Air-passage multi-tube spiral device for preparing gas through dry distillation and pyrolysis on biomass and process therefor

A biomass and spiral technology, applied in the fields of biofuels, special forms of dry distillation, petroleum industry, etc., can solve the problems of insufficient reaction of biomass in dry distillation furnaces, inability to large-scale industrial production, and furnace tubes affecting normal production, etc. Achieve the effect of realizing large-scale industrial production, reducing the content and extending the length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

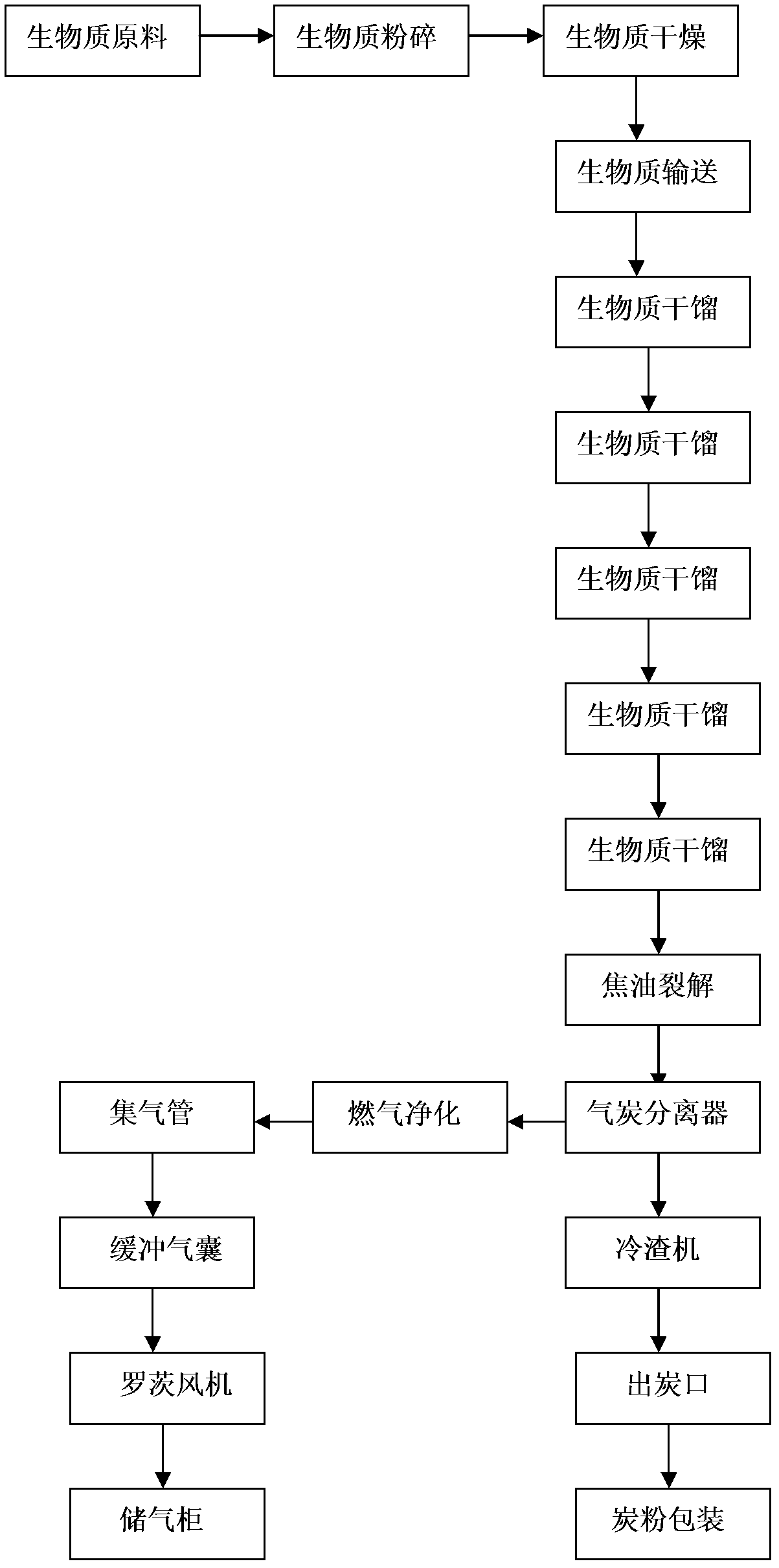

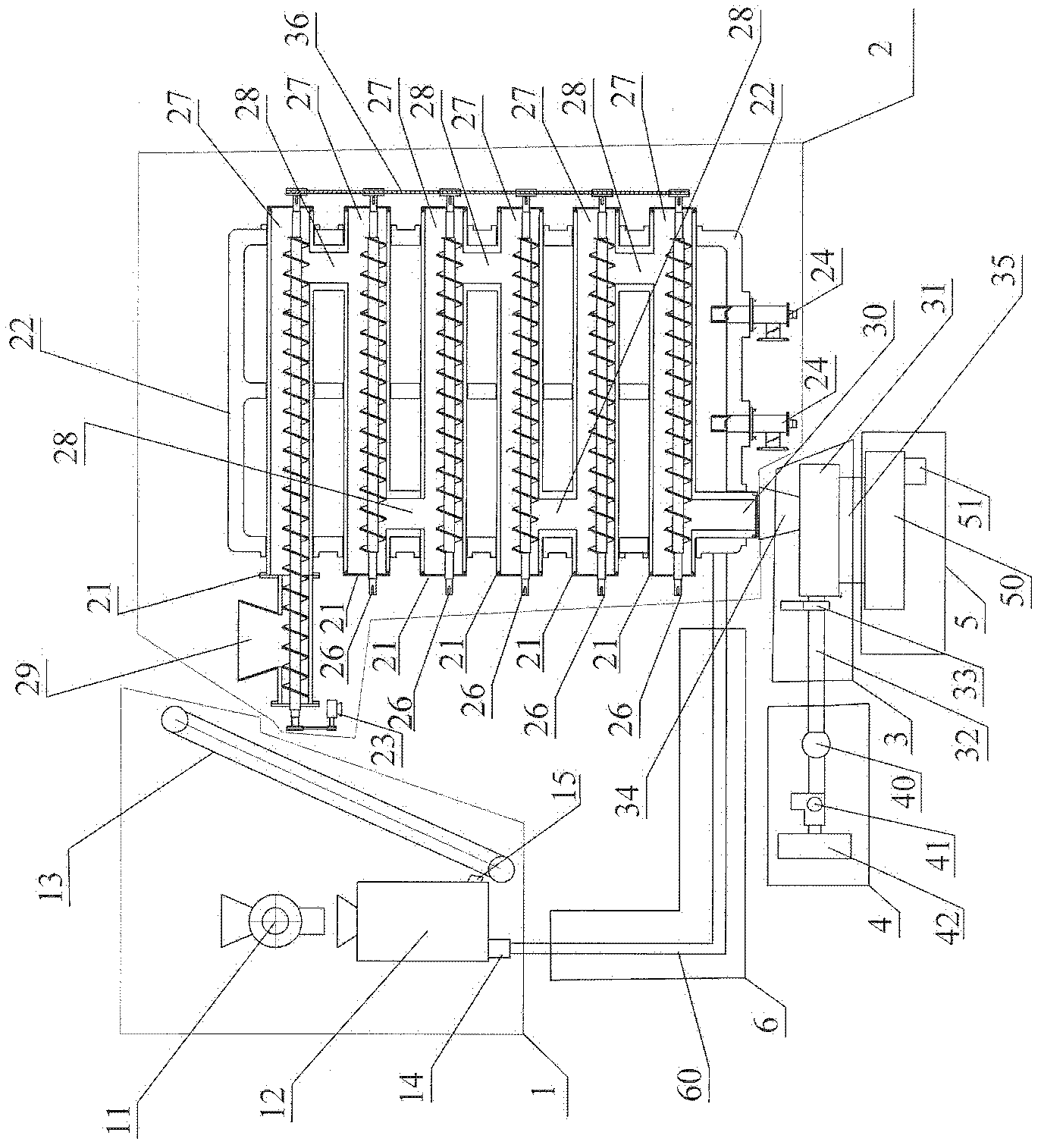

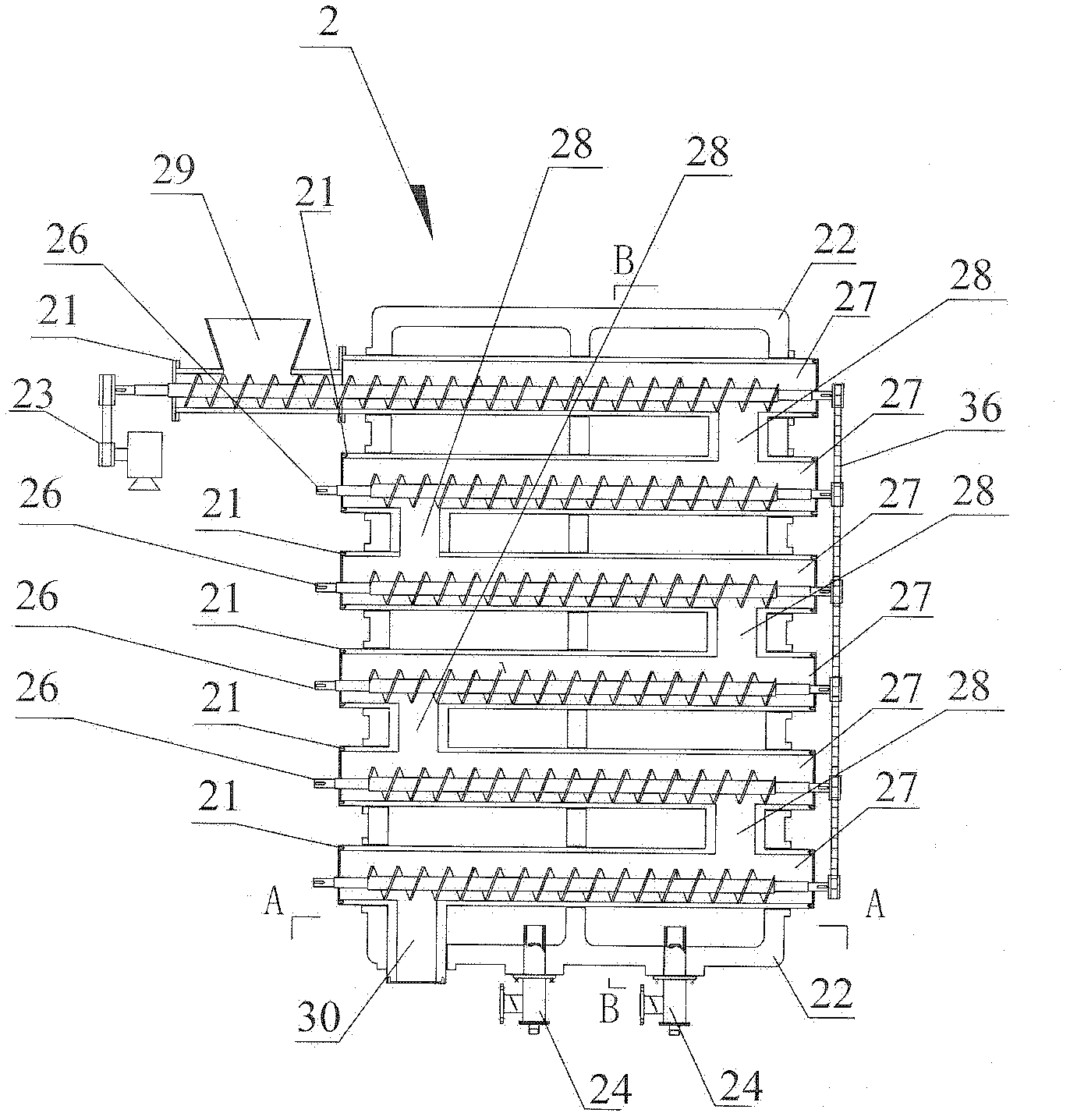

[0045] see figure 2 , image 3 , Figure 4 with Figure 5 As shown: the device for producing gas by multi-tube spiral biomass carbonization and pyrolysis with gas channel according to the present invention is composed of biomass raw material pretreatment system 1, biomass carbonization and cracking system 2, gas and carbon powder separation and purification system 3 , gas transmission and storage system 4, carbon powder cooling collection system 5 and waste heat utilization system 6, wherein the biomass raw material pretreatment system 1 is set before the biomass dry distillation cracking system 2, and the gas and carbon powder separation and purification system 3 is set in the biomass After the material dry distillation cracking system 2 is connected with it, the gas transportation and storage system 4 is connected with the gas and charcoal powder separation and purification system 3, the charcoal powder cooling collection system 5 is connected with the gas and charcoal po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com