Process of treating fluoride and organic matter in drinking water and its electrical flocculator

A treatment method and technology of organic matter, applied in water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the complex operation and management, low removal efficiency, large dosage of fluorine removal, etc. problems, to achieve the effect of reducing costs, simplifying operation and operation and maintenance work, and stabilizing and reliable water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

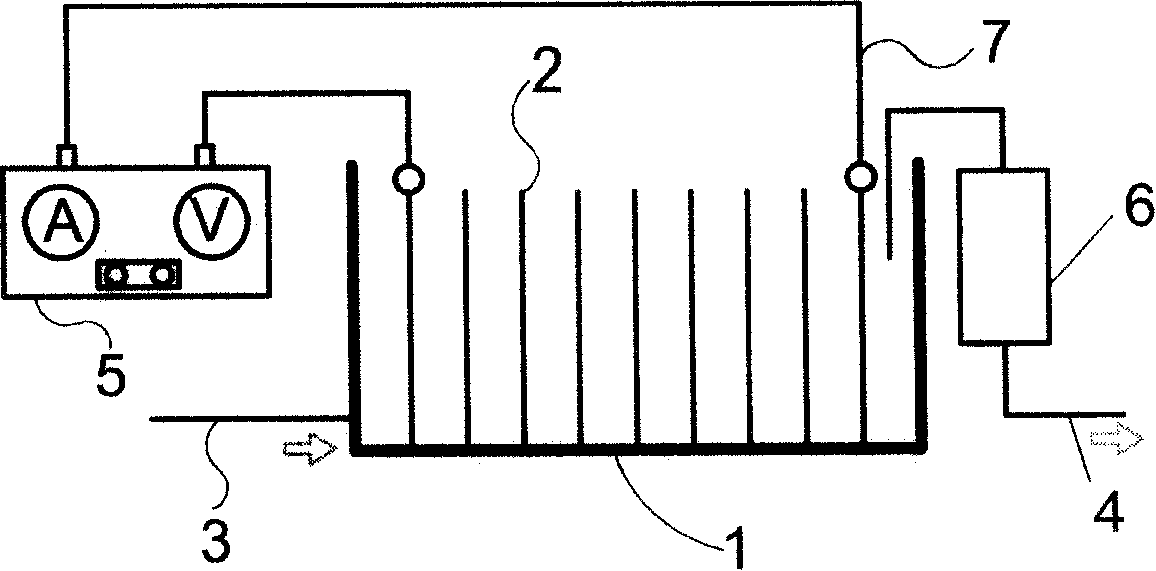

[0030] Example 1: 16 electrode plates are arranged in parallel in the electrolytic cell, the distance between the plates is 1.0 cm, and the current density is 15.7 A / m 2 , the residence time is 20 minutes, under the condition that the influent pH value is 7.2, the fluoride ion concentration is 5.0mg / L, and the organic matter concentration is 8.0mg / L, the effluent water in the electrolytic cell is filtered by the microfiltration membrane module, and the effluent water The fluoride ion concentration of the water is less than 0.8mg / L, which meets the standard of the fluoride ion concentration of less than 1.0mg / L stipulated in the national drinking water hygiene standard GB5749-85. The concentration of organic matter in the effluent is lower than 3.0mg / L.

Embodiment 2

[0031] Example 2: 16 electrode plates are arranged in parallel in the electrolytic cell, the distance between the plates is 0.5cm, and the current density is 5A / m 2 , the residence time is 5 minutes, under the condition that the influent pH value is 7.5 and the fluoride ion concentration is 3mg / L, after the effluent water in the electrolytic cell is filtered by the microfiltration membrane module, the fluoride ion concentration in the effluent water is lower than 0.9mg / L L.

Embodiment 3

[0032] Embodiment 3: 8 electrode plates are arranged in parallel in the electrolytic cell, the distance between the plates is 2.0cm, and the current density is 30A / m 2 , the residence time is 30 minutes, under the conditions of influent pH value of 7.0 and organic matter concentration of 10mg / L, the concentration of organic matter in the effluent water is lower than 5.0mg / L after the effluent water in the electrolytic cell is filtered by the microfiltration membrane module.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com