Method for treating sewage with low carbon nitrogen ratio

A low carbon-to-nitrogen ratio, sewage technology, applied in sustainable biological treatment, chemical instruments and methods, biological water/sewage treatment, etc., can solve high cost, difficult control of liquid organic carbon dosage, secondary pollution of methanol, etc. problems, to achieve purification and standard discharge, improve treatment performance, and reduce the concentration of organic matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

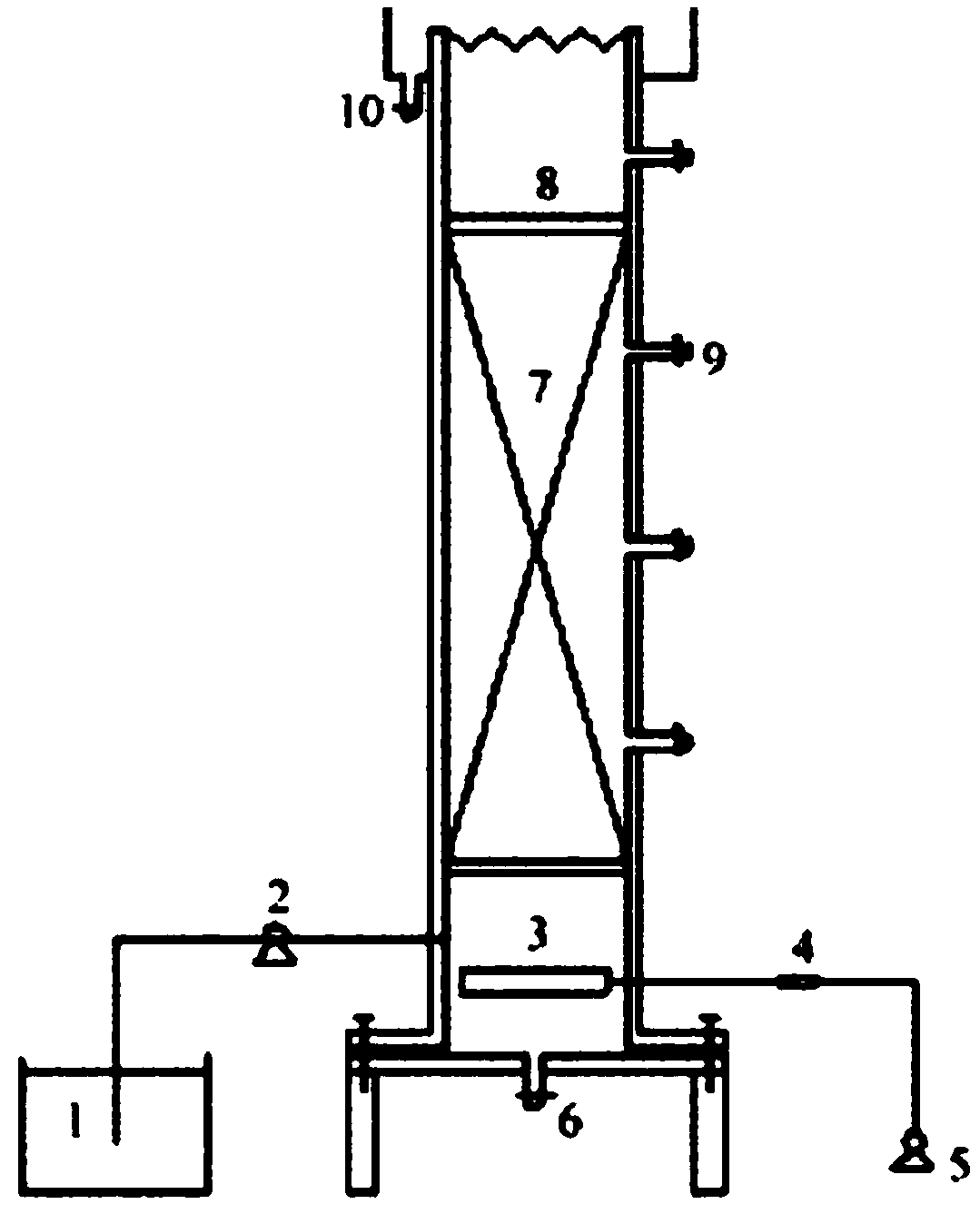

[0041] Example 1: A low-carbon source sewage treatment method

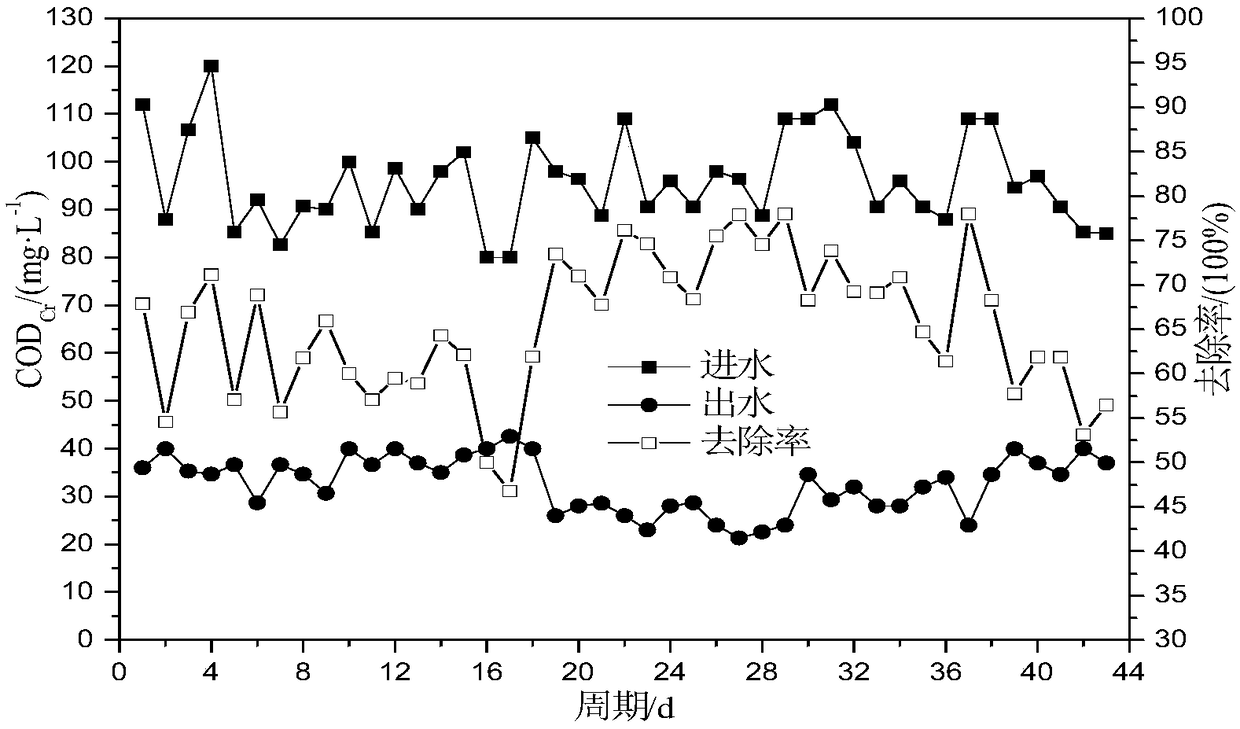

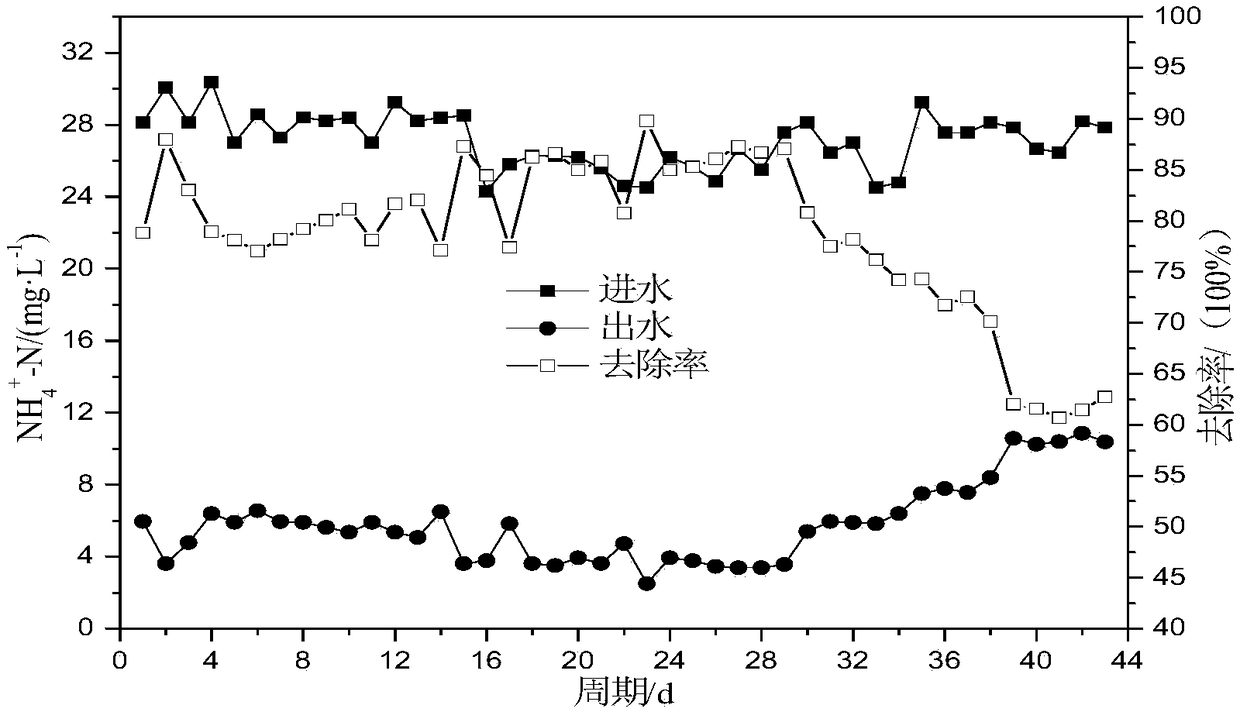

[0042] (1) Preparation of solid carbon source filler biofilm reactor: interlace the solid carbon source material loofah in layers, and fill them on the perforated supporting plate in the biofilm reactor with a filling rate of 40%. The inoculated activated sludge and sewage are poured into the biofilm reactor at a mass ratio of 1:3 from the top, and left for 24 hours to make the sludge fully contact with the natural loofah crops, and then emptied from the sludge outlet, and then exposed Sewage is continuously fed into the biofilm reactor from the water inlet tank in the gas state. Keep the pH at 7.5±0.1 and DO control at 4.0±0.1mg·L during film hanging -1 , The hydraulic load is 0.045m 3 ·M -2 ·H -1 . When the effluent COD of the water outlet of the biofilm reactor Cr , NH 4 + -N removal rate is above 60% and fluctuates within ±3%, and the effluent COD Cr , NH 4 + -N concentration is lower than 50mg·L -1 And 8mg·L -1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com