Multipurpose tooling assembly and assembling tooling for loudspeaker

A loudspeaker and component technology, applied to sensors, electrical components, etc., can solve the problems of unusable upper or lower molds, production efficiency to be improved, and high production costs, achieving simple and fast and reliable assembly. Simple and fast assembly Enhanced reliability, usability and versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

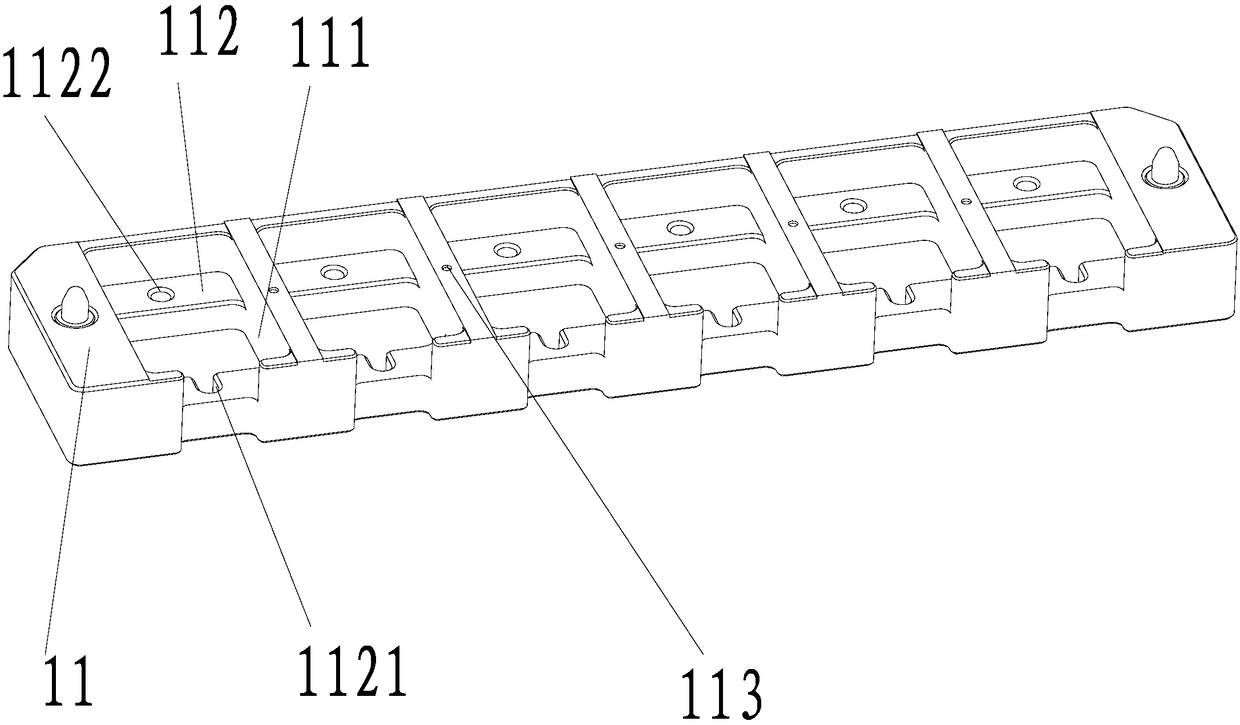

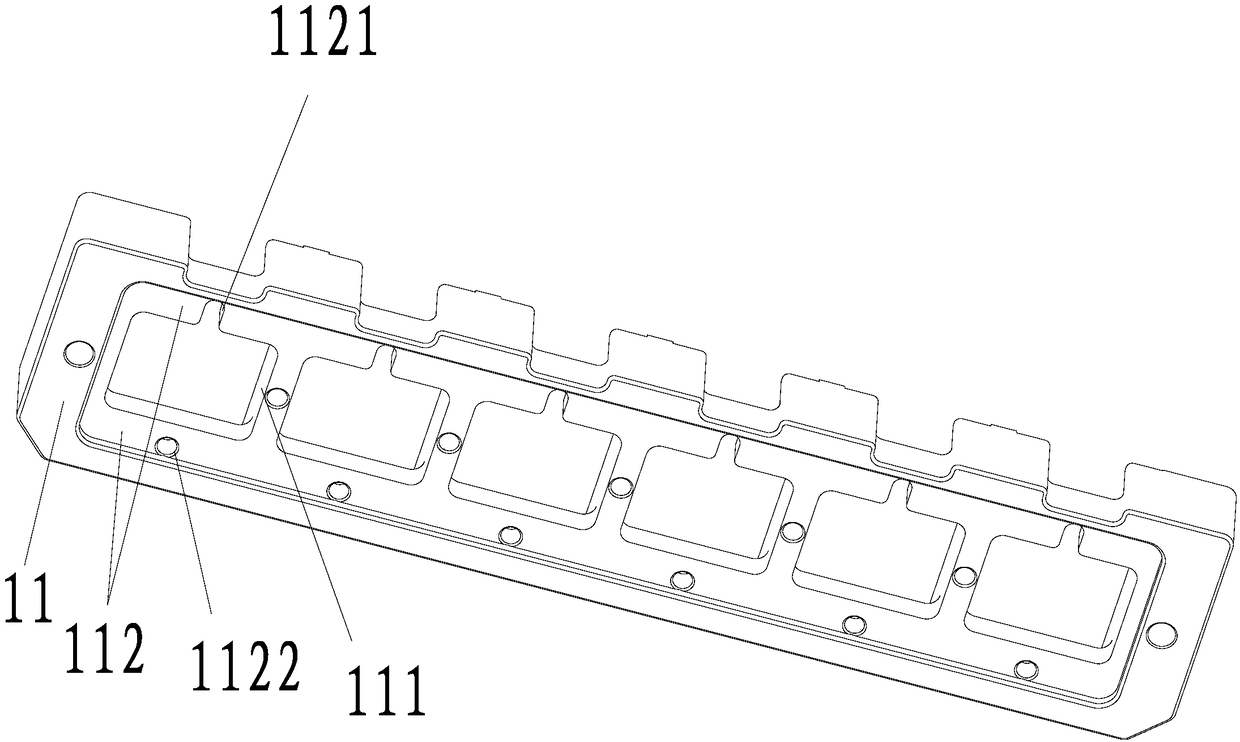

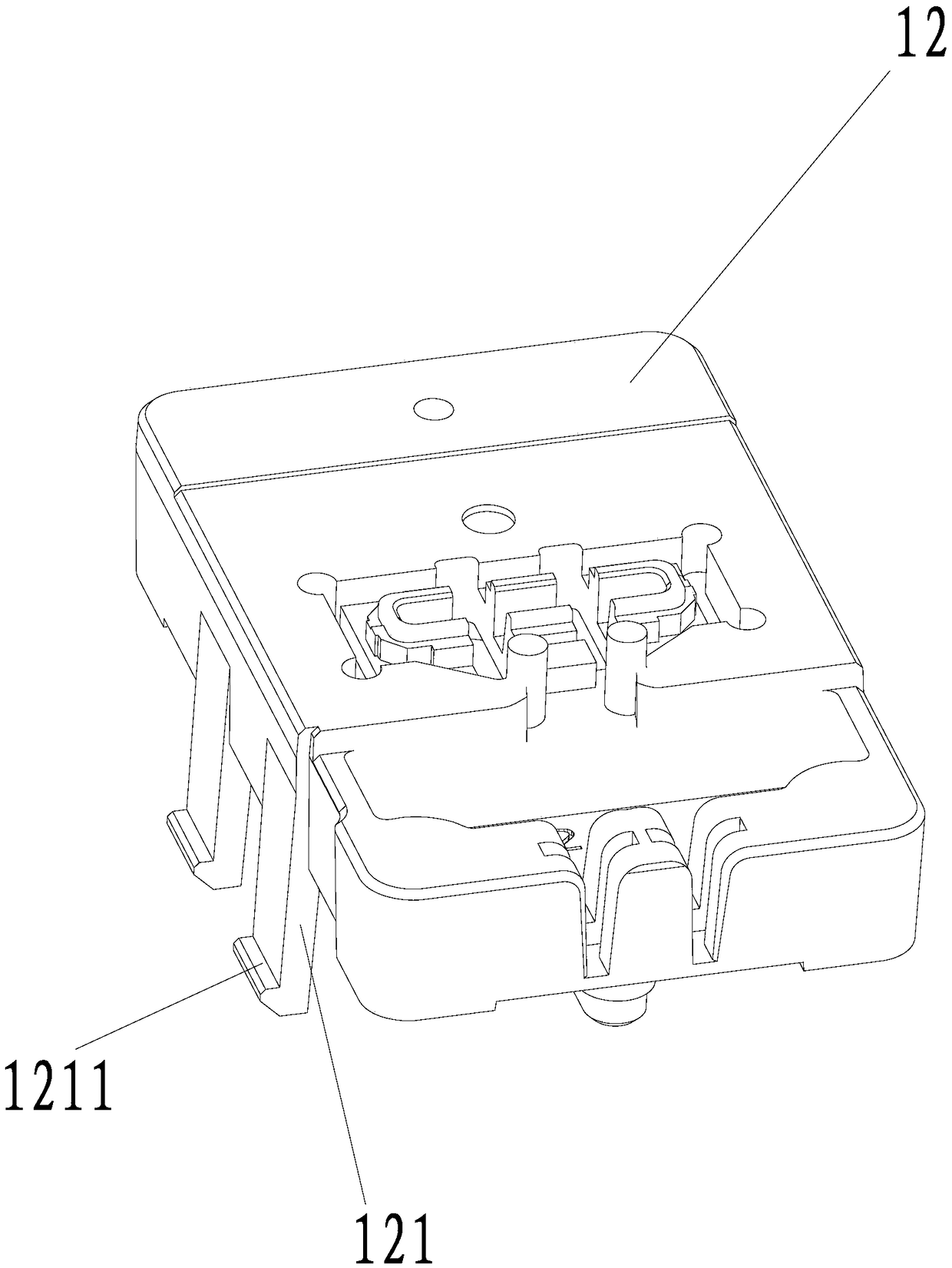

[0030] A loudspeaker assembly tool adopts a multi-purpose tool component. For the multi-purpose tooling components, refer to Figures 1 to 11 , comprising an upper mold 1 and a lower mold 2; the upper mold 1 is assembled from an upper base 11 and an upper tooling 12, and the lower mold 2 is assembled from a lower base 21 and a lower tooling 22; the upper The base 11 and the lower base 21 are respectively provided with accommodating cavities for accommodating the upper tooling 12 and the lower tooling 22 respectively; the upper tooling 12 and the lower tooling 22 are respectively provided with connection assemblies, The assembly direction of the upper tooling 12 and the lower tooling 22 and the upper base 11 and the lower base 21 is set; the upper base 11 and the lower base 21 are provided with a connection matching assembly along the assembly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com