Graphic data high-speed transmission device of direct-writing photoetching equipment and transmission method thereof

A graphics data, high-speed transmission technology, used in microlithography exposure equipment, optical fiber transmission, opto-mechanical equipment, etc., can solve the problems of untimely graphics transmission, equipment capacity cannot be improved, etc., to improve the productivity per unit time, fast and accurate exposure. , the effect of improving the transmission rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing:

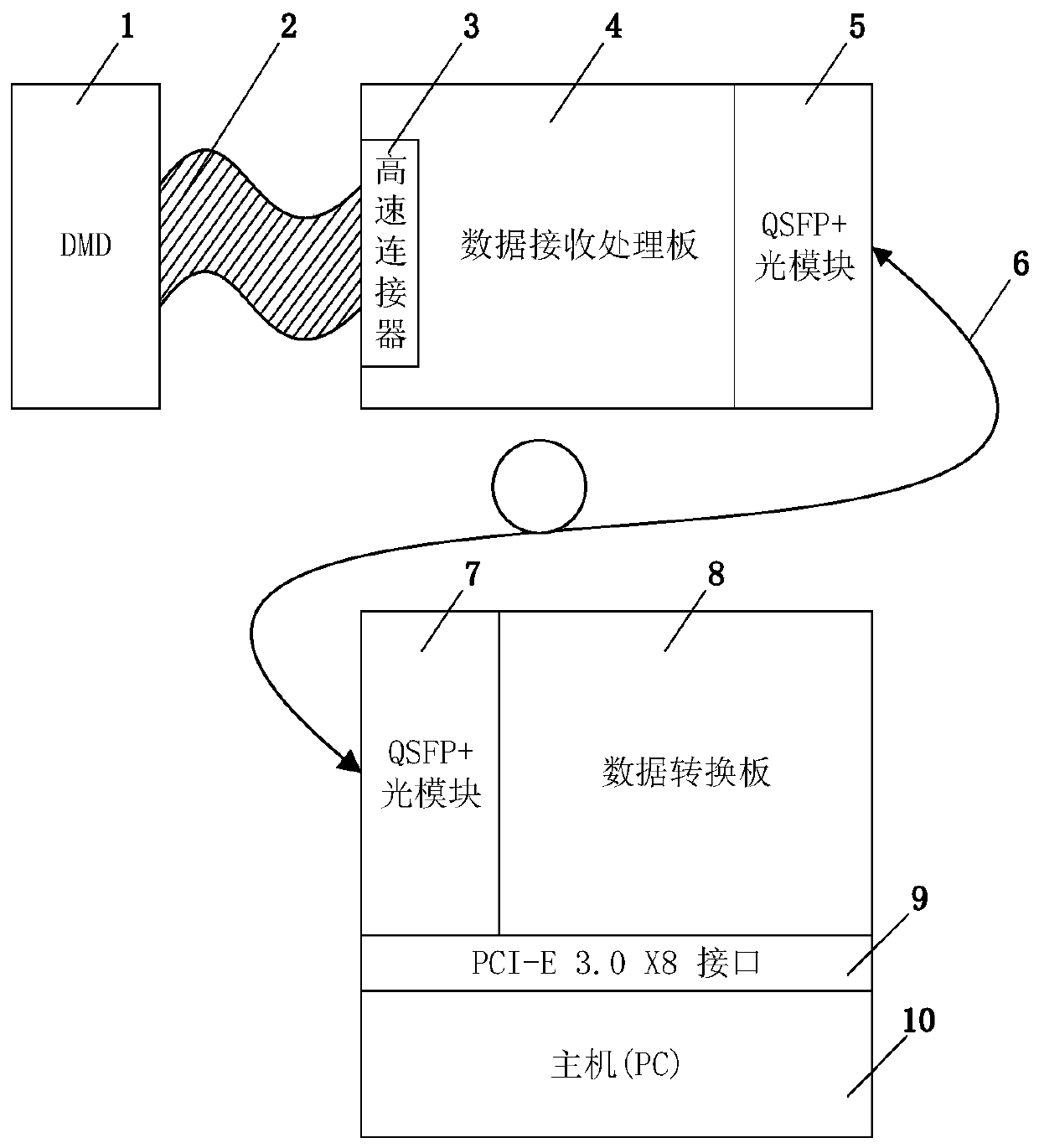

[0030] like figure 1 A high-speed graphic data transmission device for direct writing lithography equipment shown, including a graphic display device (DMD) 1, a data receiving and processing board 4 connected to the graphic display device (DMD) 1 through a rigid-flexible board 2, and a multi-mode The optical fiber 6 is connected to the data conversion board 8 connected to the data receiving and processing board 4 and the host computer 10 connected to the data conversion board 8 . DMD: DigitalMicromirror Device, digital micromirror device; a digital device composed of millions of small micromirrors.

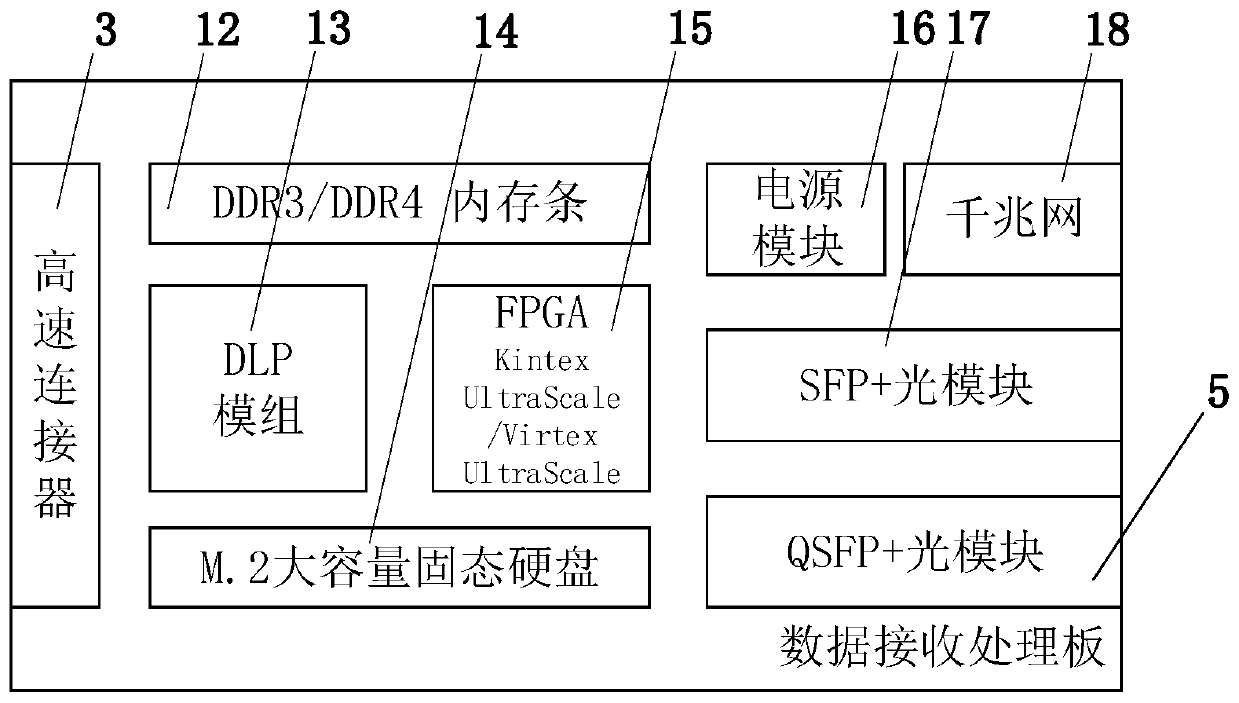

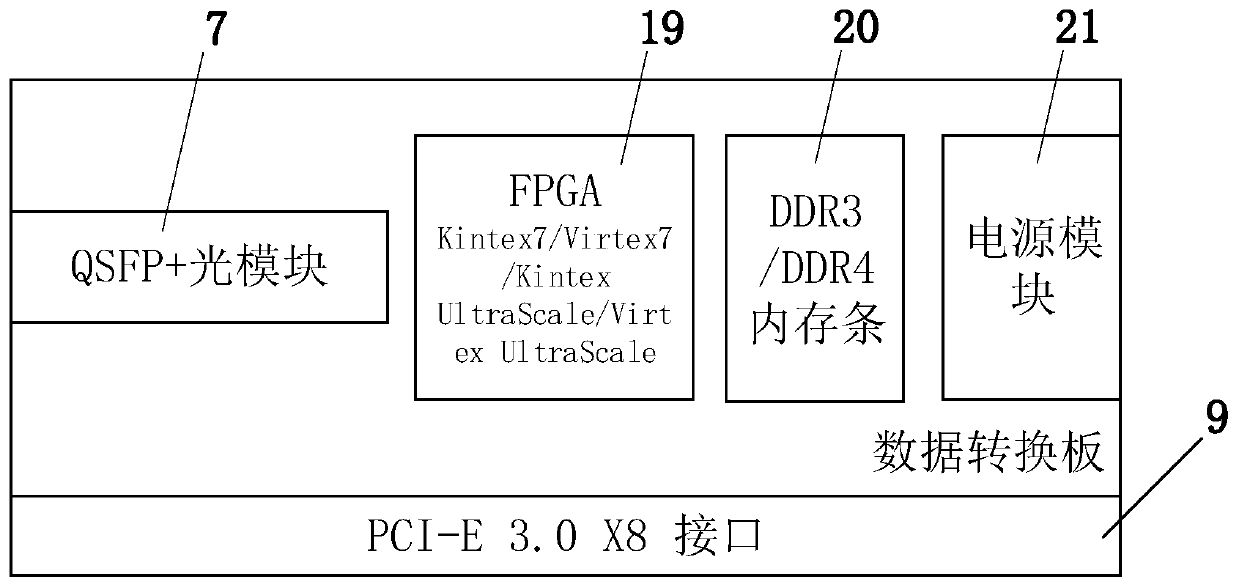

[0031] Specifically, as figure 2 As shown, the data receiving and processing board 4 includes an FPGA chip one 15, a high-speed connector 3, an SFP+ optical module 17 and a QSFP+ optical module one 5. The FPGA chip-15 is connected to the high-speed connector 3, the SFP+ opt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com