Secondary crystallization equipment and crystallization method thereof

A technology of secondary crystallization and equipment, applied in the direction of solution crystallization, etc., can solve the problems of unsatisfactory crystallization effect, uneven heating of crystallization, stacking, etc., to improve the quality of secondary crystallization, increase production capacity per unit time, and ensure uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

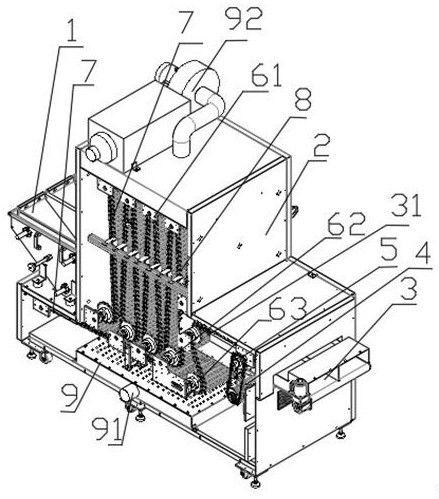

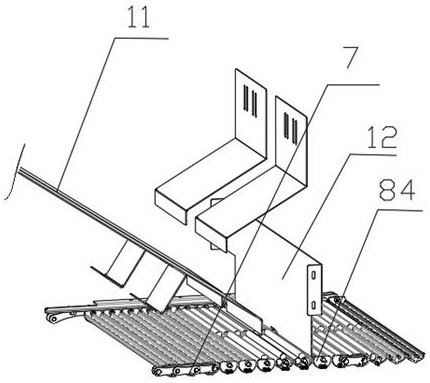

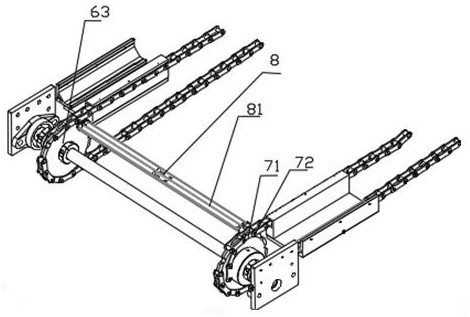

[0028] The following examples are combined with Figure 1-Figure 7 Describing the technical solution of the present invention, the present invention discloses a secondary crystallization equipment, which sequentially includes a feeding zone 1, a heating zone 2 and a discharging zone 3, and the three zones form a continuous circulation transmission through a transmission chain. In the following, when the product to be crystallized is a straw, a specific description will be given.

[0029] Specifically, the top and bottom of the heating zone 2 are respectively provided with a circulating heating component formed by an upper heating component and a lower heating component, and a transmission component is arranged between the heating components. The heating assembly includes a bellows 9, the surface of the bellows 9 is evenly distributed with air outlet holes, and the bellows 9 is provided with an air inlet. The upper part of the bellows at the top of the heating zone is also pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com