Self-moving type water jet drilling machine

A water jet, self-moving technology, used in rotary drilling rigs, drilling with liquid/gas jets, drill pipes, etc., can solve the problem of inconvenient, time-consuming and labor-intensive prop erection and movement, increase the weight and volume of the system, and affect the drilling rig. Assembly, disassembly and movement, etc., to achieve the effect of strong chemical reaction resistance, small size and low labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

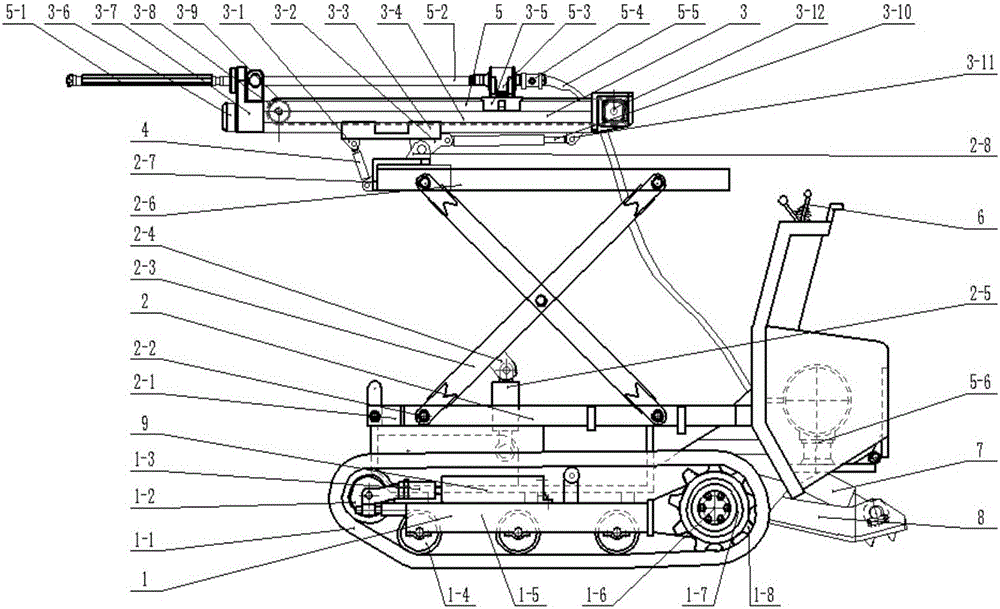

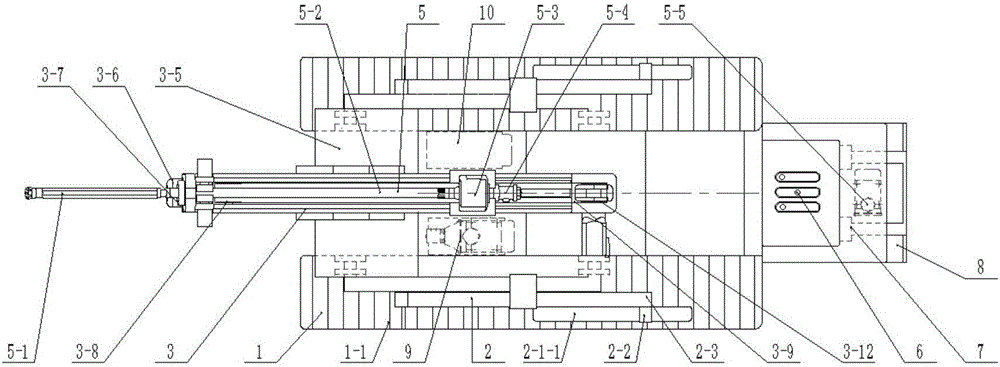

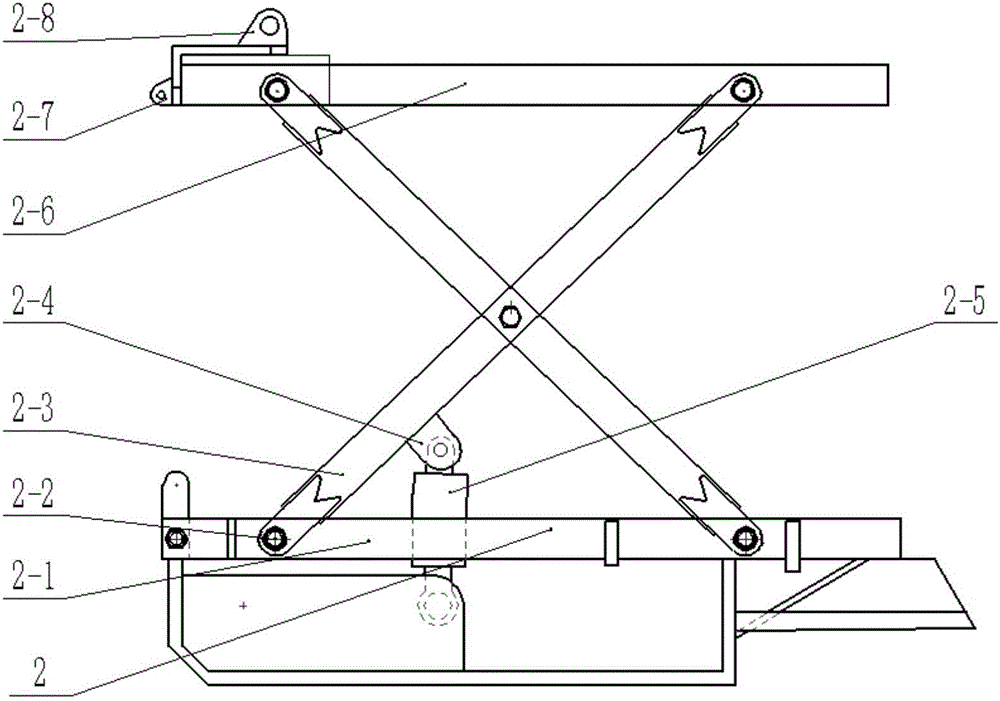

[0022] Examples, see attached Figure 1 to Figure 5 , Self-moving water jet drilling rig consists of walking device 1, lifting device 2, feeding device 3, tilting cylinder 4, water jet drilling device 5, joystick 6, rear support cylinder 7, rear support beam 8, hydraulic pump station 9. The water tank is composed of 10.

[0023] The walking device 1 is composed of a crawler belt 1-1, a tensioning wheel 1-2, a tensioning oil cylinder 1-3, a supporting wheel 1-4, a crawler frame 1-5, a traveling motor 1-6, and a speed reducer 1-7 , sprocket 1-8 composition. The travel motor 1-6 is installed inside the crawler belt 1-1, and the travel motor 1-6 is coaxially connected with the reducer 1-7 and the sprocket 1-8; the travel motor 1-6 rotates under the action of hydraulic oil to drive the deceleration The machine 1-7 rotates, and after inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com