Novel welding equipment and welding method for photovoltaic cell

A technology for photovoltaic cells and welding equipment, applied in welding equipment, metal processing equipment, circuits, etc., can solve problems such as inability to achieve precise control, and achieve the effects of increasing productivity per unit time, improving welding efficiency, and high energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

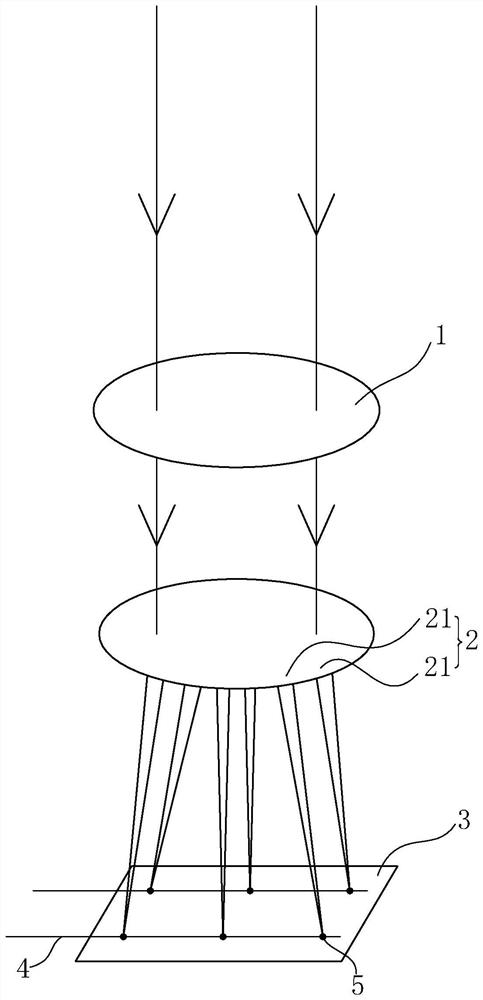

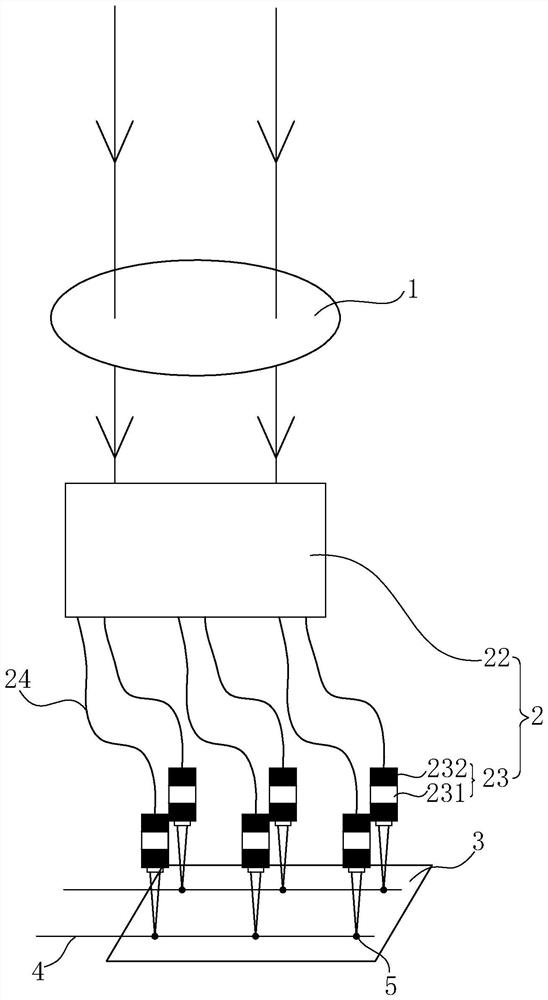

[0046] Attached to the following Figure 1-2 This application will be described in further detail.

[0047] In order to make the objectives, technical solutions and advantages of the present application clearer, the embodiments of the present application will be further described in detail below with reference to the accompanying drawings.

[0048] The embodiment of the present application discloses a new type of welding equipment for photovoltaic cells, refer to figure 1 and figure 2 , including a welding frame, and the welding frame is provided with a homogenizing mirror module and a beam gathering assembly 2 in sequence from top to bottom. A photovoltaic cell 3 is placed on the welding frame, and the photovoltaic cell 3 is arranged directly below the beam gathering assembly 2 , and two sets of welding strips 4 are laid on the main grid line on the front of the photovoltaic cell 3 .

[0049] In practice, the homogenizing mirror module 1 is used to convert the laser beam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com