Gas inlet regulating method of double-cyclone dust collector

An adjustment method and an air inlet technology, which are applied in the direction of the device where the axial direction of the swirl can be reversed, the swirl device, etc., to reduce the dust treatment load, facilitate automatic control, and prevent damage

Inactive Publication Date: 2012-05-30

北京钢研新冶工程设计有限公司

View PDF0 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the cross-section of the air inlet of the double-cyclone dust collector is constant, so it is difficult to ensure that the air inlet of the double-cyclone dust collector enters the air at the best air velocity, resulting in unstable dust separation effect of the double-cyclone dust collector

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0053] Embodiment two

Embodiment 2

[0055] Embodiment three

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

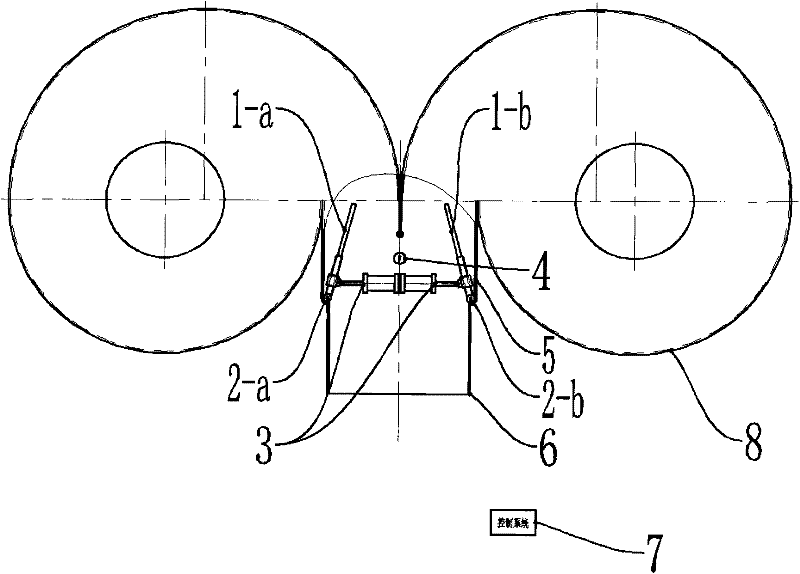

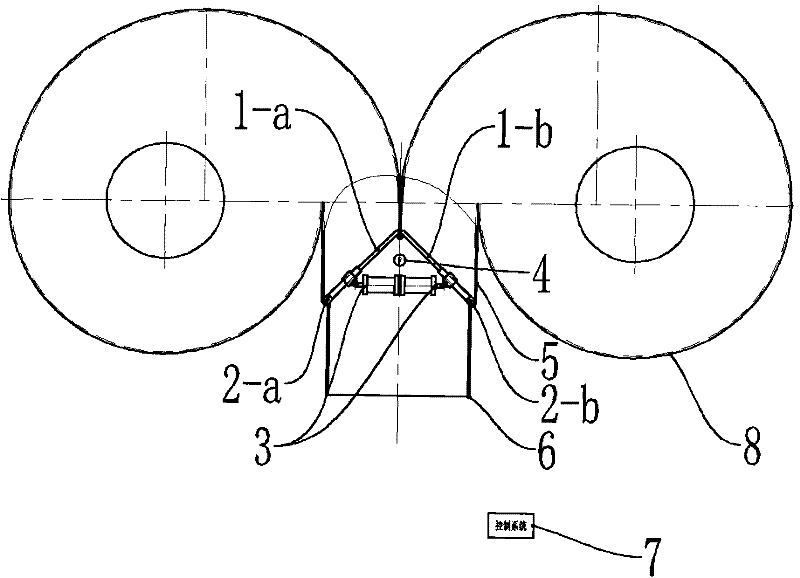

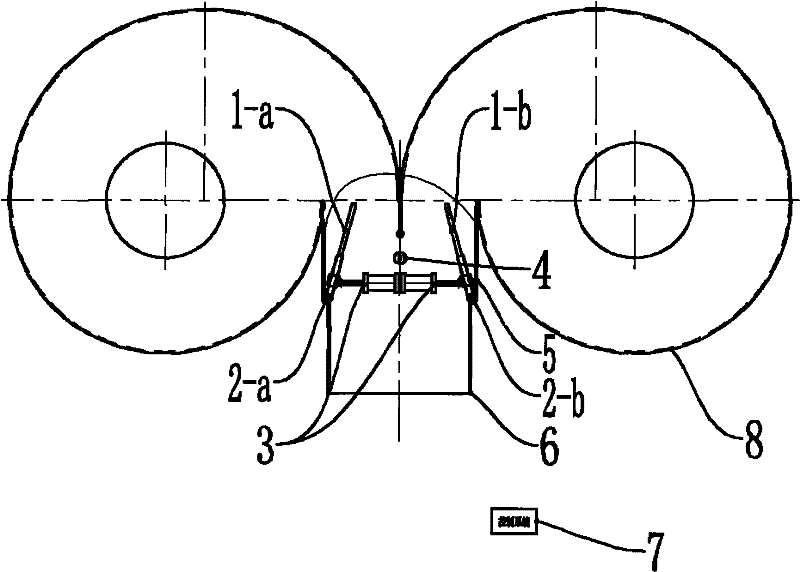

The invention relates to a method for regulating a gas inlet regulating device of a double-cyclone dust collector, including the following steps: (a) a gas flow rate monitoring unit (4) feeding back measured air inlet pipeline flue gas flow rate of the double-cyclone dust collector (8) in real time to a control system (7); (b) the control system (7) issuing a command to a valve plate opening drive device (3) according to a preset flue gas flow rate range; (c) the valve plate opening drive device (3) regulating the opening of a first valve plate (1-a) and a second valve plate (1-b), regulating the cross section of an air inlet of the double-cyclone dust (8) or turning off the air inlet, further changing the flue gas flow rate to the preset flow rate range; (d) when the flue gas flow rate is regulated within the preset flue gas flow rate range, the valve plate opening drive device (3) stopping working. The regulating method of the invention can optimize the working condition at the air inlet of the double-cyclone dust collector and improve the efficiency of the double-cyclone dust collector under different working conditions.

Description

technical field [0001] The invention relates to a method for adjusting an air inlet of a double cyclone dust collector, which is mainly used in an acid regeneration unit of a spray roasting method, and is also applicable to other cyclone dust removal equipment used for processing dust-containing flue gas. Background technique [0002] Acid regeneration by spray roasting method is a resource recovery technology for waste acid produced in the strip pickling process, and it is widely used at present. The double cyclone dust collector is an important equipment of the acid regeneration unit of the spray roasting method, which is mainly used to separate the iron oxide powder particles in the roasting flue gas. The equipment's separation efficiency of iron oxide powder will directly affect the dust treatment effect of downstream process equipment and the dust concentration in the exhaust gas from the chimney of the scrubber. [0003] Among the many factors affecting the dust remo...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B04C5/02

CPCB04C5/04B04C5/28

Inventor 张振林王海林苏泽杨绿郭振英

Owner 北京钢研新冶工程设计有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com