A kind of beryllium aluminum alloy powder and its preparation method and application

A technology of beryllium-aluminum alloy and vacuum environment, which is applied in the field of beryllium-aluminum alloy powder and its preparation, can solve the problems of affecting powder fluidity, low powder proportion, and many satellite powders, and achieve high production efficiency, good sphericity, and increased production efficiency. The effect of low oxygen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] In an exemplary embodiment of the present invention, the preparation method of the beryllium aluminum alloy powder may include the following steps:

[0028] The vacuum smelted beryllium aluminum alloy rods or beryllium aluminum alloy rods produced by powder metallurgy are processed into consumable electrode raw material rods (also called raw material rods, beryllium aluminum alloy rods, beryllium aluminum alloy raw material rods, etc.) .

[0029] Put the raw material rod into the arc melting rotary atomization device, extract the vacuum, and then pass the mixed inert gas into the device.

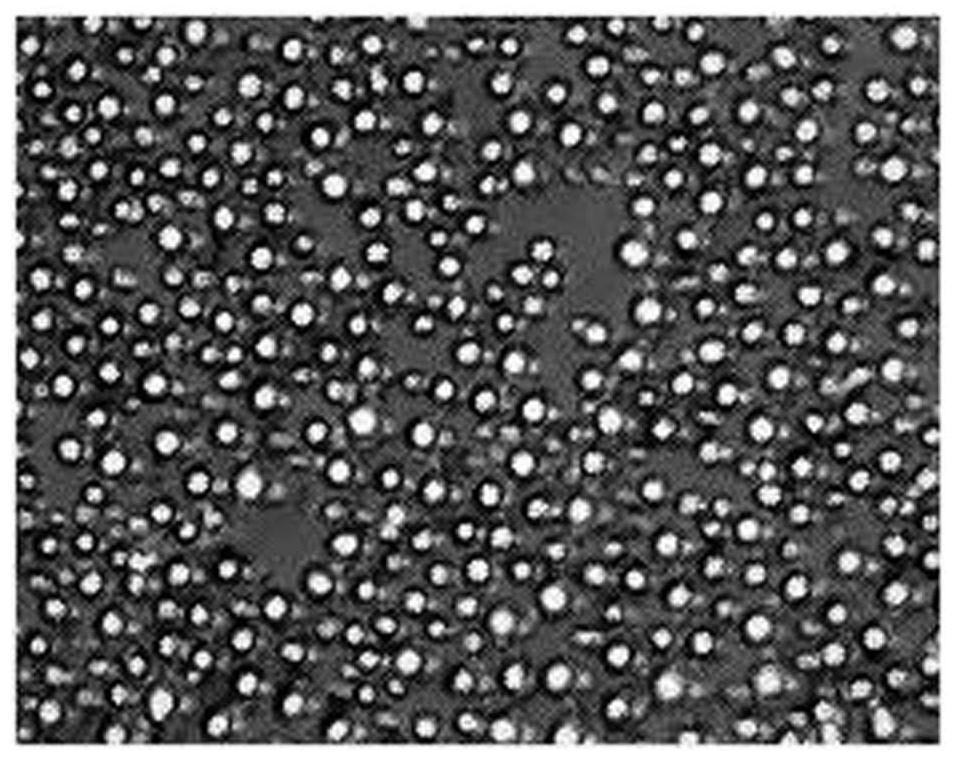

[0030] Under the protection of inert gas, the plasma arc is turned on to melt the front end of the raw material rod into a liquid film, and the rotation speed of the rotating raw material rod is controlled. The liquid film melted at the front end of the raw material rod is broken into fine droplets under the action of centrifugal force. The proportion of beryllium-aluminum alloy liqu...

example 1

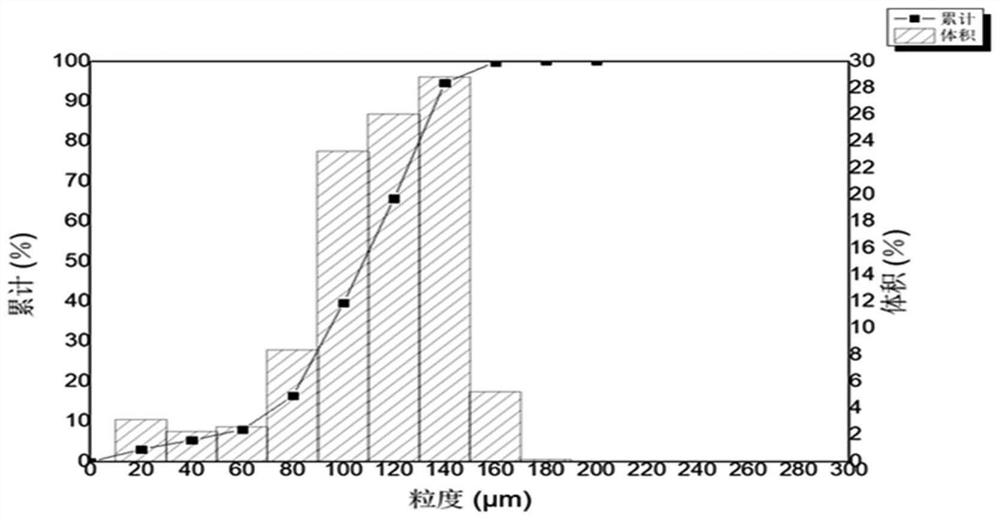

[0058] The rod prepared by powder metallurgy isostatic pressing sintering is used as a beryllium aluminum alloy raw material rod, the mass fraction of beryllium in the raw rod is 62%, the mass fraction of aluminum is 37.5, and the relative density is greater than 97%. Process the raw material rod into Ф50×600mm, remove the oxide and impurities on the surface of the raw material rod, put the raw material beryllium rod into the arc melting rotary atomization device, and vacuumize it to 3×10 -3 Pa, and then pass a mixed inert gas into the device to ensure that the oxygen content in the atomization chamber is 3ppm. Under the protection of inert gas, the arc melting rotary atomization device is turned on, and the arc melting power is controlled by adjusting the working current to control the melting speed of the beryllium aluminum alloy rod. The working current output is 1300A, the arc length is 70mm, and the raw material beryllium rod The rotating speed is 19000rpm. The front end ...

example 2

[0066] Take a beryllium aluminum alloy extruded rod with a relative density greater than 99%, whose chemical composition is shown in Table 2, and process it into a raw beryllium rod with a diameter of Ф100×350mm.

[0067] After the surface oxide and impurities are removed from the raw material beryllium rod, the raw material beryllium rod is placed in the arc rotating electrode device, and the vacuum degree is 6×10 -3 Pa, and then pass a mixed inert gas into the device to ensure that the oxygen content in the atomization chamber is 4ppm.

[0068] Under the protection of inert gas, the arc melting rotary atomization device is turned on, and the arc melting power is controlled by adjusting the working current to control the melting speed of the beryllium aluminum alloy rod. Among them, the working current output is 2100A, and the arc length is 45mm; rotating beryllium aluminum Alloy raw material rod, the rotation speed is 16000rpm, the front end of the raw material rod is melted...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| fluidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com