Production method of high-bulk density and high-stability vanadium trioxide

A vanadium trioxide, high-stability technology, applied in the direction of vanadium oxide, etc., can solve problems such as high maintenance and operation requirements, high production costs, and long reaction time, so as to reduce material flying loss, increase production capacity per unit time, and improve Effect of system vanadium yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

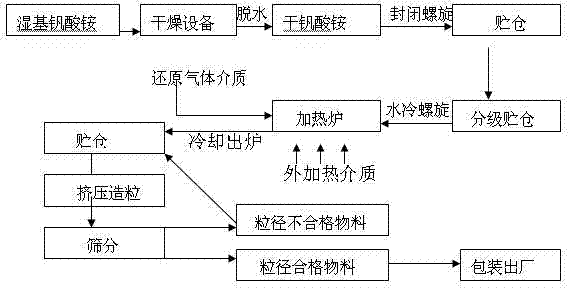

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: The concrete technique of the production method of this vanadium trioxide is as follows.

[0019] The ammonium polyvanadate with a water content of 20.22wt% was transported to the air dryer by a screw conveyor at a drying temperature of 300°C, and the water content of the dried ammonium polyvanadate was 0.49wt%. The dry-based ammonium polyvanadate is transported to the reduction kiln by a water-cooled screw, and the reduction kiln is heated by gas, the feeding speed is 450kg / h, and the coke oven gas flow rate is 160m 3 / h, the temperature of the preheating zone in the kiln is 620°C, the temperature of the reaction zone is 750°C, and the temperature of the cooling discharge zone is 570°C. The dry-based ammonium polyvanadate was reacted in the reduction kiln for 50 minutes, and the material was discharged when the temperature was adjusted to 150°C by water cooling to obtain powdery vanadium trioxide with a total vanadium content of 64.13%. The powdered vana...

Embodiment 2

[0021] Embodiment 2: The concrete technique of the production method of this vanadium trioxide is as follows.

[0022] The ammonium metavanadate on a wet basis with a water content of 49.65wt% is transported to a flash dryer by a screw conveyor at a temperature of 500°C, and the ammonium metavanadate obtained on a dry basis has a water content of 0.45wt%. The dry-based ammonium metavanadate is transported to the fluidized furnace through a water-cooled screw, and the electric heating element is used to heat the fluidized furnace. The feeding speed is 200kg / h, and the converter gas flow rate is 80m 3 / h, the temperature of the preheating zone of the fluidized furnace is 800°C, the temperature of the reaction zone is 1000°C, and the temperature of the cooling discharge zone is 700°C. Dry base ammonium metavanadate was reacted in a fluidized furnace for 20 minutes, and the material was discharged when the temperature was adjusted to 70°C by water cooling to obtain powdery vanadiu...

Embodiment 3

[0024] Embodiment 3: The concrete technique of the production method of this vanadium trioxide is as follows.

[0025] The wet-based ammonium polyvanadate filter cake with a water content of 35.36wt% was transported to a disc dryer by a screw conveyor at a drying temperature of 100°C to obtain a dry-based ammonium polyvanadate with a water content of 0.48wt%. The dry base ammonium polyvanadate is transported to the fluidized furnace through a water-cooled screw, and heavy oil is used to heat the fluidized furnace. The feeding speed is 380kg / h, and the hydrogen gas flow rate is 120m 3 / h, the temperature of the preheating zone in the fluidized furnace is 760°C, the temperature of the reaction zone is 885°C, and the temperature of the cooling discharge zone is 500°C. The material was reacted in the fluidized furnace for 38 minutes, and the material was discharged when the temperature was adjusted to 128°C by water cooling, and the powdery vanadium trioxide with a total vanadium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com