Patents

Literature

34results about How to "Reduce oxygenation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

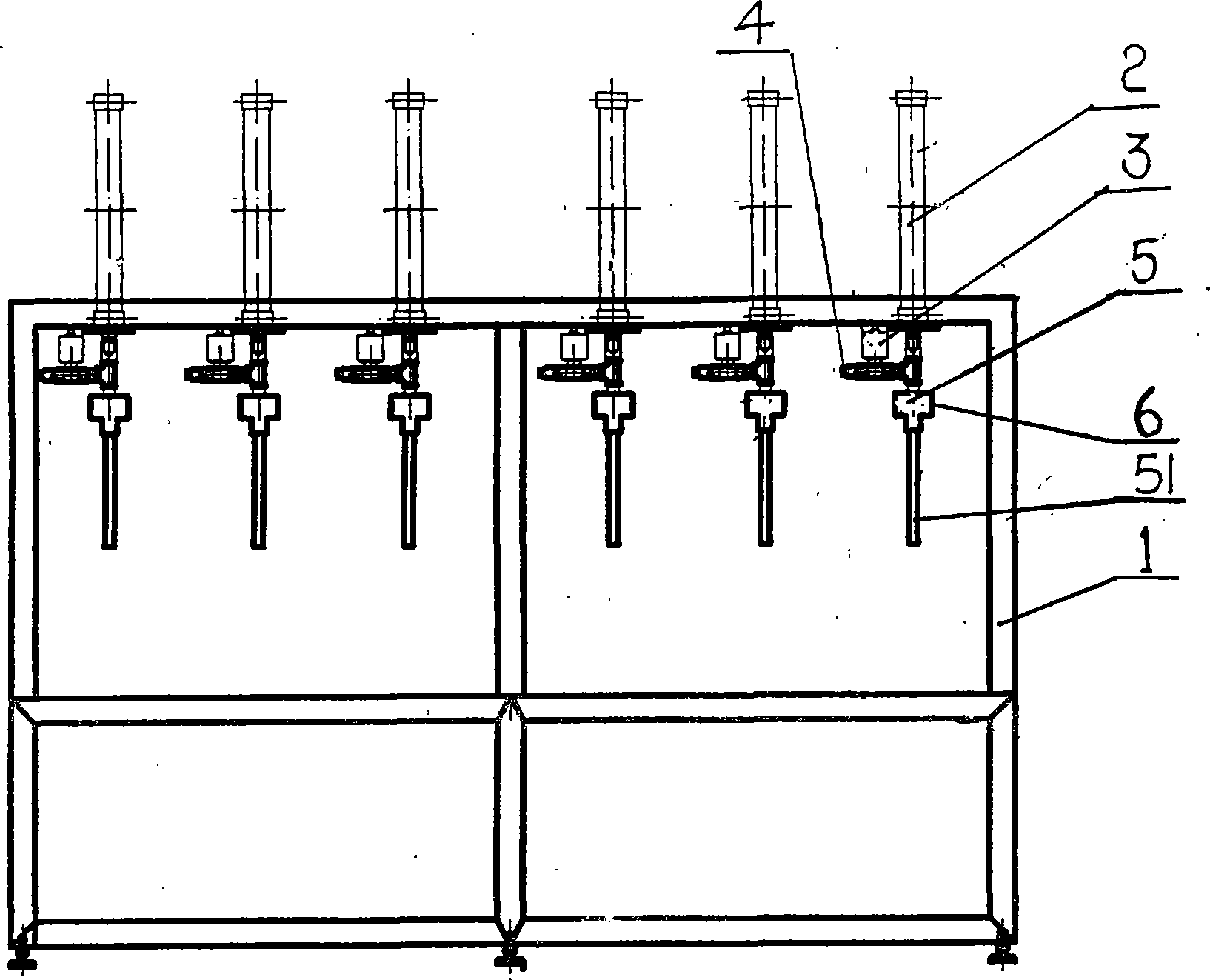

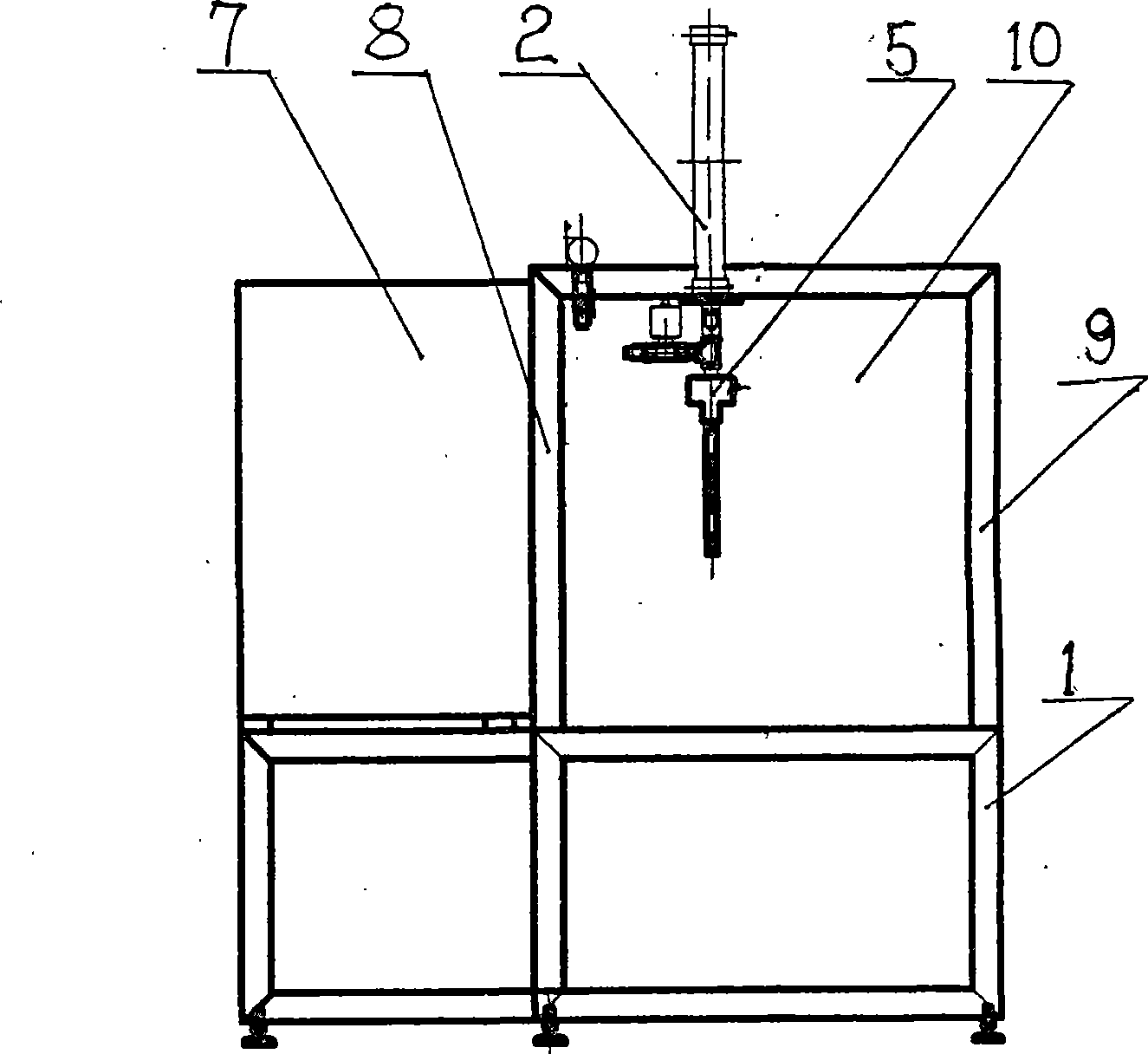

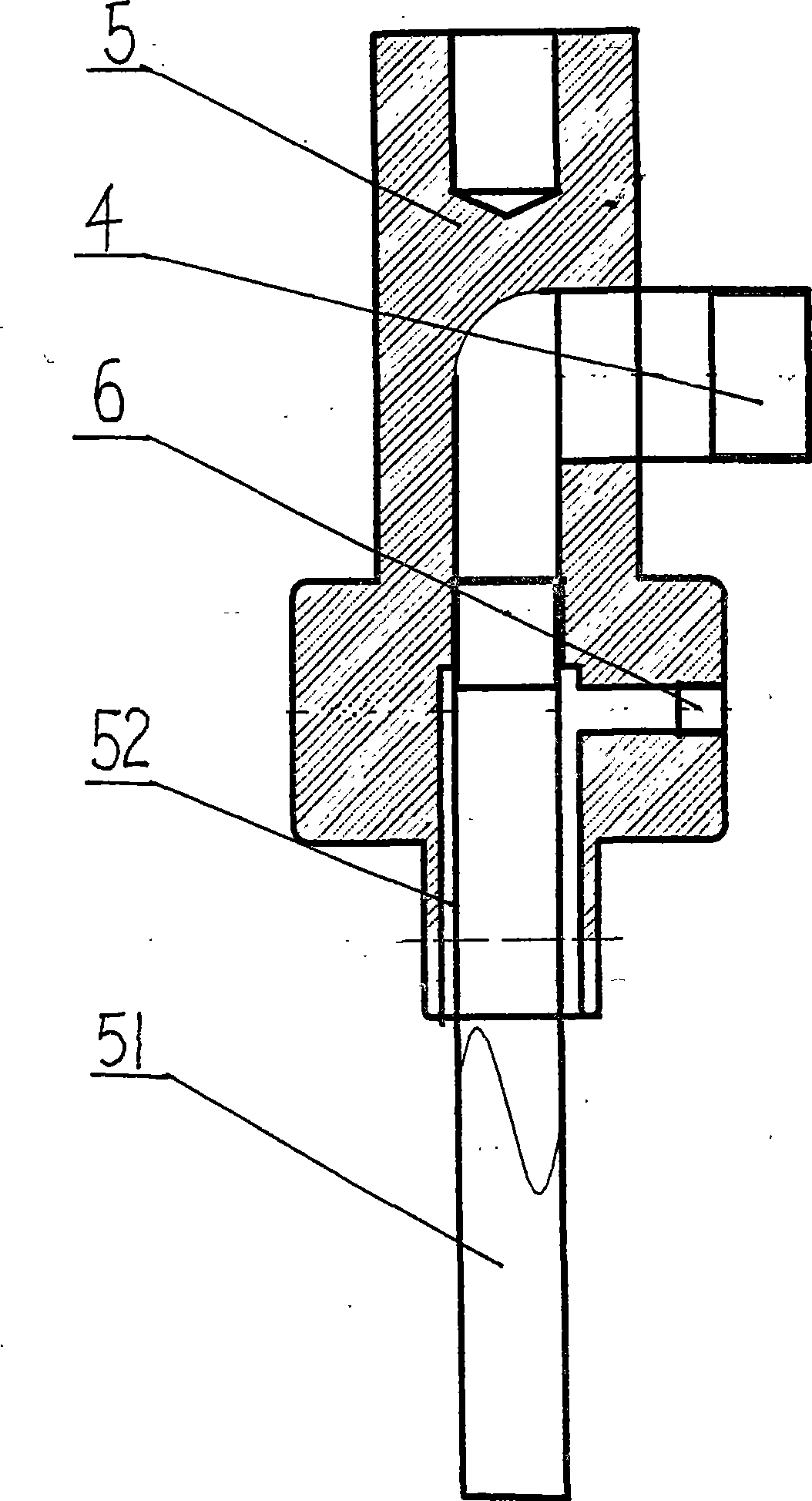

Beer sterilized bottle filler

InactiveCN101391735AReduce usageReduce oxygenationLiquid fillingBottle-handling machinesPositive pressureSolenoid valve

The invention discloses a beer aseptic filling machine which belongs to the light industrial machinery field and aims to solve the defects of the existing equipments that the universality is poor and the cost is high. The beer aseptic filling machine comprises a frame and a filling mechanism arranged on the frame and is characterized in that: the filling mechanism comprises lifting-controllable filling heads; the filling heads are connected with beer inlets controlled by solenoid valves; the beer inlets are communicated with long tubes provided with bottom ends adjacent to bottoms of filling containers; clearances are arranged at the lower ends of the jointing parts between the filling heads and the long tubes and the clearances are communicated with vents arranged on the filling heads; both the filling heads and the long tubes are arranged in the aseptic positive-pressure environment formed by an air outlet of a film filtration fan. The filling machine can realize the automatic aseptic filling and the cleaning is convenient and thorough without dead angles, the universality is better, the cost is low, therefore the beer aseptic filling machine can be applicable to various small and medium size containers for realizing the aseptic filling of beer or beverage.

Owner:济南百脉泉啤酒饮品有限公司

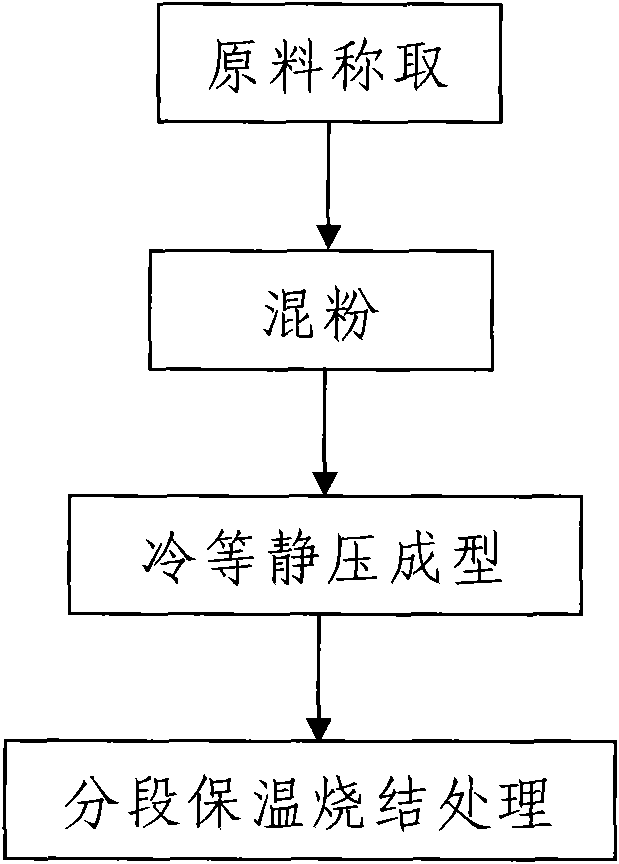

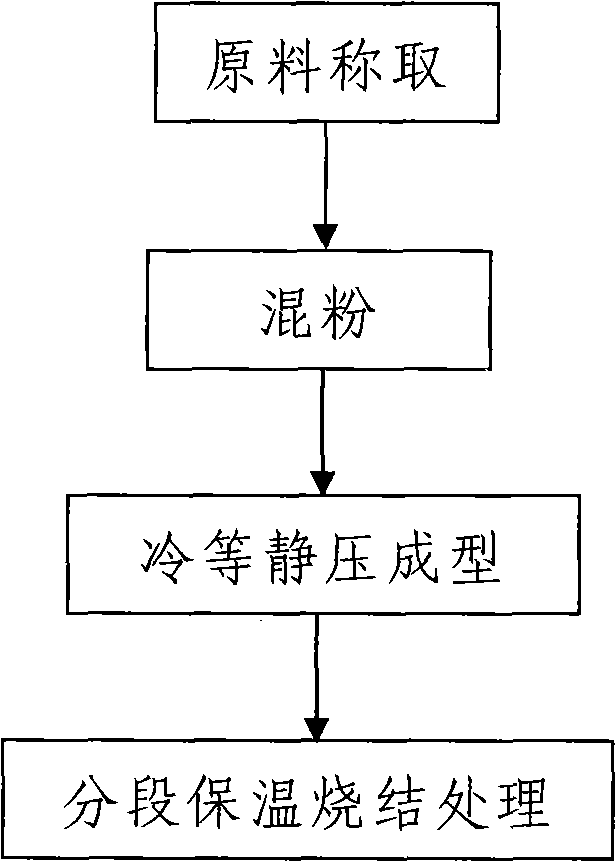

Method for preparing large powder metallurgy TZM blank with uniform carbon and oxygen distribution

The invention discloses a method for preparing a large powder metallurgy TZM blank with uniform carbon and oxygen distribution, which comprises the following steps of: 1, weighing raw materials; 2, mixing powder, namely mixing the weighed four raw materials twice under vacuum or the protection of inert gas, mixing titanium hydride powder, zirconium hydride powder and carbon black powder to prepare mixed powder, adding a volatile organic solvent into the mixed powder, uniformly stirring to prepare suspension, adding the weighed molybdenum powder into the suspension for uniform mixing, and adding residual molybdenum powder for uniform mixing; 3, performing cold isostatic pressing; and 4, sintering by keeping the temperature at stages, namely adopting a vacuum sintering furnace and sintering at three stages, wherein the process comprises the following steps of: raising the temperature at the first stage, raising the temperature at the second stage, and sintering at high temperature. The preparation method has the advantages of reasonable design, simple and convenient operation, and good using effect. The carbon content in the center and on the surface of the prepared larger-size TZM blank can be controlled to be approximately consistent, and the oxygen content in the center and on the surface of the TZM blank also can be reduced to a lower level.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

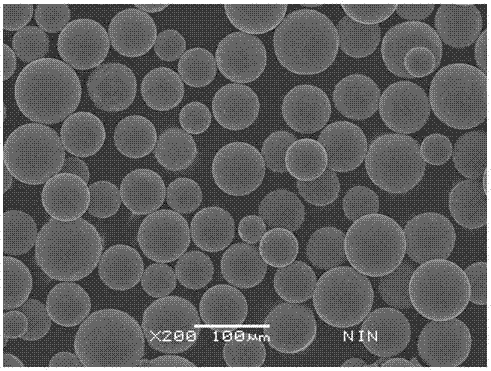

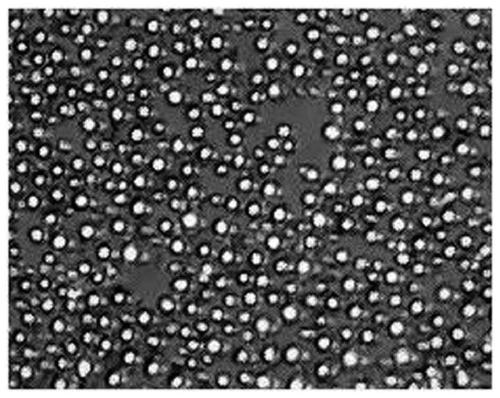

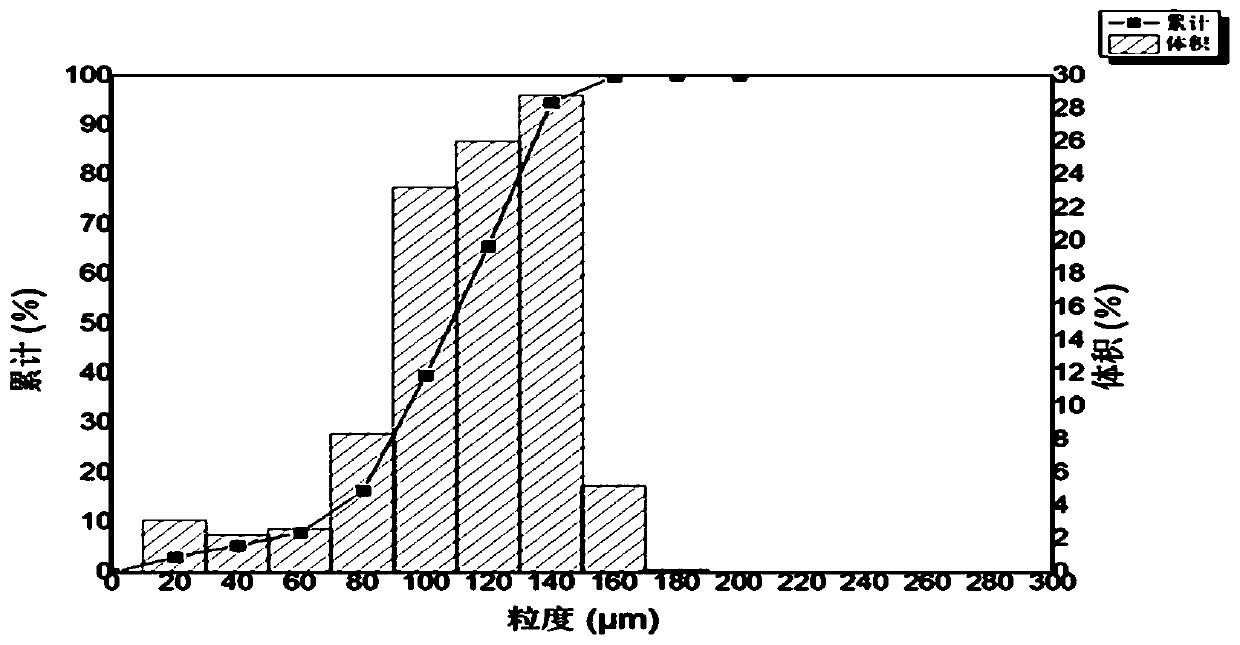

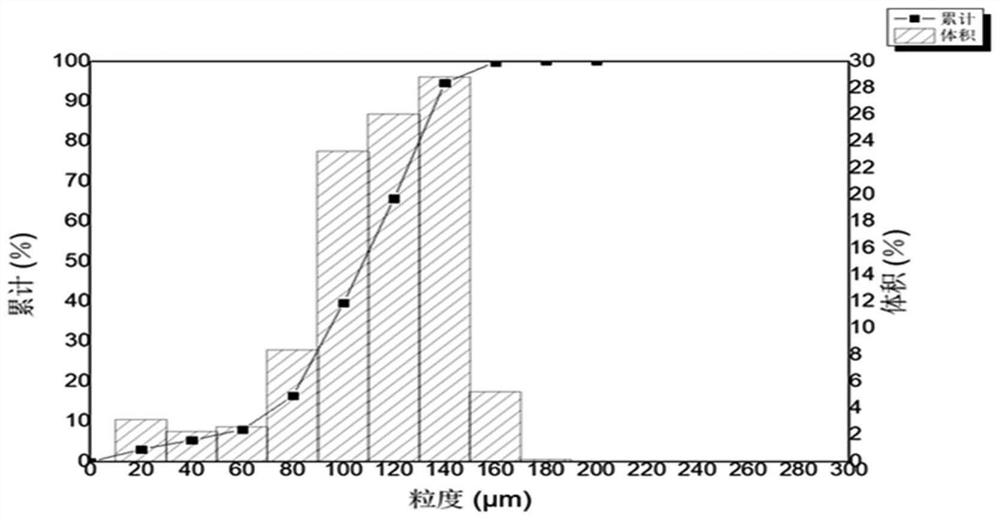

Preparation method of high-quality gamma-TiAl spherical powder

A preparation method of high-quality gamma-TiAl spherical powder comprises the following steps that (1) a gamma-TiAl alloy bar is smelted according to ingredient compounding of a gamma-TiAl base alloy; (2) the smelted gamma-TiAl alloy bar is subjected to forging so as to remove internal defects, and stress relief annealing is performed; (3) annealed gamma-TiAl alloy bar is subjected to finish turning processing to obtain a high-precision alloy bar; (4) the gamma-TiAl alloy bar is loaded to a reaction chamber, and the reaction chamber is vacuumized and filled with inert gas; (5) the end part of the high-precision alloy bar is heated by PREP powder making equipment, atomized drops are thrown away from the end part of the alloy bar, the drops are cooled rapidly into spherical particles in the inert gas environment, and the spherical particles fall into a collector; (6) prepared gamma-TiAl alloy powder is screened and packaged in the inert gas protection environment; (7) the gamma-TiAl alloy powder prepared with the method has the advantages that the degree of sphericity is high, the oxygen increase is low, no mixing exists, and the particle distribution is controllable.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

Restenosis therapy using mesenchymal stem cells

InactiveUS20050233443A1Prevent restenosisNarrows the vessel lumenPeptide/protein ingredientsArtificial cell constructsThrombusStent implantation

The present invention relates to methods for treating restenosis using mesenchymal stem cells, and in particular to treating restenosis following vascular surgery (e.g., angioplasty, stent implantation, rotoblation, atheroectomy, thrombectomy, or grafting).

Owner:BOSTON SCI SCIMED INC

Restenosis Therapy Using Mesenchymal Stem Cells

InactiveUS20070219526A1Prevent restenosisNarrows the vessel lumenPeptide/protein ingredientsMedical devicesStent implantationPercent Diameter Stenosis

The present invention relates to methods for treating restenosis using mesenchymal stem cells, and in particular to treating restenosis following vascular surgery (e.g., angioplasty, stent implantation, rotoblation, atheroectomy, thrombectomy, or grafting).

Owner:BOSTON SCI SCIMED INC

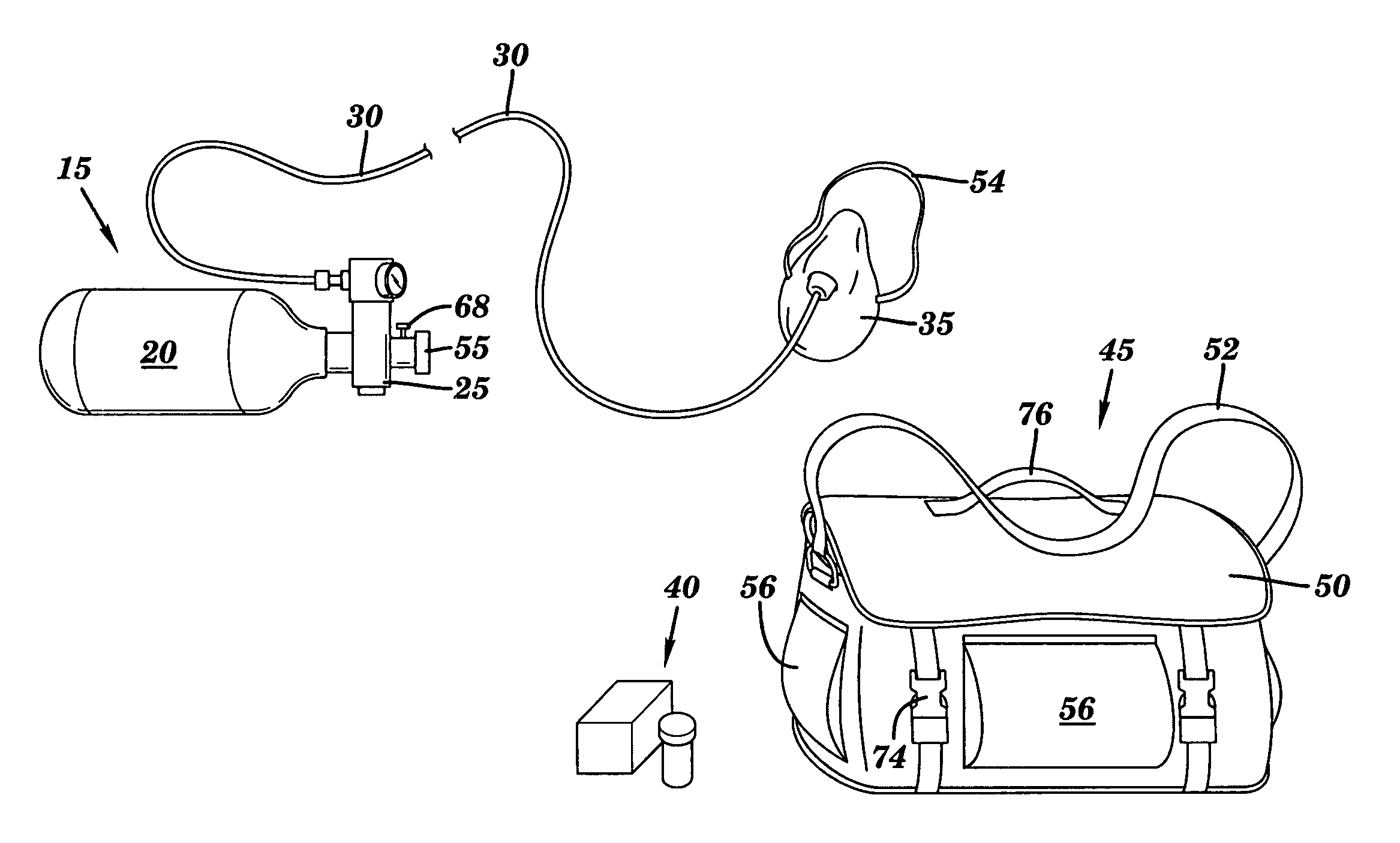

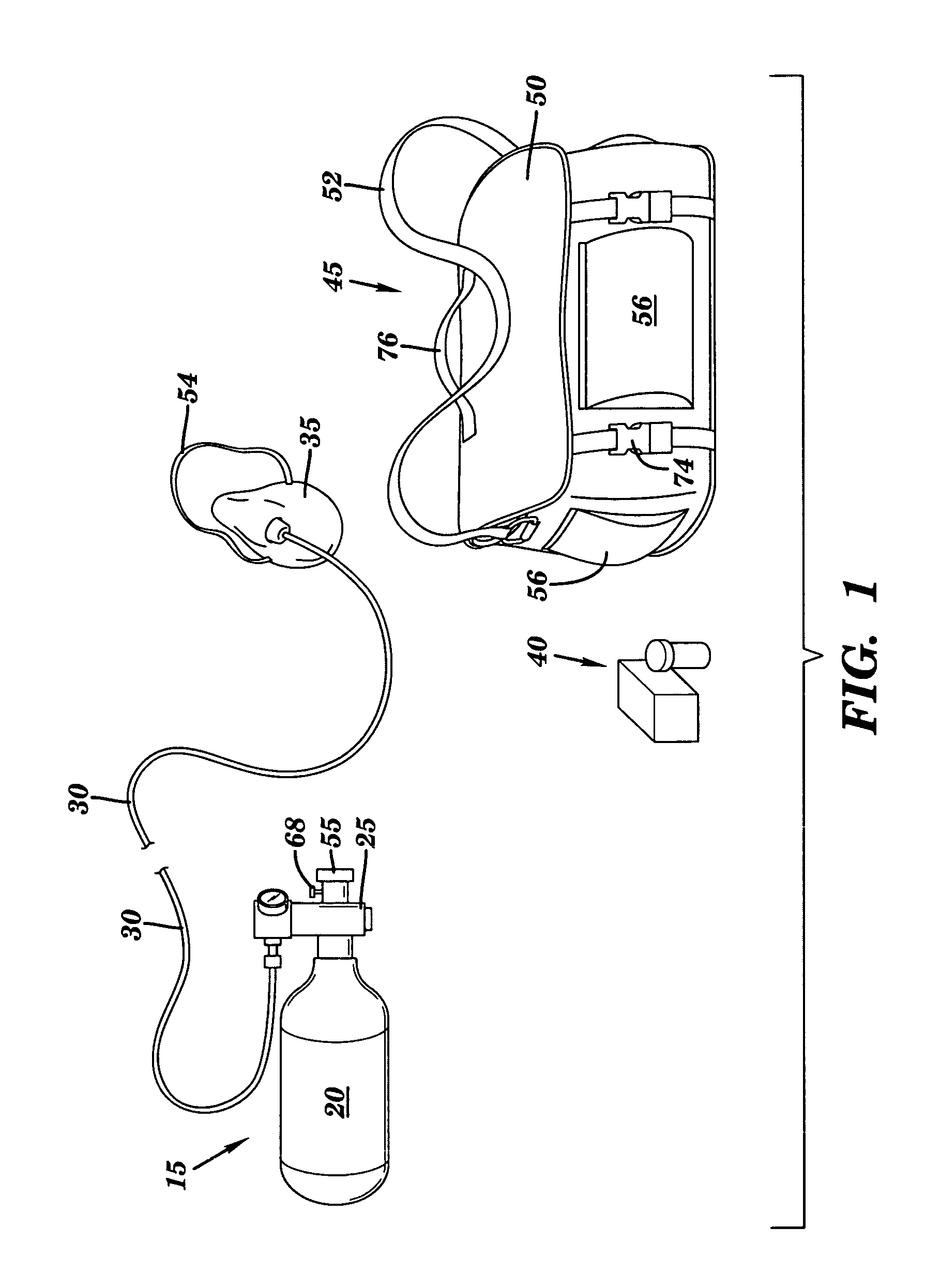

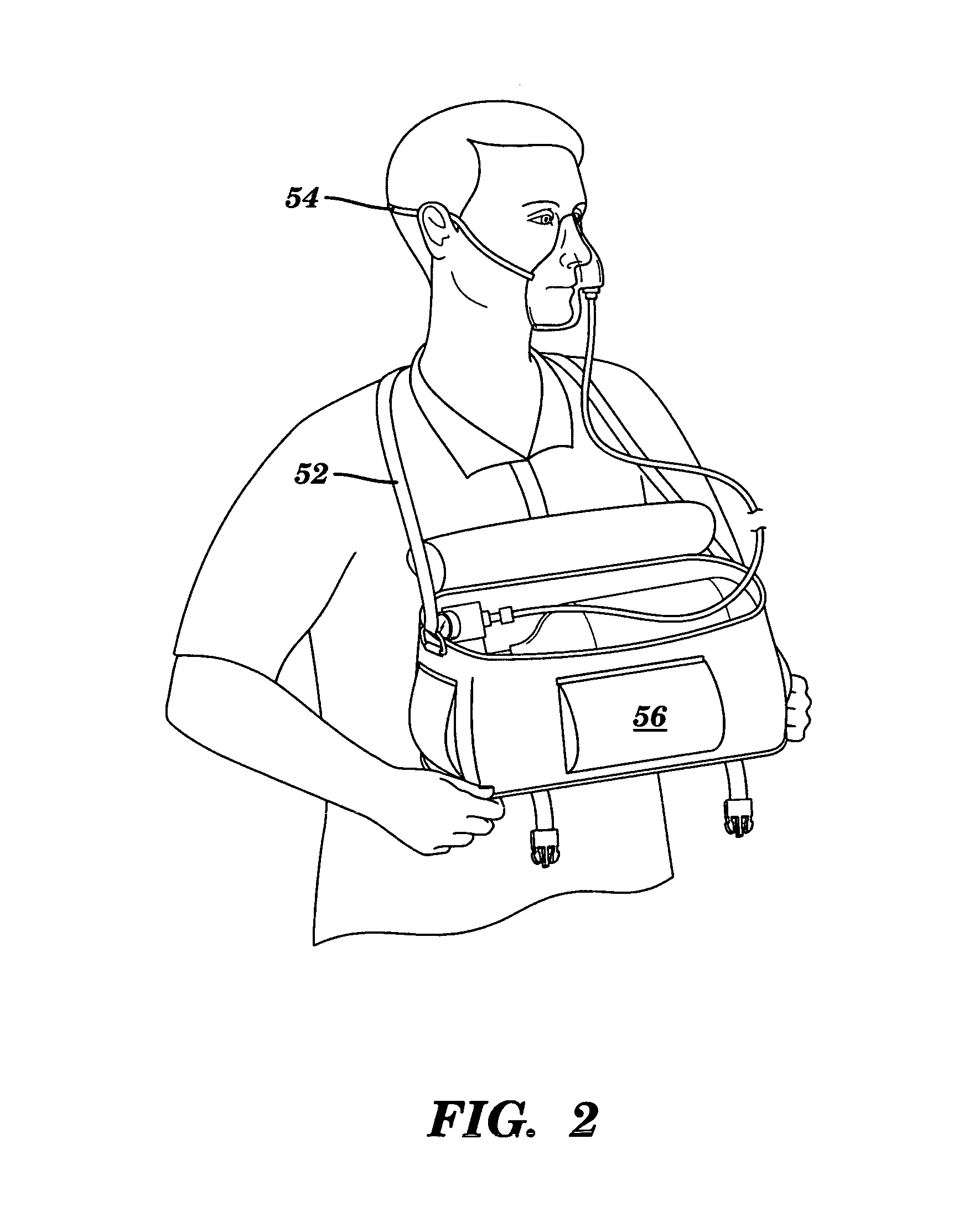

Patient usable emergency medical kit

The invention provides an emergency medical kit for use immediately upon the onset of symptoms of an attack of a vascular disease such as a heart attack or a stroke. The emergency medical kit at least includes breathable oxygen in a light weight container and may include medications for preventing thrombosis, inducing arteriolar relaxation or assisting in diminishing oxygen demand by the victim. The kit including oxygen and medication dosage may be prescribed by a physician to a person with a known susceptibility to a serious unexpected attack of a vascular disease. The treatment provided by the contents of the kit is specifically intended to save the life of an attack victim and or to reduce permanent tissue damage in the victim during the time interval between the onset of the attack and the arrival of a professional medical service provider. The kit is lightweight and readily carried by the user or stored in a location for easy access.

Owner:SPRUIELL GRAHAM LINDLEY

ADMINISTRATION OF GLUTATHIONE (REDUCED) VIA INTRAVENOUS OR ENCAPSULATED IN LIPOSOME FOR THE AMELIORATION OF TNF-alpha EFFECTS AND FLU-LIKE VIRAL SYMPTOMS AND TREATMENT AND PREVENTION OF VIRUS

InactiveUS20070077258A1Improve edemaReduce oxygenationSsRNA viruses negative-senseBiocideWhole bodyTumor necrosis factor alpha

The invention is a method of treatment of the symptoms related to inflammation that accompanies the release of Tumor Necrosis Factor-alpha in diseases such as viral infection such as those affecting the respiratory tract by providing systemic glutathione (reduced) by oral administration of glutathione (reduced) in a liposome encapsulation or by the intravenous administration of reduced glutathione. The administration of a therapeutically effective amount of oral liposomal glutathione (reduced) results in improvement of symptoms of disease induced by the release of TNF-α in infectious disease states such as respiratory and other viruses. The product is novel in that it is stable across the temperature ranges encountered in shipping and does not need to be refrigerated for storage. Compounds enhancing the effect of the liposomal glutathione as well as intravenous glutathione are contemplated such as Selenium.

Owner:GUILFORD F TIMOTHY

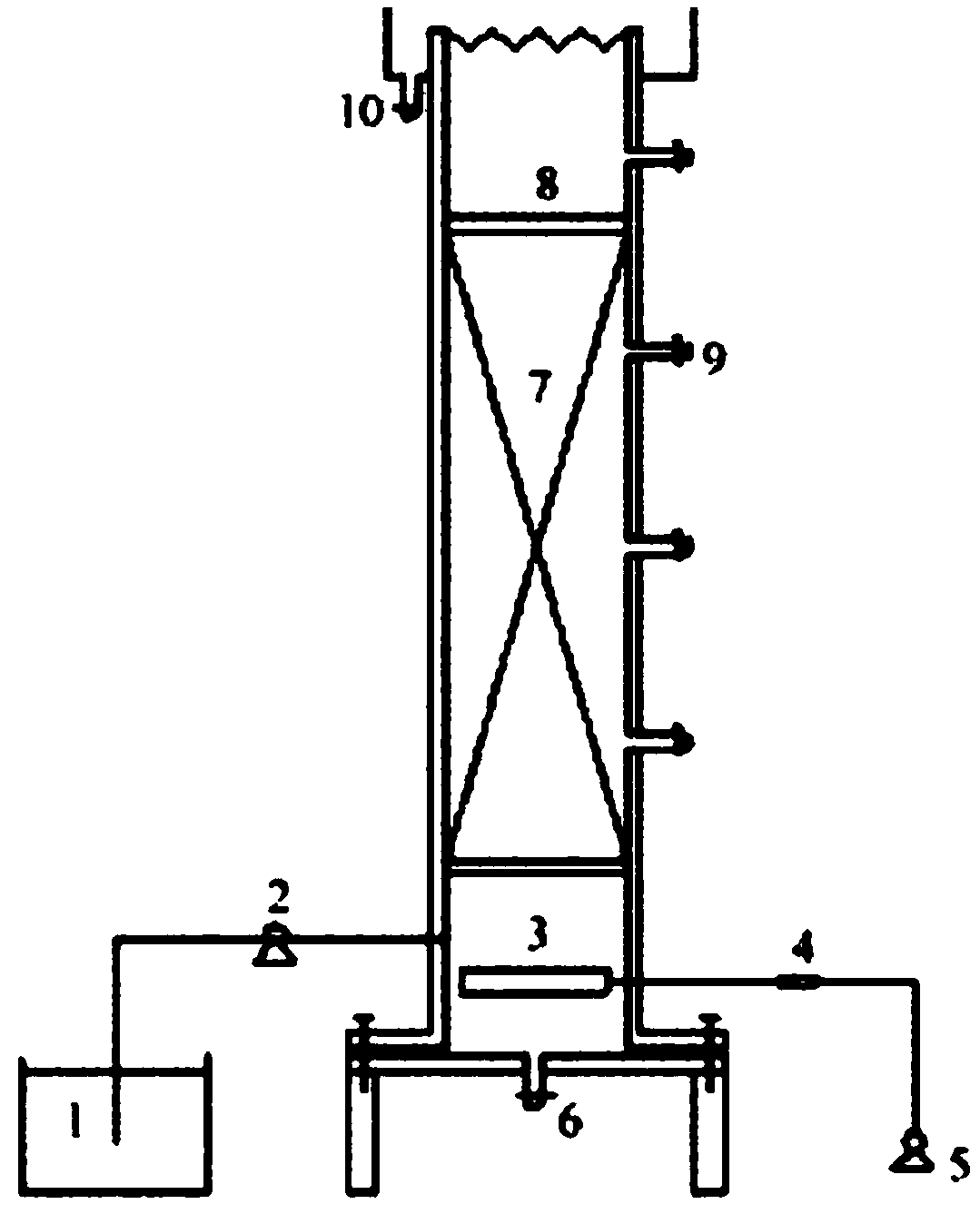

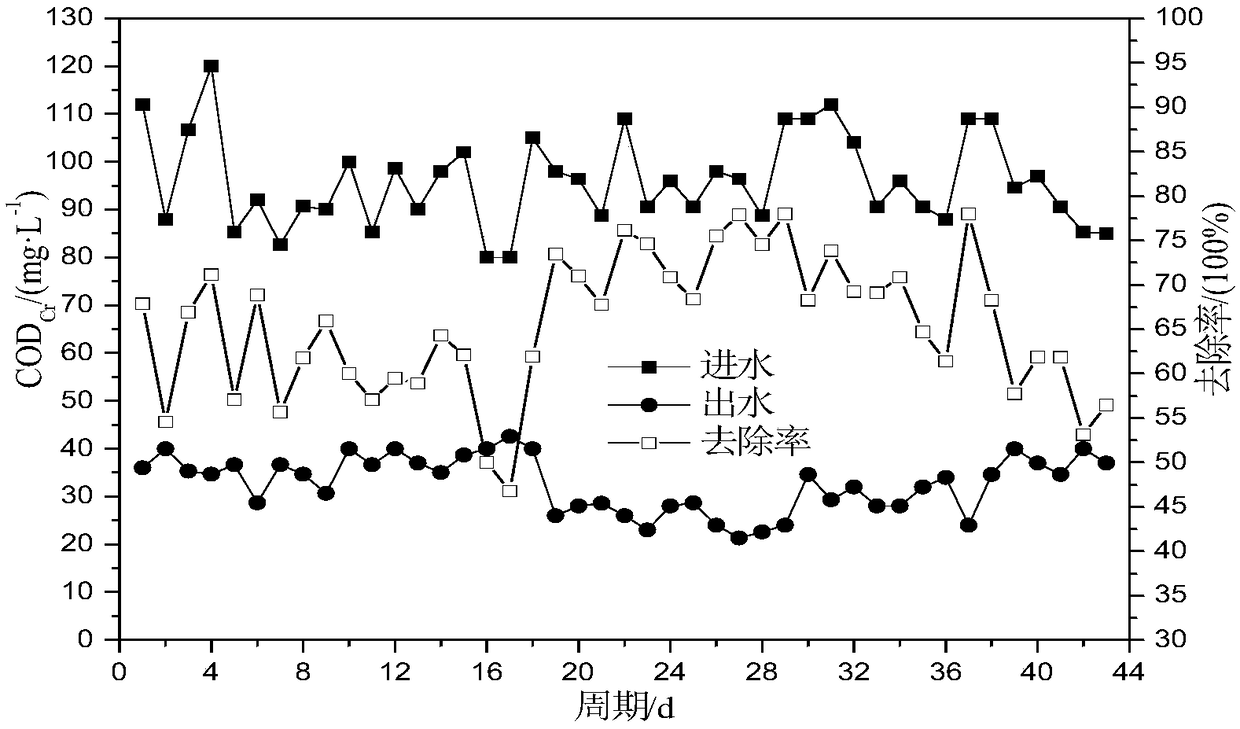

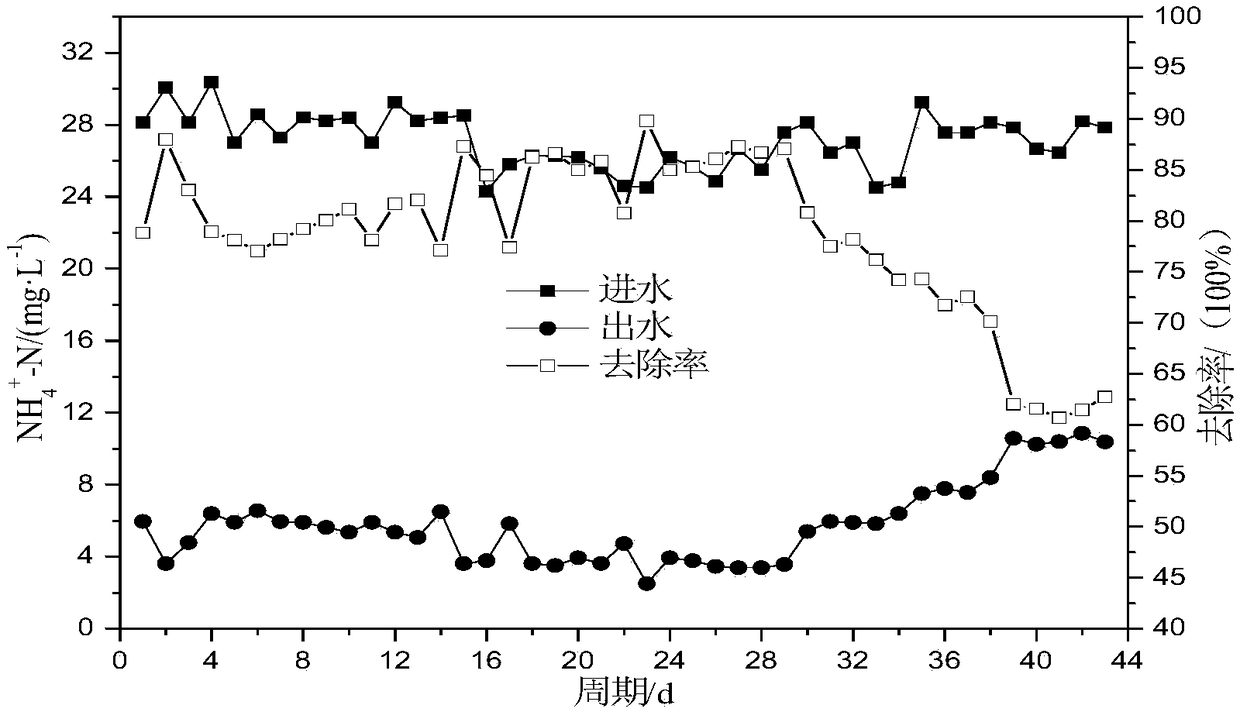

Treatment method for low-carbon-source domestic wastewater

InactiveCN103030254AImprove biodegradabilityFully degradedMultistage water/sewage treatmentExpanded clay aggregateOxygen

The invention discloses a treatment method for low-carbon-source domestic wastewater, wherein the domestic wastewater is treated through a dual-membrane process of anaerobic hydrolysis of a biological membrane zeolite and a fluidized ceramsite biological membrane filter, that is to say, the natural zeolite which is cultured by a biological membrane is taken as a filler to decompose organic matters hard to degrade in the wastewater into low molecular weight organic matters easy to degrade through the metabolism of anaerophyte, then the ceramsite is taken as a carrier to conduct aerobic treatment, and the biological membrane formed on the surface of the ceramsite fully degrades the organic matters in the wastewater. According to the invention, the carbon source in the wastewater is effectively utilized, so that a good nitrogen and phosphorus removal effect is achieved without adding any organic carbon source trophoplasm in the treatment of the low-carbon-source domestic wastewater.

Owner:GUANGZHOU UNIVERSITY

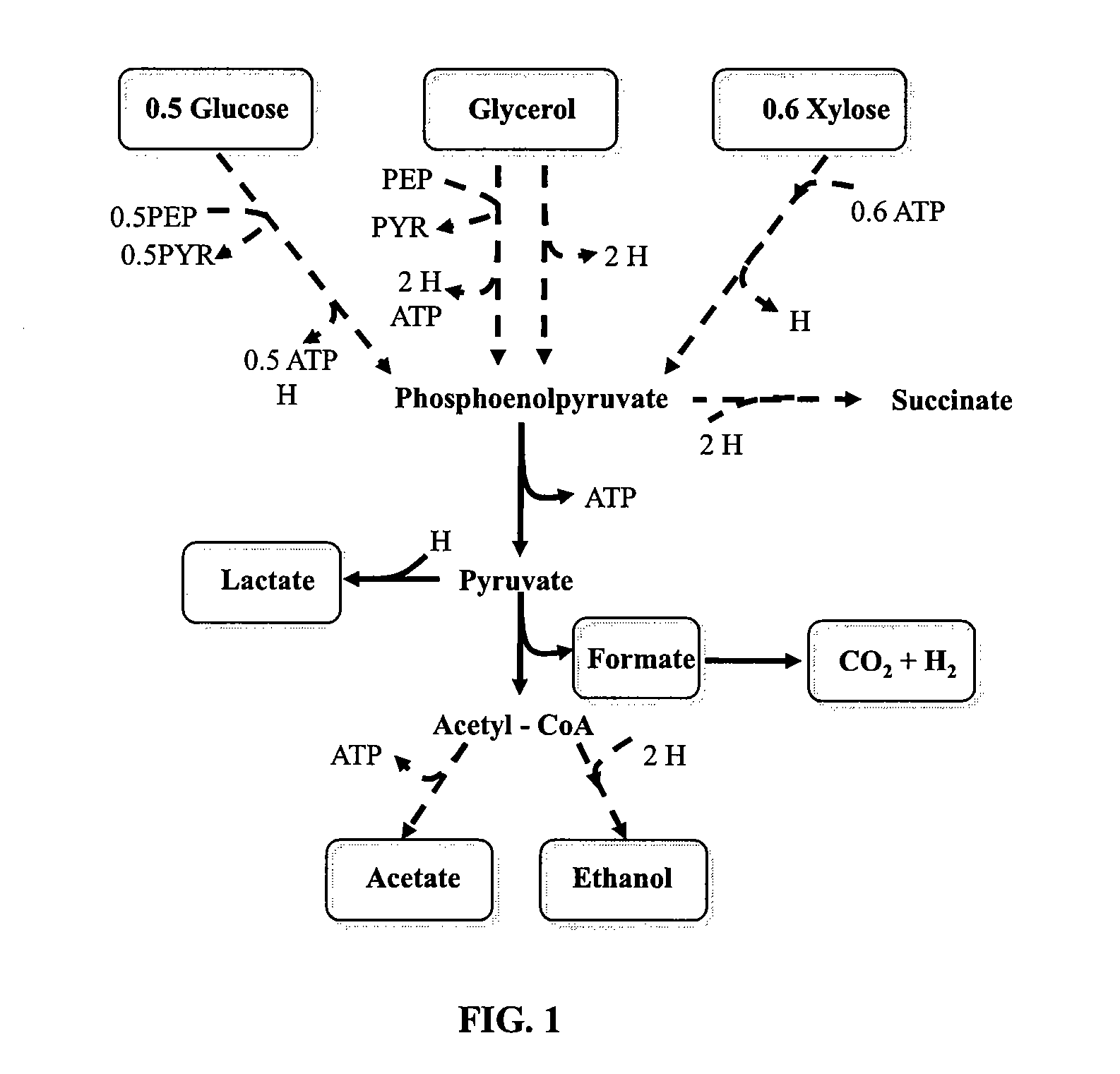

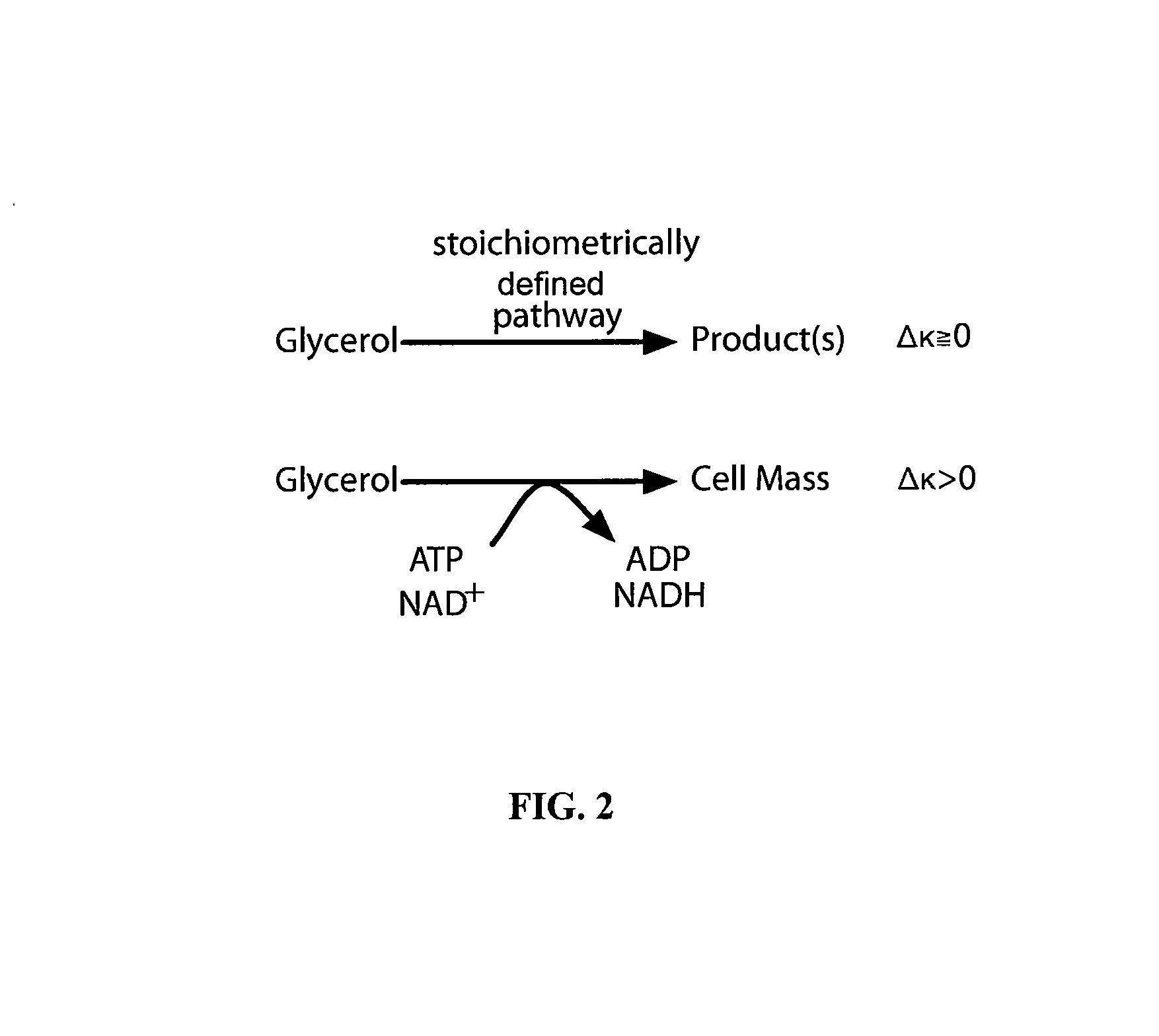

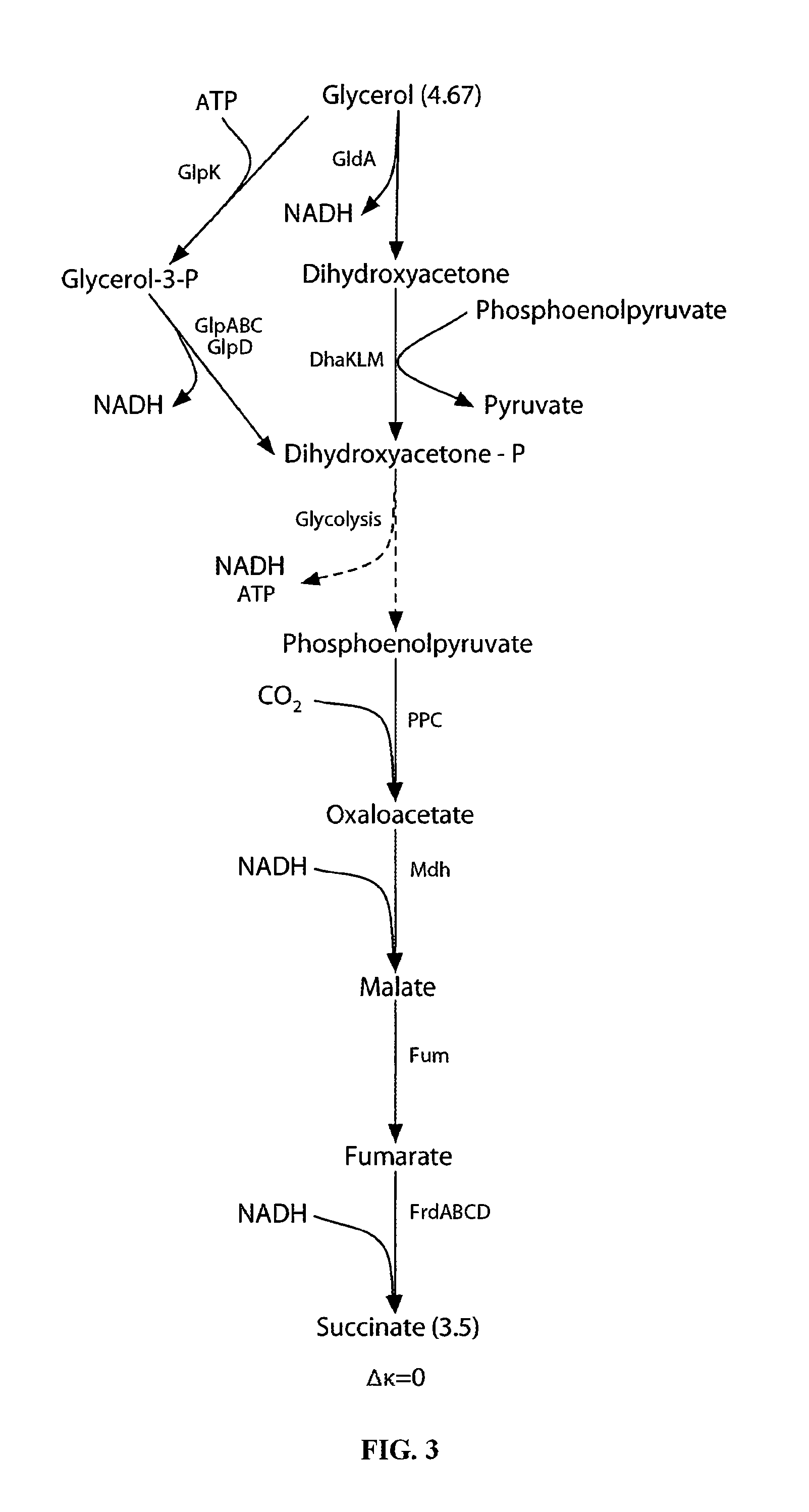

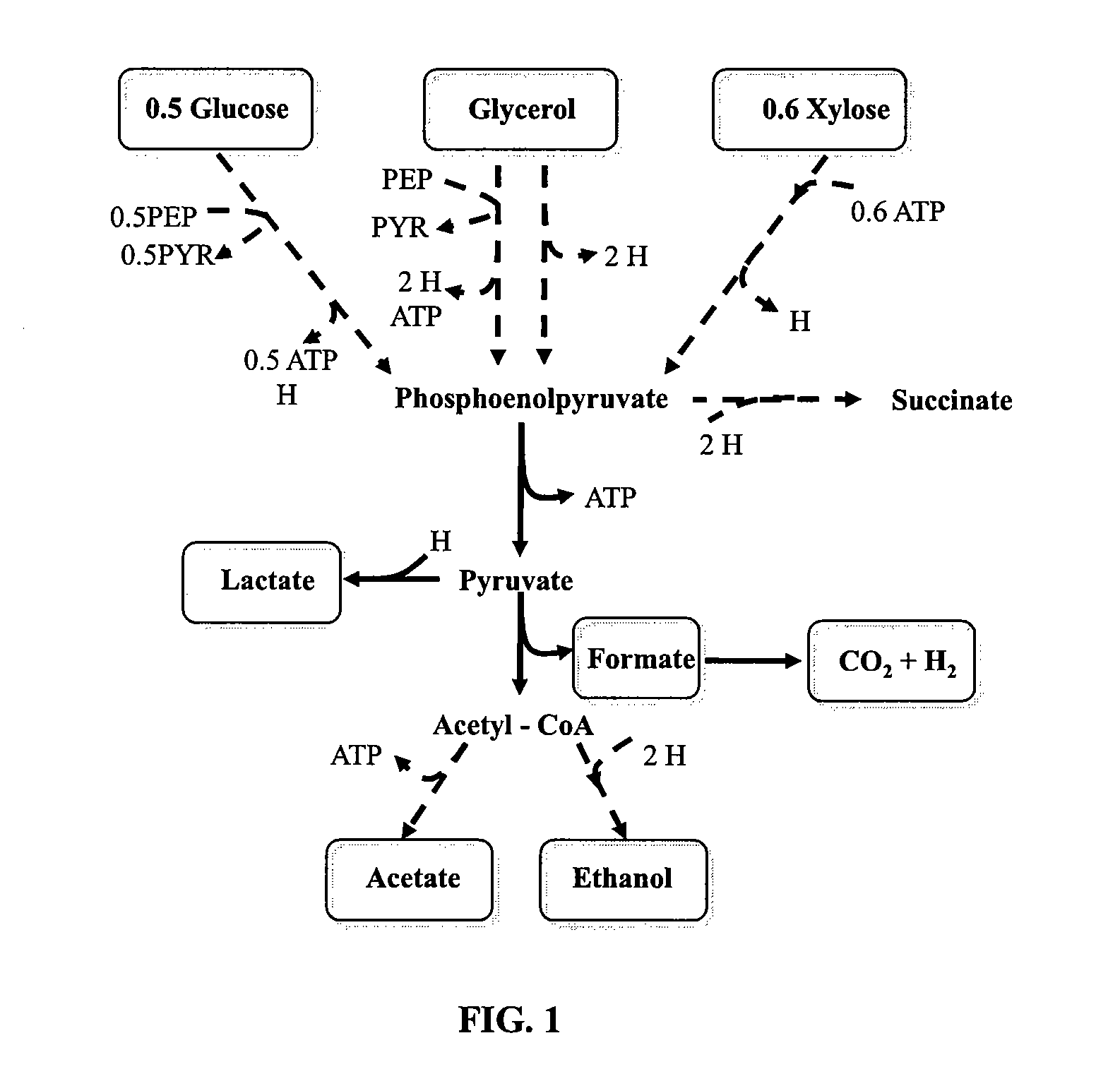

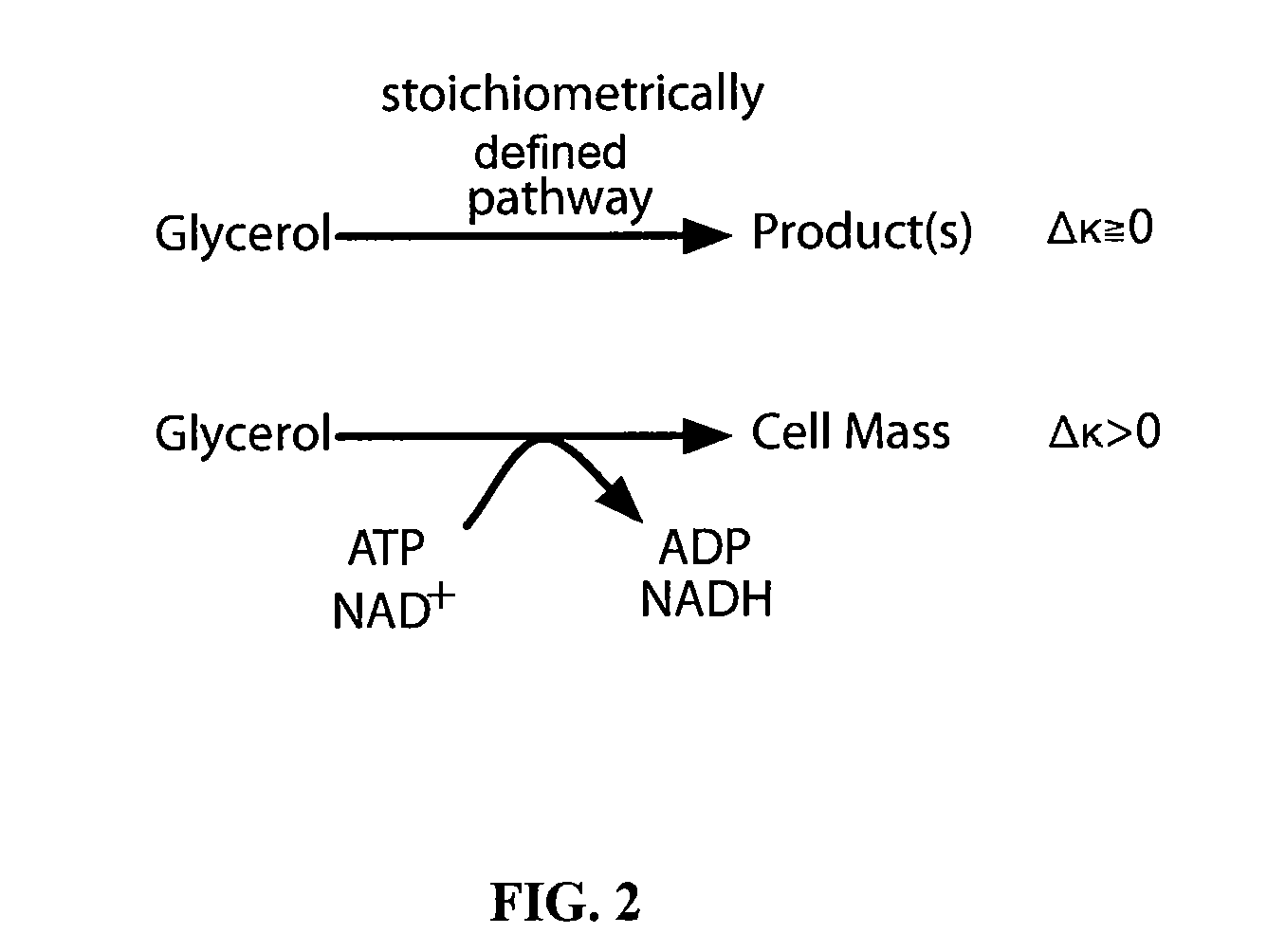

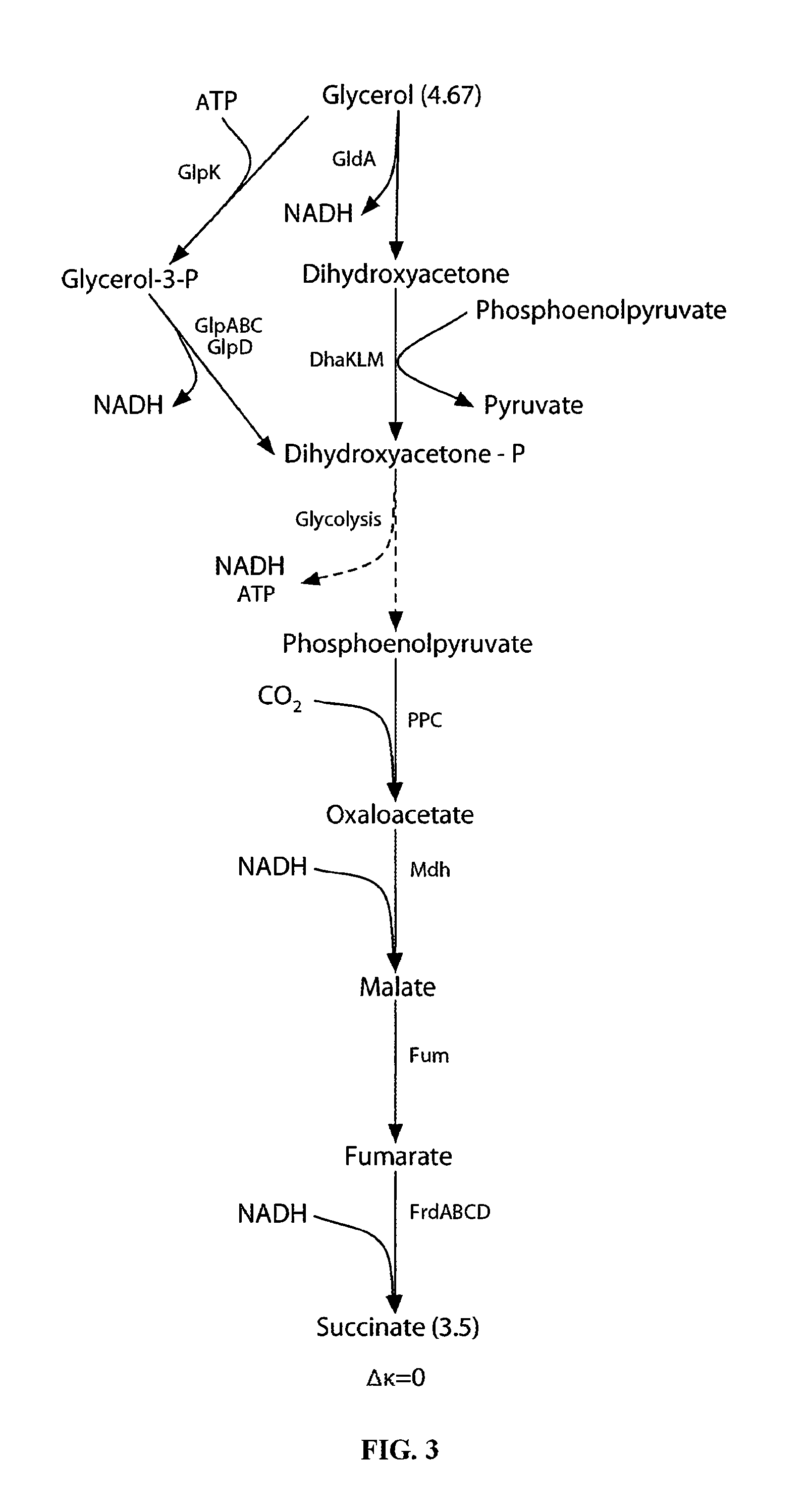

Microaerobic cultures for converting glycerol to chemicals

Glycerol or other reduced carbon sources may be used as a feedstock for the microbial production of chemical products under certain microaerobic conditions. For example, such production may occur under microaerobic or microrespiratory conditions in which electron acceptors are consumed in the reaction as quickly as they are added. In such reactions, the reaction product is at least as reduced as carbon source. Further, during such a reaction, at least some of the carbon source is used to generate cell mass. In addition, microorganisms with modified genomes are provided for carrying out the methods herein.

Owner:GLYCOS BIOTECH +1

Oxygen control slag system for electroslag furnace and preparation method thereof

The invention relates to an oxygen control slag system for an electroslag furnace and a preparation method thereof, and belongs to the technical field of metallurgical smelting. In order to solve theproblems that the deoxidation capacity of the existing premelting slag is weak and the cost is high, the invention provides the oxygen control slag system for the electroslag furnace. The oxygen control slag system for the electroslag furnace is prepared from the following components in percentage by weight: 30 to 32 percent of self-made premelting slag, 43 to 45 percent of Al2O3, 20 to 22 percentof CaO and 3 to 5 percent of MgO, wherein the self-made premelting slag has the SiO2 content of less than or equal to 1.5 percent through desilicication treatment, and also contains 2 to 3 percent ofaluminum, so that a good deoxidation effect can be achieved; and the CaO, the Al2O3 and the MgO can further improve the deoxidation capacity of the slag system. The oxygen control slag system for theelectroslag furnace provided by the invention is low in cost, simple in preparation process, good in energy saving and consumption reducing effects, and stable in remelting chemical components. The oxygen control slag system provided by the invention is utilized for melting steel, which can make the internal quality of an electroslag steel ingot uniform, the surface of a cast ingot smooth, and detection indicators excellent.

Owner:建龙北满特殊钢有限责任公司

Beryllium-aluminum alloy powder and preparation method and application thereof

ActiveCN111570813AGood sphericityIncrease productivityAdditive manufacturing apparatusTransportation and packagingOxygen contentElectron bunches

The invention provides beryllium-aluminum alloy powder and a preparation method and application thereof. The preparation method comprises the following steps of placing a beryllium-aluminum alloy rodin a vacuum environment; introducing inert gas into the vacuum environment to replace air, wherein the oxygen content in the replaced vacuum environment is smaller than 6 ppm; melting the end surfaceof the beryllium-aluminum alloy rod by means of arc to form a liquid film; crushing the liquid film to fine liquid drops by means of centrifugal force; and carrying out cooling to obtain the beryllium-aluminum alloy powder. The beryllium-aluminum alloy powder may comprise the beryllium-aluminum alloy powder prepared through the preparation method of the beryllium-aluminum alloy powder. The application may comprise application of the beryllium-aluminum alloy powder in the field of laser or electron beam additive manufacturing and / or in the field of laser or electron beam cladding. The inventionhas the beneficial effects that the preparation method is high in production efficiency and low in energy consumption; the prepared beryllium-aluminum alloy powder is good in degree of sphericity, free of hollow powder basically, low in oxygenation amount in the manufacturing process and good in flowability and is a good raw material for 3D printing.

Owner:西藏智材新材料有限公司

Method for treating sewage with low carbon nitrogen ratio

InactiveCN109368776AIncrease contactRelieve blockageWater treatment compoundsWater contaminantsSource materialChemistry

The invention belongs to the technical field of sewage treatment and discloses a method for treating sewage with a low carbon nitrogen ratio. The method comprises the following steps of (1) preparation of a solid carbon source filler bio-membrane reactor, specifically, the bio-membrane reactor is filled with a solid carbon source material, inoculated active sludge and sewage are poured into the bio-membrane reactor, the bio-membrane reactor is emptied after a period of time of standing, sewage is injected from the bottom of the bio-membrane reactor in an aerated state till biofilm formation succeeds; and (2) synchronous nitrification and denitrification of the sewage, specifically, the sewage is injected continuously from the bottom of the solid carbon source filler bio-membrane reactor inthe aerated state, the sewage is subjected to synchronous nitrification and denitrification when flowing through the solid carbon source material, and then water is discharged from the upper part ofthe solid carbon source filler bio-membrane reactor. The method effectively reduces the concentration of organic matter, reduces the aeration amount required for the aerobic reaction, and improves thesewage treatment efficiency. According to the method, the cost is low, the energy consumption of projects is reduced, the occupied space is small, and the characteristics of being flexible, economical, environmentally friendly and the like are achieved.

Owner:GUANGZHOU UNIVERSITY

Manufacturing method of sintered neodymium iron boron

InactiveCN111739729AHigh dimensional accuracyGood dimensional stabilityMagnetic materialsPermanent magnet manufactureOrganic solventHigh density

The invention belongs to the field of sintered rare earth permanent magnet material manufacturing, and particularly relates to a manufacturing method of sintered neodymium iron boron. The preparationmethod comprises the following steps: obtaining neodymium-iron-boron alloy powder by using a conventional process; dissolving an organic matter coating agent into an organic solvent to prepare an organic matter coating solution; mixing the organic matter coating solution with neodymium-iron-boron alloy powder, and uniformly mixing, so that the surface of the powder is coated with a compact organicmatter coating film so as to achieve the effects of oxidation resistance, lubrication and bonding; and putting the powder into a mold, and carrying out magnetic field molding to directly press a high-density, high-strength and low-oxygenation green body without isostatic pressing, so that the sintered product has high dimensional precision, and the method is a near-net molding method.

Owner:JIANGXI KAIYUAN AUTOMATIC EQUIP CO LTD +1

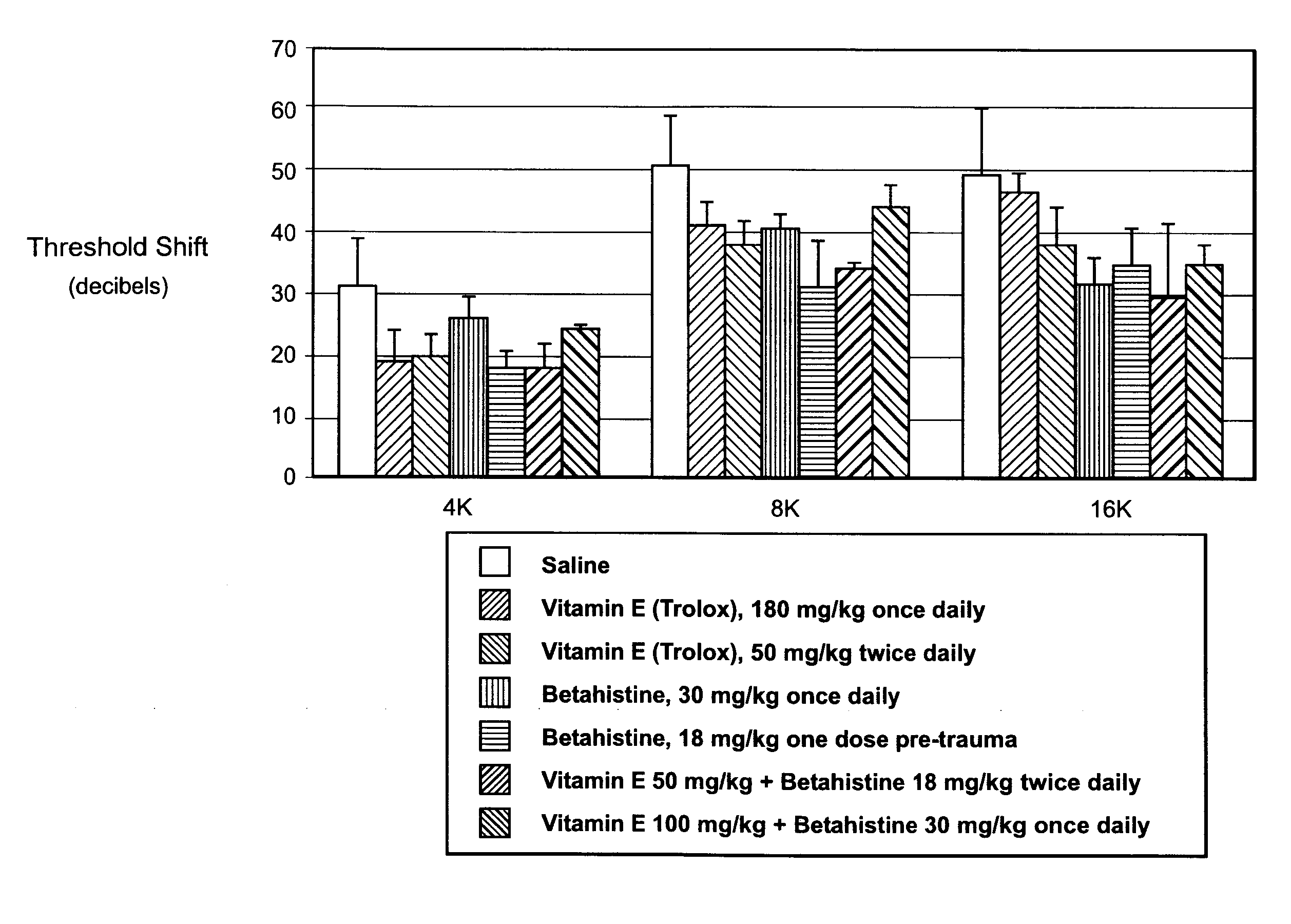

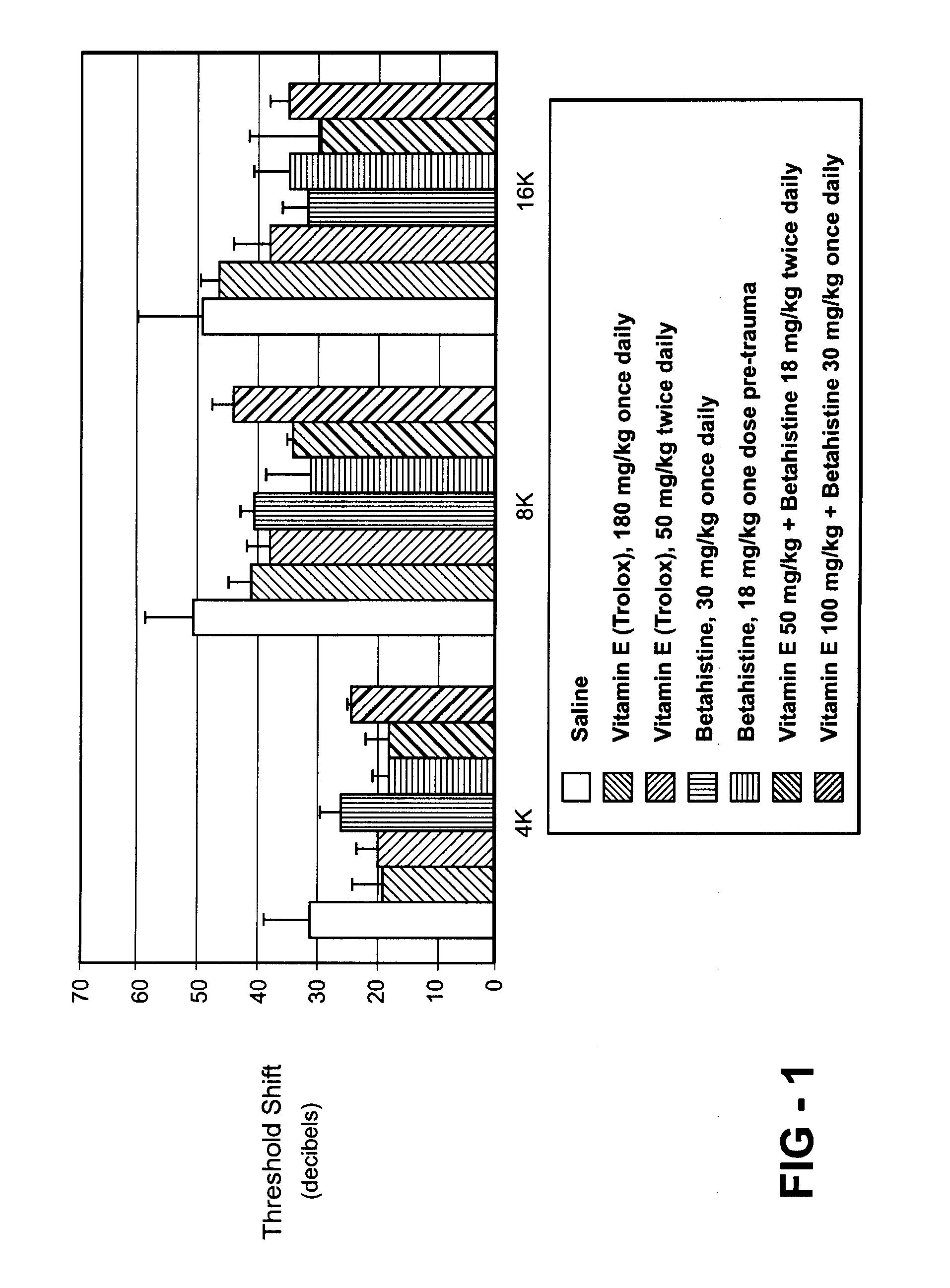

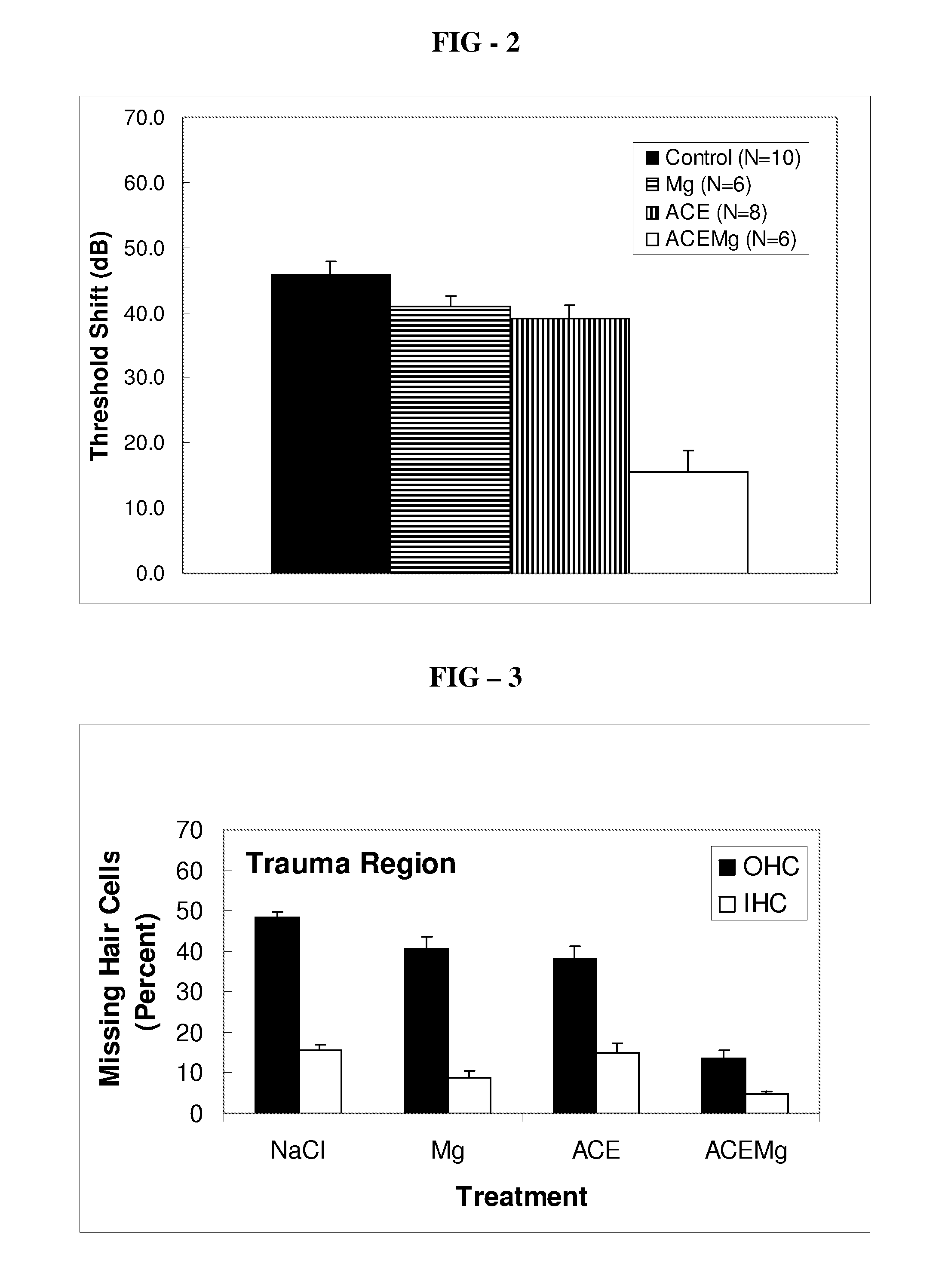

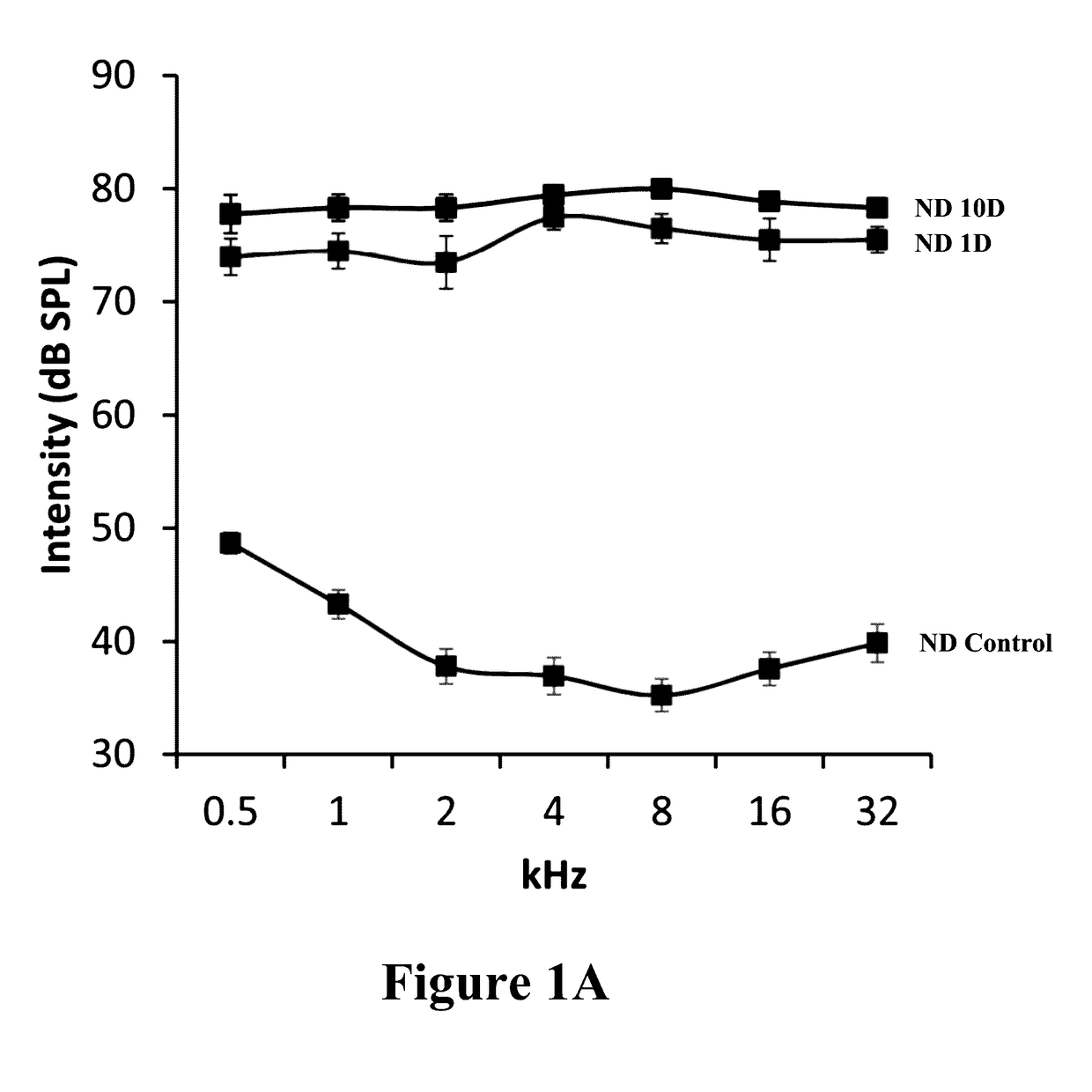

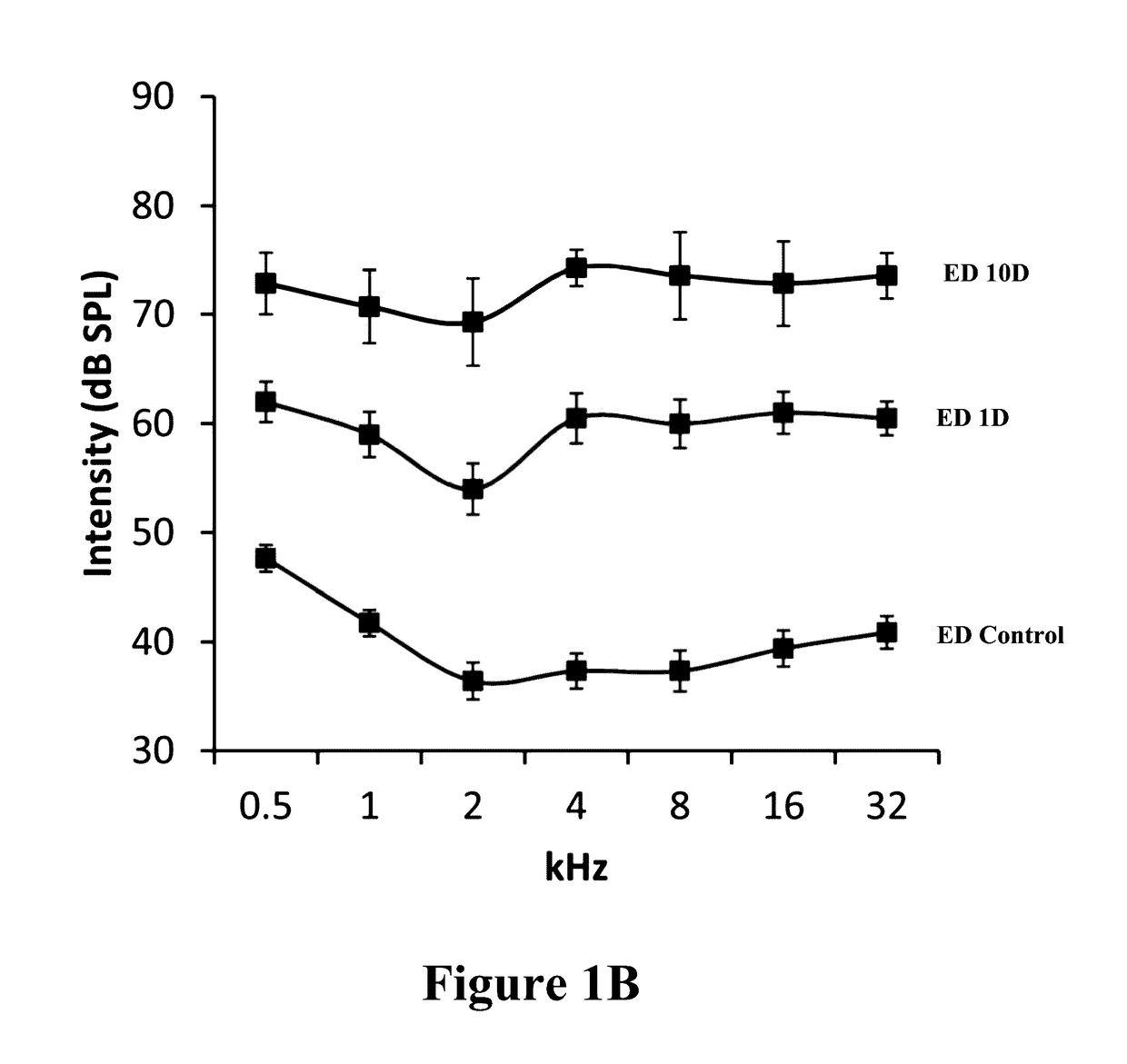

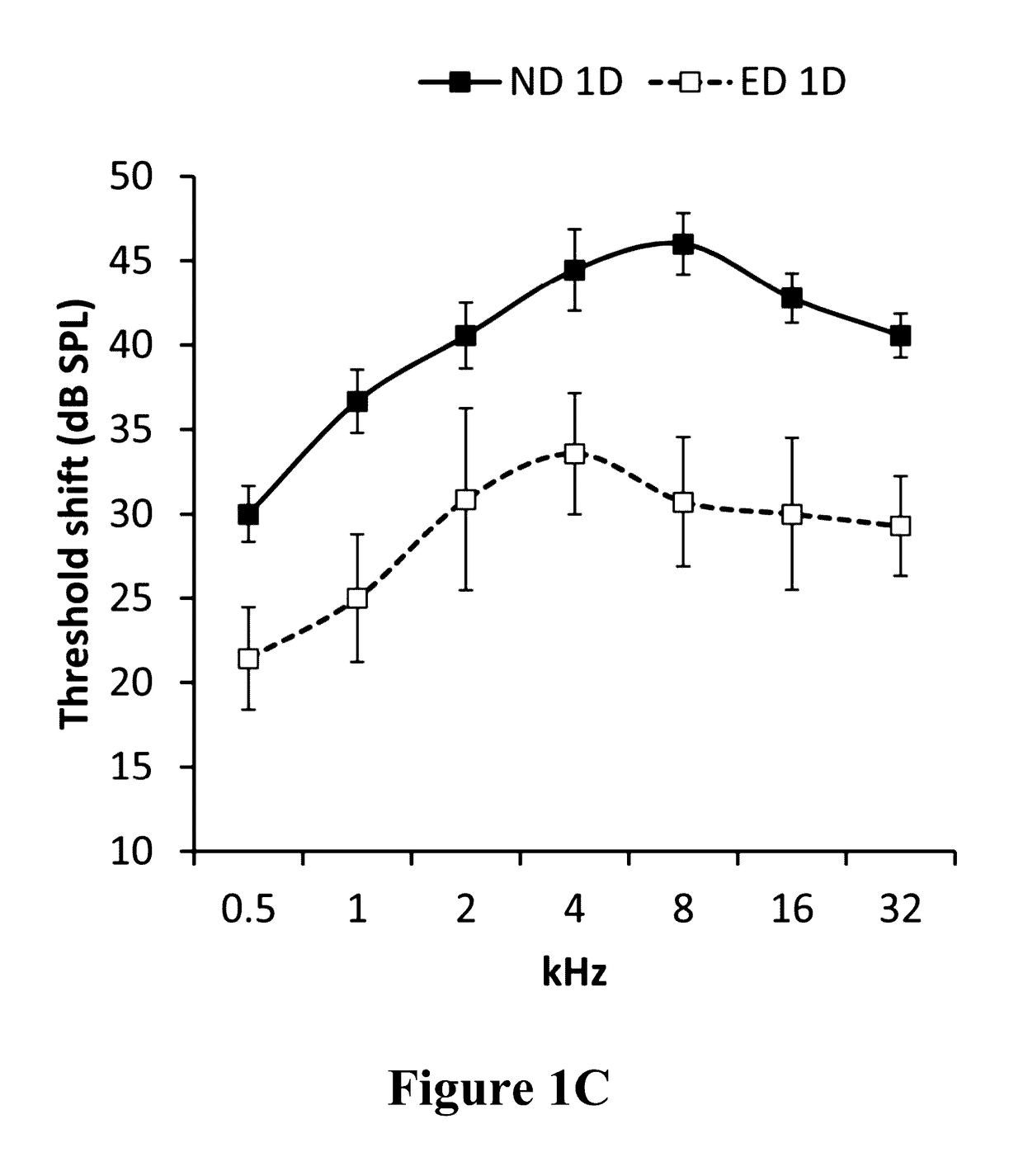

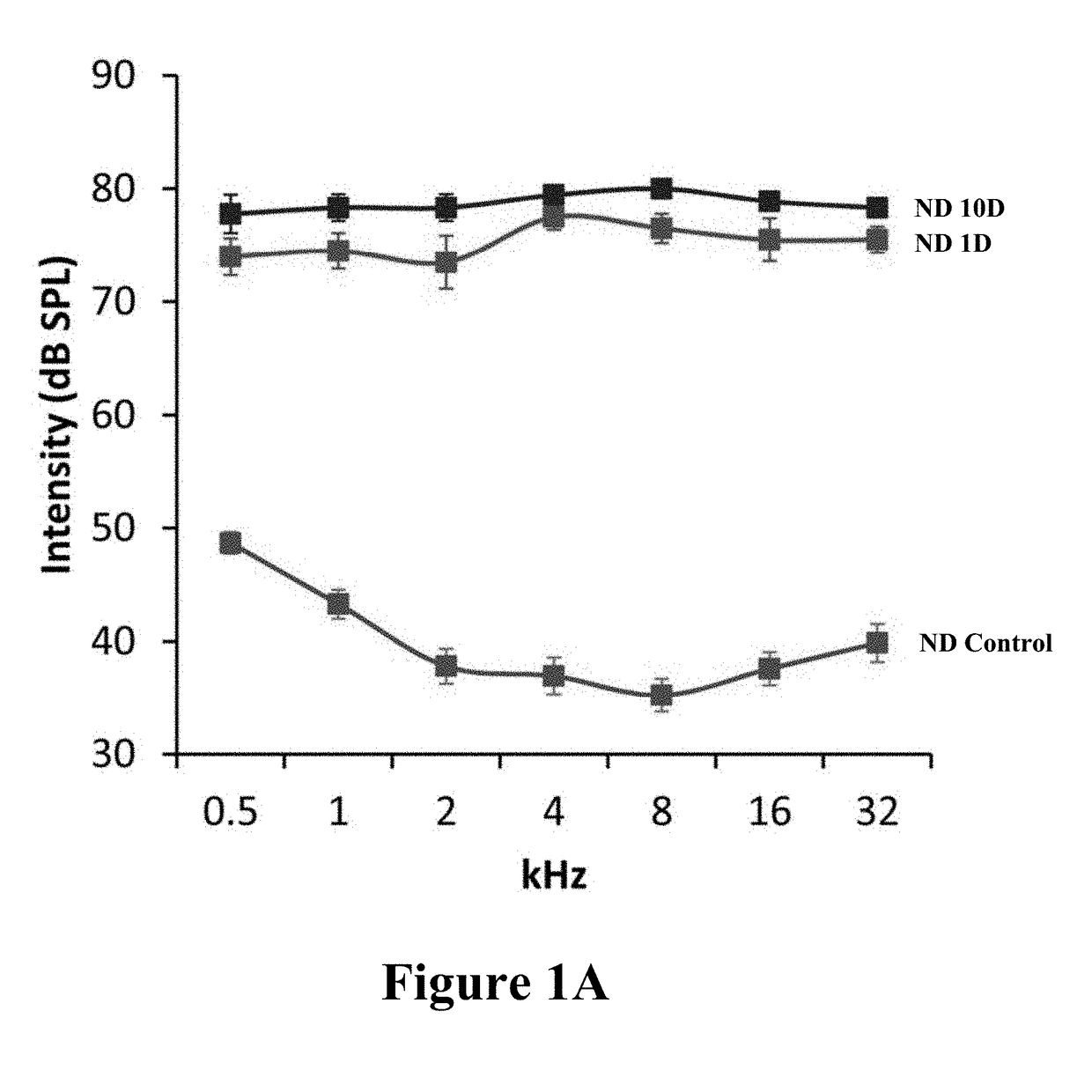

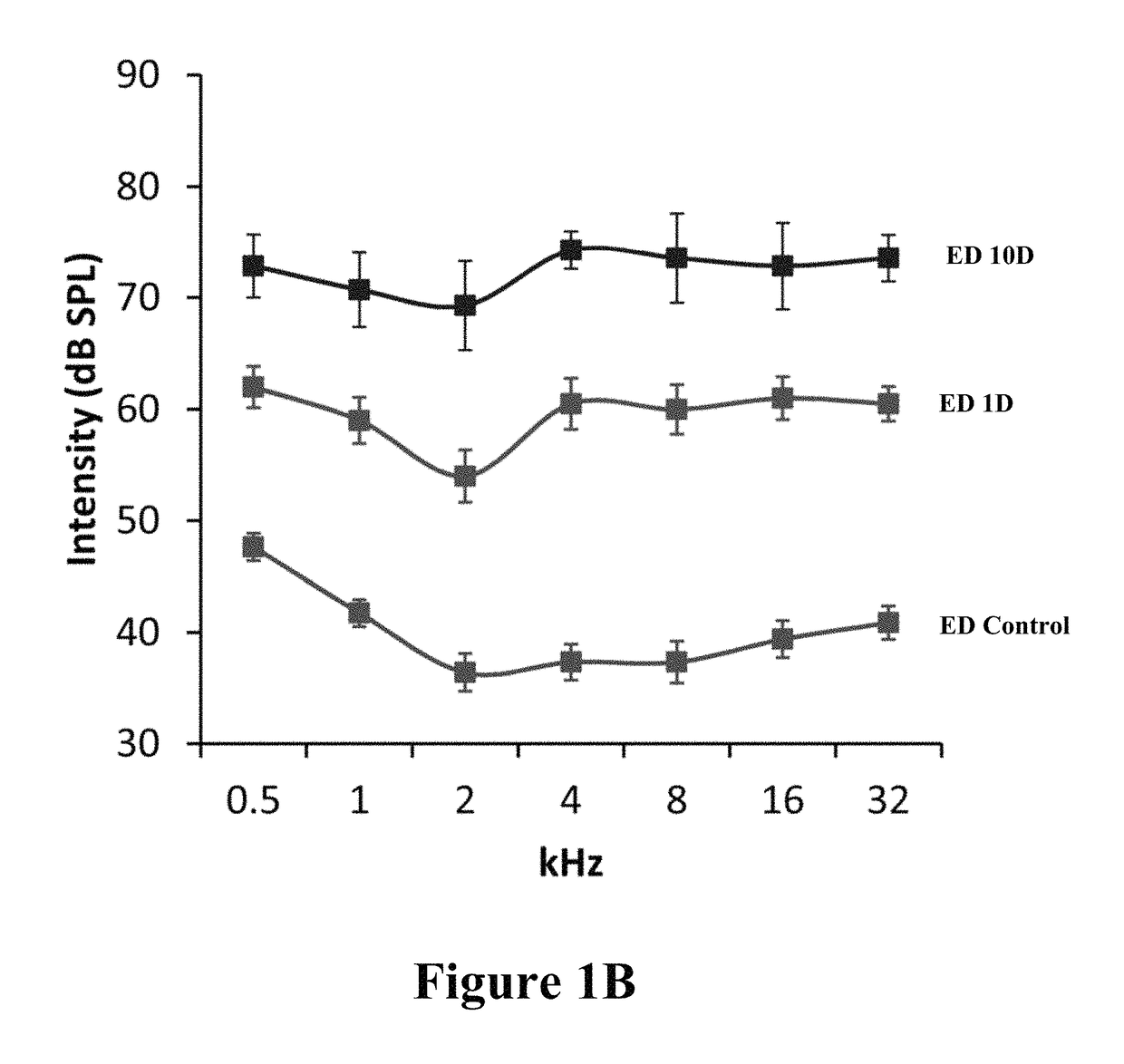

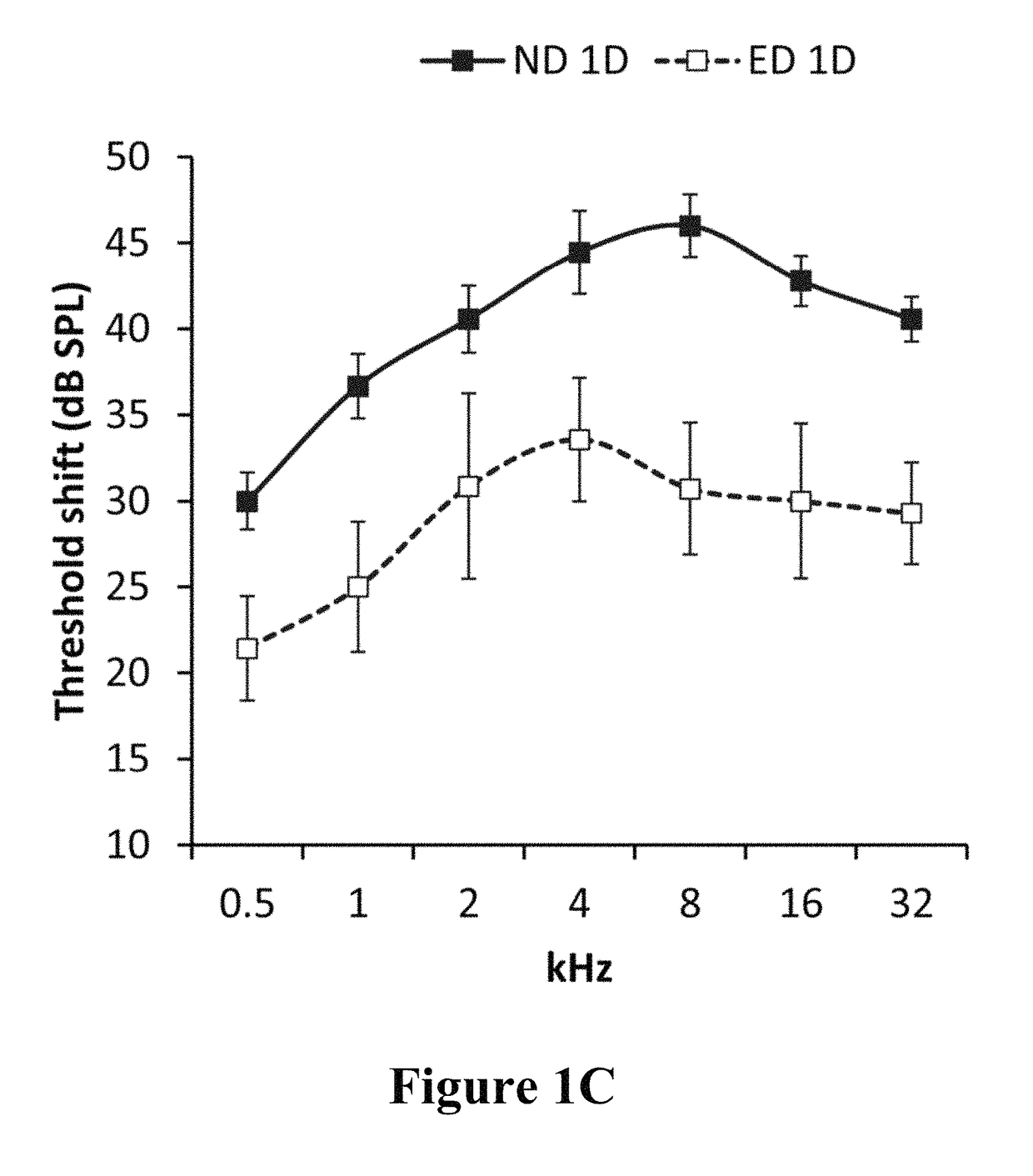

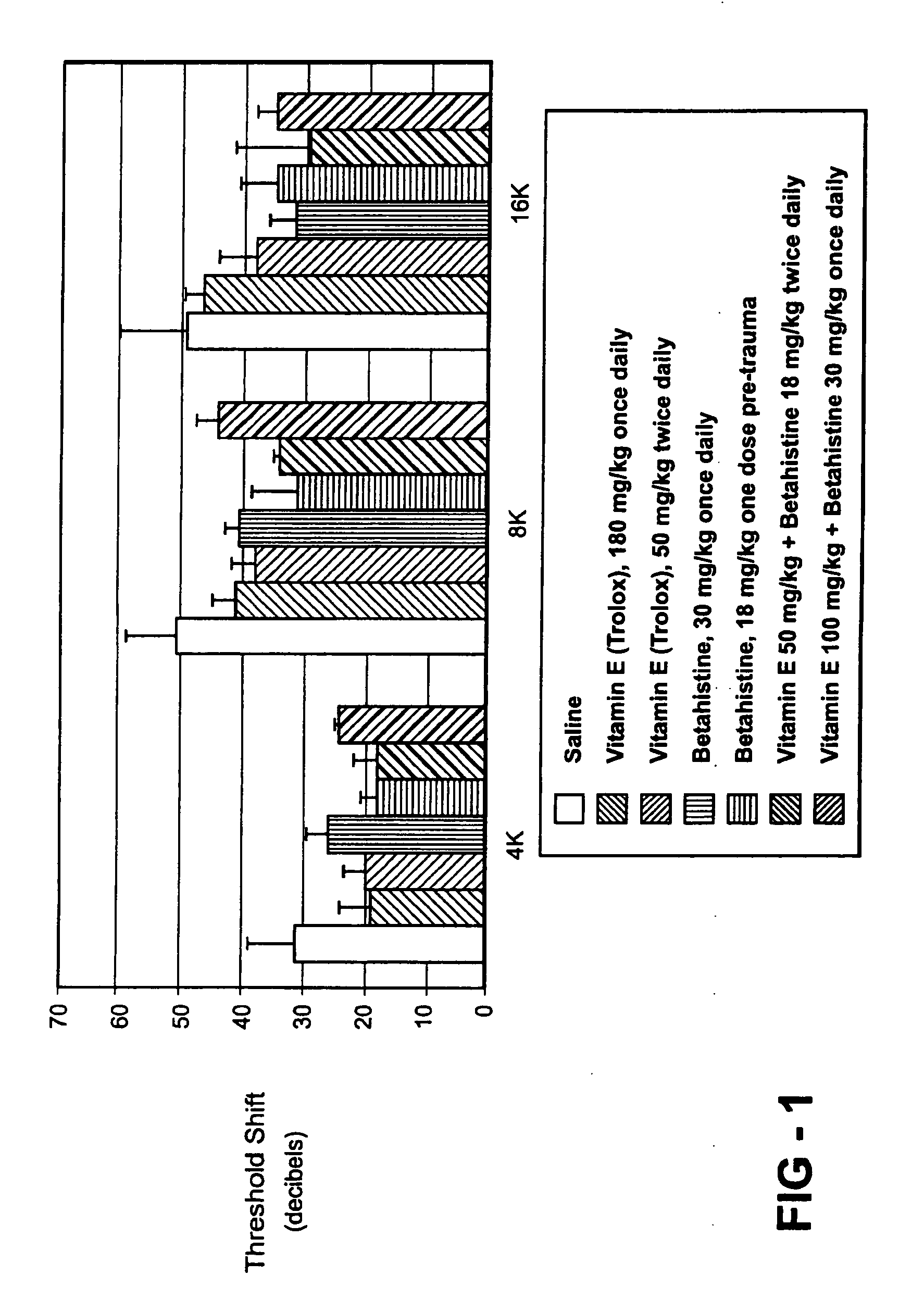

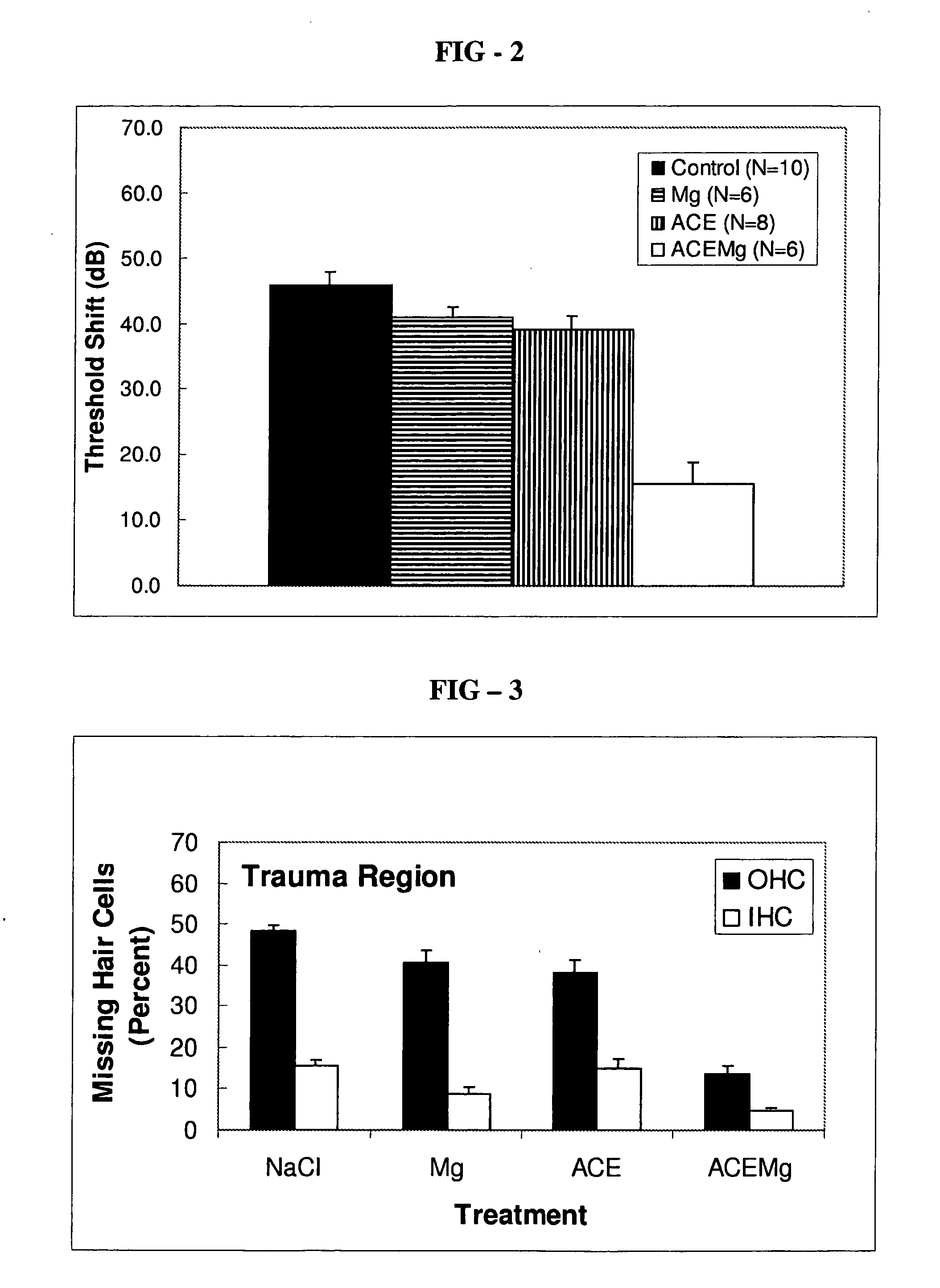

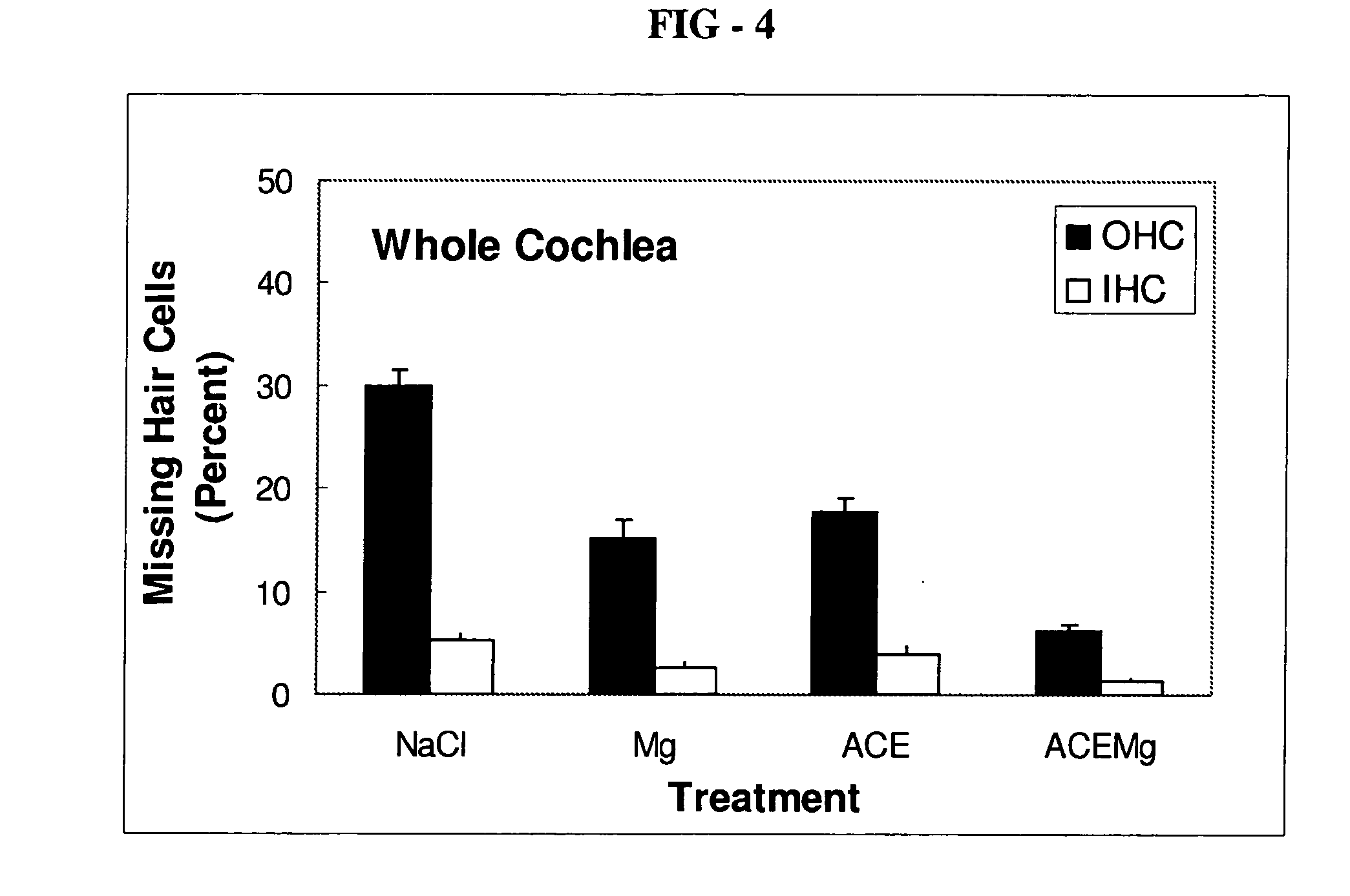

Composition And Method Of Treating Hearing Loss

ActiveUS20070165870A1Minimize hearing lossHigh incidenceBiocideSenses disorderSinglet oxygenScavenger

Owner:THE RGT OF THE UNIV OF MICHIGAN

Screening method of 3D printing powder

InactiveCN110420854AReduce in quantityAffect liquidityAdditive manufacturing apparatusGas current separationScreening methodAir classifier

The invention discloses a screening method of 3D printing powder, and the method comprises the steps of screening powder prepared by gas atomization by using an air classifier, and removing ultrafinepowder with the granularity of -15 [mu]m to obtain powder with the granularity of 15-250 [mu]m; carrying out ultrasonic screening on the powder with the granularity of 15-250 [mu]m by using a glove box to obtain printing powder with the granularity of 15-45 [mu]m; and packaging the printing powder with the granularity of 15-45 [mu]m. According to the invention, ultrafine powder and large-particle-size powder in the powder are removed in sequence by continuously screening the powder prepared by gas atomization; and the quantity of the ultrafine powder is effectively reduced by controlling the rotating speed and the air input of the wind wheel of the air classifier, the ultrasonic frequency and the screening time of an ultrasonic vibration screening machine, the humidity and the oxygen increasing amount of the printed powder are effectively reduced by controlling the parameters such as the water content and the oxygen content of the glove box, and the gas-filled packaging prevents the vacuum packaging from causing powder agglomeration and adhesion to influence the flowability of the powder..

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

Microaerobic cultures for converting glycerol to chemicals

Glycerol or other reduced carbon sources may be used as a feedstock for the microbial production of chemical products under certain microaerobic conditions. For example, such production may occur under microaerobic or microrespiratory conditions in which electron acceptors are consumed in the reaction as quickly as they are added. In such reactions, the reaction product is at least as reduced as carbon source. Further, during such a reaction, at least some of the carbon source is used to generate cell mass. In addition, microorganisms with modified genomes are provided for carrying out the methods herein.

Owner:GLYCOS BIOTECH +1

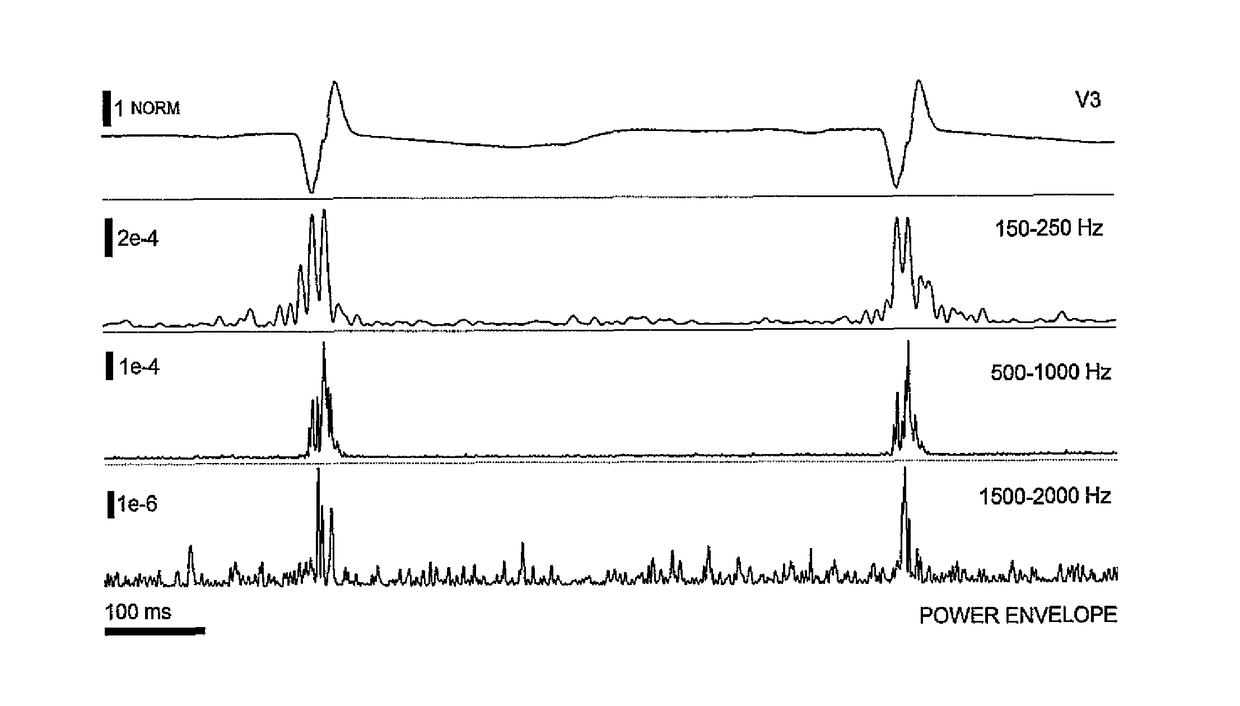

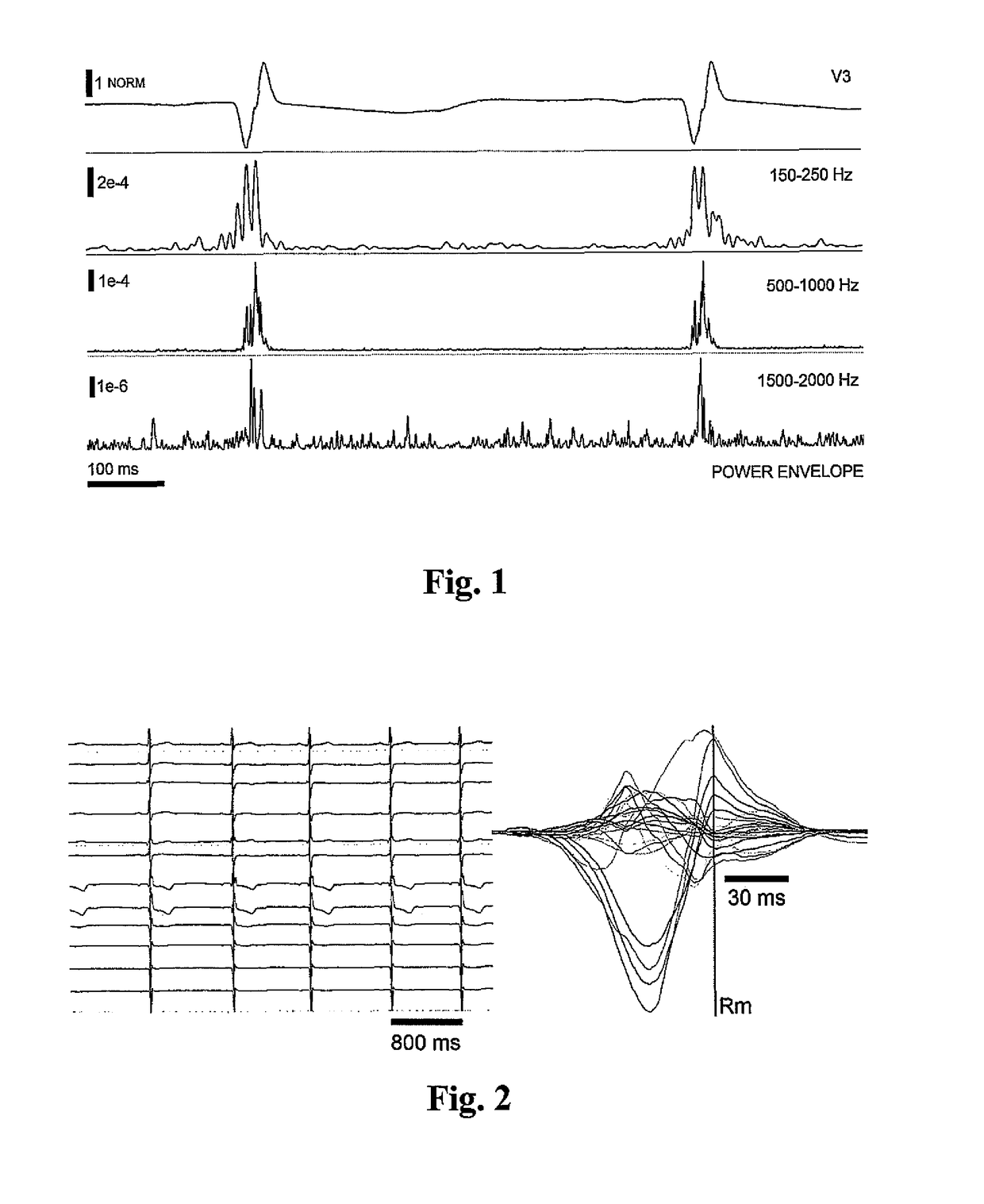

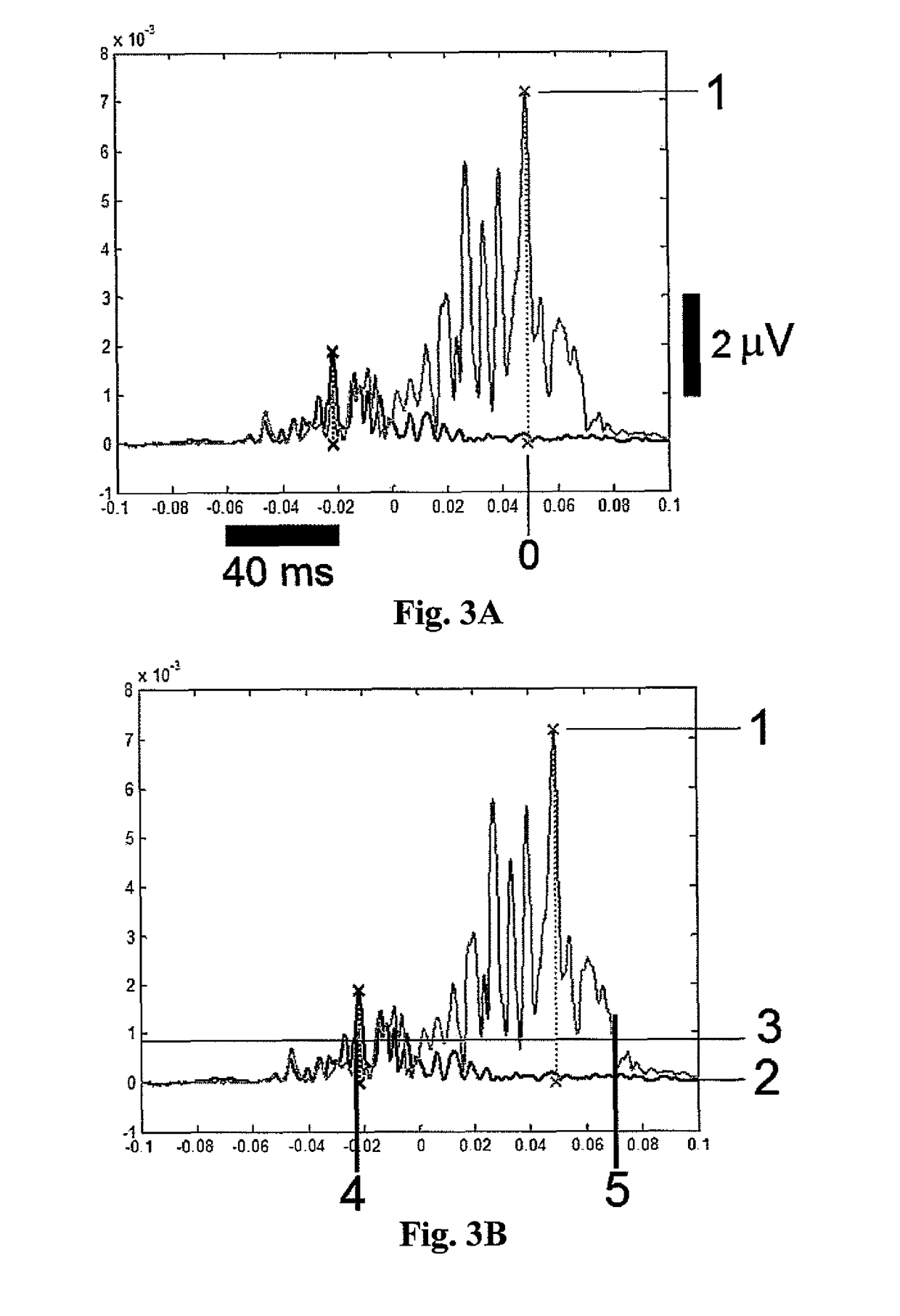

Method of EKG signal processing and apparatus for performing the method

A method of measuring and analyzing the ultra high frequency EKG is performed by measuring the EKG within the frequency range above 250 Hz with a dynamic range of at least 100 dB. In the UHF EKG signal positions of Rm of R wave in QRS complex of EKG are detected on the time axis and the EKG signal is converted to amplitude or power envelopes, the amplitude or power envelopes frequency range is anywhere within the limits from 0.2 Hz to at least 500 Hz. From these envelopes the amplitude and time numerical parameters that describe the myocardium depolarization inhomogeneity and electric myocardium dyssynchrony are determined, and these parameters are used for selecting the patients for multi-chamber stimulators implementation and optimization of their setting.

Owner:USTAV PRISTROJOVE TECHNY AV CR V I I +2

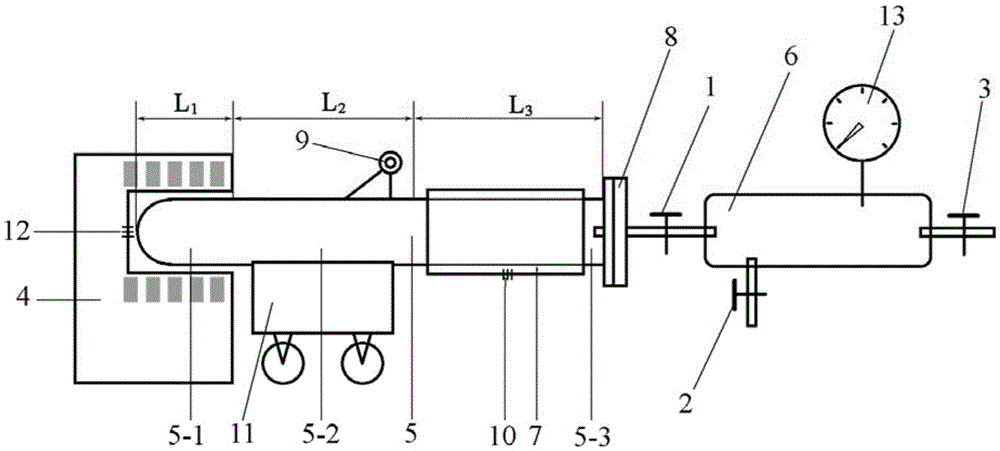

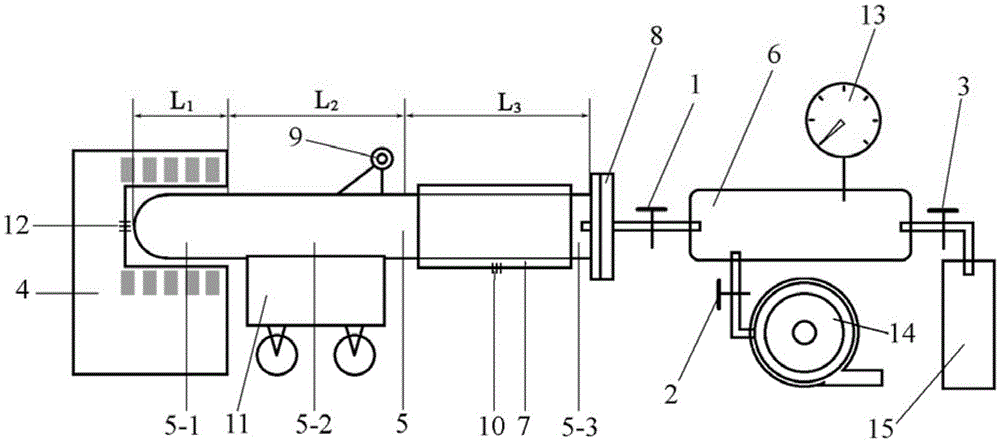

Multi-sectional hydrogenation dehydrogenation furnace and manufacturing method of low-oxygen-content titanium powder

The invention provides a multi-sectional hydrogenation dehydrogenation furnace which comprises a heating furnace, a reactor, a gas storage tank, a cooling device and a movable support, wherein the heating furnace and the reactor are horizontally placed. The reactor is a cylinder with two closed ends and formed by sequentially jointing a heating part section, a middle part section and a cooling part section, a material feeding and discharging port is formed in the end of the cooling part section and provided with a sealing cover, and a gas inflow and outflow port is formed in the sealing cover or the cylinder. The cooling device is provided with a first thermoelectric couple. The heating furnace is provided with a second thermoelectric couple. The gas storage tank is provided with a pressure gauge, a reactor joint, a vacuumizing joint and a hydrogen source joint. The reactor is installed on the movable support. The heating part section of the reactor is located in a hearth of the heating furnace. The cooling device is installed on the cooling part section of the reactor. The reactor joint on the gas storage tank is communicated with the gas inflow and outflow port of the reactor through a pipe. The invention further provides a manufacturing method of low-oxygen-content titanium powder. The oxygen content of the titanium powder manufactured through the method does not exceed 0.1wt%.

Owner:SICHUAN UNIV

Method for Treating Noise-Induced Hearing Loss (NIHL)

ActiveUS20170095506A1Reducing free radicalHinders its propagationHydroxy compound active ingredientsPharmaceutical delivery mechanismVitamin CVascular dilatation

A method for treating noise-induced hearing loss (NIHL) includes the step administering a composition to the mammal, wherein the composition consists essentially of a biologically effective amount of vitamin A, vitamin E, vitamin C, a vasodilator comprising magnesium, and, optionally, a withanolide, and / or resveratrol.

Owner:RGT UNIV OF MICHIGAN

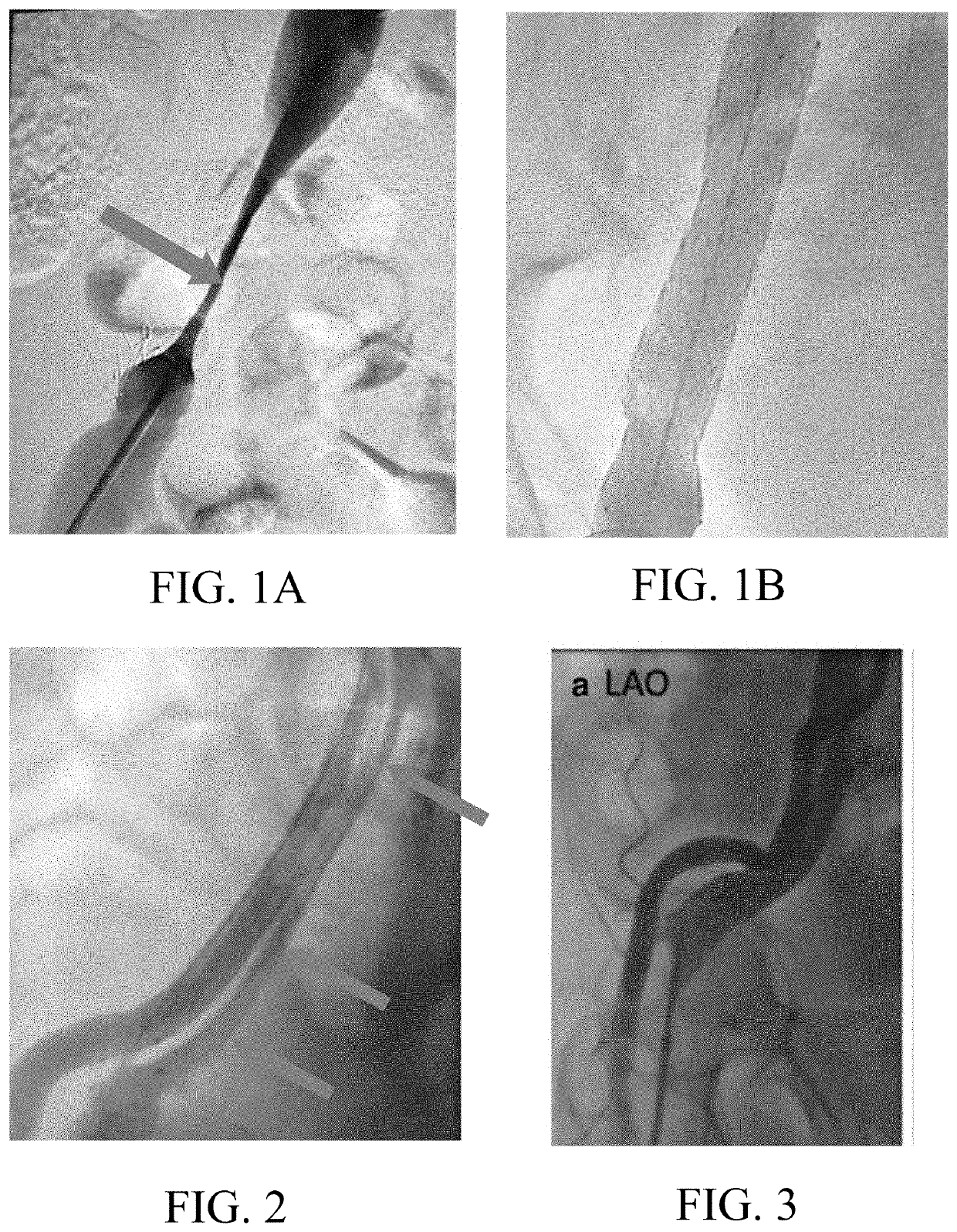

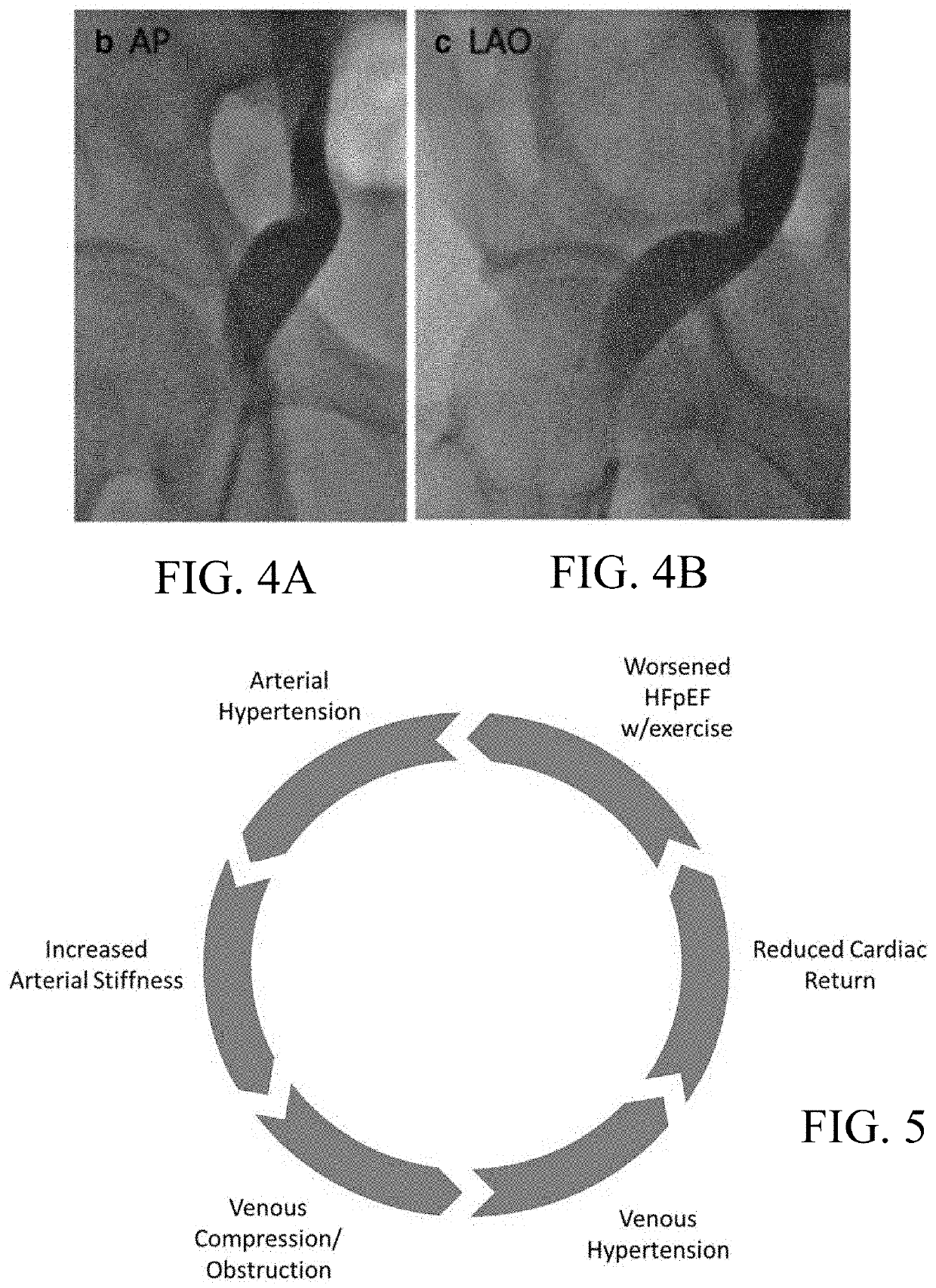

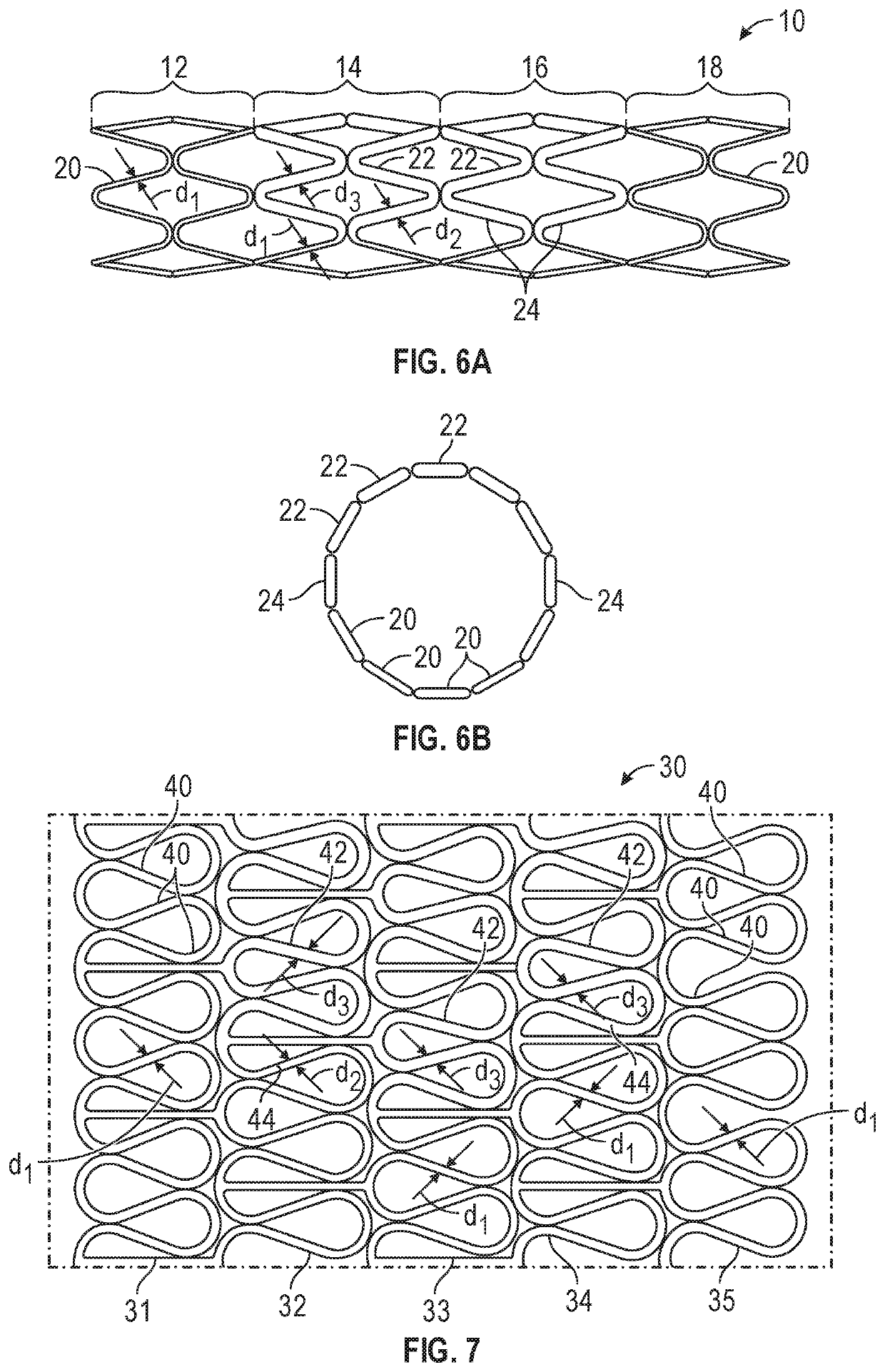

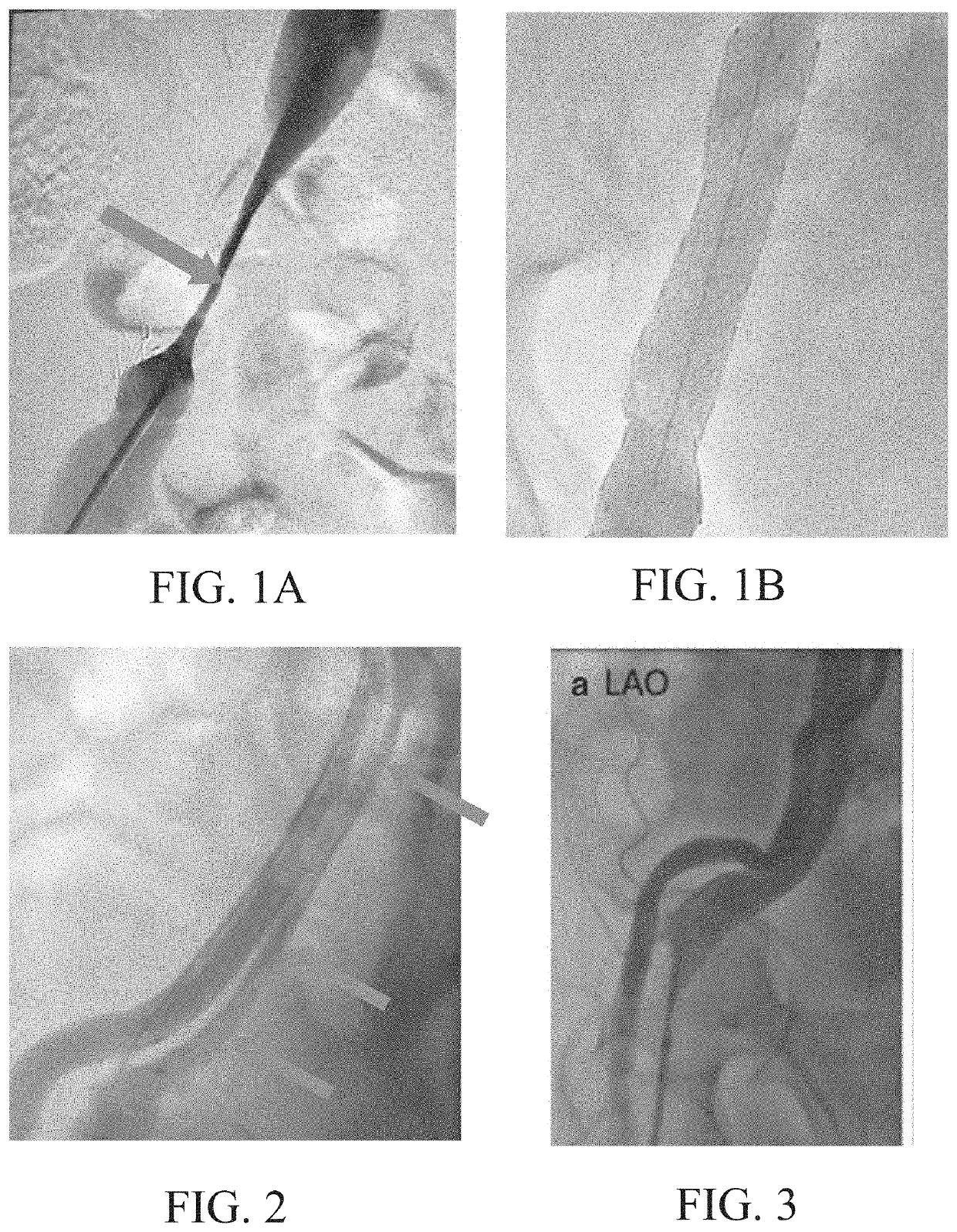

Systems and methods for treating venous compression/obstruction syndromes

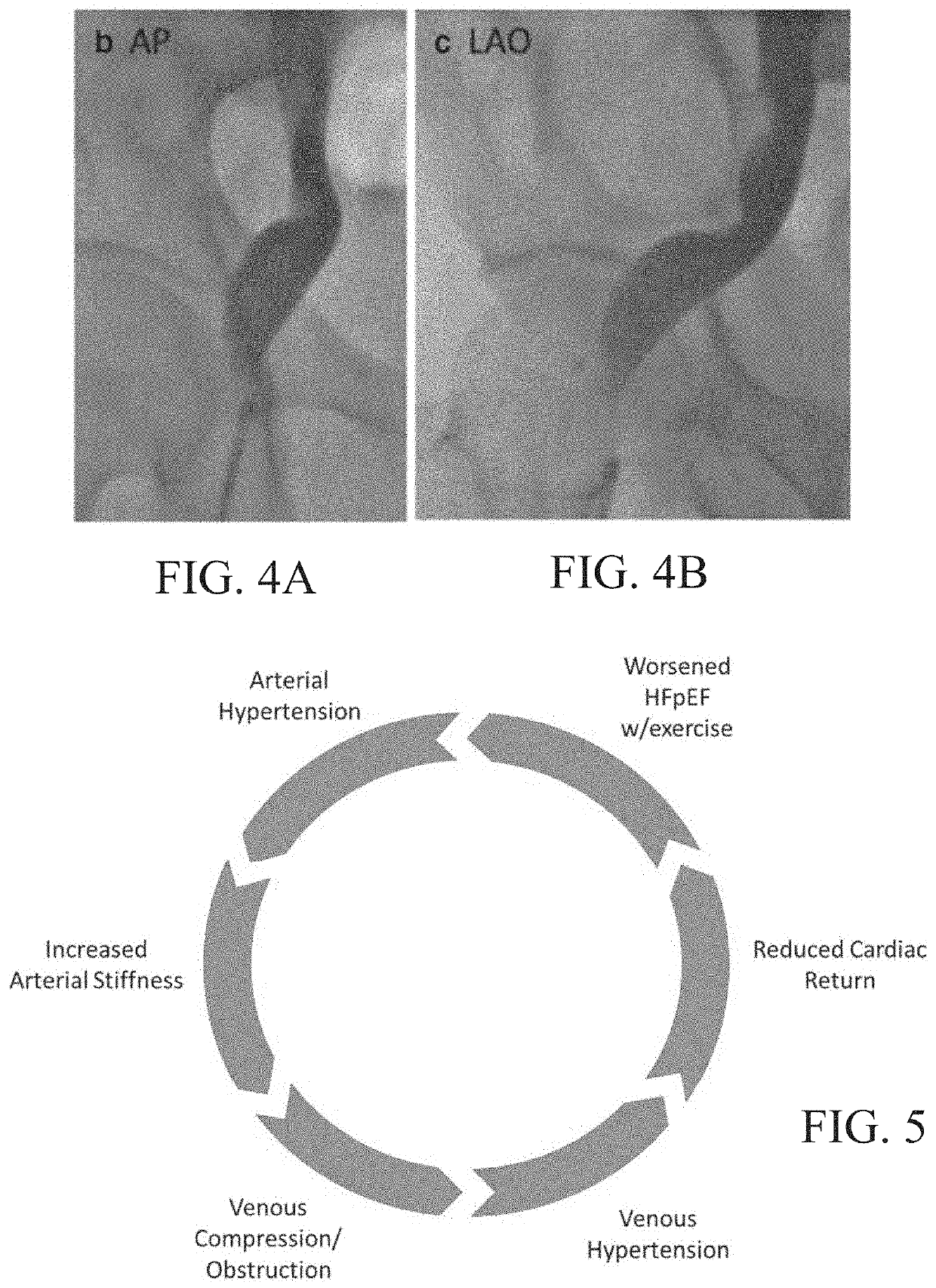

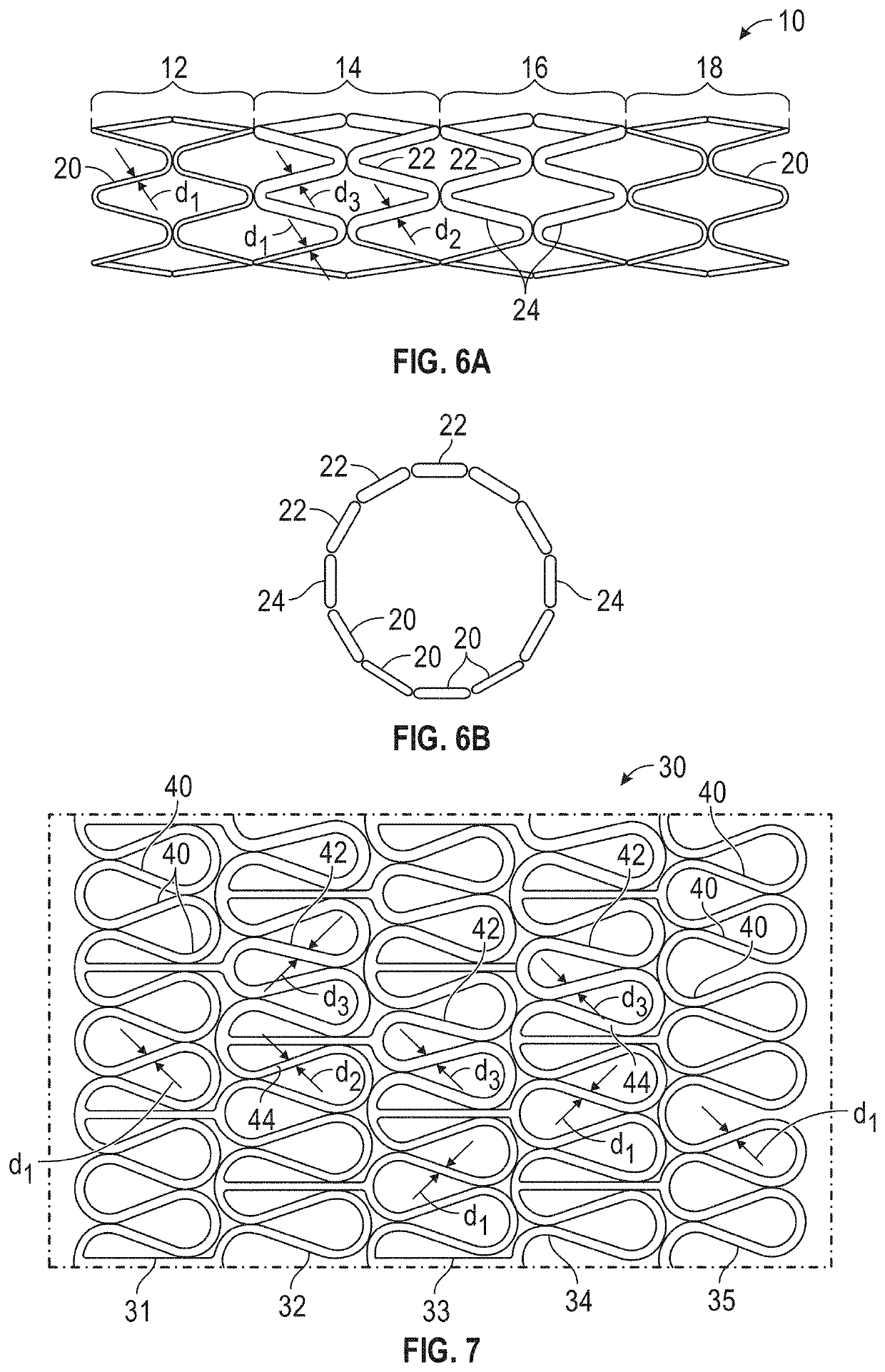

ActiveUS10881541B1Reduce returnsRaise arterial pressureUltrasonic/sonic/infrasonic diagnosticsStentsSystoleHeart failure with preserved ejection fraction

Apparatus and methods are provided for treating patients exhibiting symptoms of hypertension, isolated systolic hypertension, heart failure with preserved ejection fraction, May-Thuner Syndrome or dyspnea by diagnosing and reducing narrowing of a patient's iliac vein caused by extrinsic localized compression using a stent having circumferential differential radial stiffness and delivery catheter for aligning and deploying such stents.

Owner:ROCHA SINGH KRISHNA

Method for treating noise-induced hearing loss (NIHL)

ActiveUS9889156B2Reducing free radicalHinders its propagationSalicyclic acid active ingredientsHydroxy compound active ingredientsVitamin CVascular dilatation

A method for treating noise-induced hearing loss (NIHL) includes the step administering a composition to the mammal, wherein the composition consists essentially of a biologically effective amount of vitamin A, vitamin E, vitamin C, a vasodilator comprising magnesium, and, optionally, a withanolide, and / or resveratrol.

Owner:RGT UNIV OF MICHIGAN

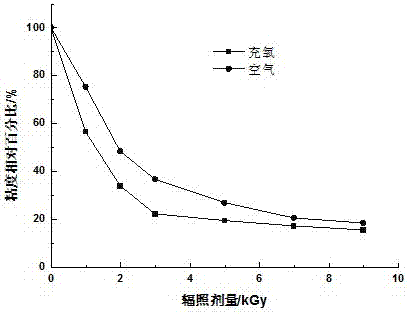

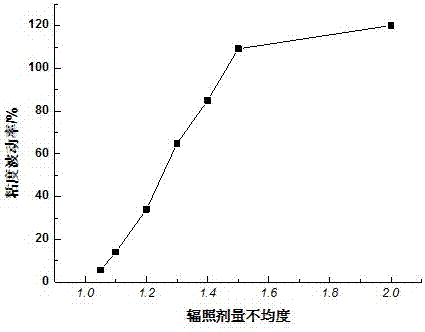

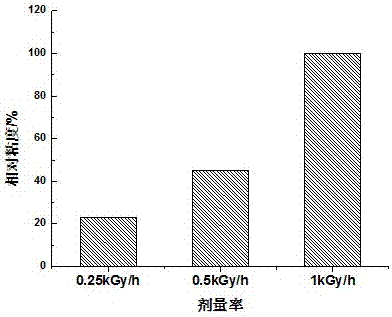

Preparation method of high-performance modified starch

ActiveCN107573421APrecisely control the viscosity valueStable viscosity value rangeDose rateLow dose rate

The invention discloses a preparation method of high-performance modified starch. The method comprises the following steps: putting dry starch into a sealed packet, firstly performing positive surfaceirradiation treatment with low dosage rate on the sealed packet, oxygenating the interior of the sealed packet, shaping the oxygenated sealed packet, and finally performing negative surface irradiation treatment with high dosage rate on the sealed packet, so as to obtain the high-performance modified starch. The method has the advantages that comprehensive irradiation technologies, such as oxygenation, alternative irradiation with different dosage rates, packaging and shaping and overturning, are adopted, so that the irradiation dosage unevenness is smaller than 1.1, the viscosity volatilityof the starch subjected to irradiation modification is smaller than 10 percent, the irradiation efficiency is high, and the cost is reduced.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

Better bite block

InactiveUS20180221611A1Reduce tissue damageReduce the impactTracheal tubesMedical devicesWhole bodyAdhesive

Patients undergoing general anesthetics frequently experience emergence clenching where the patient may bite onto their breathing tube and may clench their teeth. These activities lead to dental damage and negative pressure pulmonary edema. The invention of this patent is a simpler, better bite block that may be used to prevent these injuries. The bite block presented comprises a deformable material used as a core around which a bite-resistant material is wrapped to prevent damage to the core by patient biting. The bite-resistant material may be formed into a distal tail that the user can pull to retain or retrieve the device. It may also have a patch of adhesive to attach the bite block to locations including the patient, the surgical drapes and the patient's breathing airway, and thereby prevent loss of the bite block.

Owner:GILHULY TERENCE

Composition and method of treating temporary and permanent hearing loss

InactiveUS20090155390A1Minimize hearing lossHigh incidenceBiocideHydroxy compound active ingredientsSinglet oxygenScavenger

Owner:OTO MEDICINE

A kind of beryllium aluminum alloy powder and its preparation method and application

ActiveCN111570813BGood sphericityIncrease productivityAdditive manufacturing apparatusTransportation and packagingMetallurgyElectron bunches

The invention provides a beryllium aluminum alloy powder and a preparation method and application thereof. The preparation method may include the following steps: placing the beryllium aluminum alloy rod in a vacuum environment; passing an inert gas into the vacuum environment to replace the air, and after the replacement, the oxygen content in the vacuum environment is below 6 ppm; using an electric arc to make the beryllium aluminum alloy rod The end face is melted to form a liquid film; the liquid film is broken into fine droplets by centrifugal force; cooled to obtain beryllium aluminum alloy powder. The beryllium aluminum alloy powder may include beryllium aluminum alloy powder prepared by the above-mentioned preparation method of beryllium aluminum alloy powder. The applications may include applications in the field of laser or electron beam additive manufacturing, and / or applications in the field of laser or electron beam cladding. The beneficial effects of the present invention may include: the preparation method has high production efficiency and low energy consumption; the prepared spherical beryllium aluminum alloy powder has good sphericity, basically no hollow powder, low oxygen increase in the preparation process, good fluidity, and is 3D Good raw material for printing.

Owner:西藏智材新材料有限公司

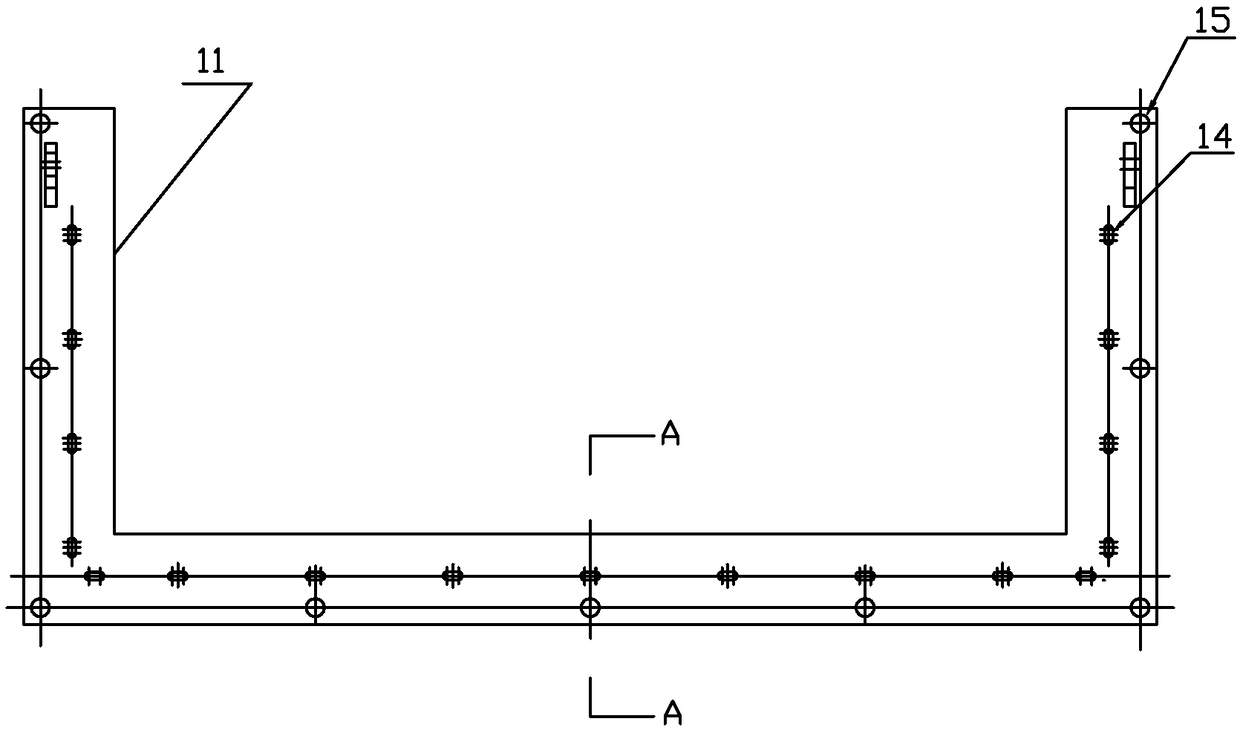

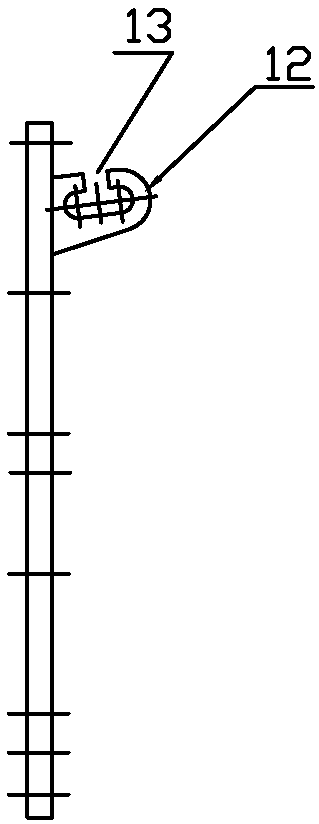

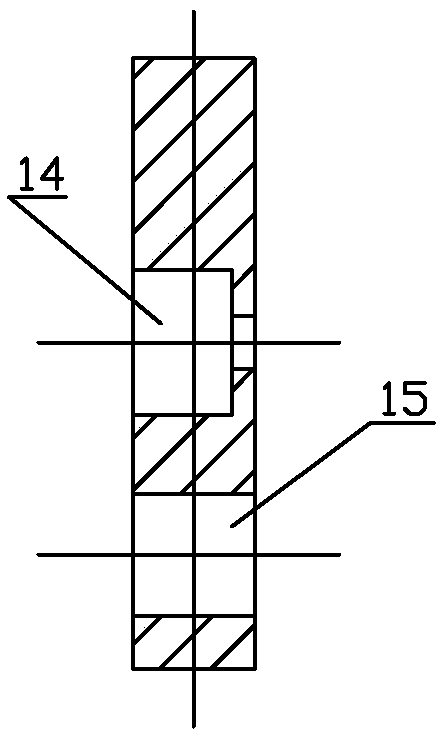

Lift well automatic opening and closing valve

ActiveCN106195287BImprove performanceReduce performanceOperating means/releasing devices for valvesLift valveFault rateValve seat

The invention discloses an automatic starting and stopping valve for a hoisting shaft, structurally comprising two major parts, namely a valve seat assembly and a valve assembly. The valve assembly slips from a rotating shaft outlet / inlet formed in an open pothook arranged on the valve seat assembly into an elongated hole of the open pothook through a rotating shaft arranged on the upper end parts of the left and right sides of the valve assembly, so that the valve assembly is hung and attached to the open pothook, and meanwhile, the valve assembly is fitted together with the valve seat assembly. The automatic starting and stopping valve is safe and reliable in use, stable in operation, excellent in performance, low in mechanical fault rate, convenient o dismount and mount, free of power input and capable of realizing automatic starting or stopping by virtue of own conditions.

Owner:JIANGMEN XINHUI DISTRICT LONGQUAN SEWAGE TREATMENT CO LTD

Treatment method for low-carbon-source domestic wastewater

InactiveCN103030254BReduce concentrationReduce oxygenationMultistage water/sewage treatmentWastewaterNitrogen

The invention discloses a treatment method for low-carbon-source domestic wastewater, wherein the domestic wastewater is treated through a dual-membrane process of anaerobic hydrolysis of a biological membrane zeolite and a fluidized ceramsite biological membrane filter, that is to say, the natural zeolite which is cultured by a biological membrane is taken as a filler to decompose organic matters hard to degrade in the wastewater into low molecular weight organic matters easy to degrade through the metabolism of anaerophyte, then the ceramsite is taken as a carrier to conduct aerobic treatment, and the biological membrane formed on the surface of the ceramsite fully degrades the organic matters in the wastewater. According to the invention, the carbon source in the wastewater is effectively utilized, so that a good nitrogen and phosphorus removal effect is achieved without adding any organic carbon source trophoplasm in the treatment of the low-carbon-source domestic wastewater.

Owner:GUANGZHOU UNIVERSITY

Oxygen-controlled slag system for electroslag furnace and preparation method thereof

The invention relates to an oxygen control slag system for an electroslag furnace and a preparation method thereof, and belongs to the technical field of metallurgical smelting. In order to solve theproblems that the deoxidation capacity of the existing premelting slag is weak and the cost is high, the invention provides the oxygen control slag system for the electroslag furnace. The oxygen control slag system for the electroslag furnace is prepared from the following components in percentage by weight: 30 to 32 percent of self-made premelting slag, 43 to 45 percent of Al2O3, 20 to 22 percentof CaO and 3 to 5 percent of MgO, wherein the self-made premelting slag has the SiO2 content of less than or equal to 1.5 percent through desilicication treatment, and also contains 2 to 3 percent ofaluminum, so that a good deoxidation effect can be achieved; and the CaO, the Al2O3 and the MgO can further improve the deoxidation capacity of the slag system. The oxygen control slag system for theelectroslag furnace provided by the invention is low in cost, simple in preparation process, good in energy saving and consumption reducing effects, and stable in remelting chemical components. The oxygen control slag system provided by the invention is utilized for melting steel, which can make the internal quality of an electroslag steel ingot uniform, the surface of a cast ingot smooth, and detection indicators excellent.

Owner:建龙北满特殊钢有限责任公司

Apparatus and methods for treating venous compression/obstruction syndromes

InactiveUS20210338464A1Reduce returnsReduce complianceUltrasonic/sonic/infrasonic diagnosticsStentsSystoleHeart failure with preserved ejection fraction

Apparatus and methods are provided for treating patients exhibiting symptoms of hypertension, isolated systolic hypertension, heart failure with preserved ejection fraction, May-Thuner Syndrome or dyspnea by diagnosing and reducing narrowing of a patient's iliac vein caused by extrinsic localized compression using a stent having circumferential differential radial stiffness and delivery catheter for aligning and deploying such stents.

Owner:ROCHA SINGH KRISHNA

Low-alkalinity low-carbon tundish covering agent for wear-resistant steel and application thereof

The invention discloses a low-alkalinity low-carbon tundish covering agent for wear-resistant steel and an application thereof. The covering agent is prepared from the following components in percentage by mass: 15%-20% of CaO, 30%-40% of SiO2, 10%-20% of Al2O3, 1%-6% of MgO, 5%-10% of Na2O, 1%-10% of K2O, 1%-5% of B2O3, and 0.5%-2% of C; and the sum of the components is 100%. The covering agent has relatively low melting point and low viscosity, the spreadability is good in the casting process, air can be well isolated, and secondary oxidation is prevented. Meanwhile, the heat preservation performance is good, and the temperature drop of molten steel is low.

Owner:NANJING IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com