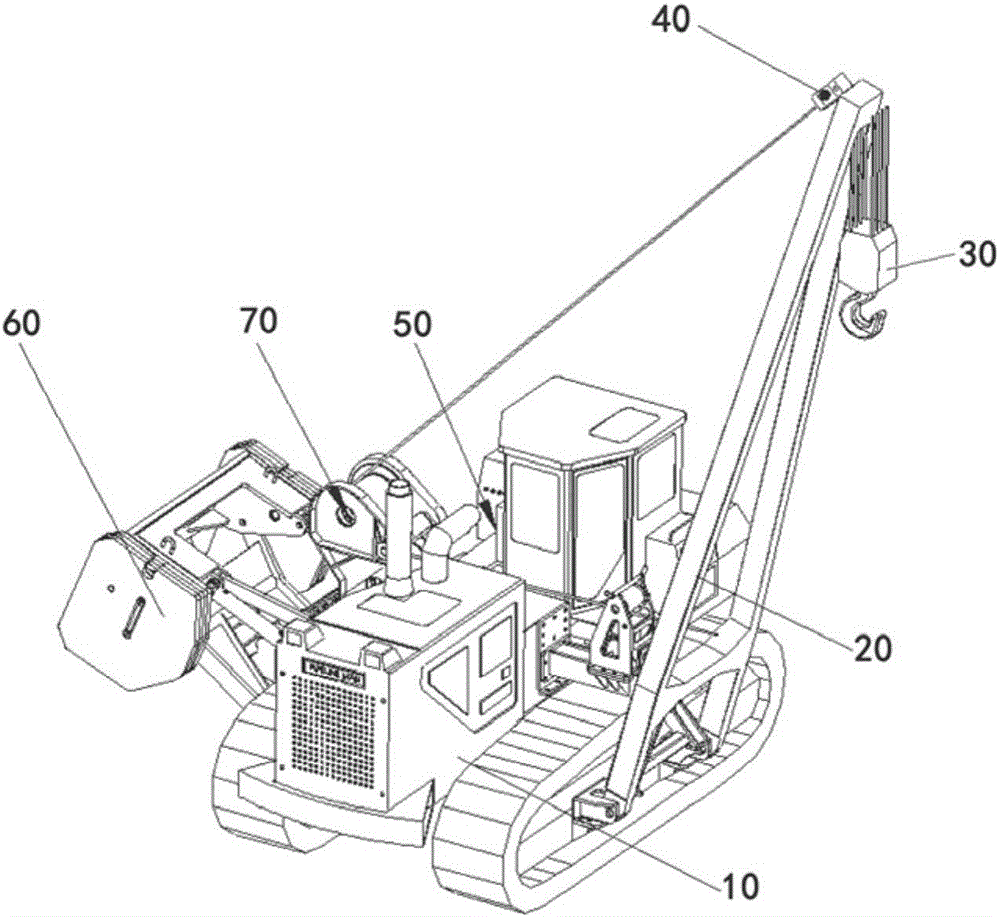

Pipe lifting device

A technology for hanging pipes and booms, which is applied in the field of pipe hanging devices, which can solve the problems of easy accidents, low utilization rate, and reduced work efficiency of steel pipe transportation, etc., and achieve the effects of stable structure operation, improved work efficiency, and improved utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

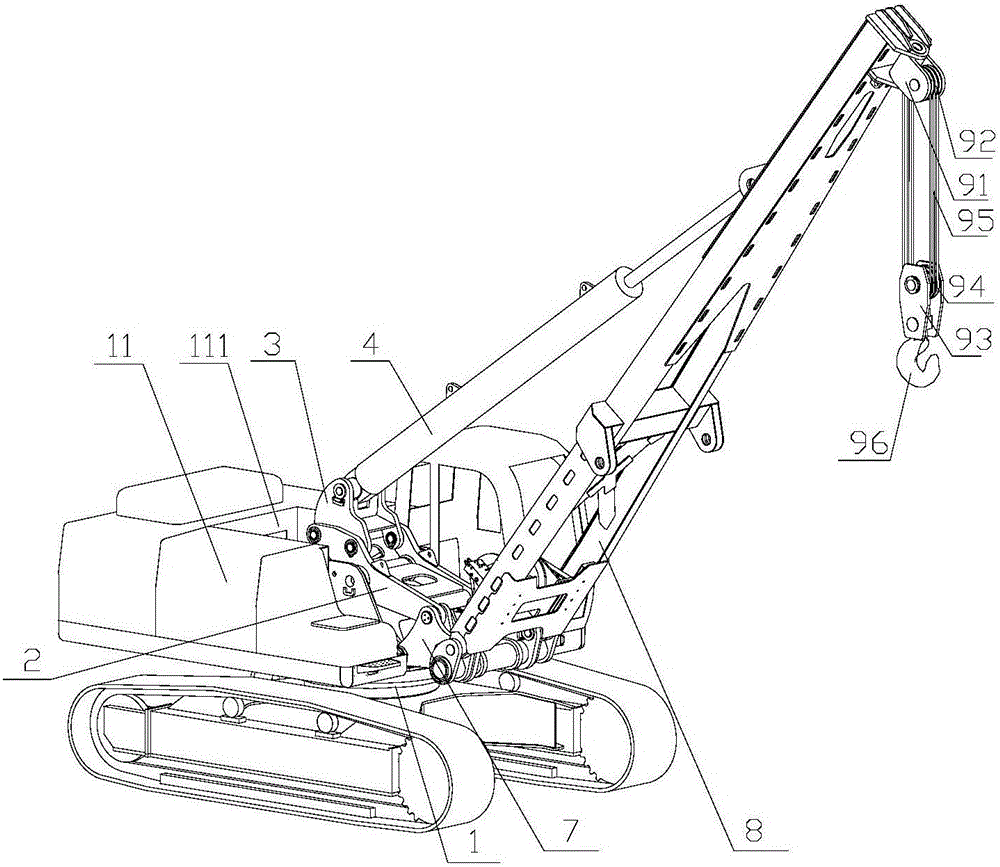

[0062] continue to combine figure 2 and Figure 5 , the luffing mechanism includes the luffing oil cylinder base 3 and the luffing oil cylinder 4, and the bottom end of the cylinder barrel of the luffing oil cylinder is provided with a circular through hole (not shown in the figure due to occlusion); the luffing oil cylinder base 3 includes two parallel The second side plate 31 is arranged and connected to each other, the luffing cylinder seat 3 is arranged between the two first side plates 21, and the second side plate 31 is attached to the first side plate 21, and the two second side plates 31 are respectively provided with two first through holes 32 opposite to the first mounting hole 22, and one is used for a second through hole 33 opposite to the circular through hole, and the first mounting hole 22 and the first through hole 32 pass through A pin is provided to connect the platform frame 2 and the luffing cylinder seat 3; a pin is provided in the circular through hole ...

Embodiment 2

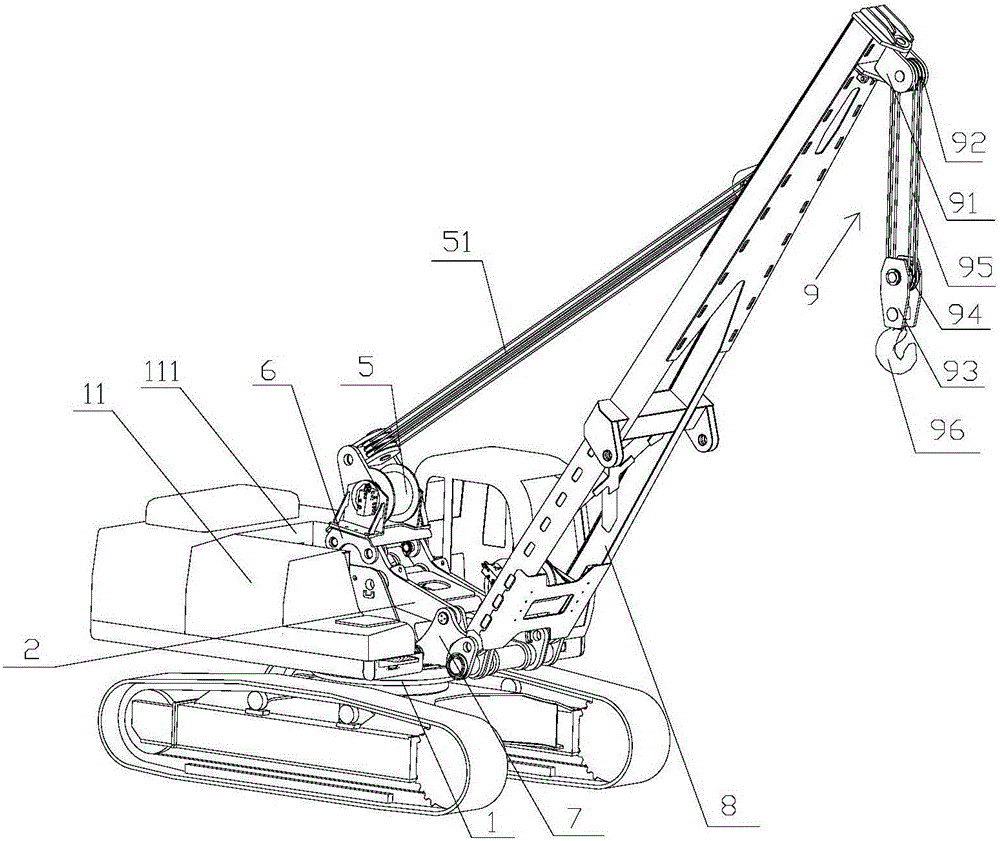

[0065] continue to combine image 3 , Figure 6 and Figure 7 , the luffing mechanism includes a luffing winch seat 6 and a luffing winch 5, and the luffing winch seat 6 includes a top plate 61 for installing the luffing winch 5 and two first clamping plates 62 respectively connected to the bottom sides of the top plate 61, The two first side plates 21 of the platform frame 2 are correspondingly inserted in the first clamping plate 62, the two first clamping plates 62 are provided with a third through hole 63 that can be opposite to the first mounting hole 22, the first mounting hole 22 and A pin shaft is passed through the third through hole 63 to detachably connect the luffing winch seat 6 to the platform frame 2 . The luffing winch 5 is a purchased part, on which a first wire rope 51 connected to the boom 8 is arranged, and the first wire rope 51 can drive the boom 8 to realize luffing under the action of the luffing cylinder 4 .

[0066] It can be seen from Embodiment 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com