Novel multifunctional opener

A multi-functional, cotton opener technology, applied in fiber opening and cleaning machines, opening and cleaning with stirring arms, static electricity, etc., can solve the problems of reducing the quality of cotton products, affecting the construction period, time-consuming and laborious, etc., to ensure good health and improve output. Cotton quality, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

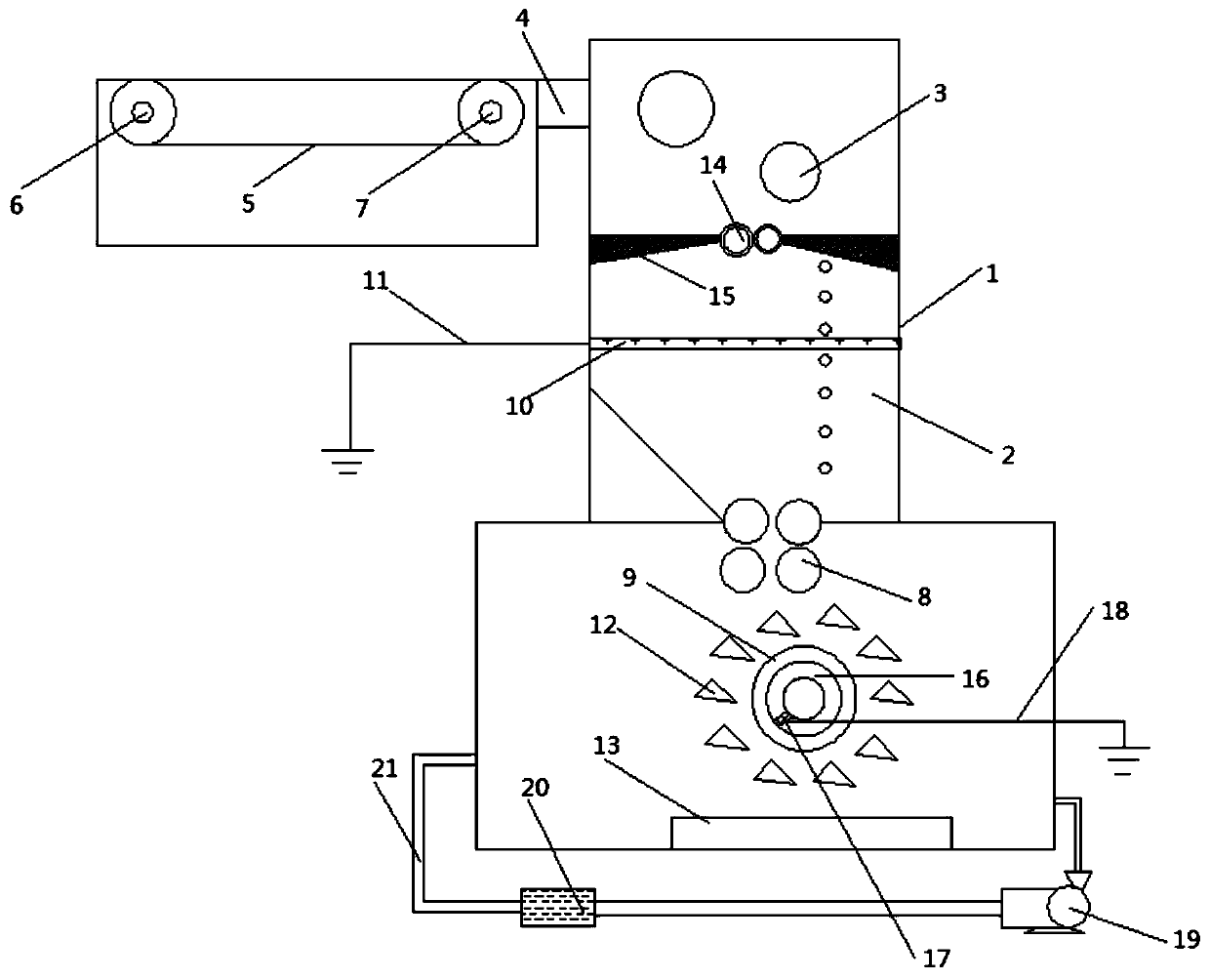

[0012] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

[0013] Refer to attached figure 1 , the present invention provides a novel multifunctional cotton opener, comprising a frame 1, a cotton delivery device and a vertical cotton box 2, a cotton condenser 3 is arranged above the vertical cotton box 2, and the cotton condenser 3 is set There is a cotton inlet 4, and the cotton delivery device is connected with the cotton inlet 4, and the cotton delivery device includes a conveyor belt 5, a driving roller 6, a driven roller 7 and a driving motor, and the conveyor belt 5 and the driving roller 6 It is connected with the driven roller 7, the driving motor is connected with the driving roller 6 and the driven roller 7, the driving motor is set as a semi-servo motor, and the cotton feeding roller 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com