Lift well automatic opening and closing valve

A technology of automatic opening and closing, lifting wells, applied in the direction of lifting valves, valve details, valve devices, etc., can solve the problems of increasing the water outlet height of lifting well 102, the impact of sewage treatment follow-up process, increasing the production cost of sewage treatment, etc., to achieve increased operation Benefits, superior performance, and the effect of improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The best embodiment of the present invention will be further described in detail below.

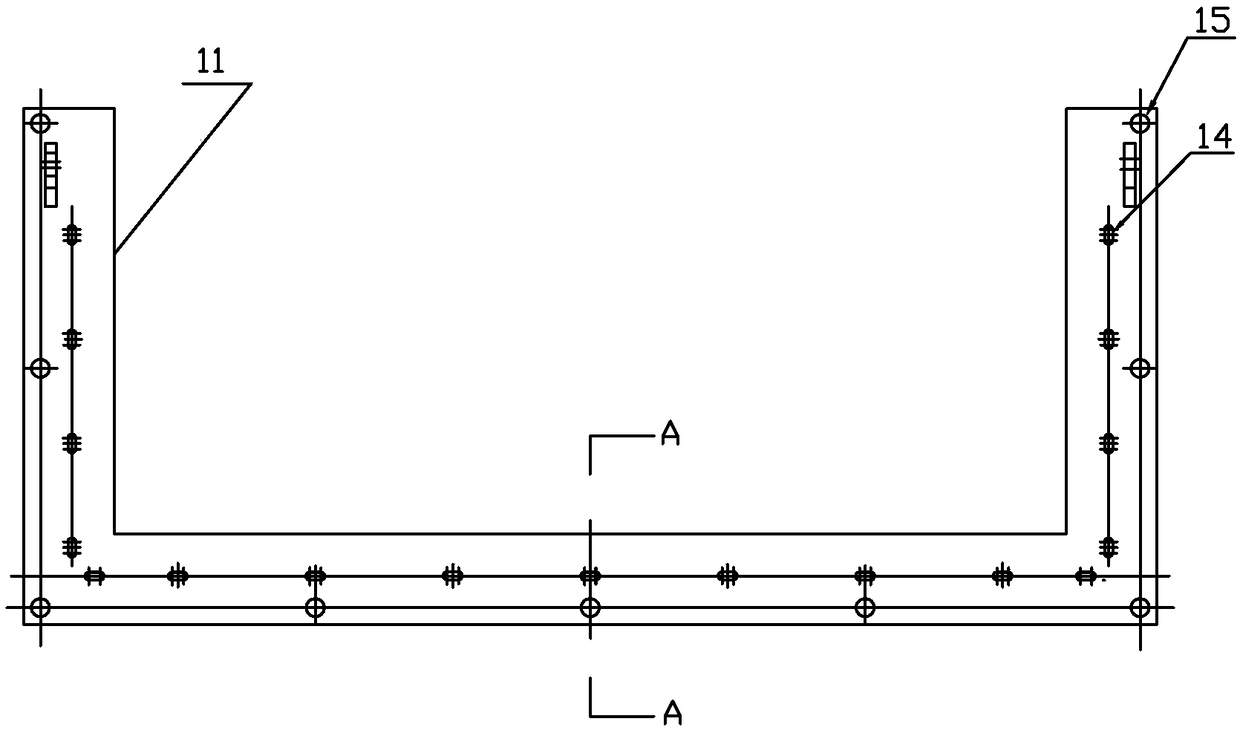

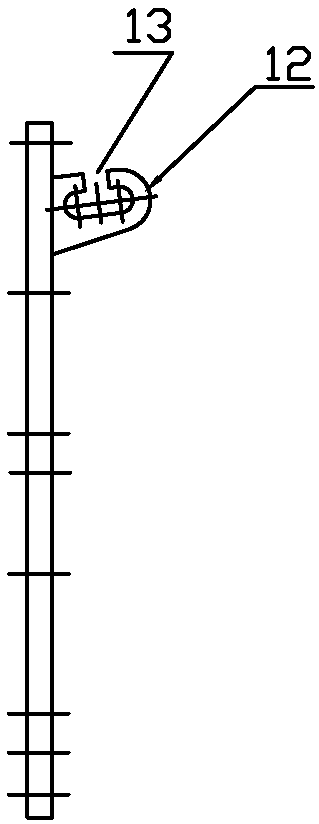

[0052]As shown in Figure 1-12, the lift shaft automatic opening and closing valve includes a valve seat assembly 51 and a valve assembly 81 . The valve assembly 81 slides into the elongated hole on the open hook 12 from the opening 13 of the opening hook 12 through the rotating shaft 62 at the end of the left and right sides of the valve assembly 81, and then the valve assembly 81 Hang on the open hook 12 and put it down gently, let it fit together with the valve seat assembly 51, and complete the assembly of the whole set of lift shaft automatic opening and closing valve 91.

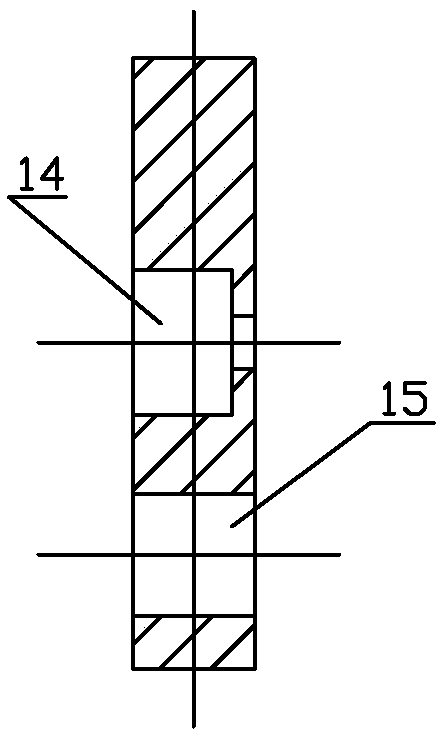

[0053] The valve seat assembly 51 includes a valve seat 11 , a sealing ring 21 and a pressing piece 31 . The valve seat 11 is a U-shaped structure, and the front of the valve seat 11 is provided with a sealing ring assembly 41 , that is, the sealing ring 21 is installed on the front of the valve seat 11 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com