Preparation method of methylphenylcarbamate

A technology of methyl phenylcarbamate and diphenylurea, applied in the field of organic chemical industry, can solve the problems of low synthesis efficiency of methyl phenylcarbamate and complicated product separation, and achieve increased production capacity per unit time, high separation degree, and shortened reaction the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

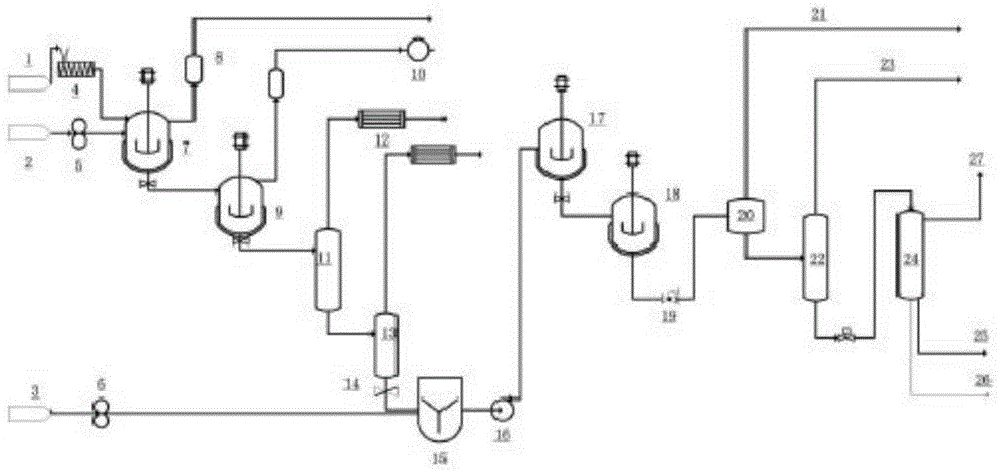

[0043] Continuously input urea and aniline into the pre-reactor 7 at a feed rate of 0.34 kg / h and 5.3 kg / h respectively, and keep it at 140° C. for 0.5 hour under agitation, and the mixed solution of the pre-reactor enters into the synthesis two through the overflow port. In the phenylurea reactor 9, the temperature is kept at 160° C. for 3 hours under a slight negative pressure of 90 kPa. The gas generated by the reaction enters the ammonia gas separation tower 8 after being condensed from the top of the kettle, and the condensed liquid aniline is recycled and reused. The reaction solution enters the falling film evaporator 11 through the regulating valve, aniline is evaporated from the top, and diphenylurea is further purified through the evaporation crystallizer, and then enters the mixing tank 15 with stirring through the discharge valve 14 as solid feed, and is massaged with methanol The feed ratio of 1:10 is stirred and mixed to form a slurry material, and then injected i...

Embodiment 2

[0046] The urea and aniline are continuously input into the pre-reactor 7 at the feed rate of 0.68kg / h and 4.2kg / h respectively, and kept at 160°C for 0.1 hour under agitation, and the mixed liquid of the pre-reactor enters into the synthesis two through the overflow port. In the phenylurea reactor 9, the temperature is kept at 180° C. for 2 hours under a slight negative pressure of 92 kPa. The gas generated by the reaction enters the ammonia gas separation tower 8 after being condensed from the top of the kettle, and the condensed liquid aniline is recycled and reused. The reaction solution enters the falling film evaporator 11 through the regulating valve, aniline is evaporated from the top, and diphenylurea is further purified through the evaporation crystallizer, and then enters the mixing tank 15 with stirring through the discharge valve 14 as solid feed, and is massaged with methanol The feed ratio of mole ratio is 1:15, which is stirred and mixed into a slurry material, ...

Embodiment 3

[0049] Continuously input urea and aniline into the pre-reactor 7 at a feed rate of 1.2kg / h and 11.2kg / h respectively, keep it at 120°C for 1 hour under stirring, and the mixed solution of the pre-reactor enters into the synthesis two through the overflow port. In the phenylurea reactor 9, the temperature is kept at 170° C. for 3 hours under a slight negative pressure of 100 kPa. The gas generated by the reaction enters the ammonia gas separation tower 8 after being condensed from the top of the kettle, and the condensed liquid aniline is recycled and reused. The reaction solution enters the falling film evaporator 11 through the regulating valve, aniline is evaporated from the top, and diphenylurea is further purified through the evaporation crystallizer, and then enters the mixing tank 15 with stirring through the discharge valve 14 as solid feed, and is massaged with methanol The feed ratio of 1:20 is stirred and mixed to form a slurry material, and then injected into the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com