Automatic deviation rectification system and method for coiled material

An automatic deviation correction and coil technology, which is applied in the field of coil deviation correction, can solve problems such as uneven winding, poor deviation correction effect, and lateral displacement of coils, and achieve fast deviation correction efficiency, small space occupation, and stable structure and operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below by means of specific embodiments:

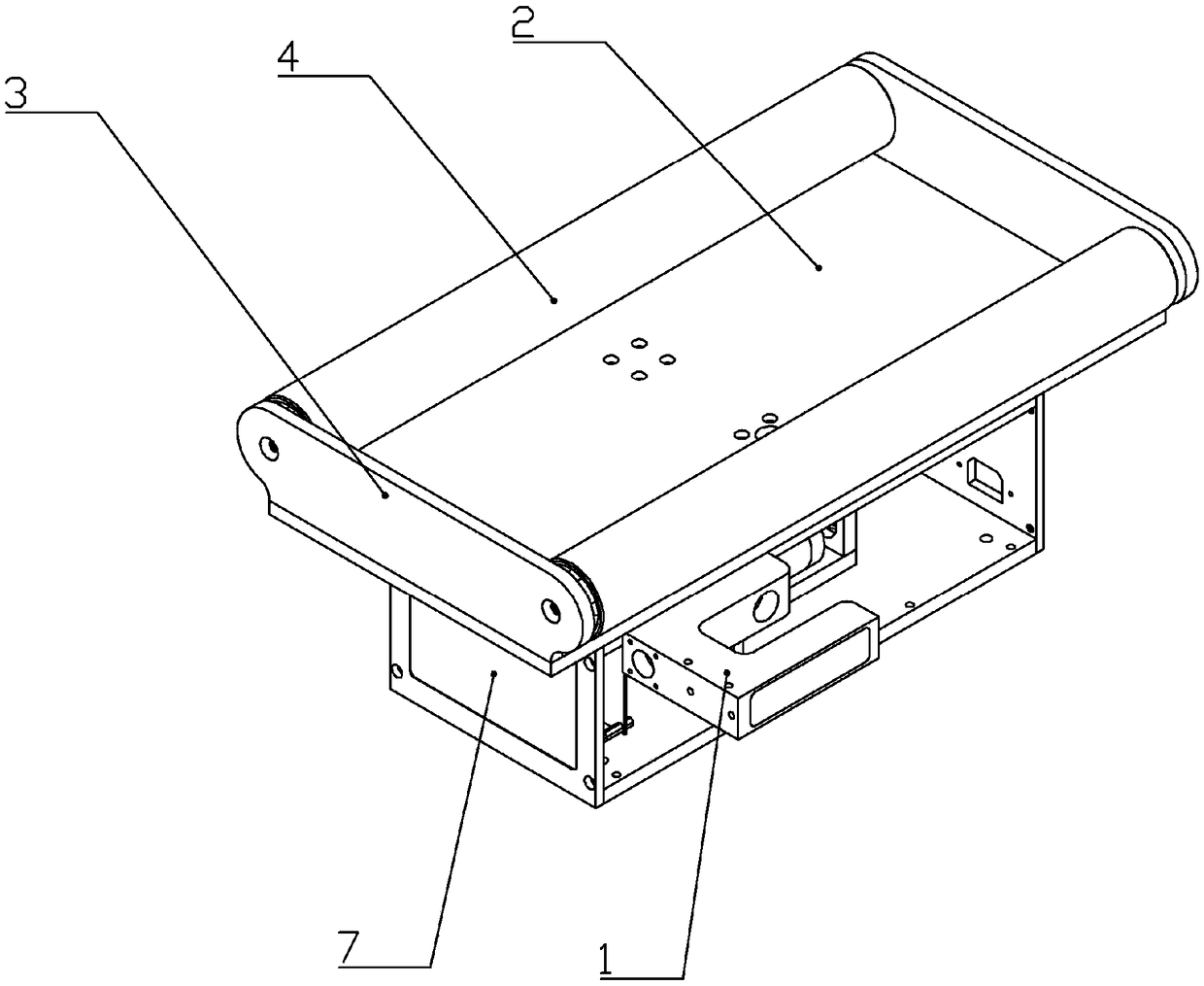

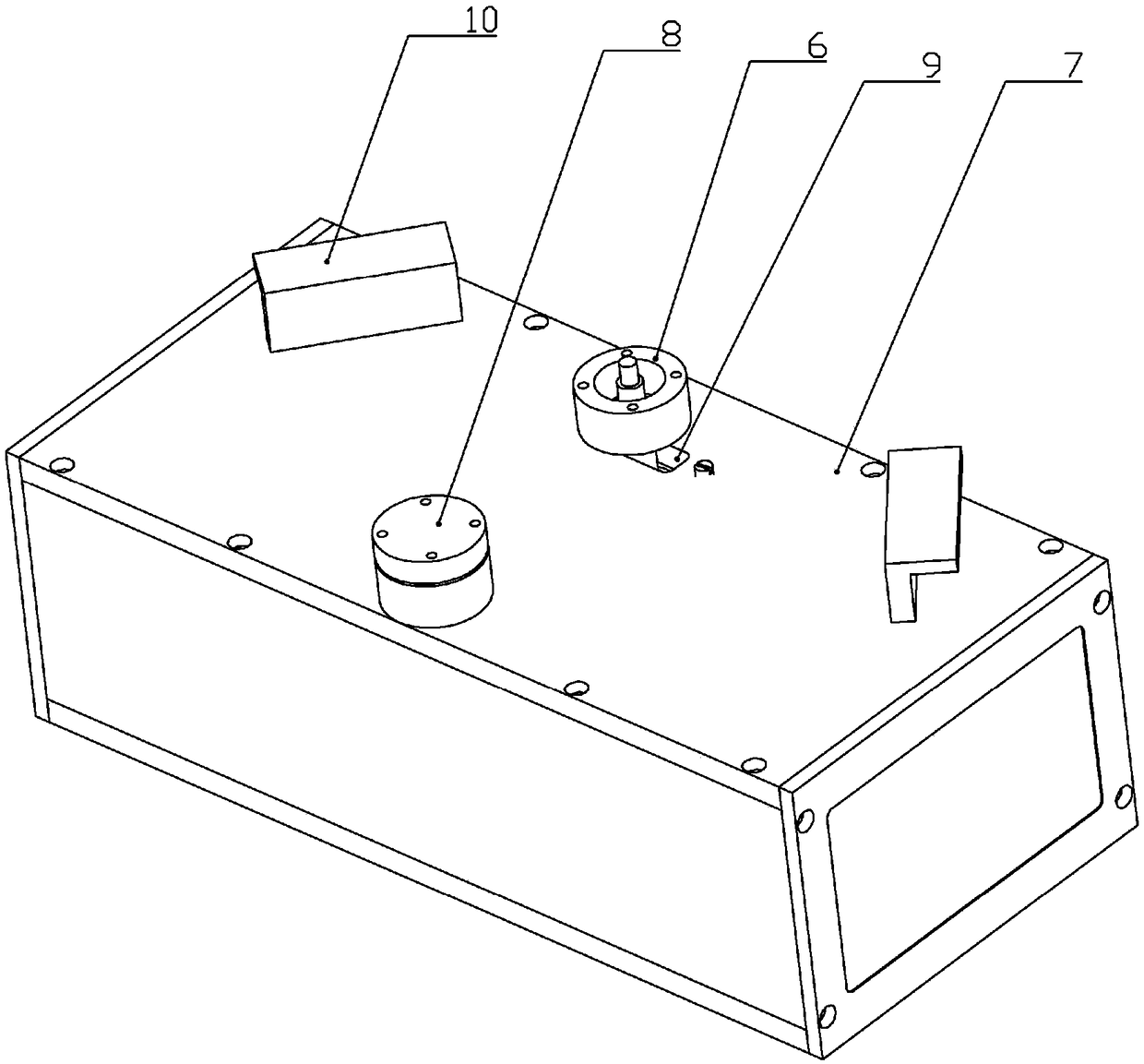

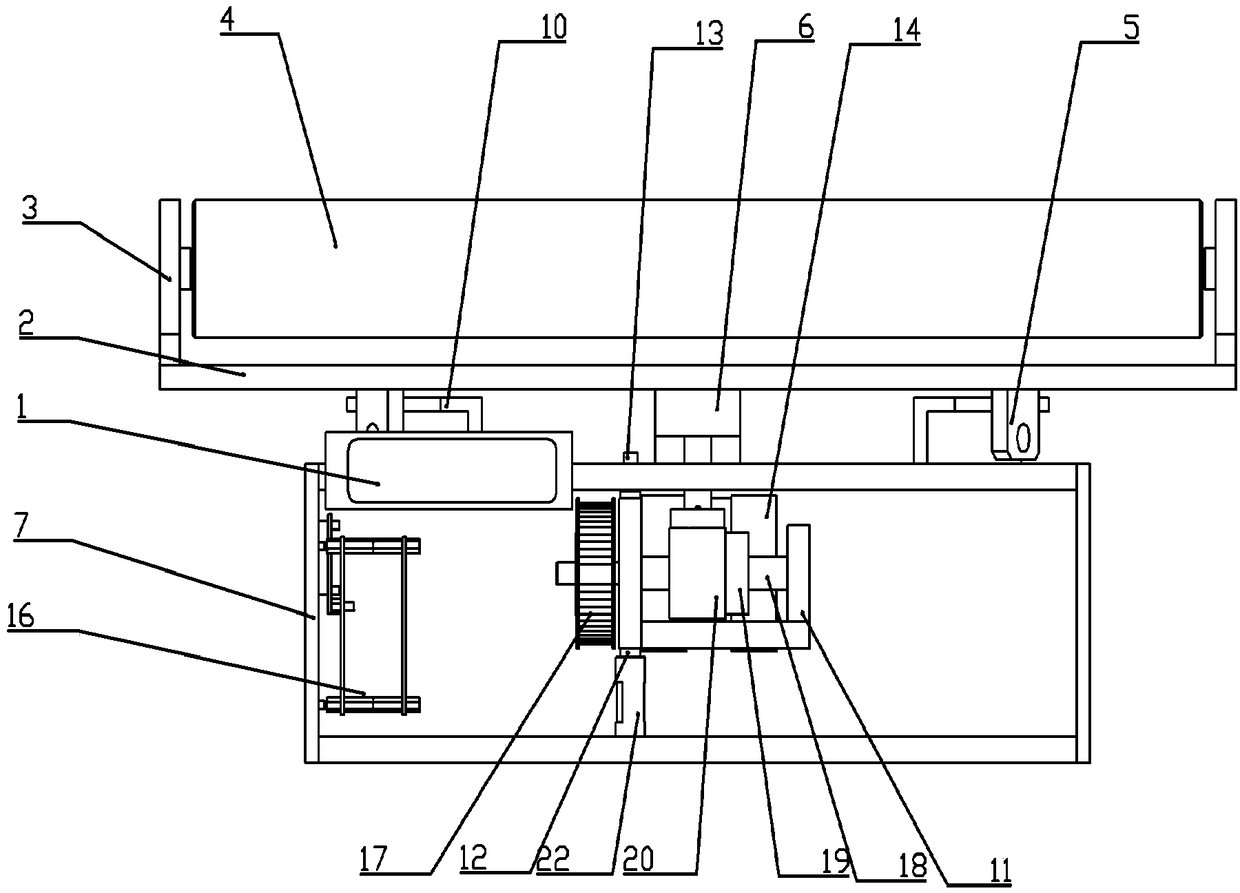

[0027] The reference signs in the drawings of the specification include: correction sensor 1, base 2, installation plate 3, guide roller 4, corner wheel fixing block 5, installation block 6, transmission box 7, support rod 8, first through groove 9, Limiting block 10, housing 11, first fixed rod 12, second fixed rod 13, first motor 14, first gear 15, deviation correction controller 16, second gear 17, screw rod 18, nut 19, push block 20, push rod 21, casing 22.

[0028] Example figure 1 with figure 2 Shown: the coil automatic correction system, including the correction controller 16, the correction sensor 1, the correction guide mechanism and the correction transmission mechanism. Connected to both sides of the base 2, the two ends of the guide roller 4 are rotatably connected to the inner walls of the two mounting plates 3 respectively, and the surface of the guide r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com