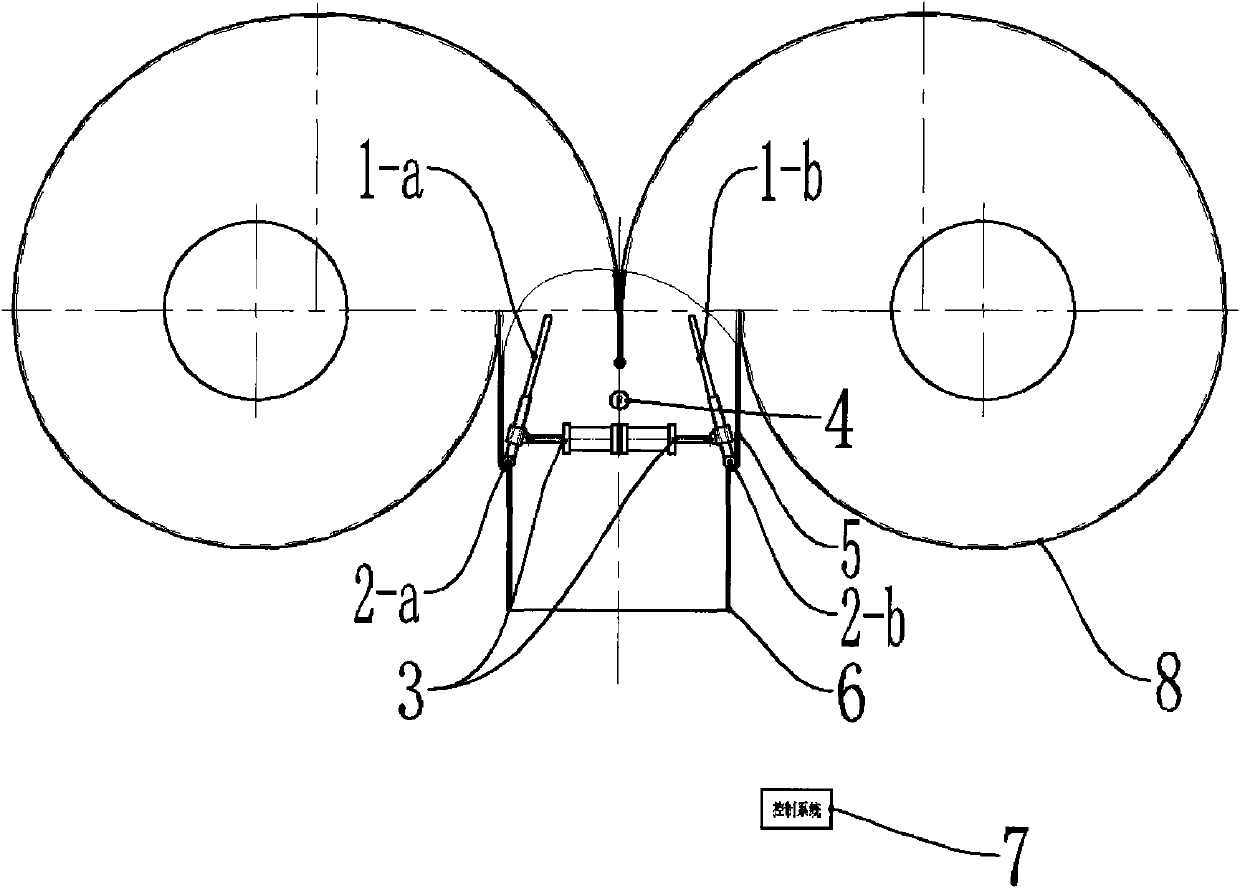

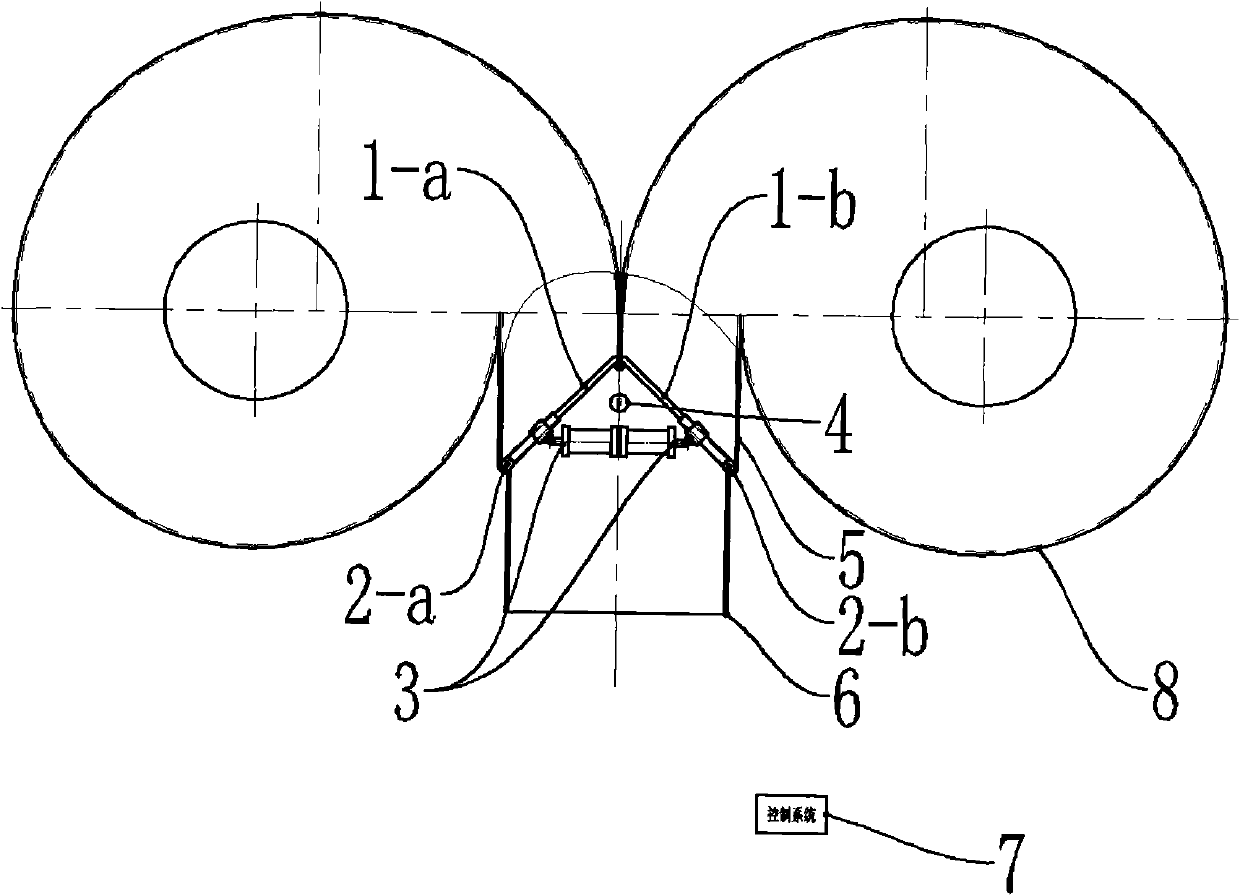

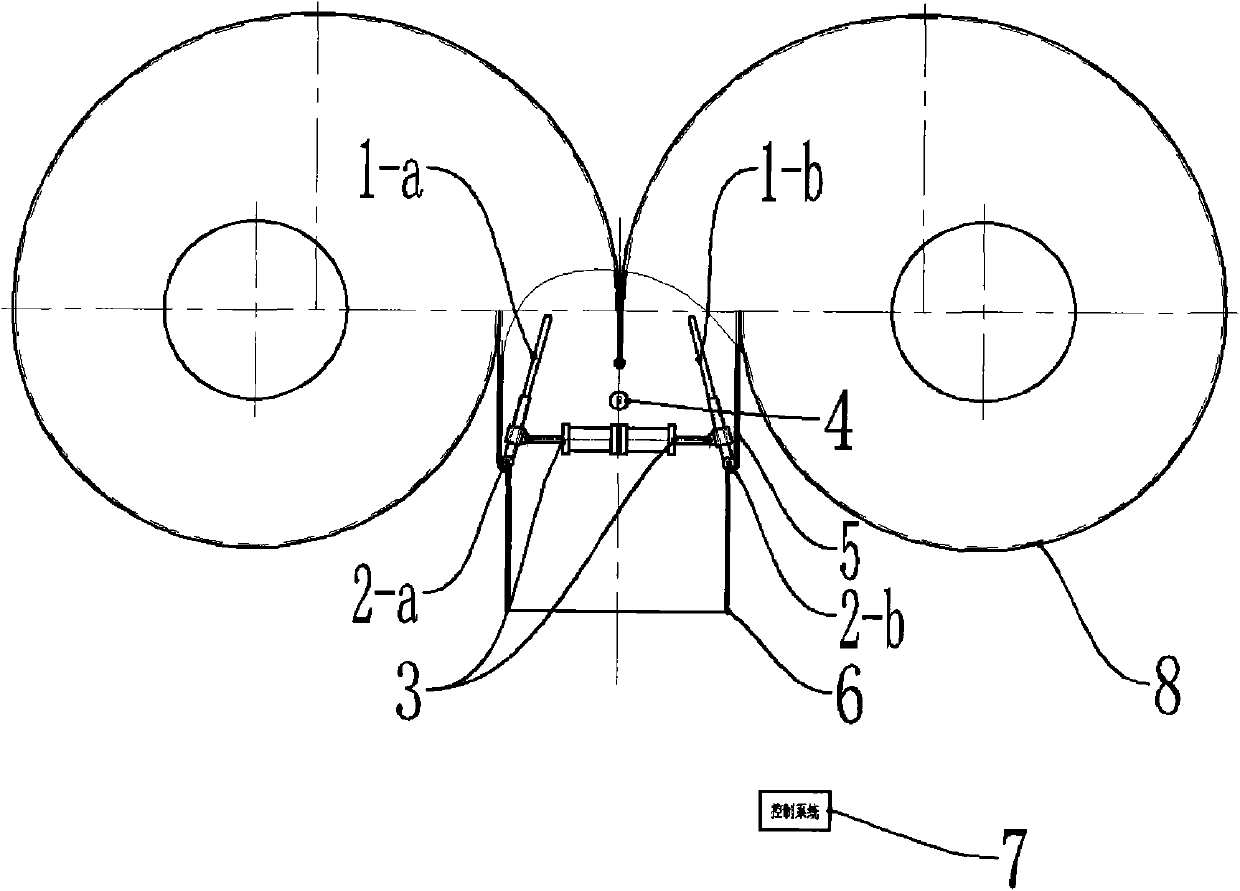

Gas inlet regulating method of double-cyclone dust collector and device thereof

A technology of an adjusting device and an adjusting method, which is applied to a device in which the axial direction of the cyclone can be reversed, a cyclone device, etc., can solve the problems of unstable dust separation effect of the double cyclone dust collector, and difficulty in ensuring the double cyclone dust collector, etc. To achieve the effect of easy automation control, prevention of damage, and reduction of dust processing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] After the spray roasting acid regeneration unit is turned on, the temperature of the roaster is raised. The gas flow rate monitoring unit will feed back the measured flue gas flow rate in the pipeline to the control system in real time. 15-20m / s), give action instructions to the valve plate driving cylinder, and the driving cylinder drives the rotating shaft of the valve plate through the connection between the guide rod and the slider to change the opening of the valve plate. When the flue gas flow rate is adjusted to the flow rate range set by the process, the cylinder will stop moving. It has been verified that during the heating process of the roasting furnace of the spray roasting acid regeneration unit, the dust emission concentration of the chimney of the washing tower can be reduced by more than 50% compared with that without adjustment.

Embodiment 2

[0054] The roasting capacity of the spray roasting acid regeneration unit is changed from 1.0m 3 / h gradually adjusted to 2.5m 3 In the process of / h, the gas flow rate monitoring unit will feed back the measured flue gas flow rate to the control system in real time, and the control system will control the parameters according to the preset process (ie: the flue gas flow rate range is controlled within 18-23m / s) , give the action command to the valve plate driving cylinder, and the driving cylinder drives the rotating shaft of the valve plate through the connection between the guide rod and the slider to change the opening of the valve plate. When the flue gas flow rate is adjusted to the flow rate range set by the process, the cylinder will stop moving. It has been verified that the roasting capacity of the spray roasting acid regeneration unit has increased from 1.0m 3 / h adjusted to 2.5m 3 / h process, after the method is used for adjustment, the dust emission concentrati...

Embodiment 3

[0056] During the shutdown operation of the spray roasting acid regeneration unit, the gas flow rate monitoring unit will feed back the measured flue gas flow rate in the pipeline to the control system in real time. / s), the action command is given to the valve plate drive cylinder, and the drive cylinder drives the rotation shaft of the valve plate through the connection between the guide rod and the slider to change the opening of the valve plate. When the flue gas flow rate is adjusted to the flow rate range set by the process, the cylinder will stop moving. It has been verified that during the shutdown operation of the spray roasting acid regeneration unit, after the method is used for adjustment, the dust emission concentration of the scrubber chimney can be reduced by more than 50% compared with that without adjustment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com