, product quality is stable, solvent consumption is low, resin utilization rate is high, and the products are applicable to industrialized enlargement.

Owner:COFCO GROUP +2

Method for separating tocopherol monomers with continuous chromatograph

ActiveCN108101877AHigh purityHigh recovery rateOrganic chemistrySolid sorbent liquid separationChromatographic separationDelta-Tocopherol

The invention relates to the field of tocopherol and discloses a method for separating tocopherol monomers with a continuous chromatograph. The continuous chromatograph comprises a feeding area and aneluting area, and multiple eluting units are contained in the eluting area. The method comprises steps as follows: a raw material solution mixed with a crude tocopherol product is injected into the continuous chromatograph through an inlet of the feeding area and is eluted in the multiple eluting units respectively by an elution solvent, and each eluting unit is only used for eluting one kind oftocopherol monomer. With adoption of the technical scheme, alpha-tocopherol, beta / gamma-tocopherol and delta-tocopherol with high purity and high recovery rate can be obtained through continuous separation based on the continuous chromatograph, product quality is stable, solvent consumption is low, resin utilization rate is high, and the products are applicable to industrialized enlargement.

Owner:COFCO GROUP +2

An intelligent sand and gravel aggregate production line

ActiveCN107153410BIncrease the level of automationReduce work intensityTotal factory controlProgramme total factory controlThe InternetElectric control

An intelligent sandstone aggregate production line, which relates to the technical field of sandstone aggregate production. The intelligent sandstone aggregate production line comprises an intelligent jaw type crusher, an intelligent impact type crusher, a vibrating screen, a vibrating feeder, a material bin, a hopper, a belt conveyor, a control-related network type integrated electric control system, a distributed control system, and an intelligent internet-of-things monitoring cloud platform. A variety of sensors are additionally mounted on the basis of an original crushing screening production line. Sensor information is transmitted to the distributed control system through the network type integrated electric control system, so that automatic regulation and control on the production process is achieved, and then, the sensor information is transmitted to the intelligent internet-of-things monitoring cloud platform; and by means of cloud computation, production data storage and safety are managed in a unified manner on the basis of classification and combing. The intelligent sandstone aggregate production line has a fault early-warning function and a real-time alarm function, and quickly increases the response speed; the internet-of-things intelligent control and remote monitoring are introduced, the production process is automatically regulated and control, operation is performed with optimal load, the yield is increased, and the downtime maintenance is reduced.

Owner:SHANGHAI UNITRUSTON INTELLIGENT TECH CO LTD

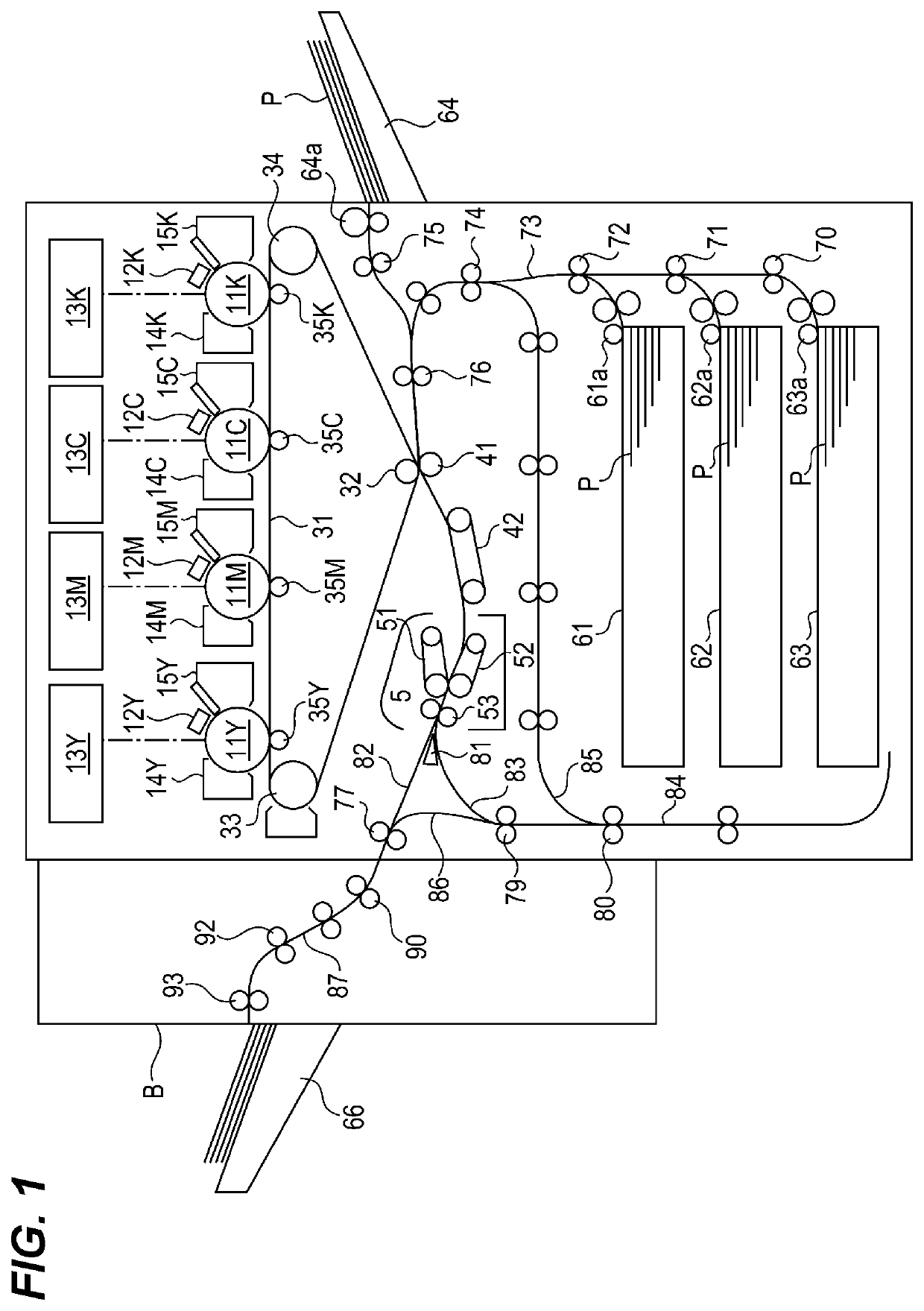

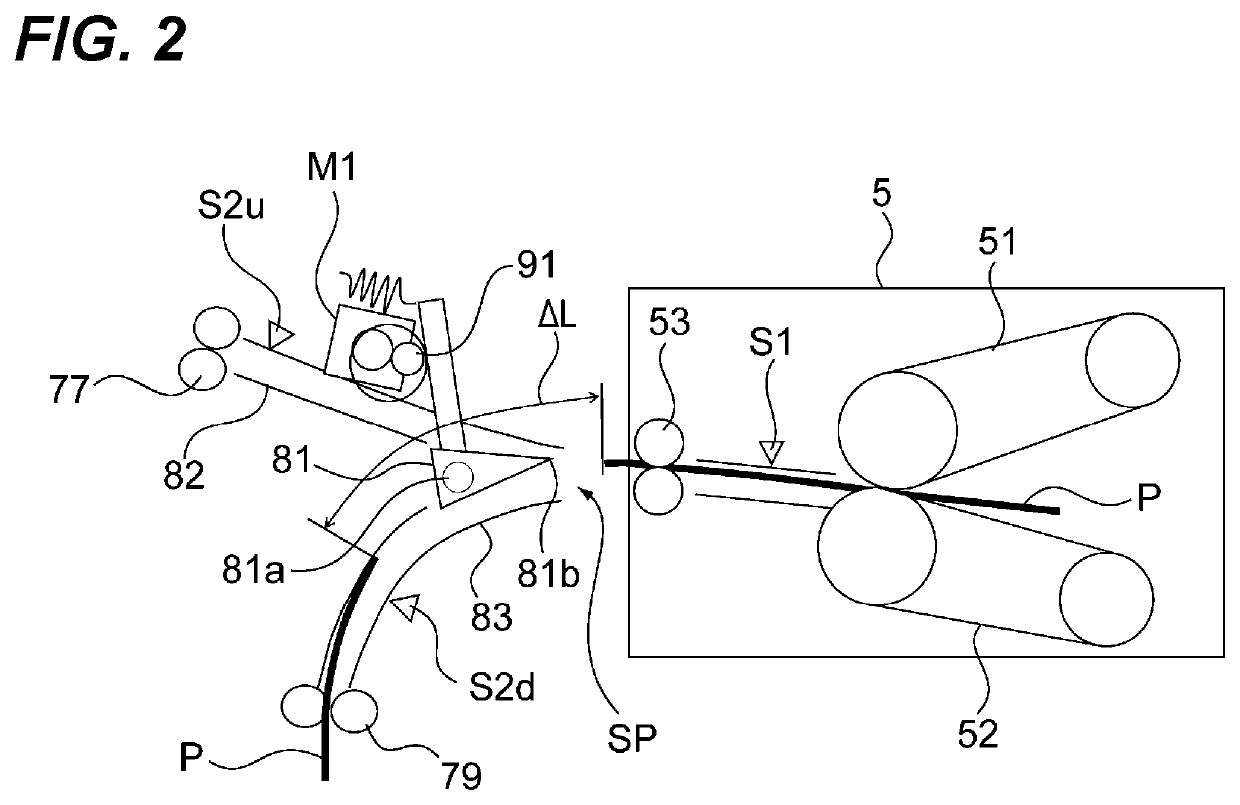

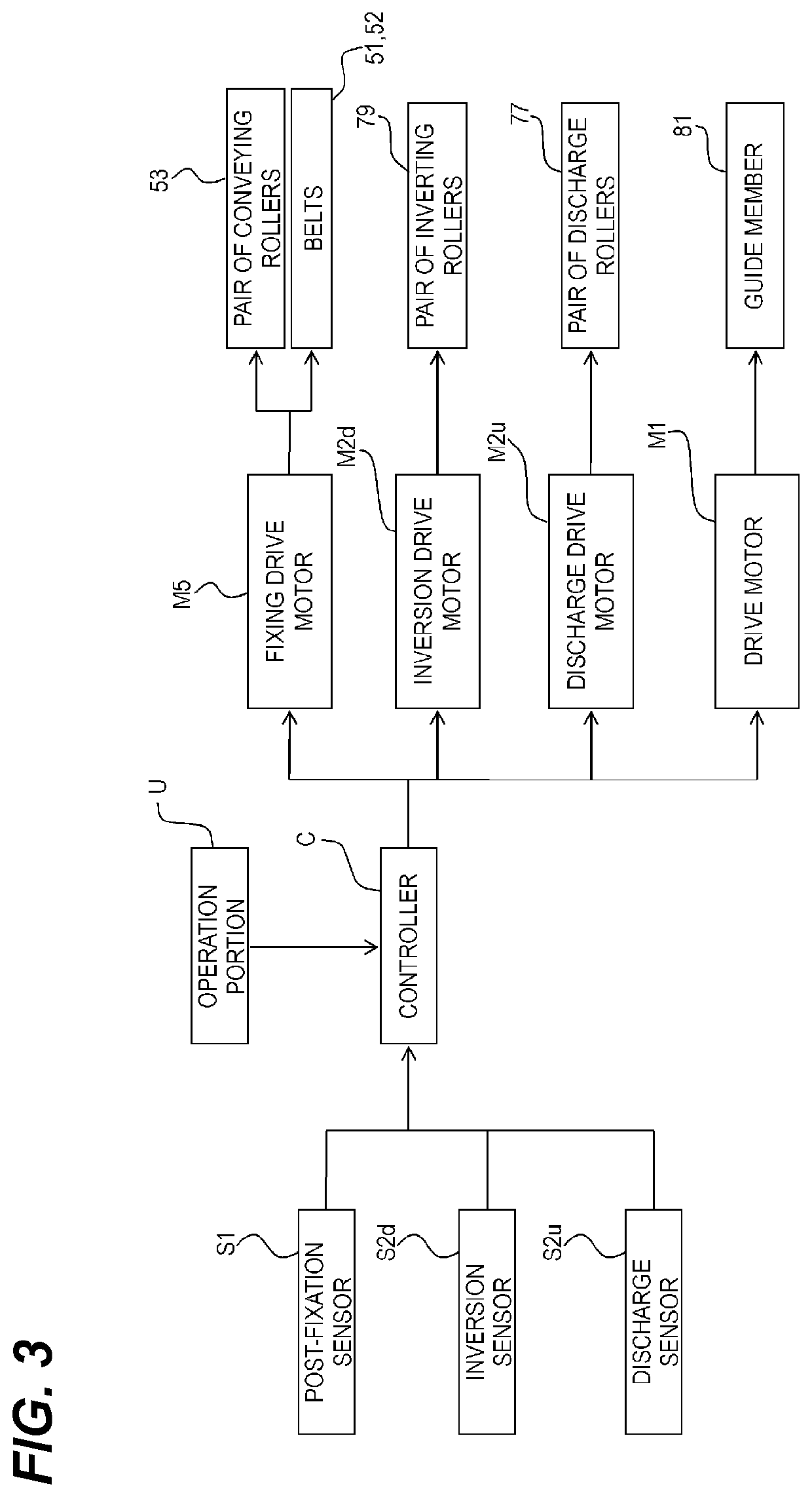

Image forming apparatus with rotating guide member that guides sheet

ActiveUS11079704B2Improve productivity per unit timeLarge basis weightElectrographic process apparatusDriver/operatorEngineering

Owner:CANON KK

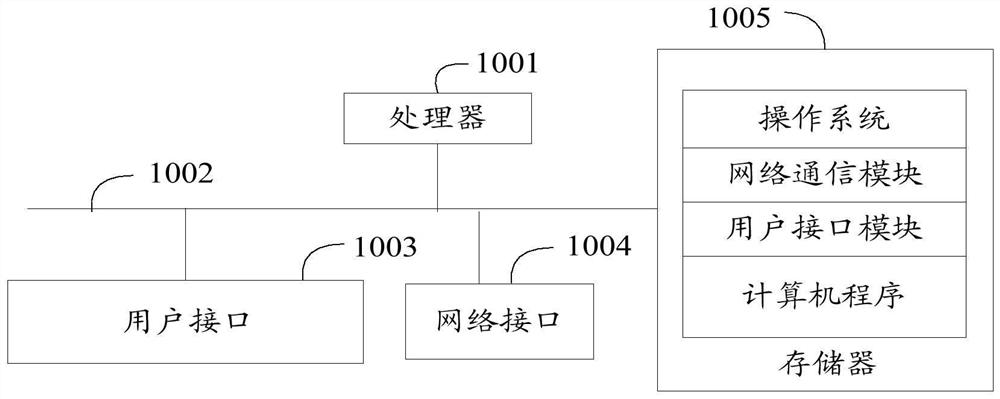

Test method, equipment and computer storage medium for asic chip wafer

The invention discloses a test method for an ASIC chip wafer. The test method for an ASIC chip wafer is applied to a test device, and the test device is connected to a test board through communication; the test method includes the following steps: when a chip test request is received, the chip is obtained Test the quantity corresponding to the test request, connect the ASIC chips of the test quantity to the test board; send the continuity test signal to the ASIC chip through the initialized test board, and obtain the continuity test data between the ASIC chip and the test board; if If the continuity test data is normal, the performance test signal is sent to the ASIC chip through the test board to obtain the performance test data of the ASIC chip; the performance test data is analyzed to obtain the test result of the ASIC chip. The invention also discloses an ASIC chip wafer testing device and a computer storage medium. The invention improves the testing efficiency of batch ASIC chips.

Owner:QINGDAO GOERTEK MICROELECTRONICS RES INST CO LTD

Secondary crystallization equipment and crystallization method thereof

PendingCN114712887AGuaranteed uniformityImprove productivity per unit timeSolution crystallizationCrystallization by component evaporationPhysicsHeating system

The invention provides secondary crystallization equipment and a crystallization method thereof.The crystallization equipment comprises a heating area, a feeding area and a discharging area, the feeding area and the discharging area are arranged on the two sides of the crystallization heating area, and a conveying assembly is arranged in the heating area; the conveying assembly comprises upper conveying wheel sets arranged on the two sides of the upper portion of the heating area and lower conveying wheel sets arranged on the two sides of the lower portion of the heating area respectively, the conveying direction of the conveying assembly is kept consistent with the feeding area and the discharging area, and the upper conveying wheel sets comprise at least two upper conveying wheels arranged in parallel in the horizontal direction. The upper transmission wheel set comprises upper transmission wheels, the lower transmission wheel set comprises lower transmission wheels, the upper transmission wheels and the lower transmission wheels are sequentially connected one by one from top to bottom through a transmission chain, and a transmission hopper used for containing products is erected on the transmission chain. According to the crystallization equipment disclosed by the invention, an up-down circulating heating system is adopted, and a conveying hopper and an ingenious conveying structure are combined, so that the uniformity of crystallization heating is ensured, continuous feeding and discharging of products are realized, and the productivity in unit time is improved.

Owner:SUZHOU IND PARK GAGB MANDE CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com