Axial opener for the treatment of fiber tufts

An opener and fiber bundle technology, applied in the field of axial flow openers, can solve the problems of fiber bundle pollution and entanglement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

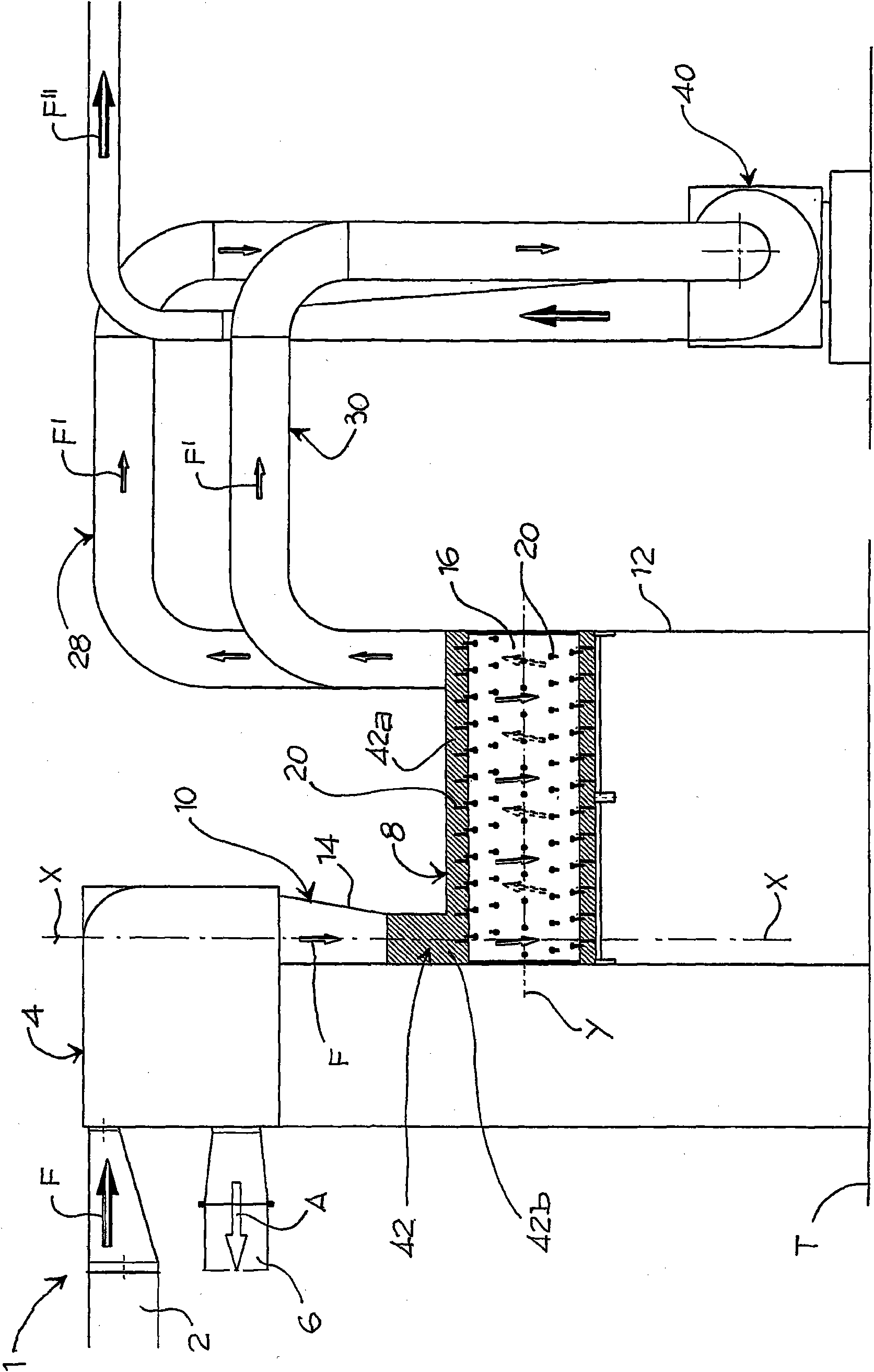

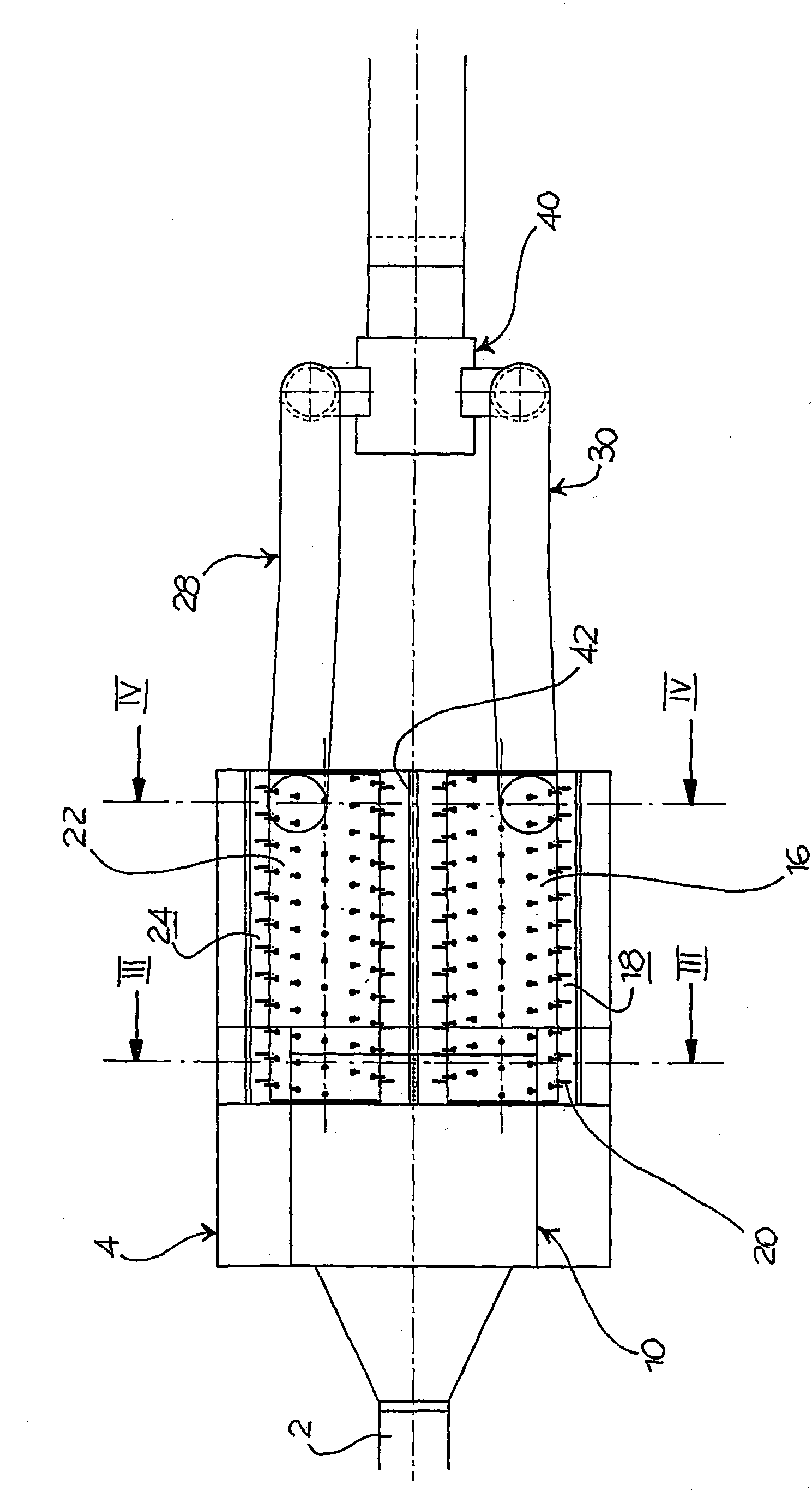

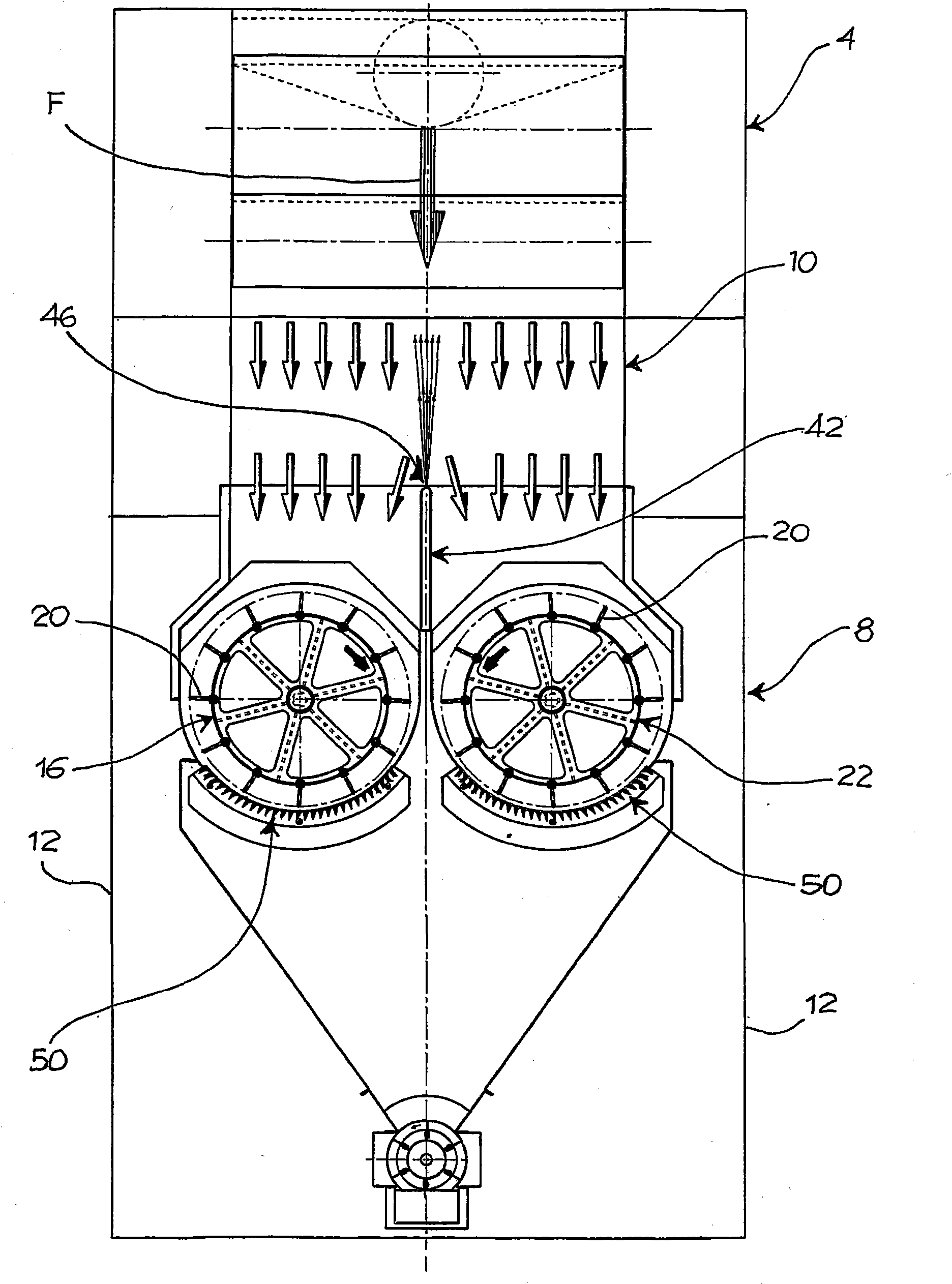

[0023] Referring to the accompanying drawings, reference numeral 1 each denotes an assembly for fiber tow processing, which constitutes a part of a fiber processing line.

[0024] The assembly comprises a supply line 2 for conveying the fibers to be processed, eg from a draw frame.

[0025] The assembly comprises a supply device 4 suitable for separating the dust laden air from the fibres. The fibers F to be processed are conveyed towards the device 4 , for example by suction applied by a fan housed in said device 4 . An exhaust pipe 6 protrudes from the device 4 to discharge the inhaled dust-laden air A.

[0026] According to an embodiment variant, the fan is housed outside the device 4 .

[0027] Furthermore, the assembly 1 comprises, downstream of the supply device 4 , an axial flow opener 8 comprising an inlet pipe 10 connecting it to said supply device 4 .

[0028] The inlet pipe 10 generally extends along an entry line X which is located approximately at a vertical po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com