Patents

Literature

63 results about "Electron-beam additive manufacturing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

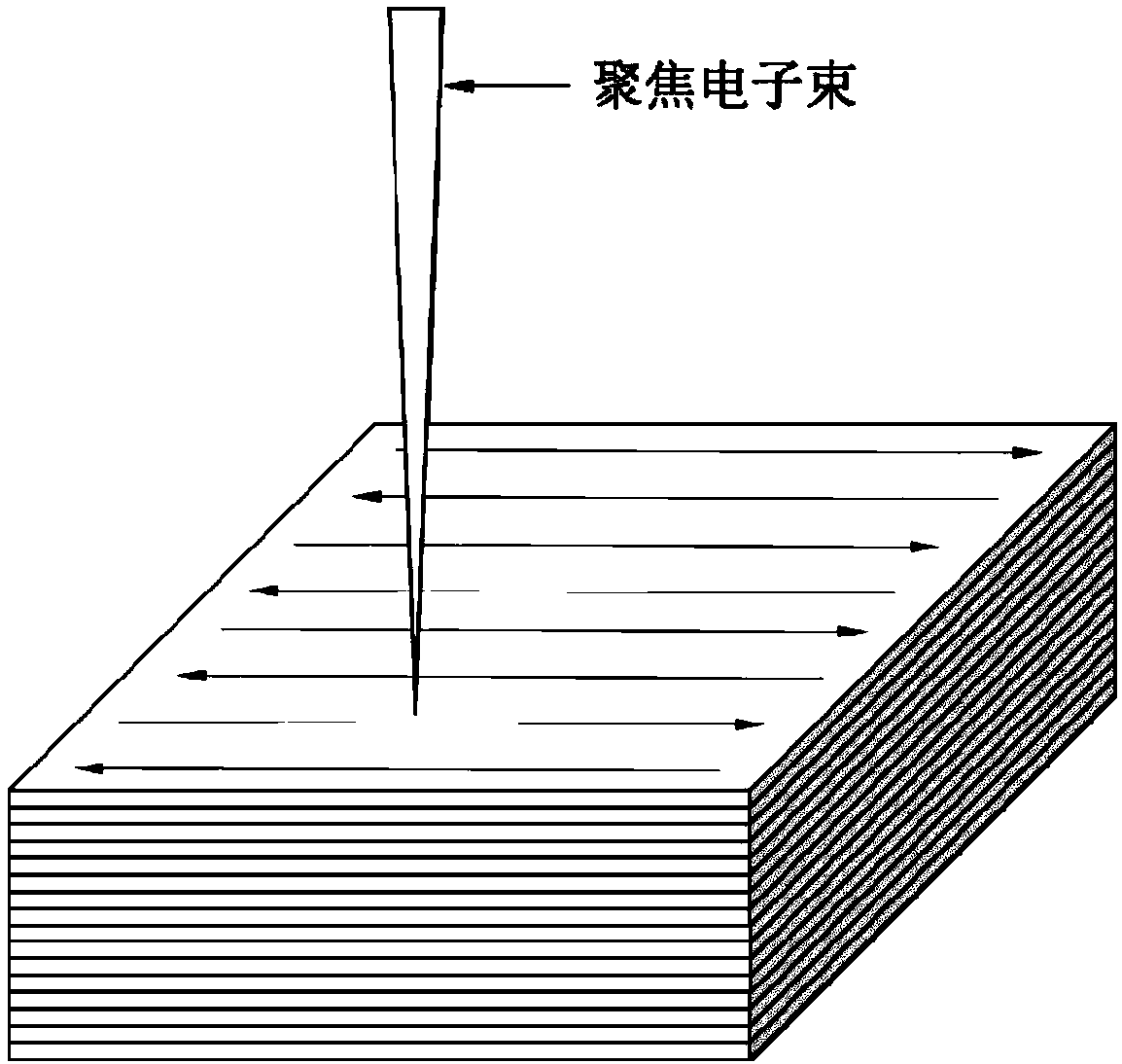

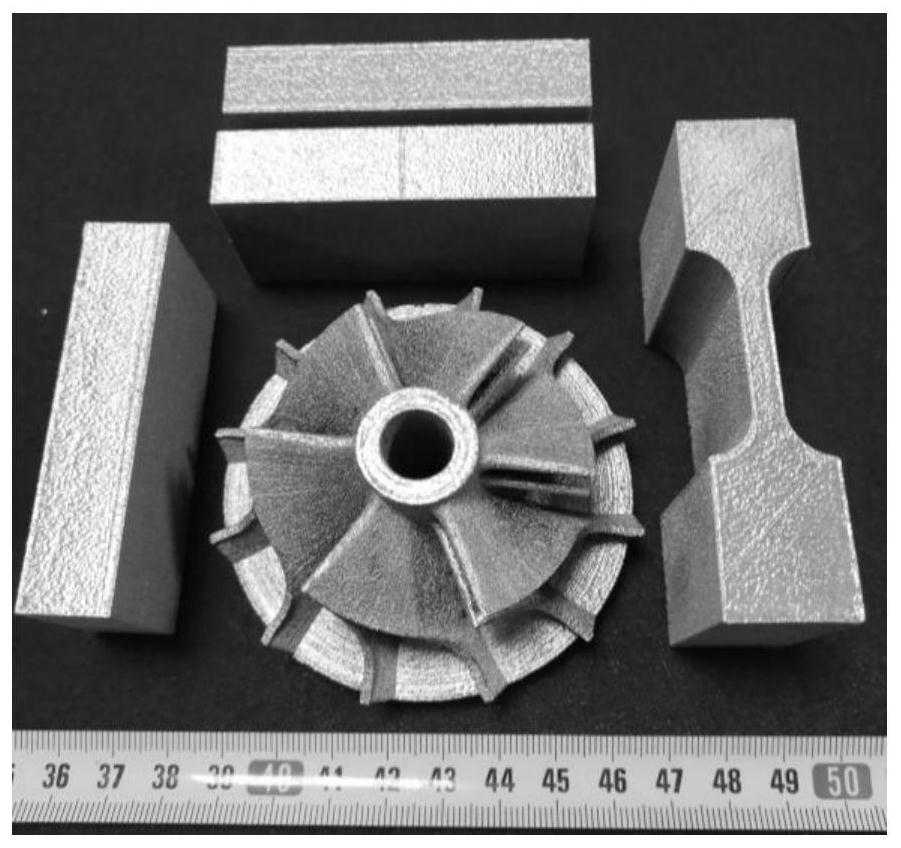

Electron-beam additive manufacturing, or electron-beam melting (EBM) is a type of additive manufacturing, or 3D printing, for metal parts. The raw material (metal powder or wire) is placed under a vacuum and fused together from heating by an electron beam. This technique is distinct from selective laser sintering as the raw material fuses having completely melted.

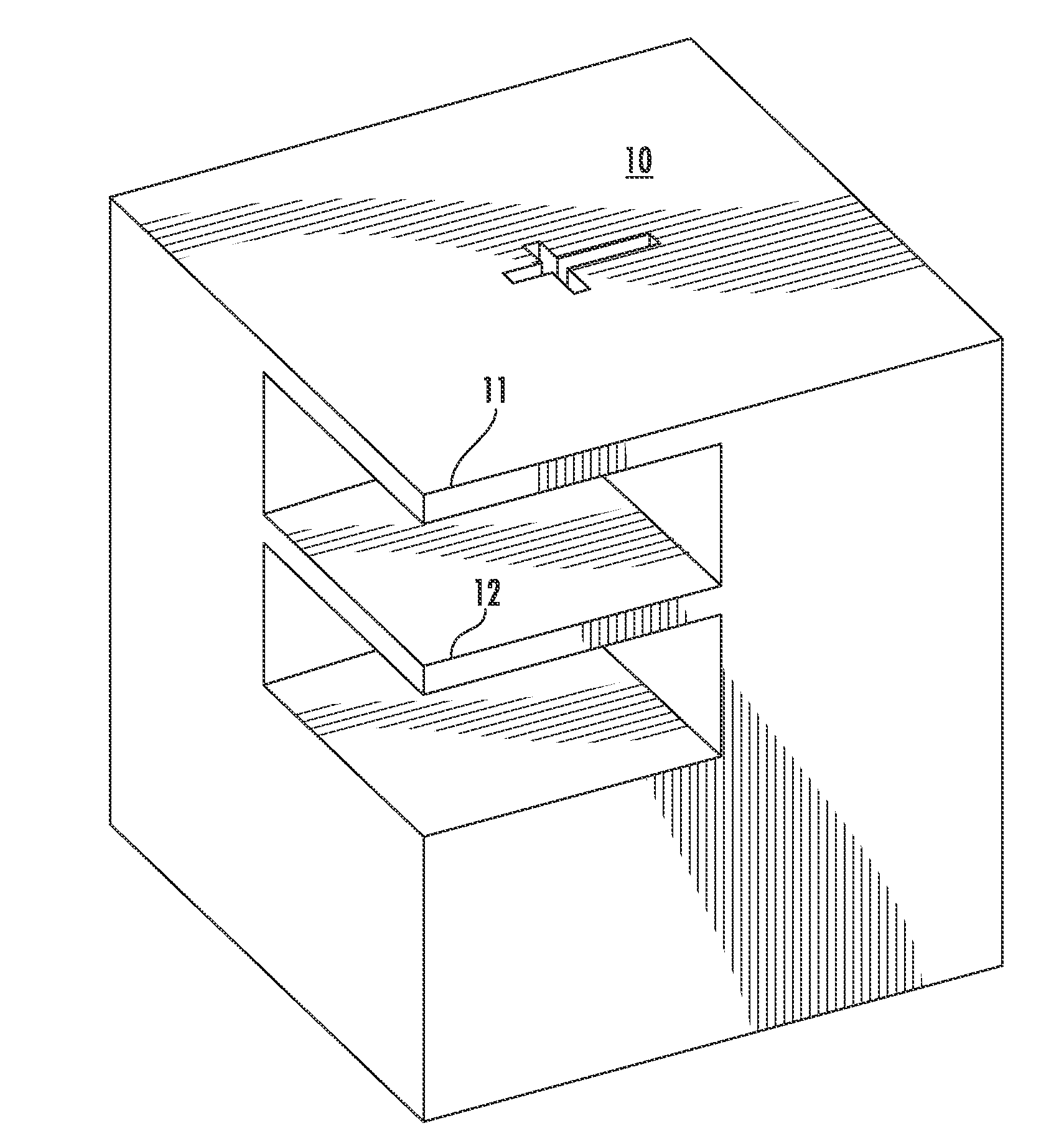

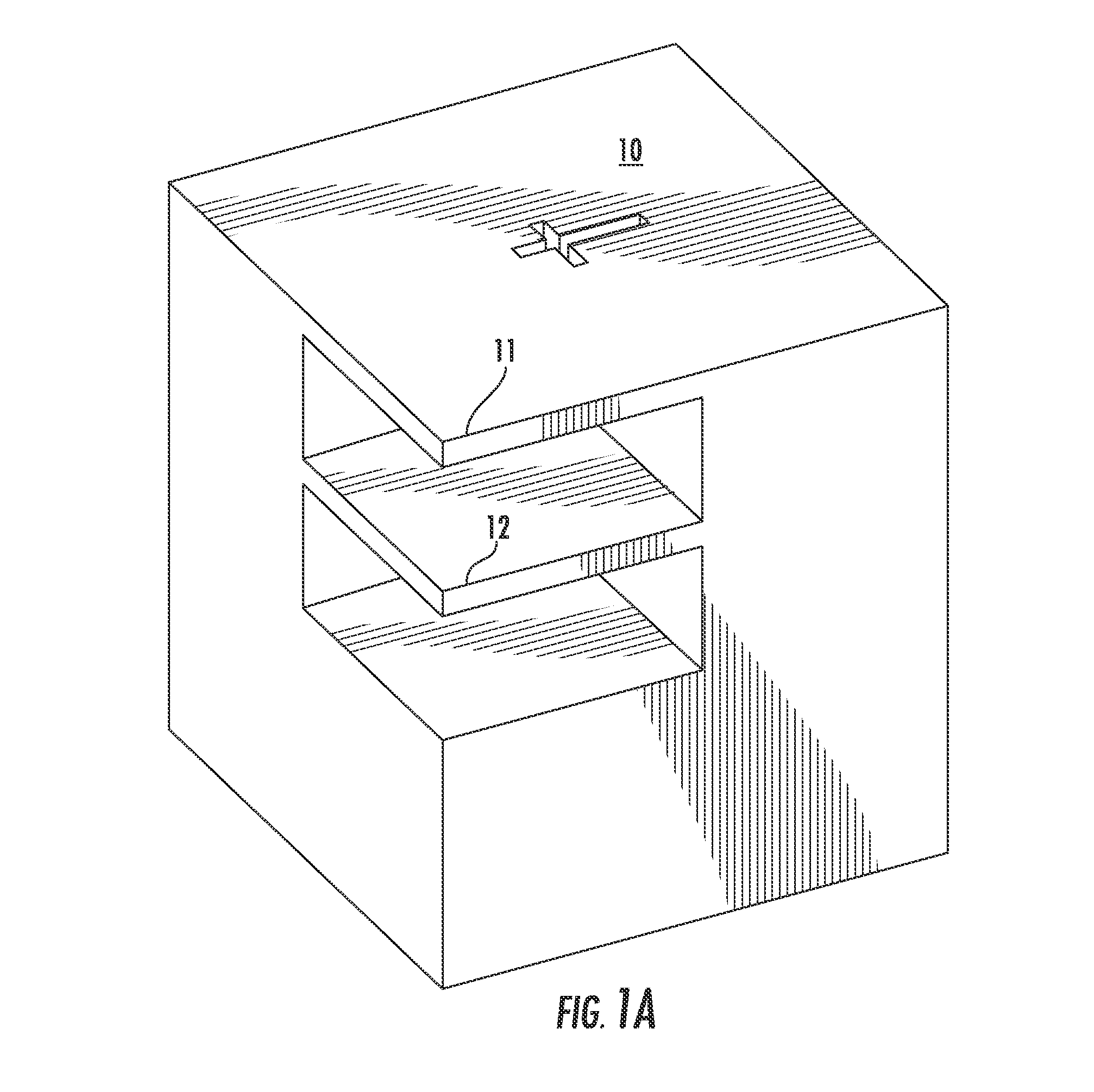

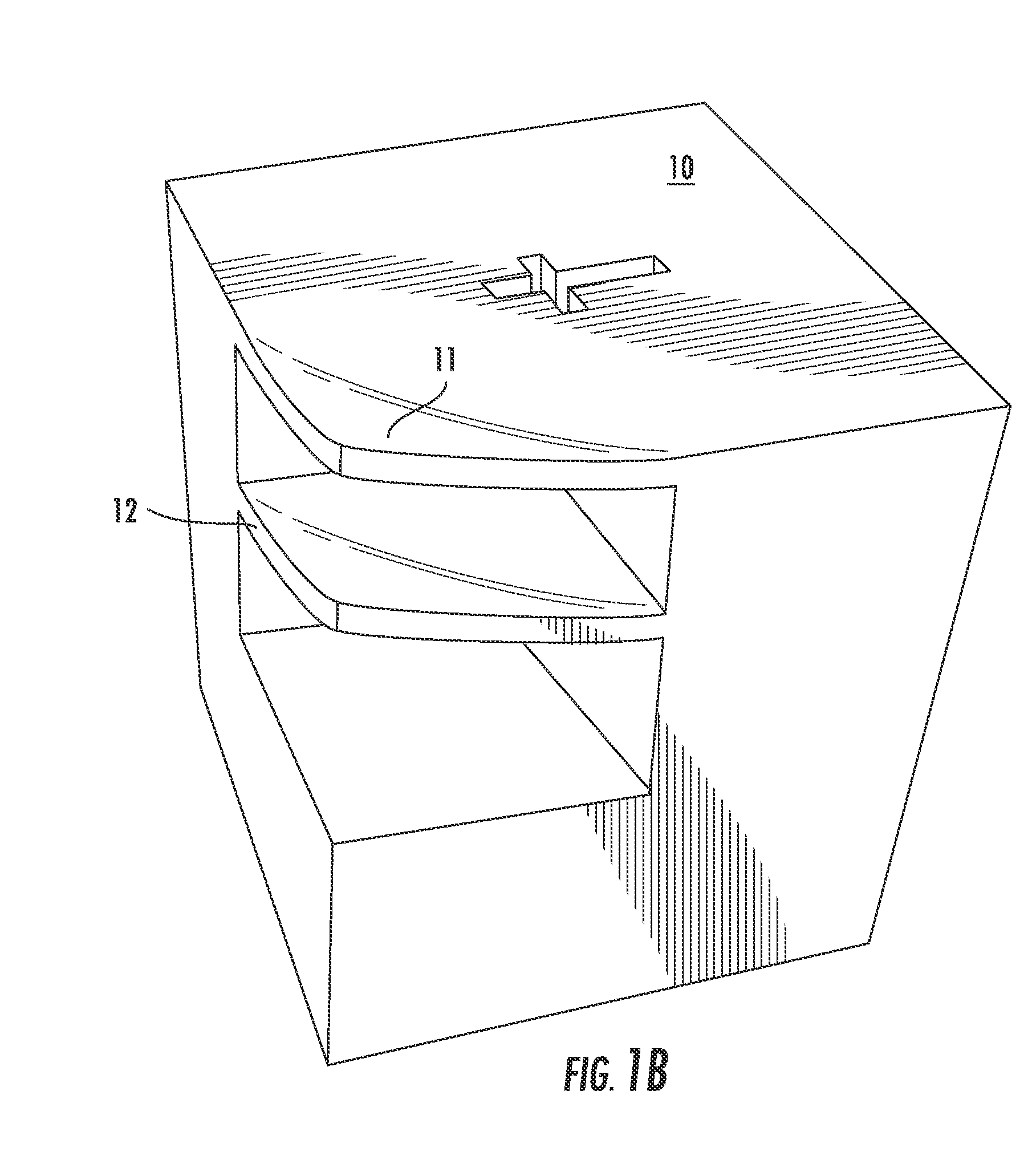

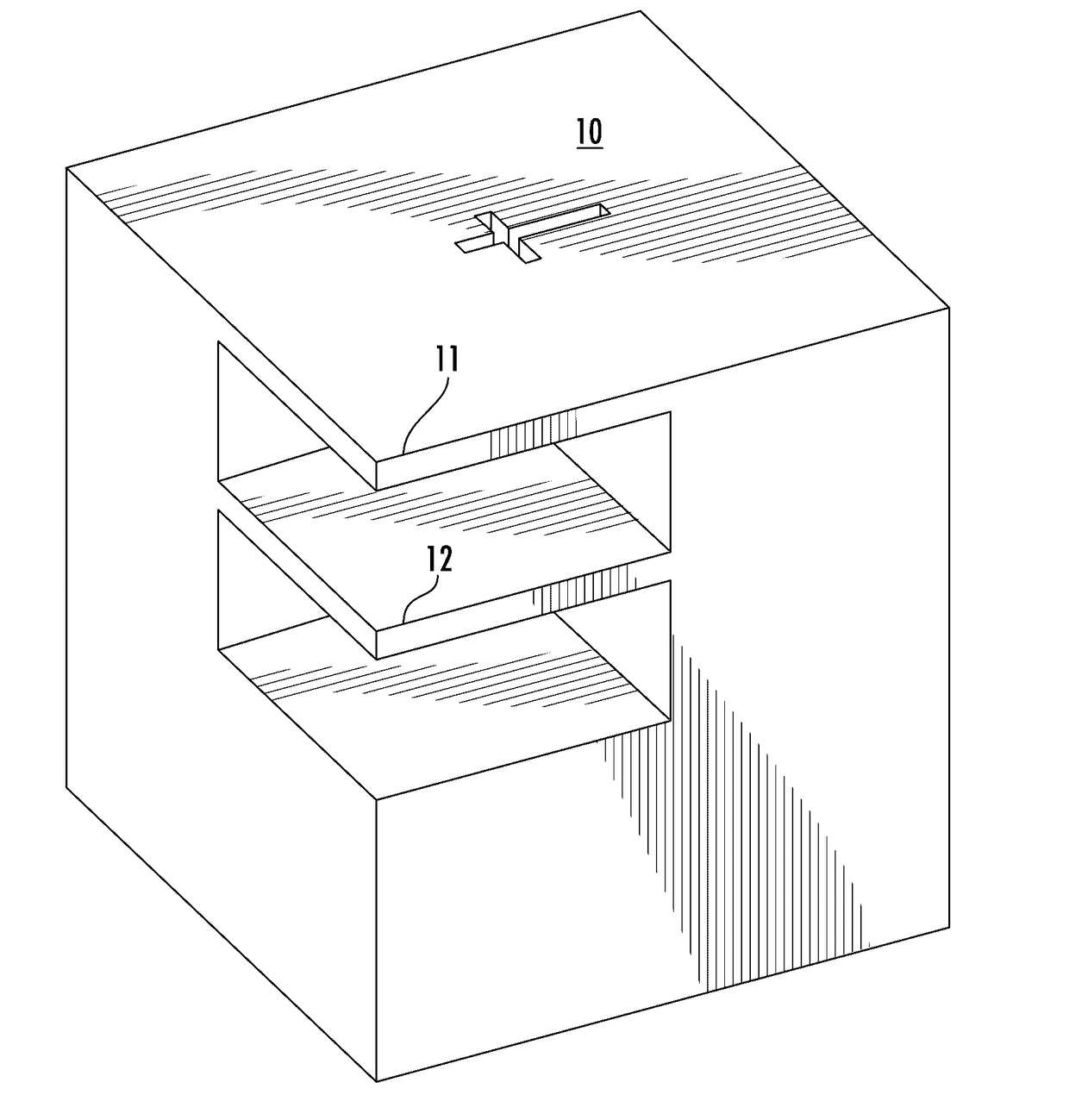

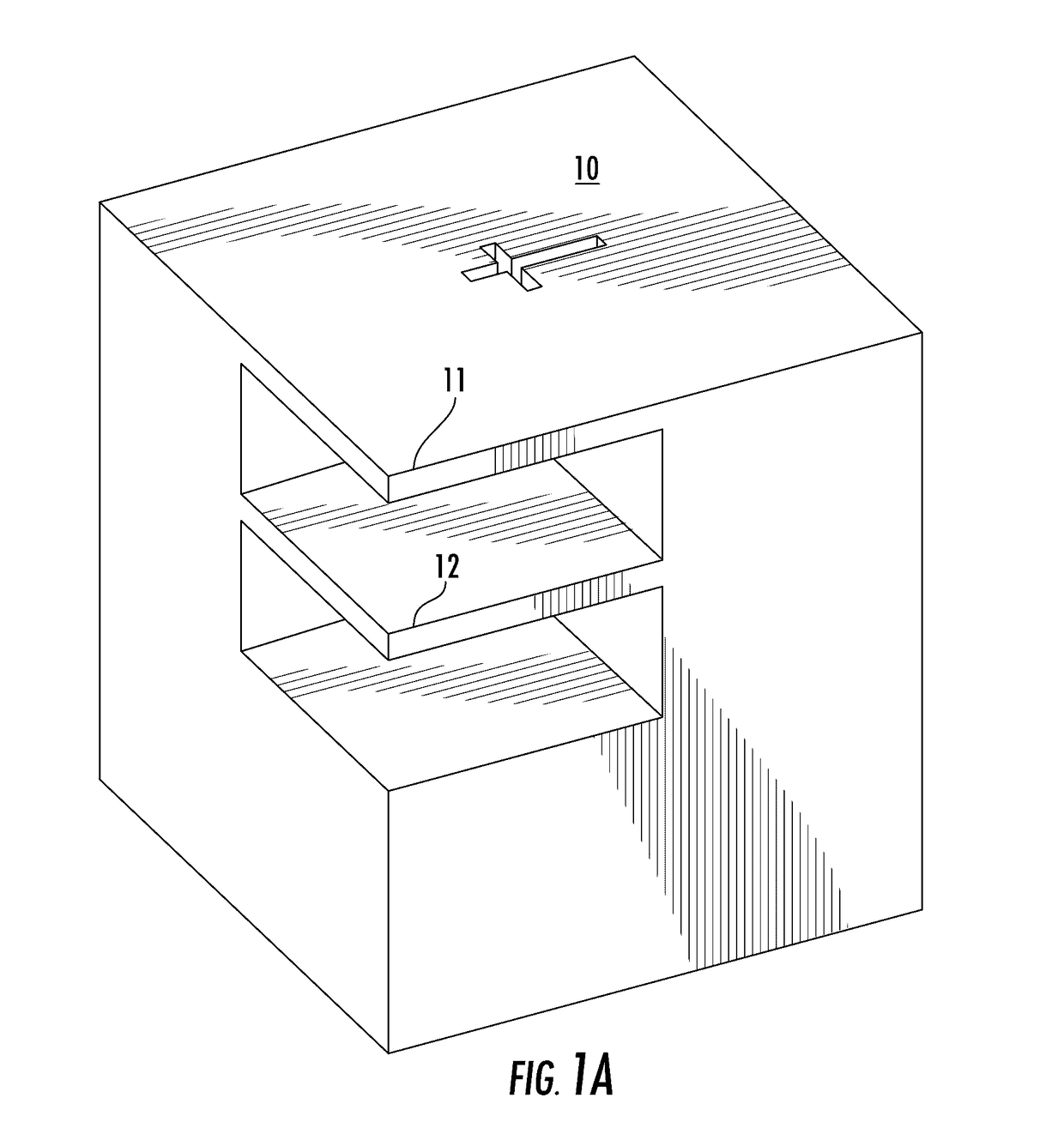

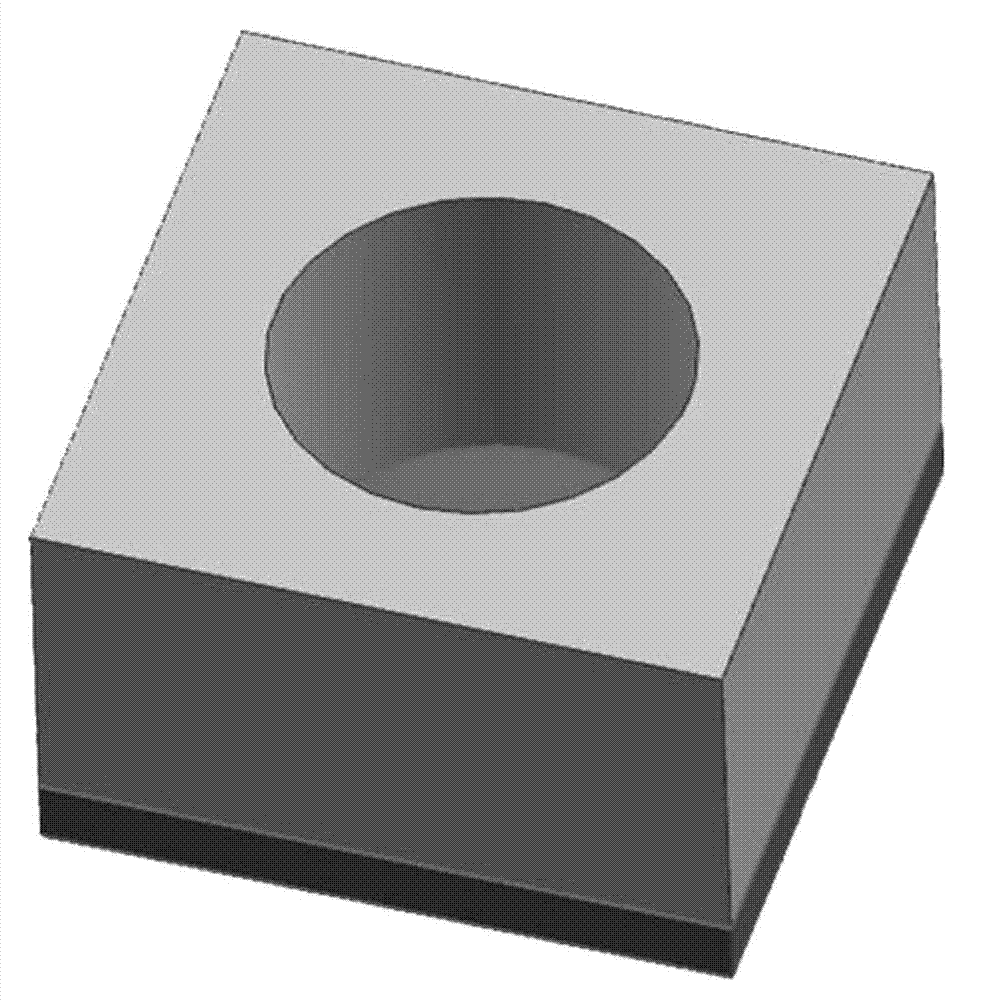

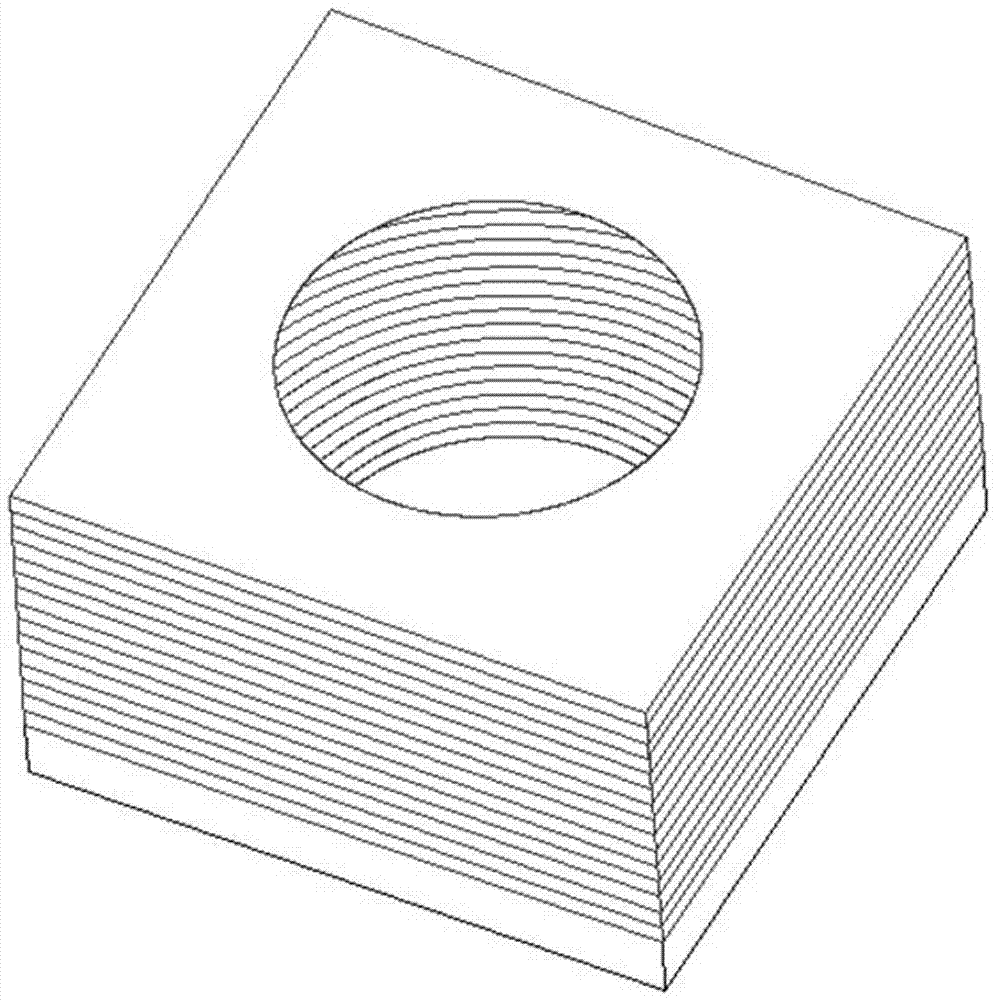

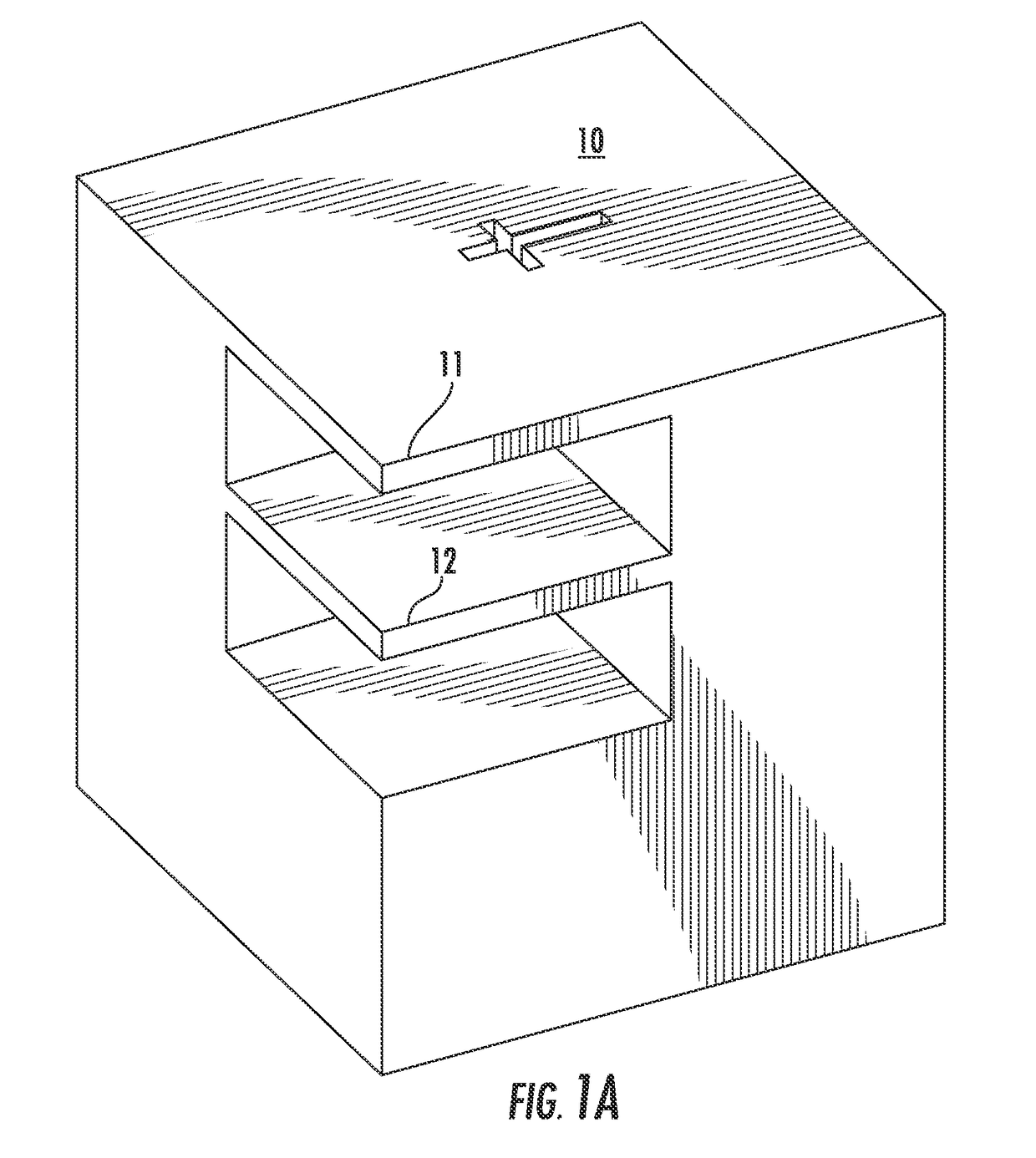

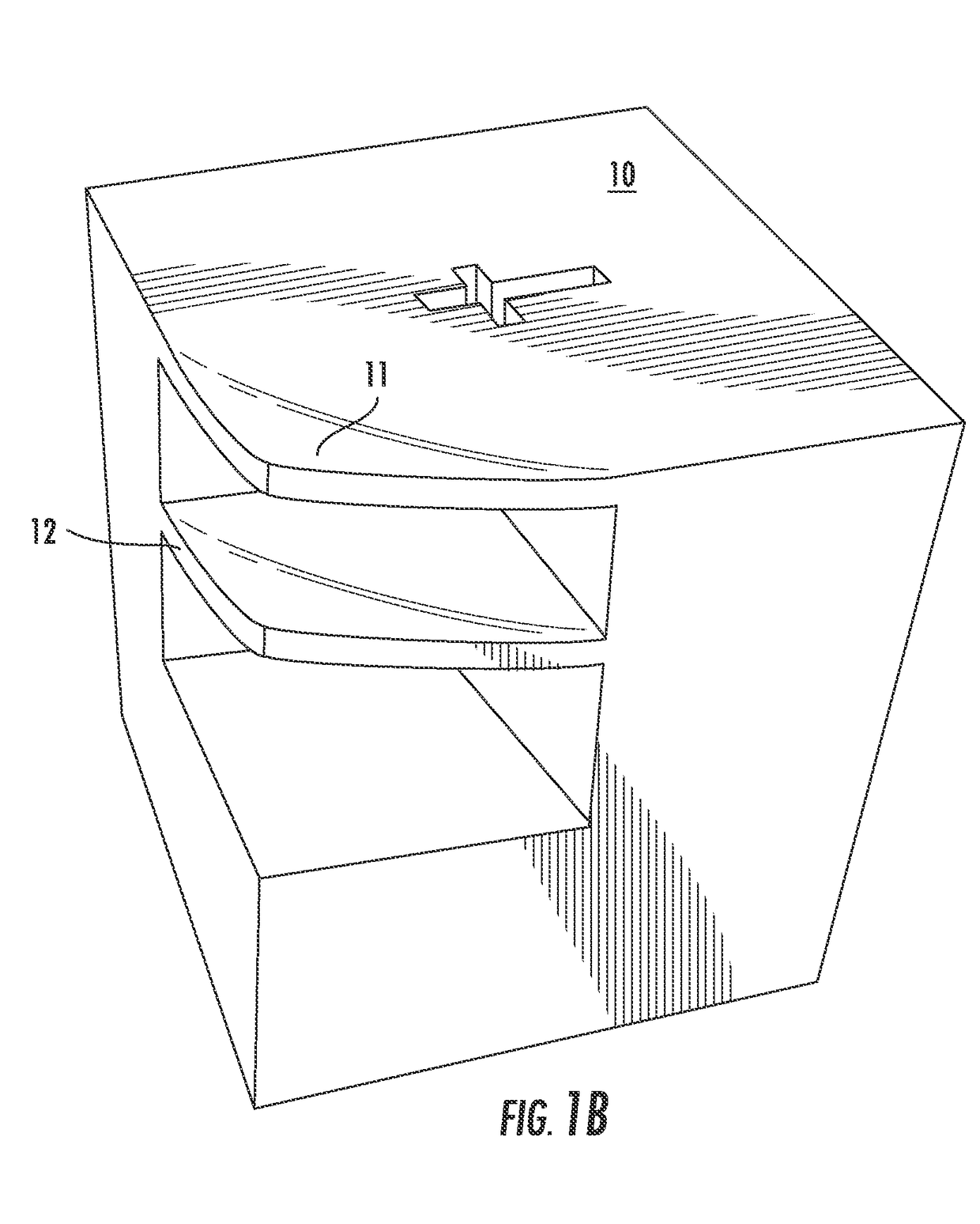

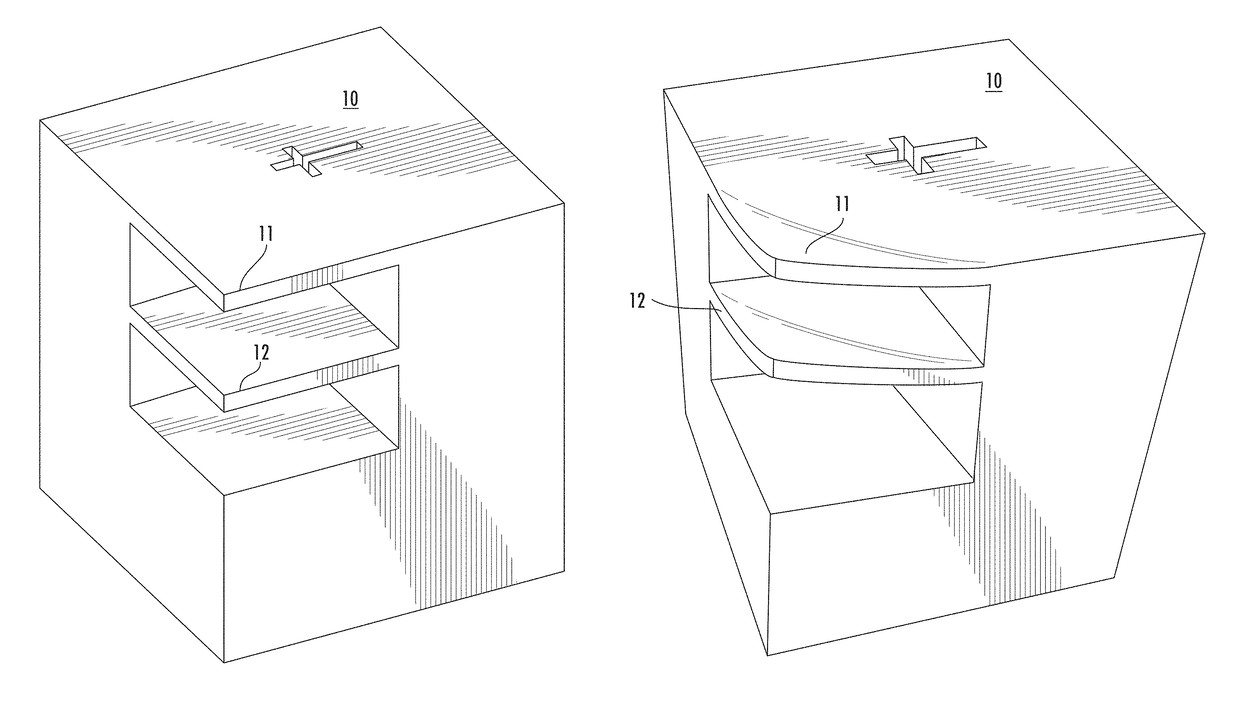

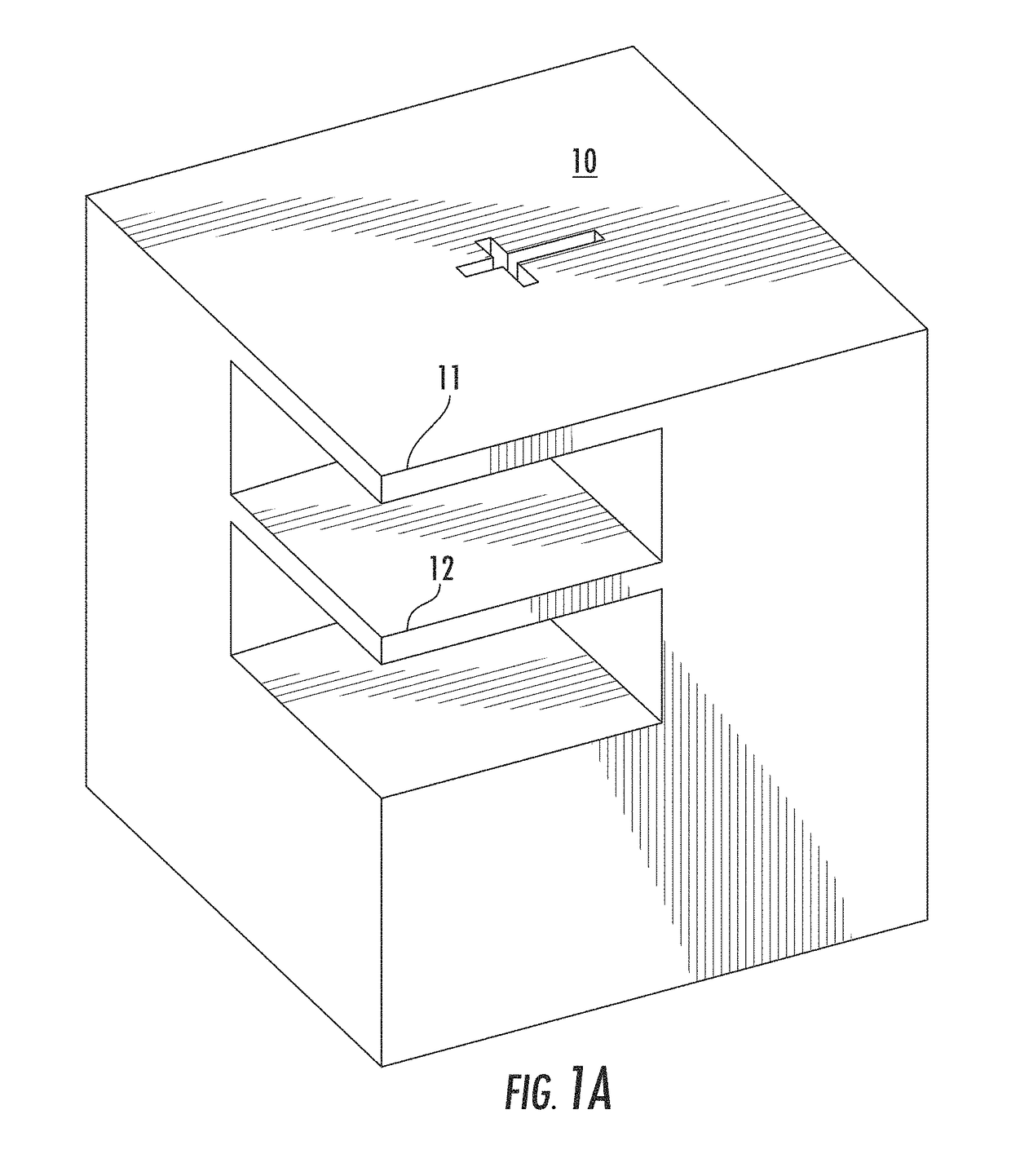

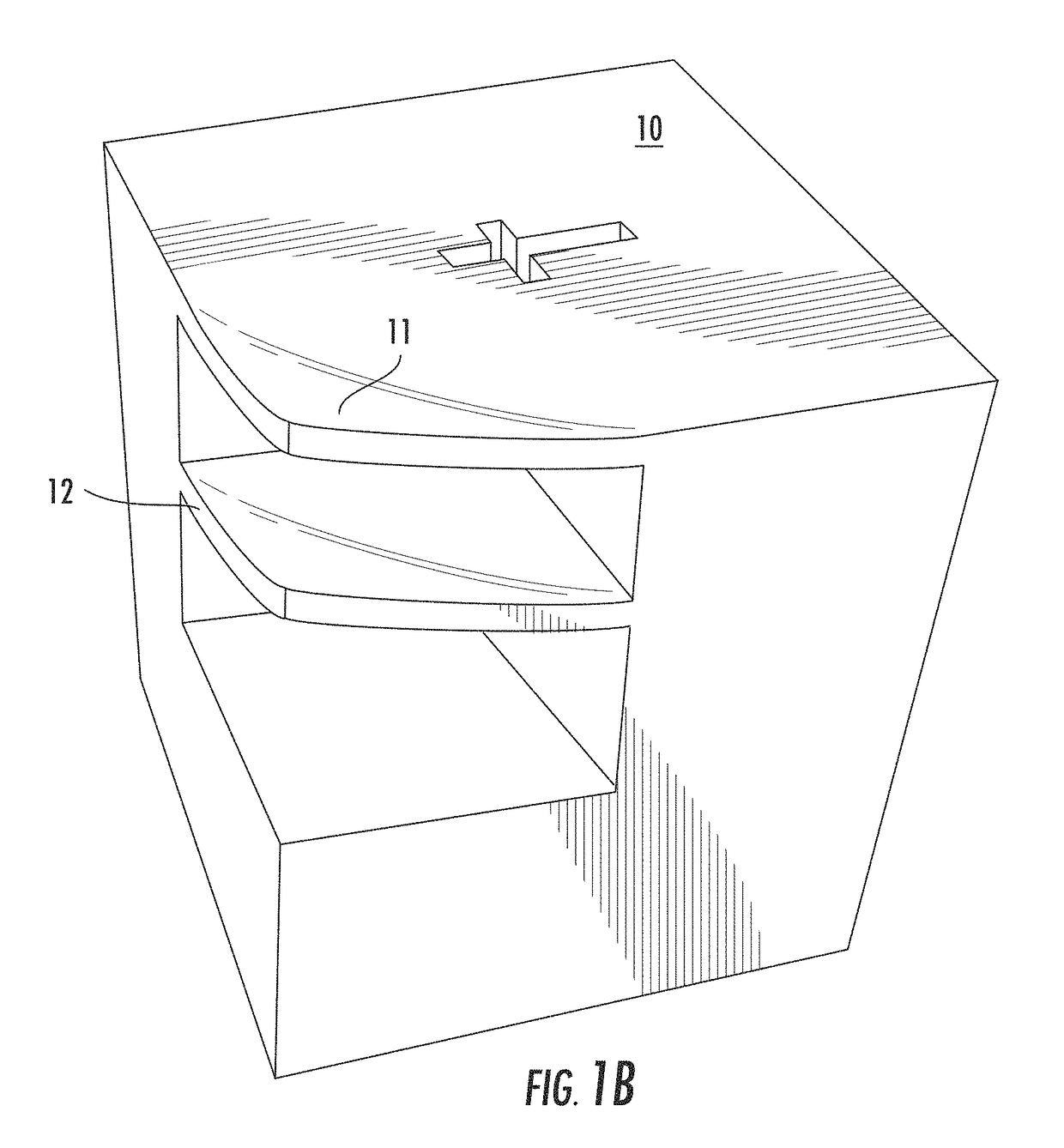

Systems and Methods for Designing And Fabricating Contact-Free Support Structures for Overhang Geometries of Parts in Powder-Bed Metal Additive Manufacturing

ActiveUS20140335313A1Improve heat transfer performanceReduce gradientAdditive manufacturing apparatusLayered productsContact freeMetal powder

Systems and methods are provided for designing and fabricating contact-free support structures for overhang geometries of parts fabricated using electron beam additive manufacturing. One or more layers of un-melted metallic powder are disposed in an elongate gap between an upper horizontal surface of the support structure and a lower surface of the overhang geometry. The powder conducts heat from the overhang geometry to the support structure. The support structure acts as a heat sink to enhance heat transfer and reduce the temperature and severe thermal gradients due to poor thermal conductivity of metallic powders underneath the overhang. Because the support structure is not connected to the part, the support structure can be removed freely without any post-processing step.

Owner:NASA +1

Systems and methods for designing and fabricating support structures for overhang geometries of parts in additive manufacturing

ActiveUS20170136539A1Improve heat transfer performanceReduce gradientAdditive manufacturing apparatusIncreasing energy efficiencyContact freeLaser additive manufacturing

Systems and methods are provided for designing and fabricating contact-free support structures for overhang geometries of parts fabricated using electron beam additive manufacturing. One or more layers of un-melted metallic powder are disposed in an elongate gap between an upper horizontal surface of the support structure and a lower surface of the overhang geometry. The powder conducts heat from the overhang geometry to the support structure. The support structure acts as a heat sink to enhance heat transfer and reduce the temperature and severe thermal gradients due to poor thermal conductivity of metallic powders underneath the overhang. Because the support structure is minimally or not connected to the part, the support structure can be removed with minimal or no post-processing step.

Owner:UNIVERSITY OF ALABAMA +1

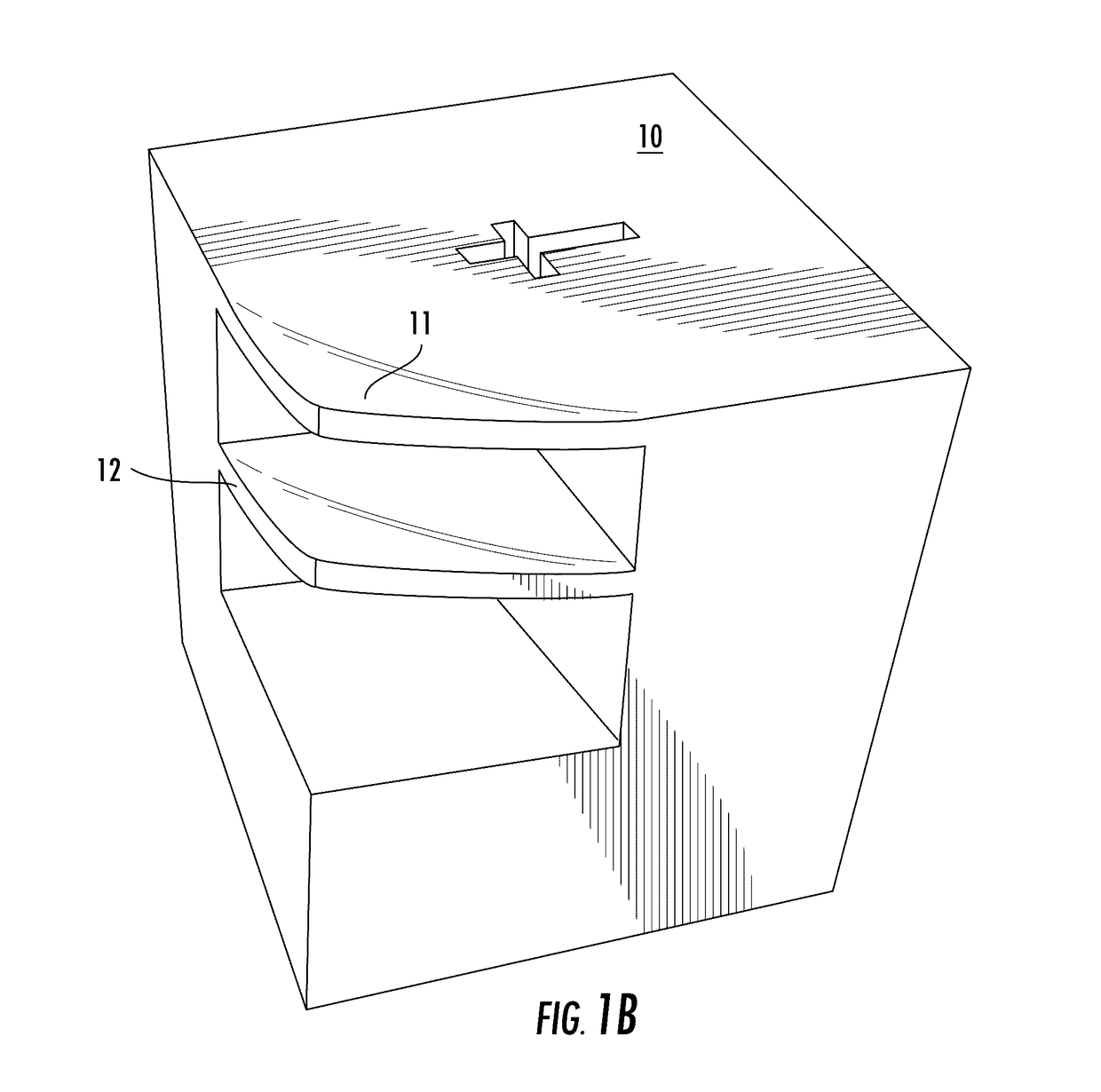

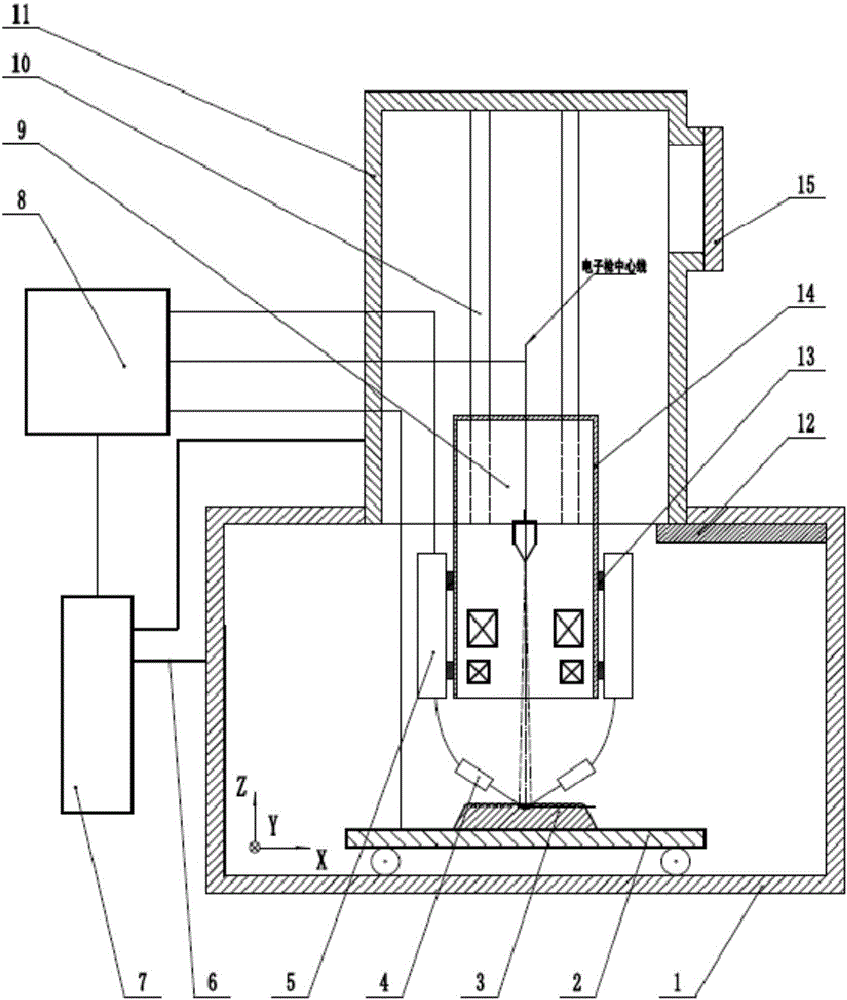

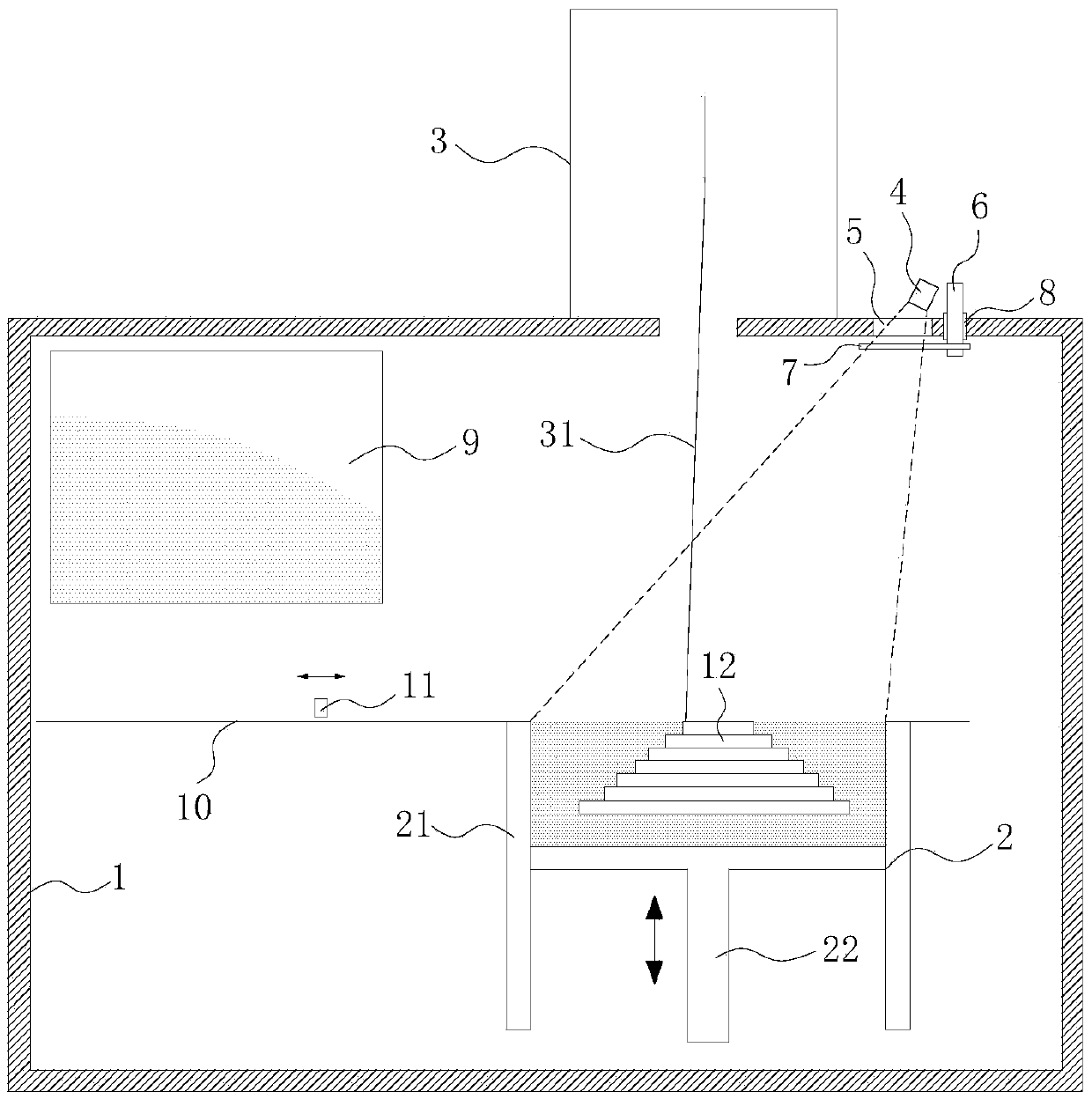

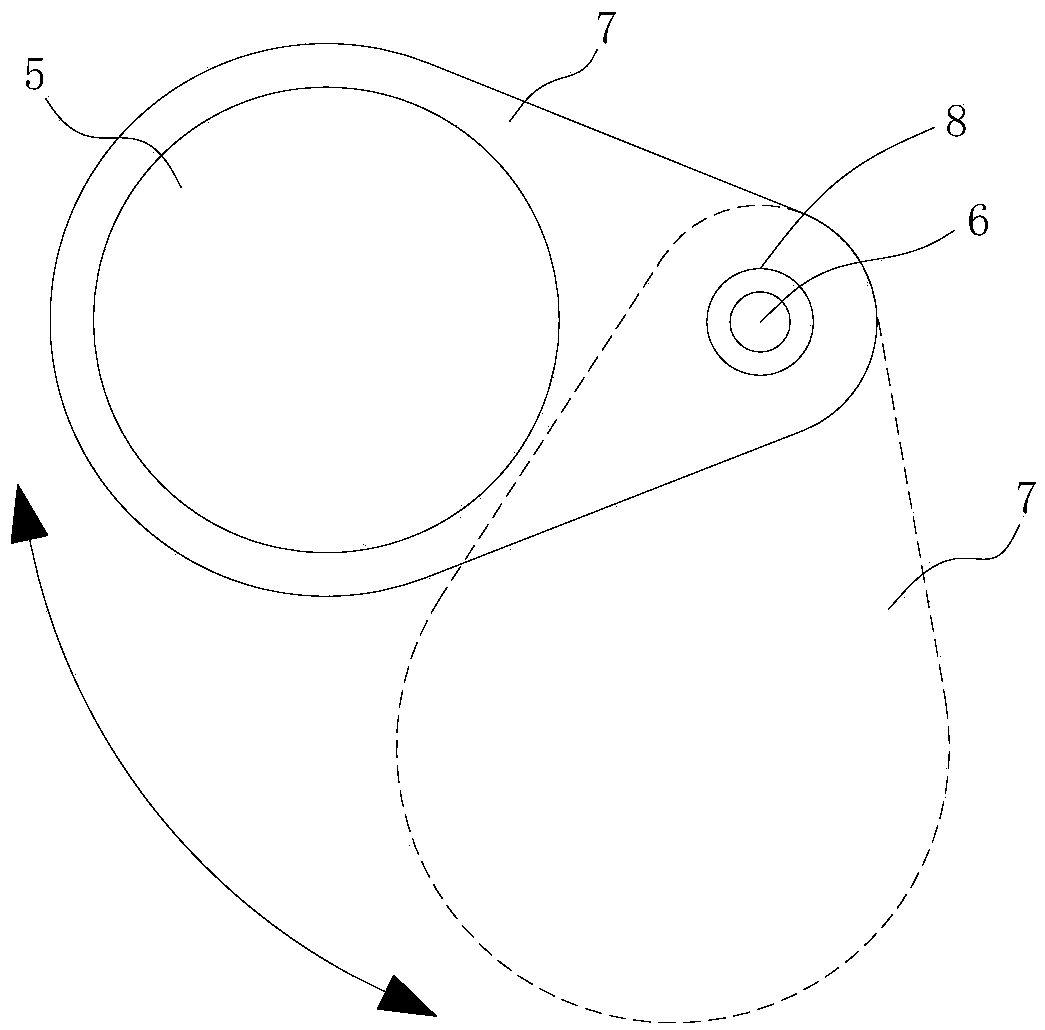

Wire-feeding type electron beam material-increasing manufacturing equipment and operating method thereof

InactiveCN105904079ASolving Online Monitoring ProblemsImprove manufacturing precisionElectron beam welding apparatusElectron beam machiningSecondary electrons

The invention discloses wire-feeding type electron beam material-increasing manufacturing equipment and an operating method thereof. A deflecting and scanning device and a secondary electron receiving device are further mounted on an electronic gun. The deflecting and scanning device and the secondary electron receiving device are connected to a central control unit. When an electron beam sent out by the electronic gun processes a manufacturing layer of a fixed segment of a workpiece, an exciting current of the deflecting and scanning device is controlled by the central control unit, so that the electron beam of the electronic gun turns around to quickly scan the manufacturing layer of the fixed segment, the secondary electron receiving device transmits secondary electronic signals received in a back-scanning process to the central control unit, and the central control unit synchronously records the secondary electronic signal of each scanning point on the fixed segment; after scanning, the central control unit analyzes and processes the recorded secondary electronic signal data so as to determine whether the edge of the manufacturing layer of the fixed segment reaches an expected value or not and determine whether the manufacturing layer of the fixed segment has hole defects or not for the convenience of immediate repair.

Owner:GUILIN THD TECH CO LTD

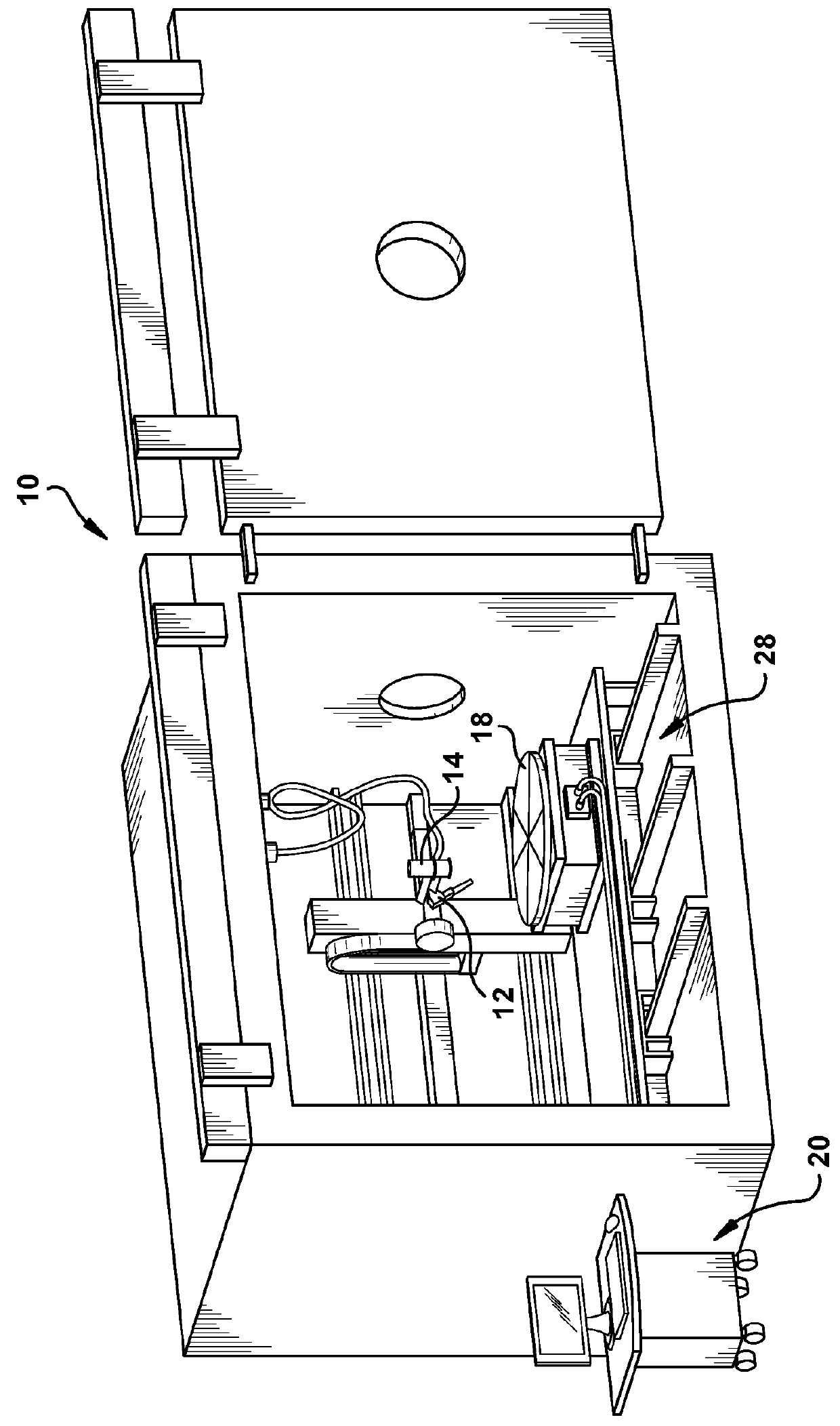

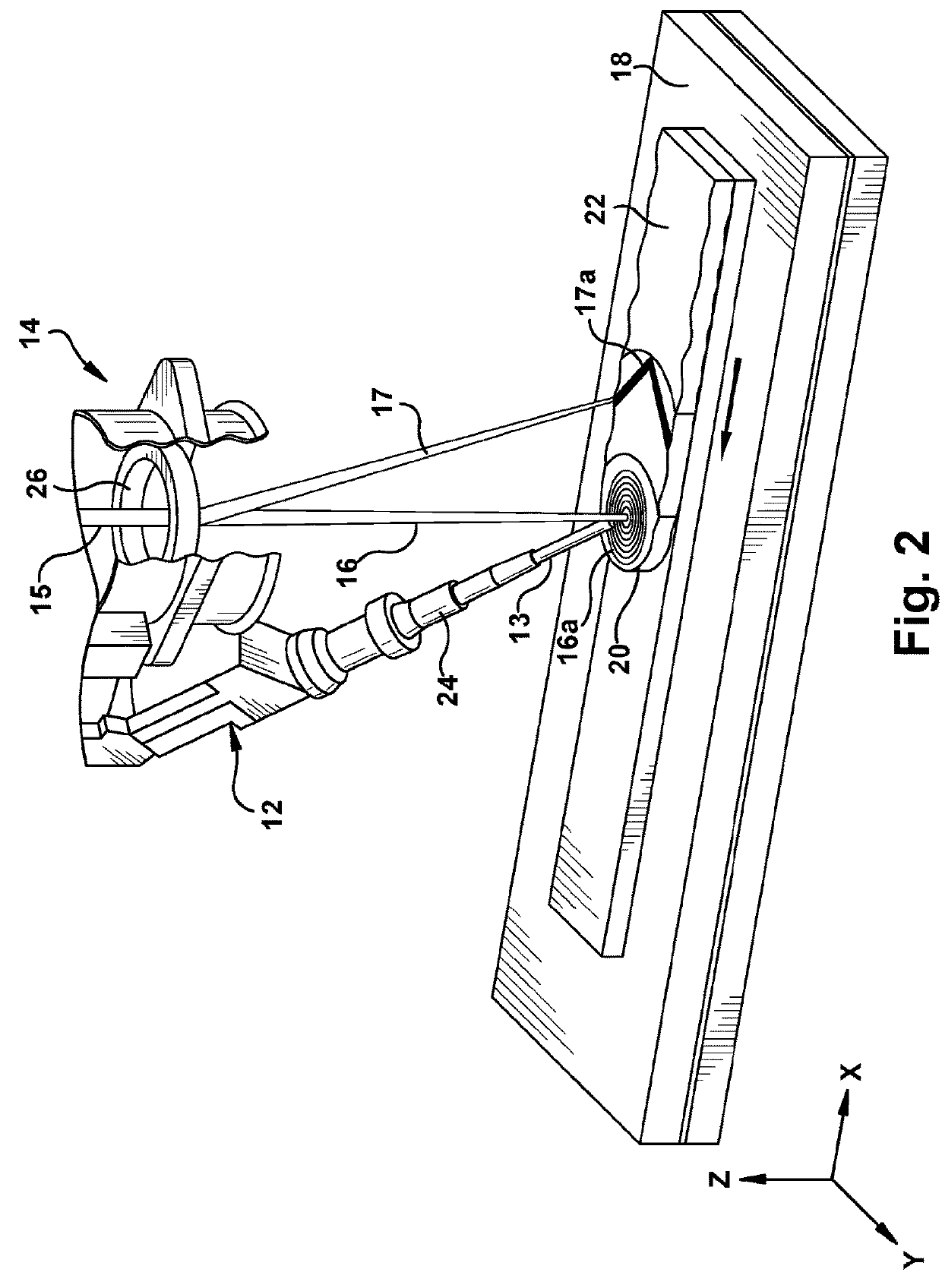

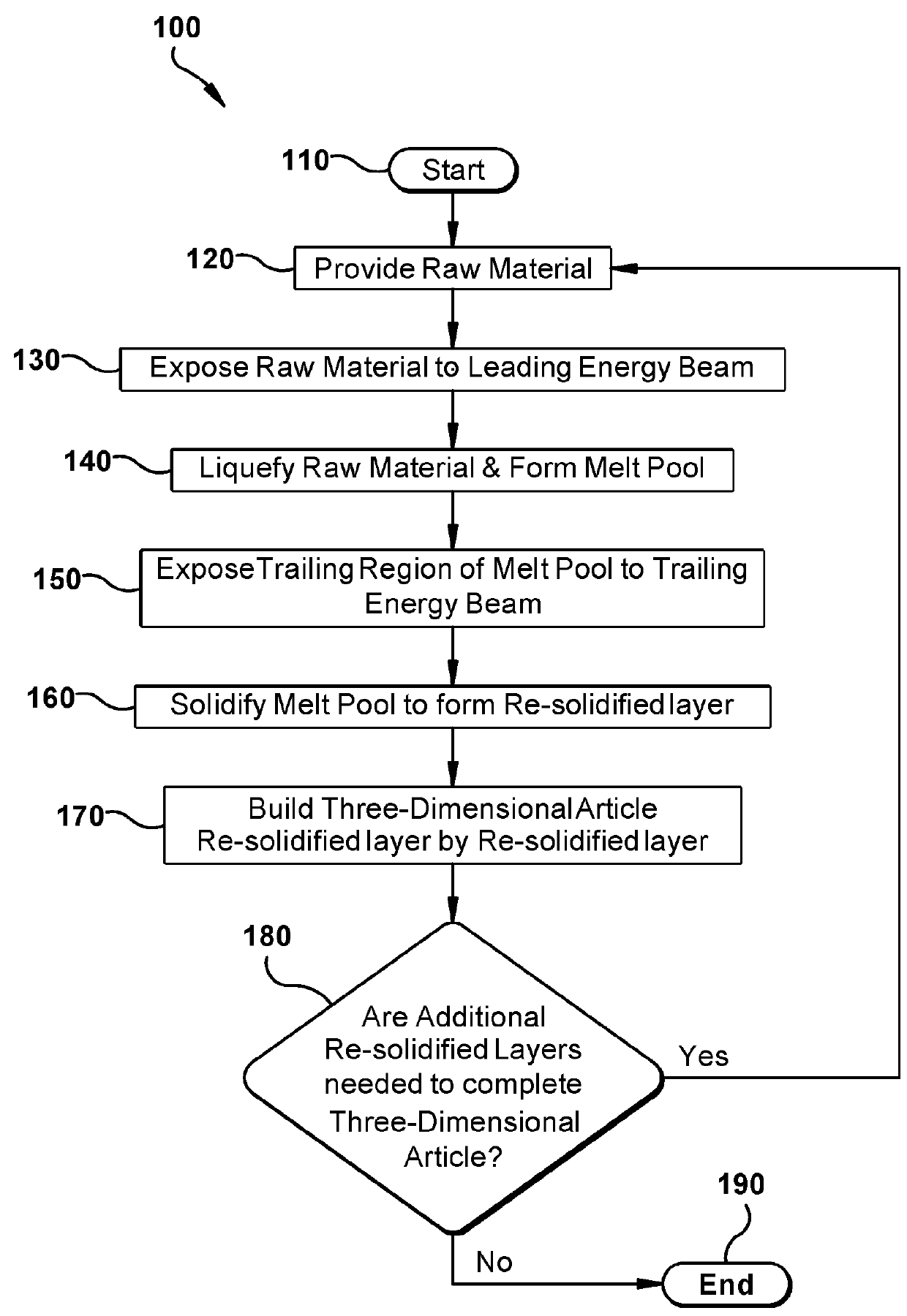

Electron beam additive manufacturing

ActiveUS20180272460A1Lower capital expenditureReduce material wasteAdditive manufacturing apparatusArc welding apparatusMelting tankPorosity

A method and apparatus particularly for additively manufacturing materials that are susceptible to hot cracking. The additive manufacturing process may include a leading energy beam (16) for liquefying a raw material to form a melt pool (20), and a trailing energy beam (17) directed toward a trailing region of the melt pool. The trailing energy beam may be configured to enhance agitation and / or redistribution of liquid in the melt pool to prevent hot cracking, reduce porosity, or improve other characteristics of the solidified part. The method and apparatus also may improve processing parameters, such as adjusting vacuum level to prevent volatilization of alloying agents, or providing a chill plate to control interpass temperature. The process may be used to form new articles, and also may be used to enhance tailorability and flexibility in design or repair of pre-existing articles, among other considerations.

Owner:RAYTHEON CO

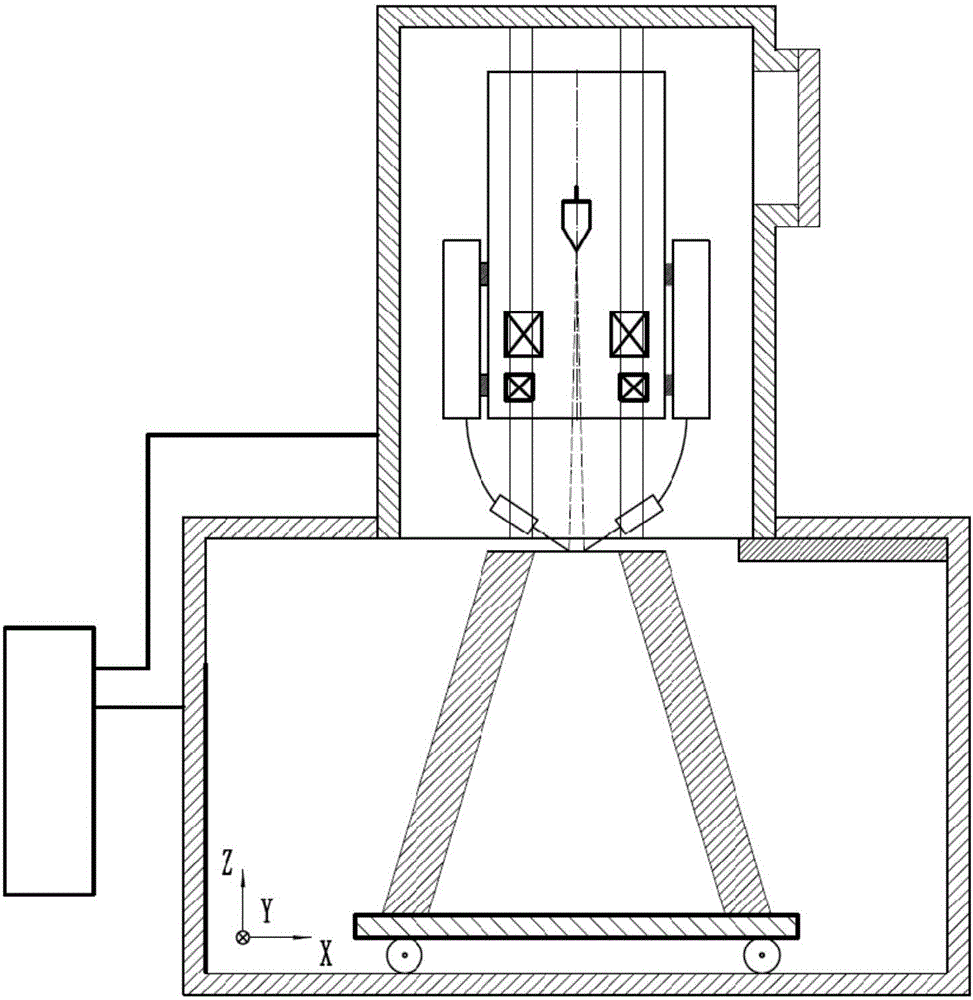

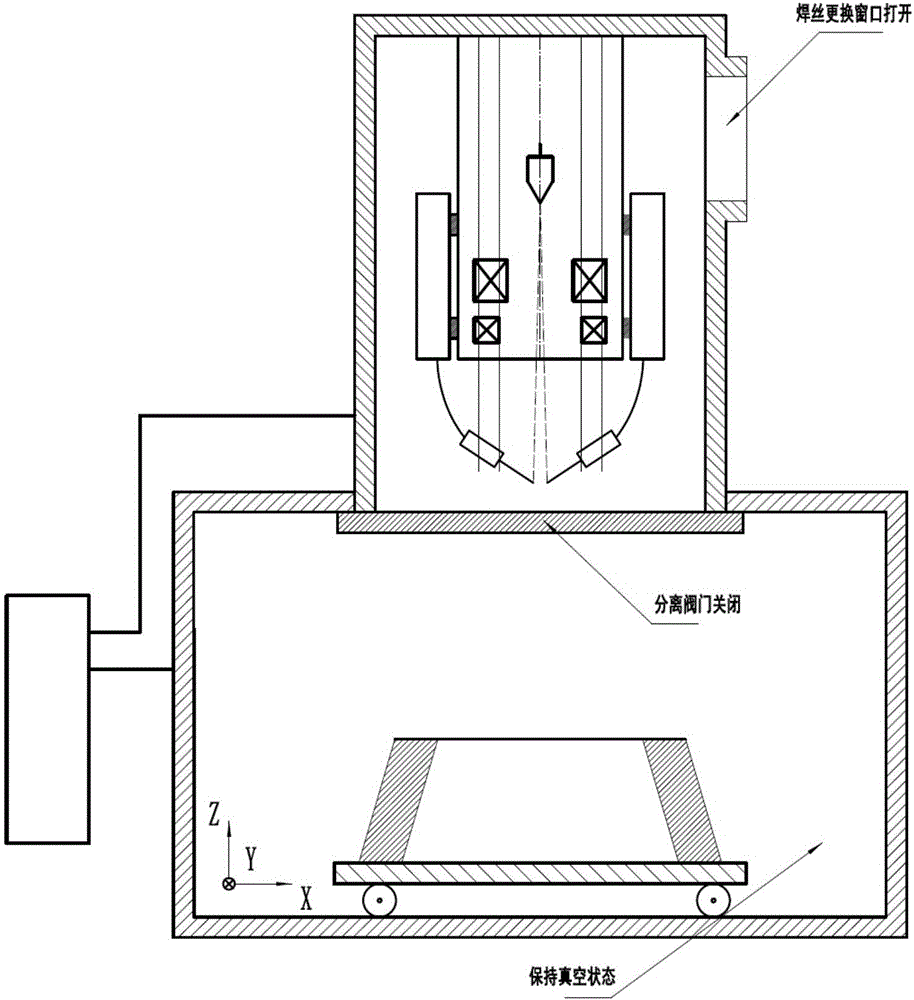

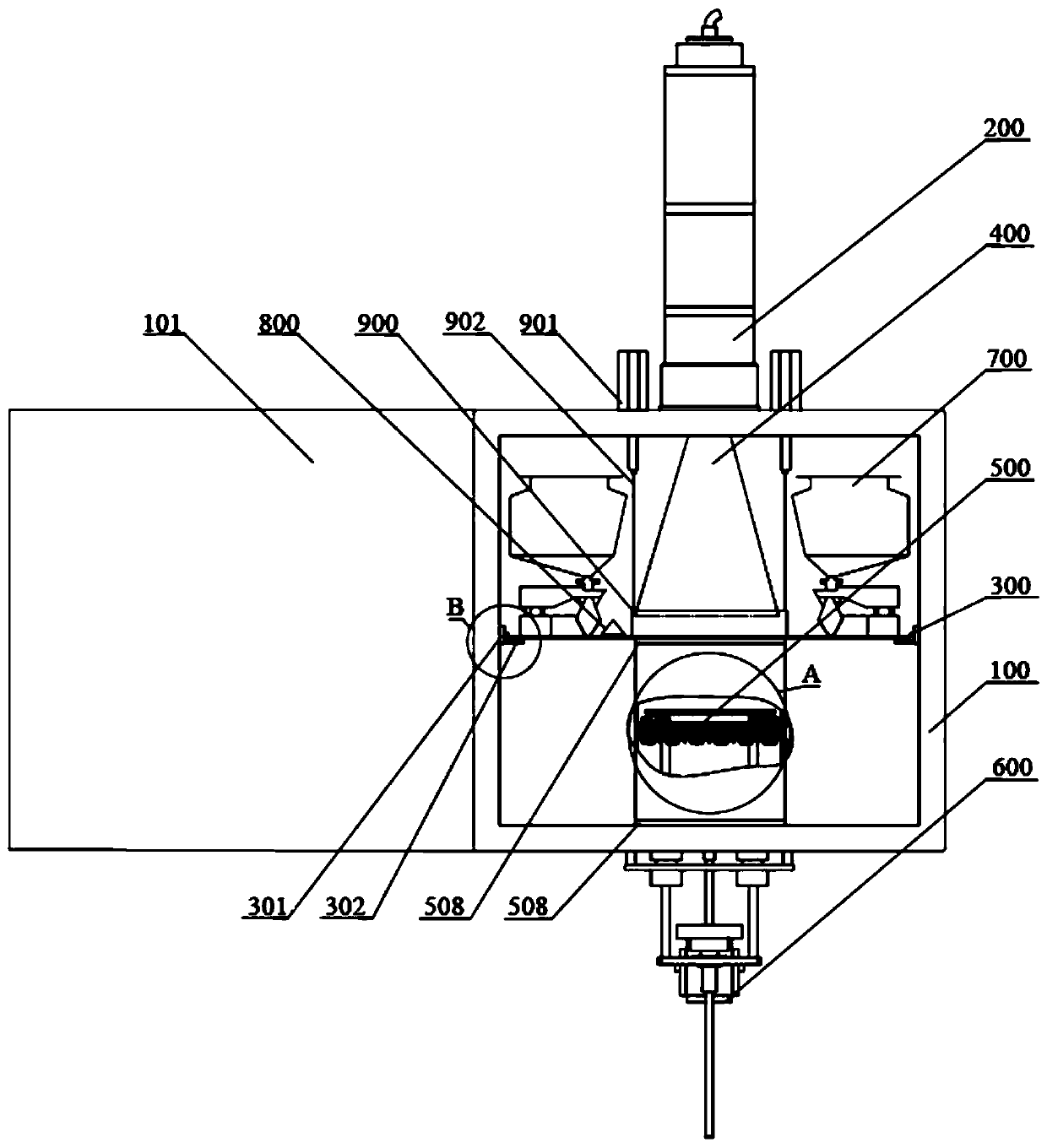

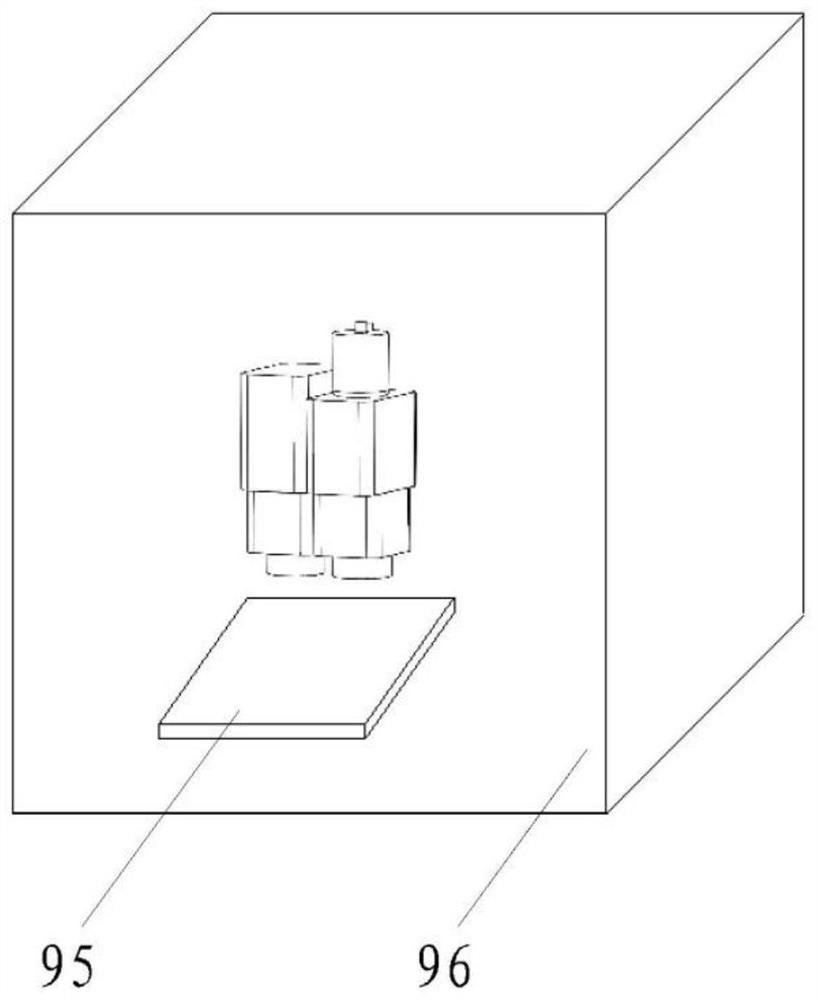

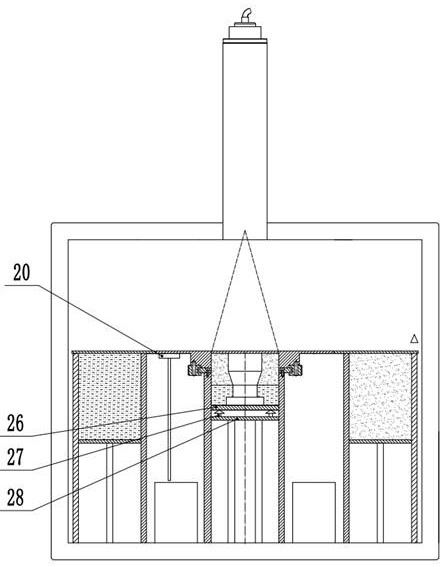

Electron beam additive manufacturing device

ActiveCN106424732AGood formabilityEasy to manufactureAdditive manufacturing apparatusIncreasing energy efficiencyEngineeringVacuum chamber

The invention provides an electron beam additive manufacturing device. The electron beam additive manufacturing device comprises a vacuum forming chamber, a part bearing platform, an electronic gun and an electronic gun vacuum chamber; the electronic gun vacuum chamber is mounted at the top of the vacuum forming chamber, and communicates with the vacuum forming chamber; the part bearing platform is mounted in the vacuum forming chamber; an electronic gun lifting guide rail is arranged in the electronic gun vacuum chamber; and the electronic gun is mounted on the electronic gun lifting guide rail, and can move up and down along the electronic gun lifting guide rail. The electron beam additive manufacturing device is higher in production efficiency and forming precision.

Owner:XIAN ZHIRONG METAL PRINTING SYST CO LTD

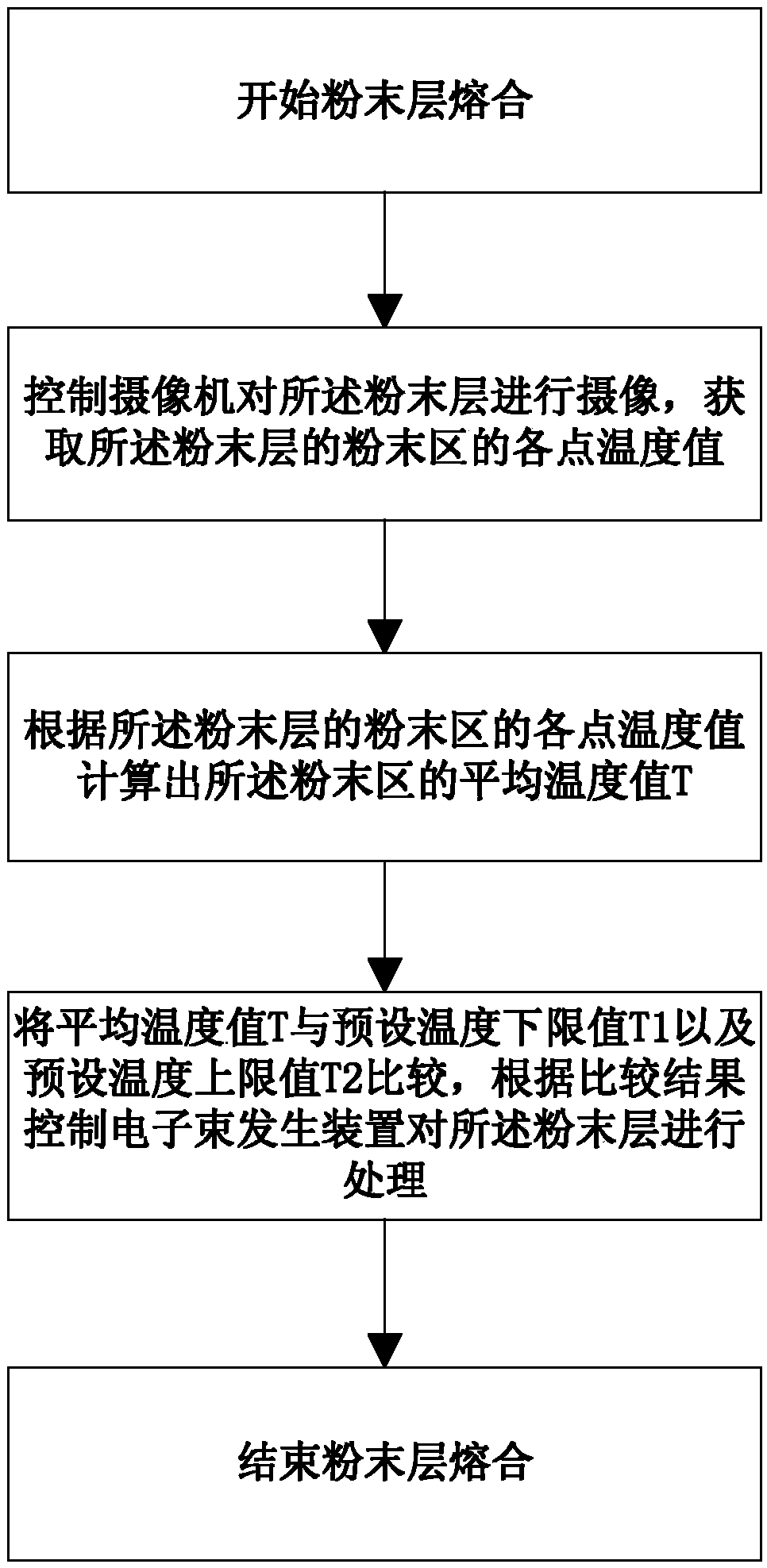

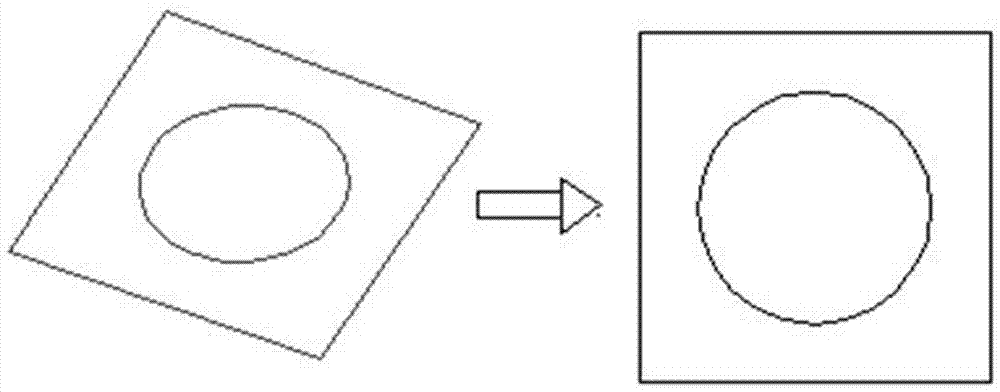

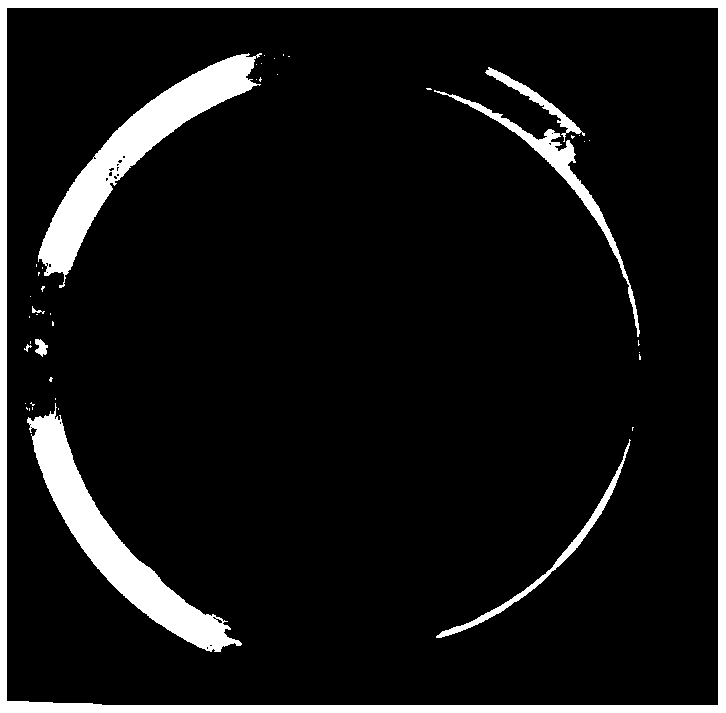

Control device and method for heat stress in powder bed type electron beam additive manufacturing

ActiveCN105499567AEasy to controlReduce frictionAdditive manufacturing apparatusIncreasing energy efficiencyGlass windowElectron-beam additive manufacturing

The invention discloses a control device for heat stress in powder bed type electron beam additive manufacturing. The control device comprises a transparent glass window located on a vacuum chamber and arranged in the shooting direction of a camera; the camera shoots images of the interior of the vacuum chamber through the glass window, and the shot images comprise a powder layer and the temperature distribution information of the powder layer; a rotating shaft which penetrates through the vacuum chamber in a sealing mode and can rotate is arranged on one side of the glass window and is fixedly connected to a baffle located in the vacuum chamber, and the baffle is driven by the rotating shaft to switch between the position of shielding the glass window and the position of avoiding the glass window. The invention further provides a control method for controlling the heat stress in additive manufacturing. According to the invention, the camera shoots the images of the interior of the vacuum chamber through the glass window, the shot images comprise the powder layer and the temperature distribution information of the powder layer, and therefore the heat stress in additive manufacturing can be controlled better; by arranging the baffle, the transparency of the glass window can be effectively maintained, and the replacement frequency of the glass window is lowered.

Owner:QUICKBEAM CO LTD +1

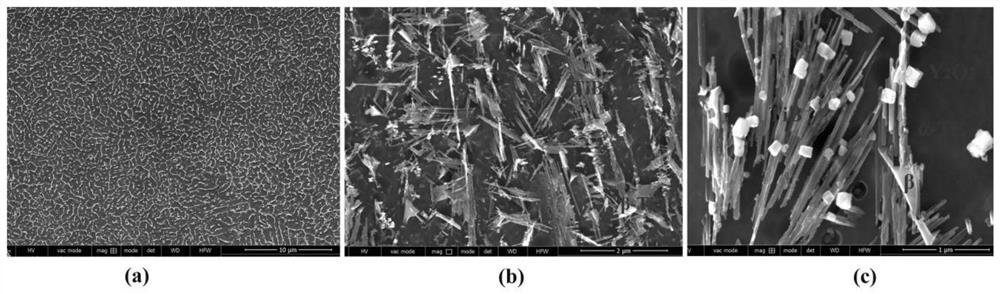

Electron beam additive manufacturing method for nickel base alloy structural component

InactiveCN107127343AImprove performanceNo pollutionAdditive manufacturing apparatusIncreasing energy efficiencyNumerical controlAlloy

The invention discloses an electron beam additive manufacturing method for a nickel base alloy structural component. The method comprises the steps that under the condition of a vacuum chamber, a nickel base alloy base body is placed in a working table in advance, and the pressure intensity inside the chamber is made to reach 4.8*10<2> Pa; a specially-made powder delivering device is utilized to spray Ni powder, Nb powder, Mo powder, Cr powder and rear earth CeO2 superfine metal powder which are uniformly mixed according to a certain mass compounding ratio into a molten pool through which electron beams are generated, so that an electron beam cladding layer metallurgically bonded with the base body; and then, layer-by-layer electron beam cladding is achieved through a numerical control processing procedure adopted for each layer, so that the three-dimensional metal component is obtained finally. By means of the electron beam additive manufacturing method, the nickel base alloy structural component which has the structural characteristic, namely rapid solidification and is high in performance, fully compact and complex in shape is manufactured. The manufacturing method is low in manufacturing cost, short in manufacturing cycle, high in material utilization rate and stable in performance, the complex component can be manufactured rapidly, and structural strength of the nickel base alloy structural component can be remarkably improved; and structural defects such as pores, cracks and residual stress inside an alloy are reduced.

Owner:GUILIN UNIV OF ELECTRONIC TECH

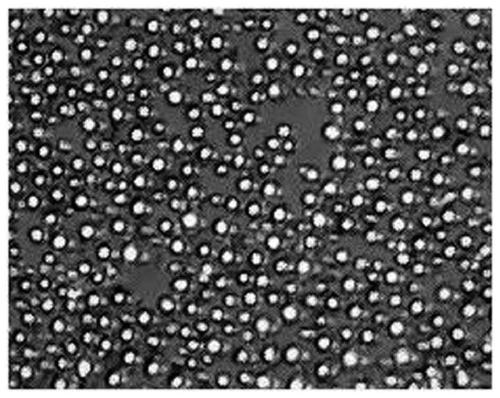

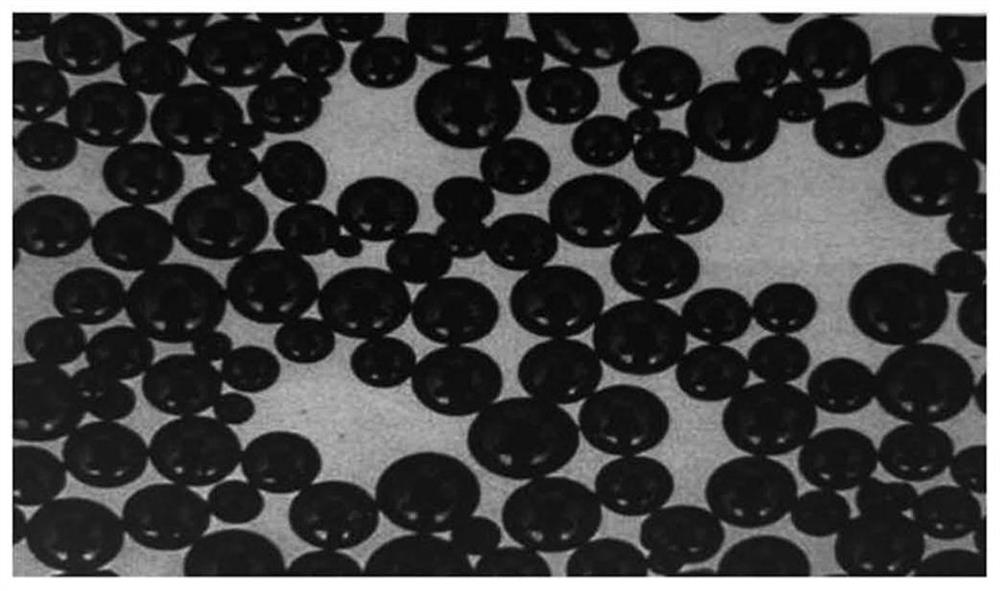

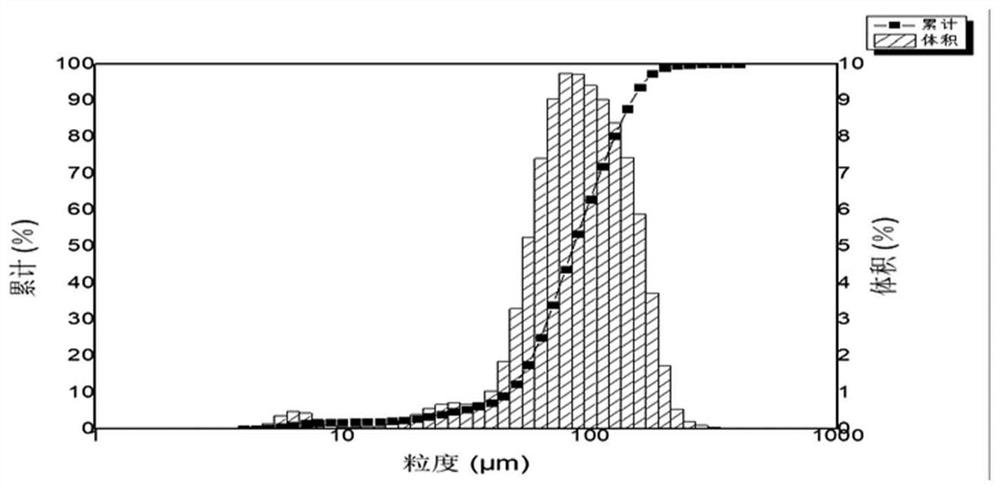

Electronic beam added material manufacturing method of molybdenum base alloy powder

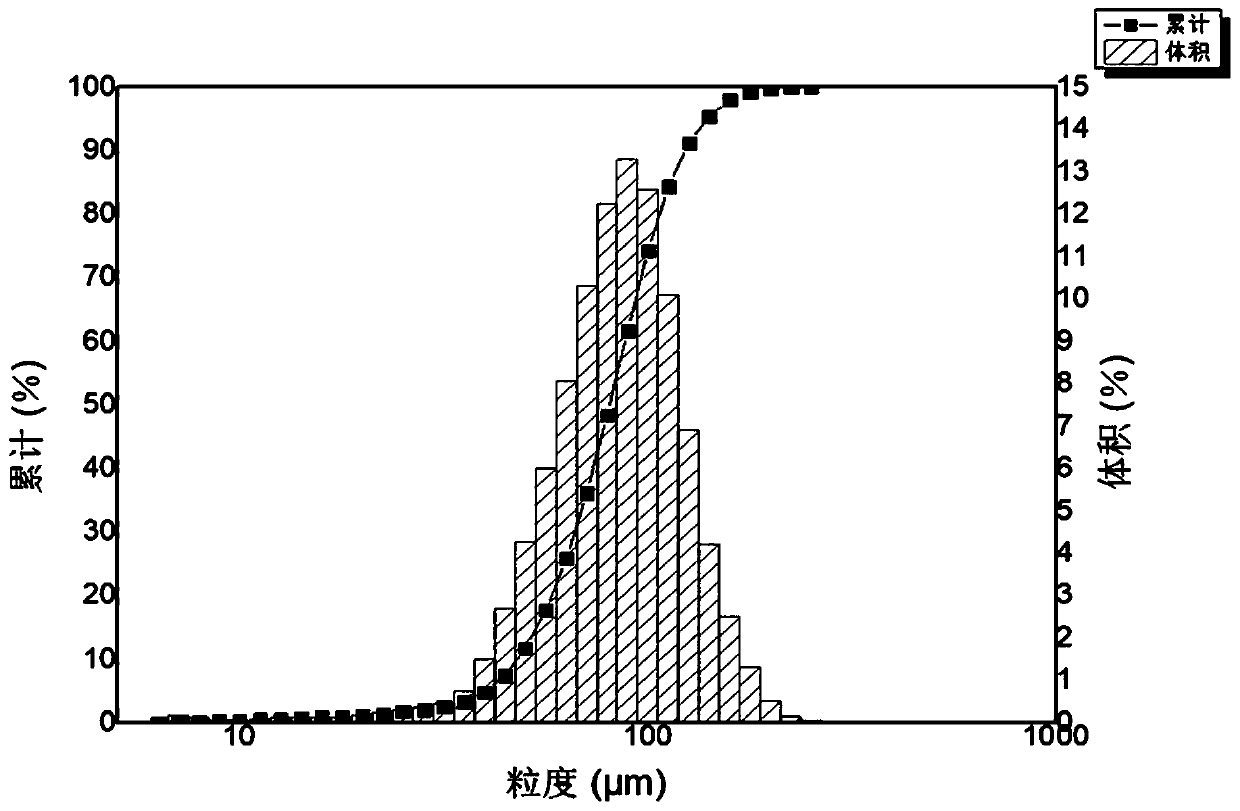

ActiveCN110181048AHigh densityUniform tissueAdditive manufacturing apparatusIncreasing energy efficiencyAlloyAdditive layer manufacturing

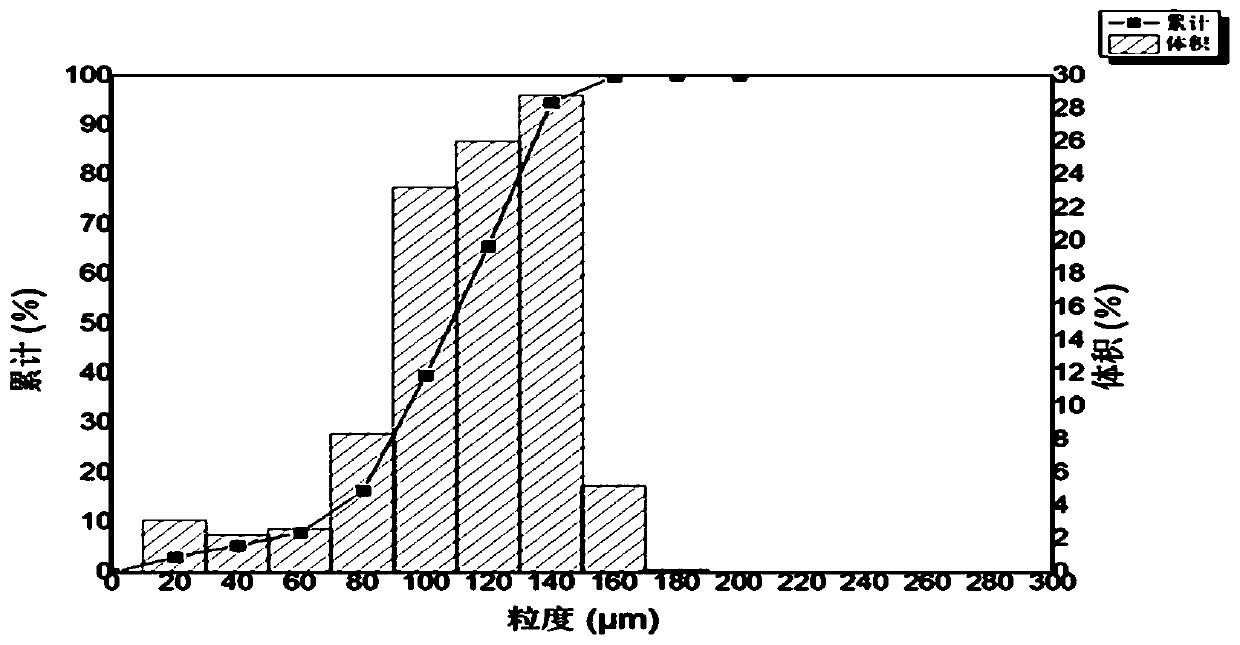

The invention discloses an electronic beam added material manufacturing method of molybdenum base alloy powder. The particle size of the used molybdenum base alloy powder is 55-85 microns; and when powder layers are scanned by electronic beams, a twice scanning mode is adopted. The molybdenum base alloy electronic beam added material manufacturing process finds out manufacturing process parametersof added materials with the highest compactness, and adopts the twice scanning mode to solve the nodulizing and powder splashing problems in the manufacturing of the electronic beam added materials to improve the compactness of components to the casting level.

Owner:TSINGHUA UNIV

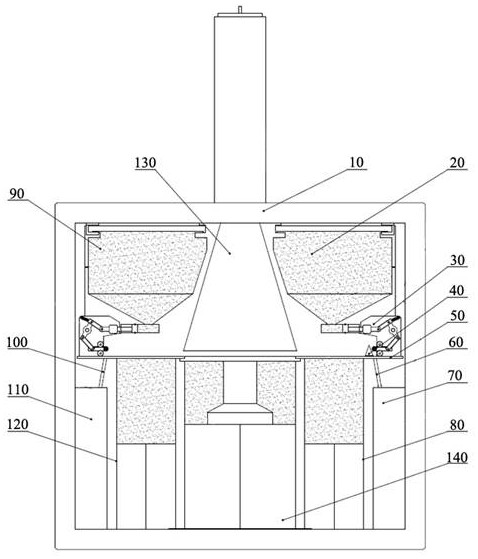

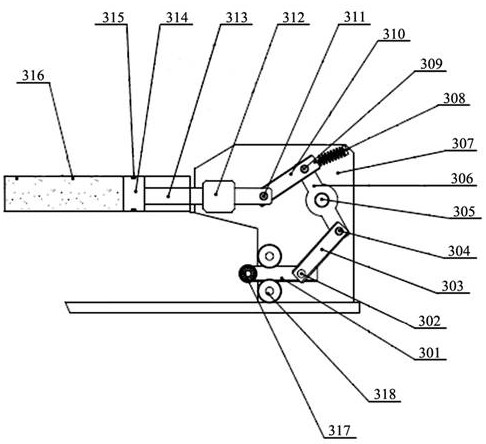

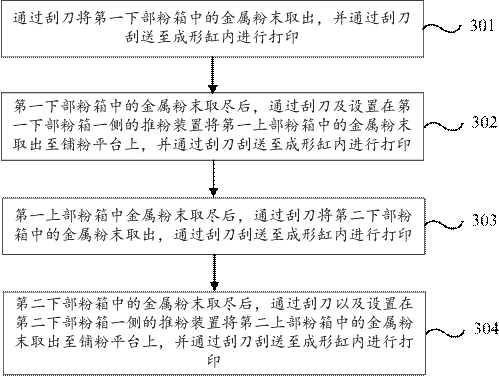

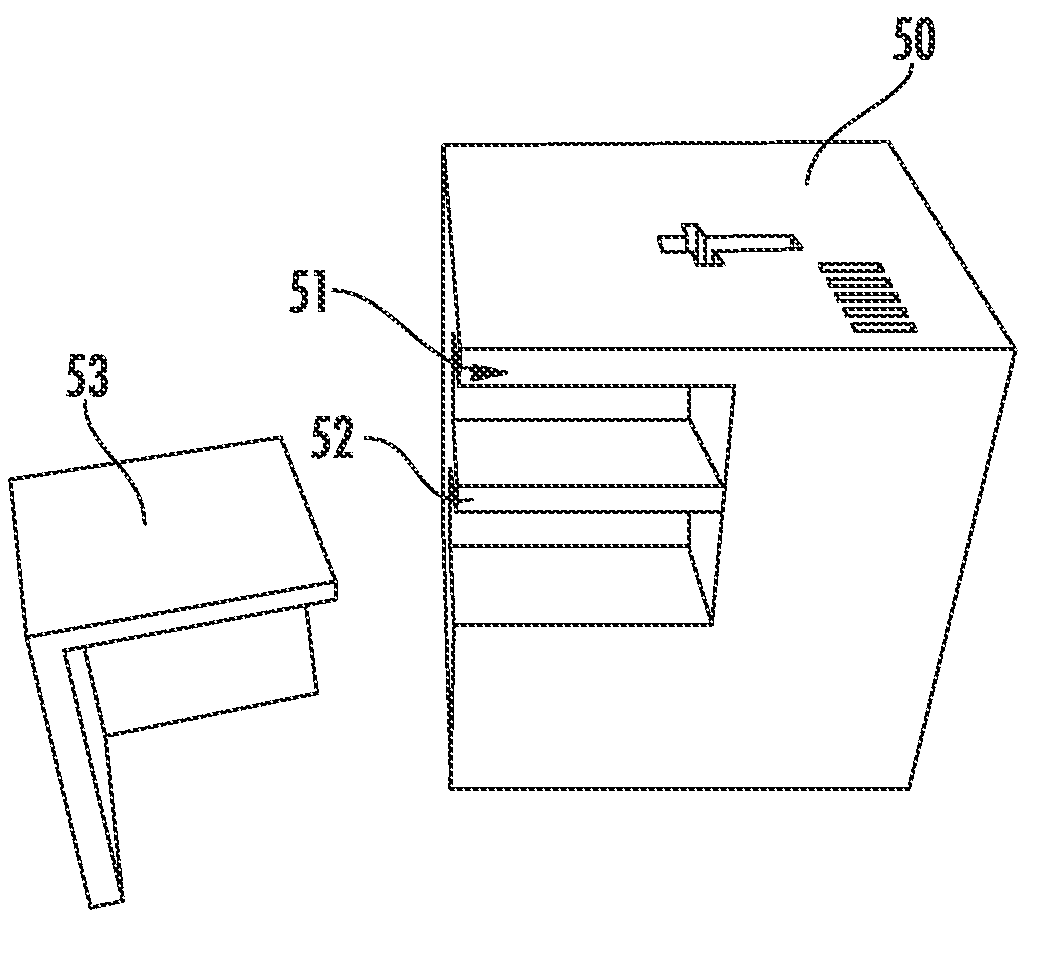

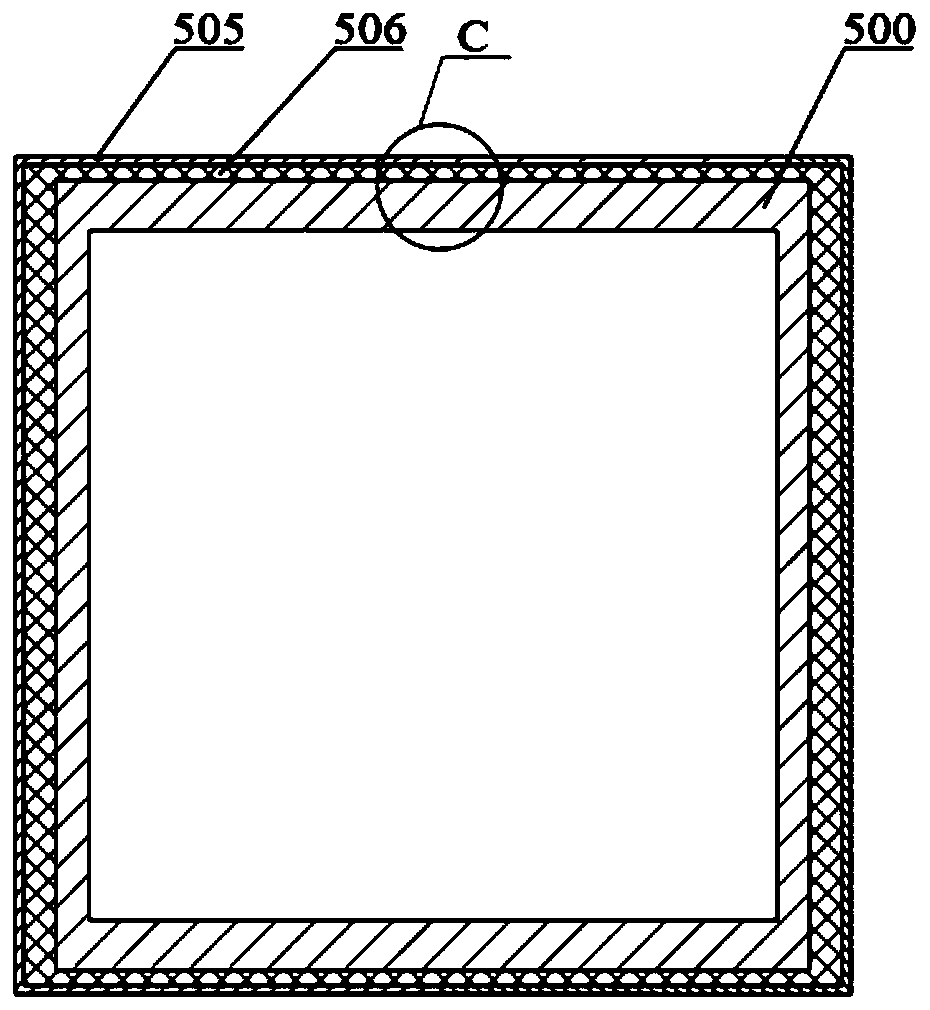

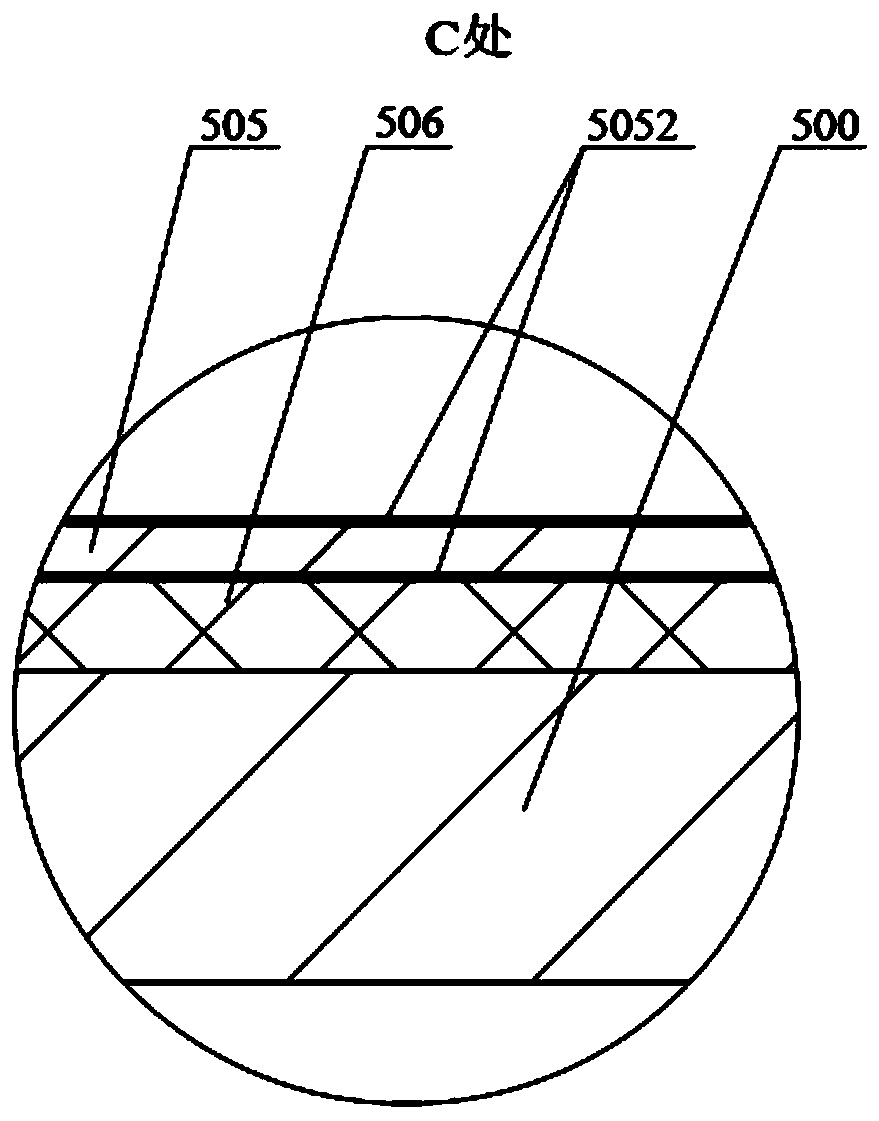

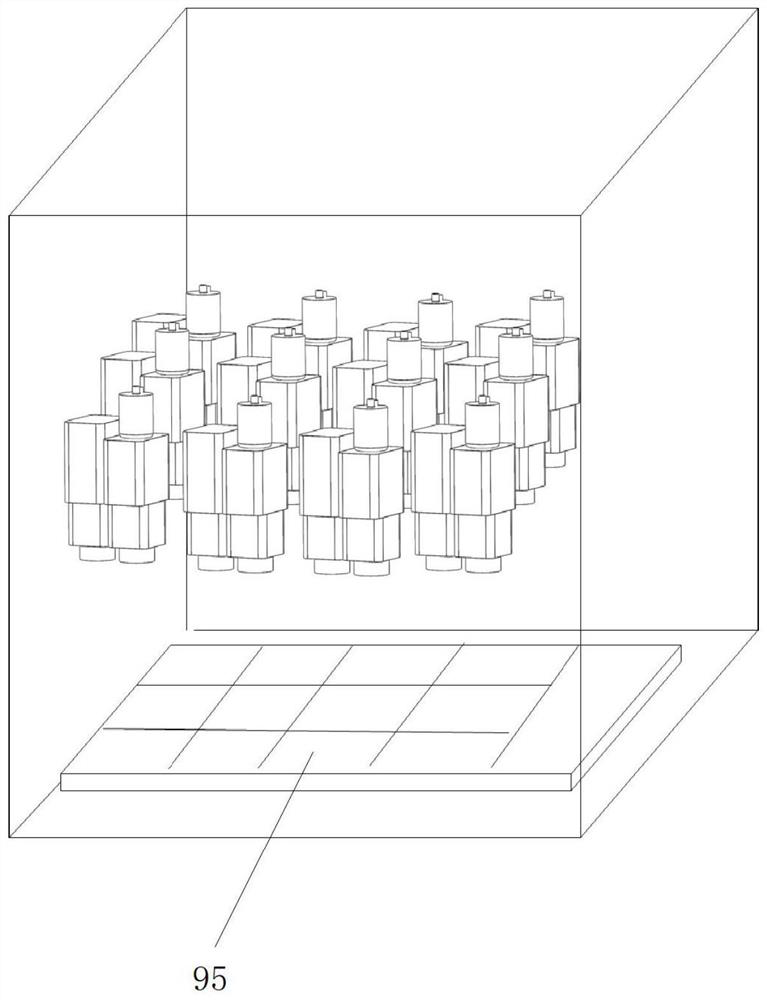

Powder bed electron beam additive manufacturing equipment and manufacturing method

ActiveCN112496351ATo achieve the purpose of indirect powder extractionTo achieve the purpose of receiving powderAdditive manufacturing apparatusThermal insulationEngineering

The invention discloses powder bed electron beam additive manufacturing equipment and manufacturing method. The equipment comprises a forming chamber which is internally provided with a thermal insulation frame, a powder laying platform, a scraper and a forming cylinder, a first upper powder box and a second upper powder box which are arranged on the two sides of the thermal insulation frame respectively, a first lower powder box and a second lower powder box which are arranged on the two sides of the forming cylinder respectively, and two powder pushing devices which are arranged on the two sides of the powder laying platform respectively, wherein each powder pushing device comprises a supporting plate, a powder pushing groove and a linkage assembly. According to the equipment and the method, on the premise that the sizes of the forming chamber and the internal structure are not changed, the internal space of the forming chamber is effectively utilized, the quantity of powder capableof being contained in the powder boxes is greatly increased, and therefore the problem that printing is stopped due to the fact that metal powder is insufficient when large-size parts are printed canbe effectively solved, and enough powder ensures that the equipment can print small-size parts and also can form large-size printed parts.

Owner:西安赛隆增材技术股份有限公司

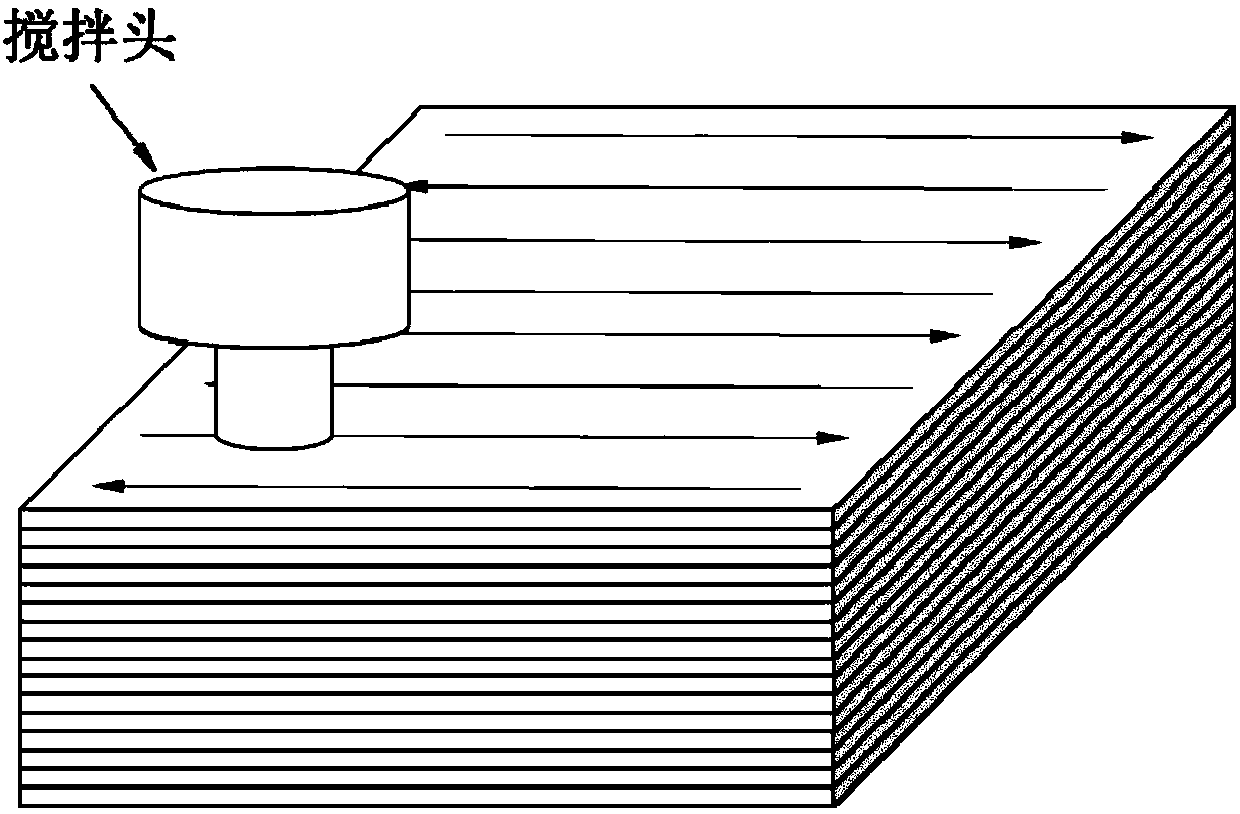

Electron beam-friction-stir composite additive manufacturing method

InactiveCN107812944AGood mechanical propertiesImprove mechanical propertiesAdditive manufacturing apparatusIncreasing energy efficiencyGrain structureFriction stir processing

The invention provides an electron beam-friction-stir composite additive manufacturing method and belongs to the technical field of manufacturing of an additional material. The electron beam-friction-stir composite additive manufacturing method comprises the following technologic steps: manufacturing a layer of an electron beam additive material, and subsequently processing and modifying the layerof material by using a region-selected friction-stir processing method so as to obtain excellent tissues. In the additive manufacturing process, each layer is subjected to electron beam sintering andfriction-stir processing repeatedly so as to obtain a complicated work piece which is small in grain structure, excellent in mechanical property and less in internal defects. The electron beam-friction-stir composite additive manufacturing method provided by the invention can solve the problems that a conventional additive material manufactured work piece has solidified cracks and is uneven in tissues and poor in physical property; meanwhile, an additive manufacturing material can form nanometer crystals after the electron beam sintered additive manufactured layer is subjected to the friction-stir process, so the tissues of the work piece are improved, and the physical property of the work piece is improved. Besides, by region-selected friction-stir, internal defects formed in a sinteringprocess can be eliminated, second-phase dispersive distribution of the material is realized, and the tissue performances of the work piece are improved.

Owner:HARBIN INST OF TECH AT WEIHAI

Systems and methods for designing and fabricating contact-free support structures for overhang geometries of parts in powder-bed metal additive manufacturing

ActiveUS9767224B2Improve heat transfer performanceReduce gradientAdditive manufacturing apparatusIncreasing energy efficiencyContact freeLaser additive manufacturing

Systems and methods are provided for designing and fabricating contact-free support structures for overhang geometries of parts fabricated using electron beam additive manufacturing. One or more layers of un-melted metallic powder are disposed in an elongate gap between an upper horizontal surface of the support structure and a lower surface of the overhang geometry. The powder conducts heat from the overhang geometry to the support structure. The support structure acts as a heat sink to enhance heat transfer and reduce the temperature and severe thermal gradients due to poor thermal conductivity of metallic powders underneath the overhang. Because the support structure is not connected to the part, the support structure can be removed freely without any post-processing step.

Owner:NASA +1

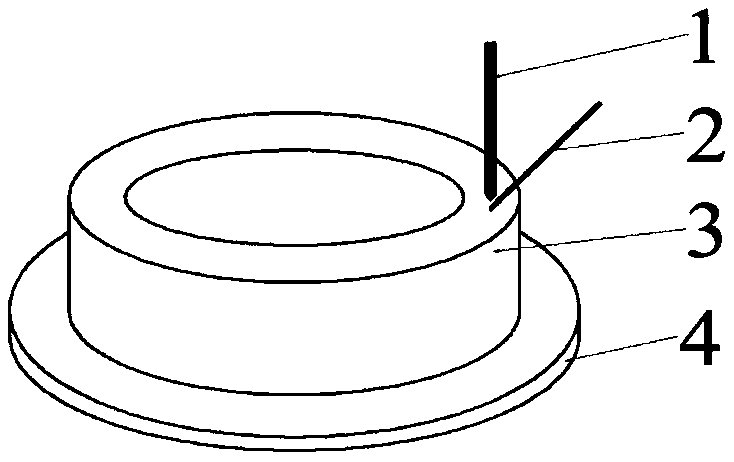

Electron beam fusing additive blank manufacturing and ring-rolling forming method for large-size metal annular piece

InactiveCN109434264AAvoid punchingImprove fatigue lifeAdditive manufacturing apparatusElectron beam welding apparatusManufacturing technologyRoll forming

The invention provides an electron beam fusing additive blank manufacturing and ring-rolling forming method for a large-size metal annular piece. According to the method, a precision ring-rolling technology and an electron beam fusing additive manufacturing technology are combined, a roller is used for rolling an electron beam additive manufactured blank for deformation, and thus precise and rapidforming of the high-performance annular piece is achieved. The prepared large-size metal annular piece has a fine and uniform deformed structure, the defects of an as-cast structure, pores, non-fusion and the like of an electron beam fusing additive manufactured blank part are eliminated, residual stress and distribution in the part are reduced and improved correspondingly, and stability and reliability of performance of the large-size metal annular piece prepared through electron beam additive manufacturing in the using process are remarkably improved. Meanwhile, by means of the method, forming procedures of the annular piece are greatly reduced, production efficiency is improved, and the production cost of the part is lowered.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

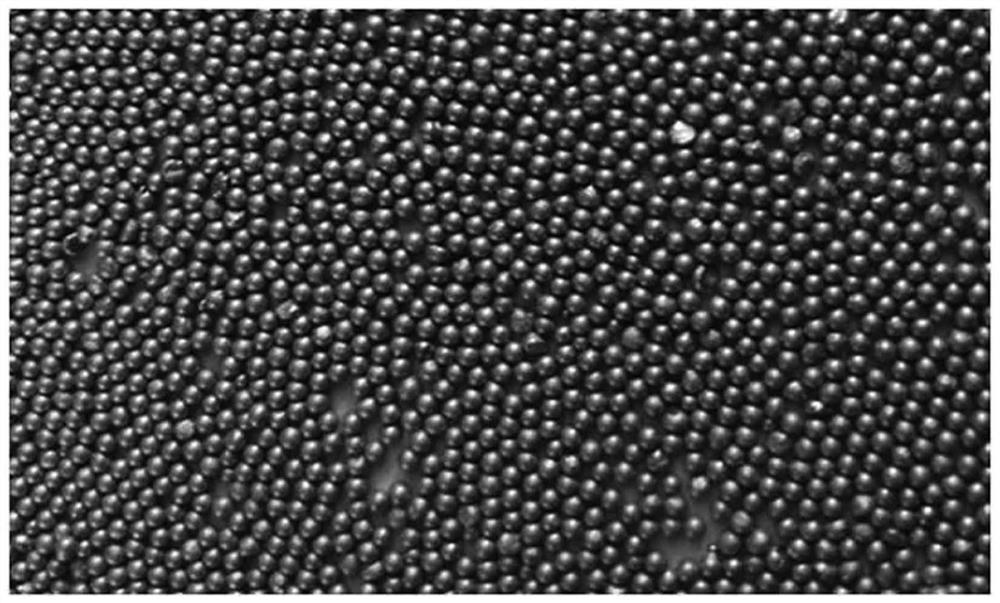

Beryllium-aluminum alloy powder and preparation method and application thereof

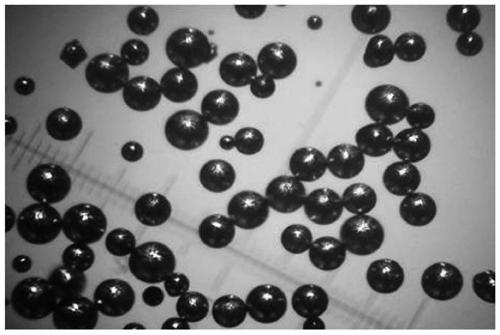

ActiveCN111570813AGood sphericityIncrease productivityAdditive manufacturing apparatusTransportation and packagingOxygen contentElectron bunches

The invention provides beryllium-aluminum alloy powder and a preparation method and application thereof. The preparation method comprises the following steps of placing a beryllium-aluminum alloy rodin a vacuum environment; introducing inert gas into the vacuum environment to replace air, wherein the oxygen content in the replaced vacuum environment is smaller than 6 ppm; melting the end surfaceof the beryllium-aluminum alloy rod by means of arc to form a liquid film; crushing the liquid film to fine liquid drops by means of centrifugal force; and carrying out cooling to obtain the beryllium-aluminum alloy powder. The beryllium-aluminum alloy powder may comprise the beryllium-aluminum alloy powder prepared through the preparation method of the beryllium-aluminum alloy powder. The application may comprise application of the beryllium-aluminum alloy powder in the field of laser or electron beam additive manufacturing and / or in the field of laser or electron beam cladding. The inventionhas the beneficial effects that the preparation method is high in production efficiency and low in energy consumption; the prepared beryllium-aluminum alloy powder is good in degree of sphericity, free of hollow powder basically, low in oxygenation amount in the manufacturing process and good in flowability and is a good raw material for 3D printing.

Owner:西藏智材新材料有限公司

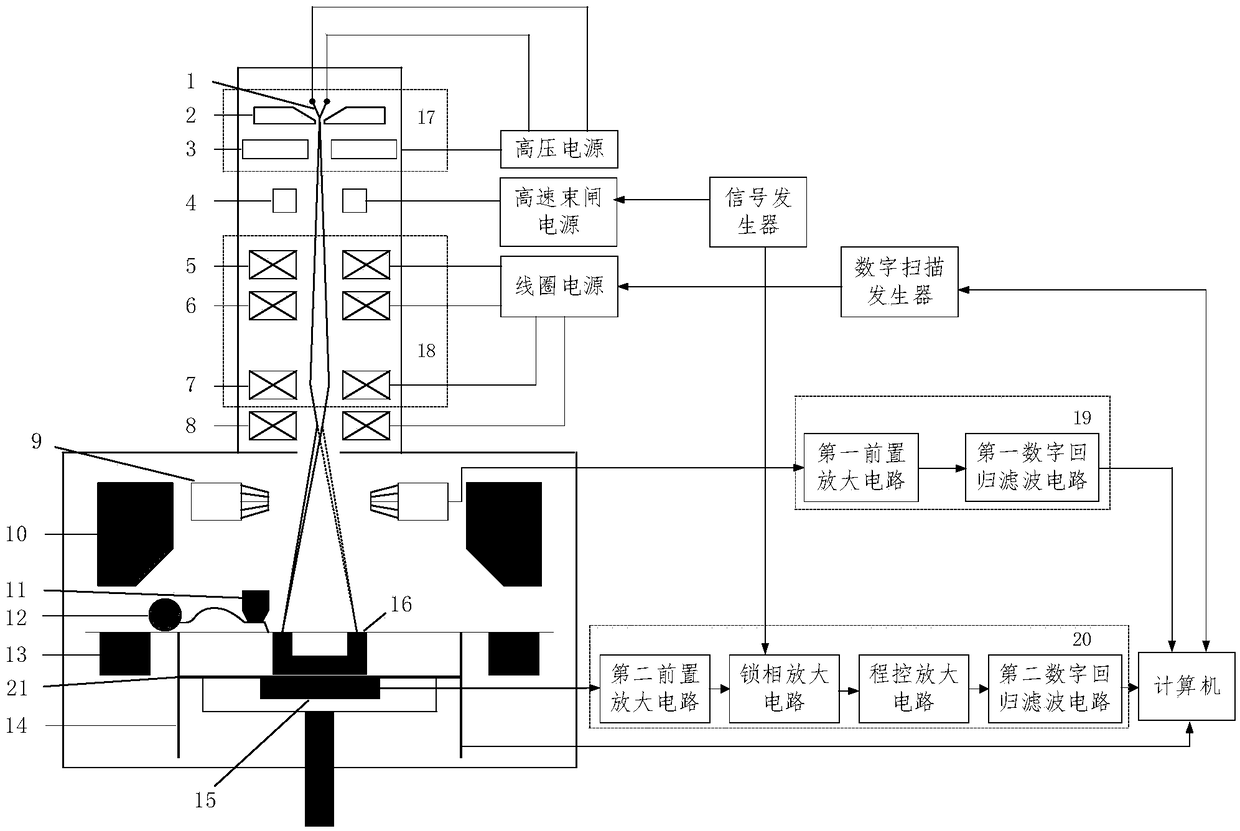

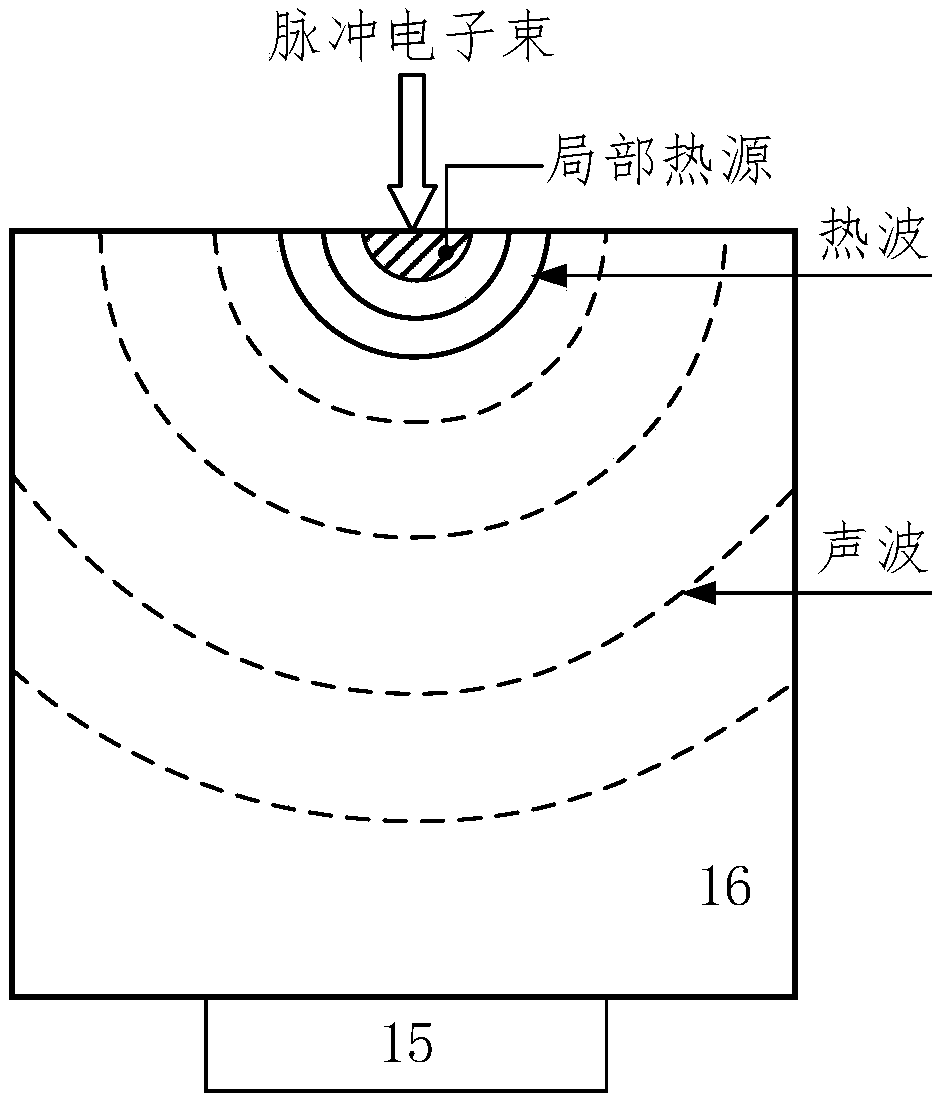

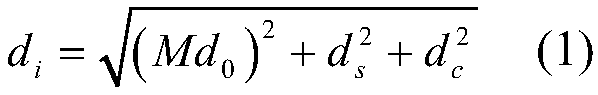

Electro-acoustic effect-based in-situ detection method and device for electron beam additive manufacturing

InactiveCN109001239ARealize closed-loop controlMonitor manufacturing qualityAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterial analysis using wave/particle radiationTransducerSecondary electrons

The invention discloses an electro-acoustic effect-based in-situ detection method and device for electron beam additive manufacturing and belongs to the technical field of additive manufacturing. Surface topography characteristics of a workpiece are obtained after a pulsed electron beam interacts with the surface of the workpiece, meanwhile, a heat wave generated after the pulsed electron beam interacts with the surface of the workpiece is conducted towards the inside of the workpiece along the surface of the workpiece to form an acoustic wave, and the acoustic wave is received to achieve electro-acoustic signal detection through adding a transducer to the lower part of the workpiece, thereby obtaining internal layered structure characteristics of the workpiece. The detection device comprises a secondary electron or backscattered electron detection system, an electro-acoustic signal detection system, a signal generator and a digital scanning generator. The method and the device disclosed by the invention are used for detecting the surface topography characteristics and the internal layered structure characteristics of the workpiece in the additive manufacturing process and monitoring the manufacturing quality; the detection device is small in size, simple in structure and good in coupling property; and the cost and the complexity are not additionally increased.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

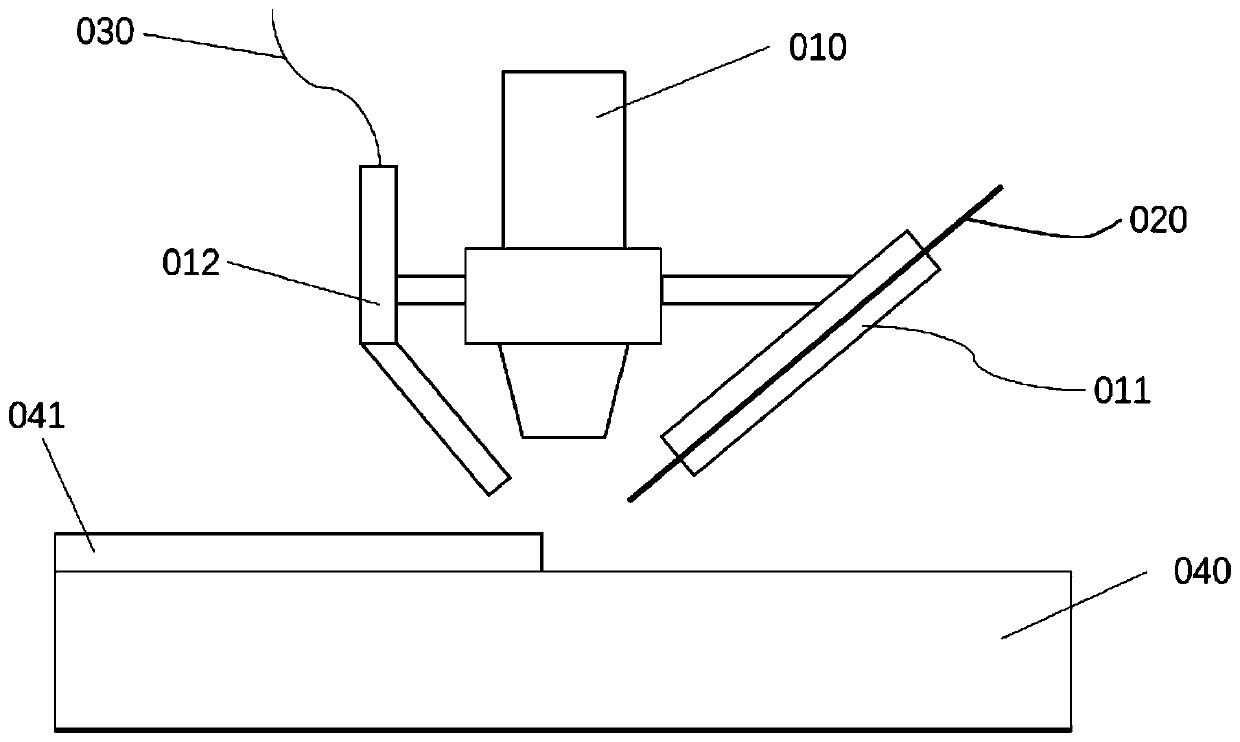

Combined electron beam additive manufacturing device and process

InactiveCN111151757AImprove printing efficiencyReduce precisionAdditive manufacturing apparatusIncreasing energy efficiencyMetal filamentSpray nozzle

The invention relates to a combined electron beam additive manufacturing device and process. A wire feed spray nozzle and a powder feed spray nozzle are mounted on a base of an electron beam gun of the device, the powder feed spray nozzle is connected with a power feed system, and a metal wire is fed into the wire feed spray nozzle through a wire feeder to form a combined electron beam additive melting system. An XYZ-coordinate movement driving mechanism is arranged on the base of the electron beam gun. The XYZ-coordinate movement driving mechanism is connected with an XYZ-coordinate movementdriving controller. The XYZ-coordinate movement driving controller controls the XYZ-coordinate movement driving mechanism to accurately move the electron beam gun according to the part molding requirements and controls the wire feed spray nozzle and the powder feed spray nozzle to move synchronously to carry out deposition on a required position of a part. The electron beam gun emits an electron beam to melt the surfaces of the metal wire and a molded base plate, and a deposition layer is formed on the surface of the molded base plate after solidification. The combined electron beam additive manufacturing device melts metal powder to be deposited on the surface of the molded base plate to form the deposition layer. Thus, combined additive manufacturing of the part is realized, and the requirements for the manufacturing efficiency and accuracy are met.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

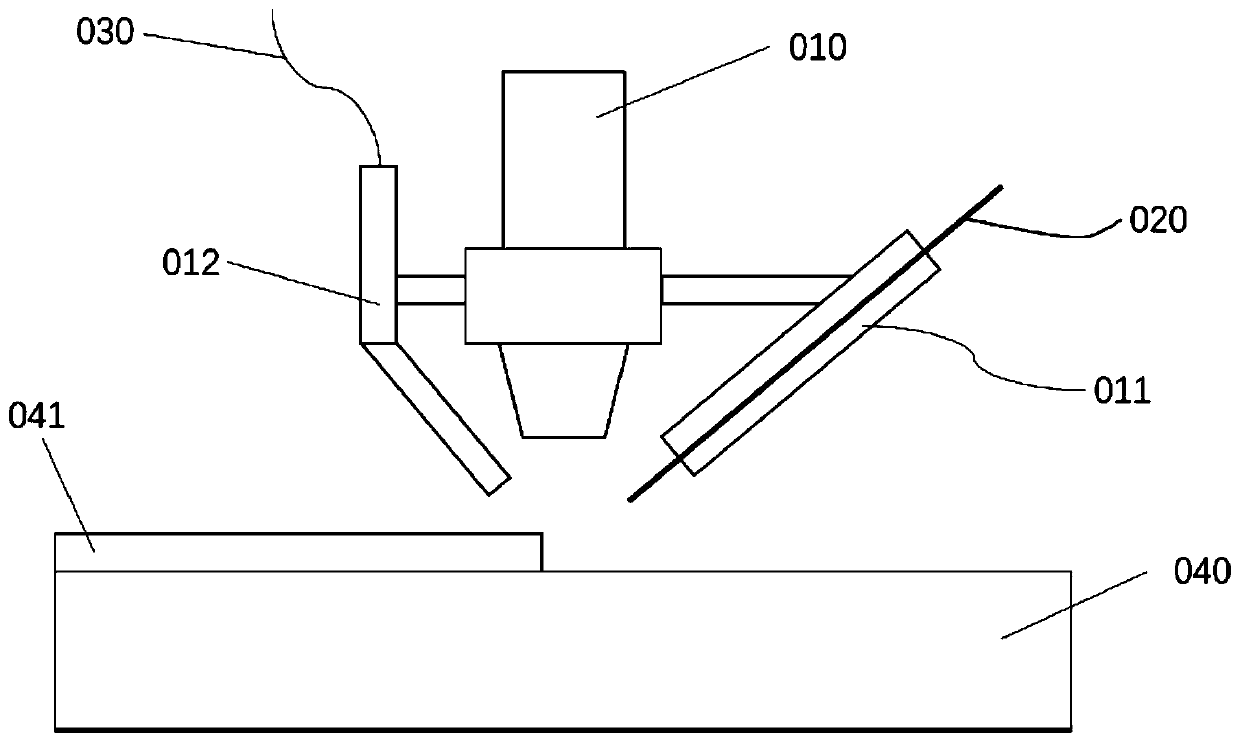

Electronic gun for filament feeding type electron beam additive manufacturing equipment

ActiveCN105655215AMobile and flexibleGood flexibilityElectrode and associated part arrangementsAcceleratorsTransformerEngineering

The invention discloses an electronic gun for filament feeding type electron beam additive manufacturing equipment. The electronic gun mainly comprises a high-voltage cable, a high-voltage cable outgoing terminal, an electronic gun casing, an insulation component, a beam-forming electrode, a cathode and beam-forming electrode component, an anode, a filament head-end electrode, a filament tail-end electrode and a filament transformer, wherein the filament transformer is soaked in insulation cooling oil in an upper cavity and comprises a core, a primary winding and a secondary winding; the core is wound with the primary winding, and two ends of the primary winding are led out of the electronic gun casing simultaneously through outgoing plugs and connected to a filament power supply; the core is also wound with the secondary winding, one end of the secondary winding is connected with the filament head-end electrode, and the other end is connected with the filament tail-end electrode. A voltage stabilizing element is connected between the beam-forming electrode and the filament head-end electrode. Flexible movement of the electronic gun and prolonging of the service life of a filament are facilitated, and electron beams during discharge of the electronic gun can be inhibited effectively.

Owner:GUILIN THD TECH CO LTD

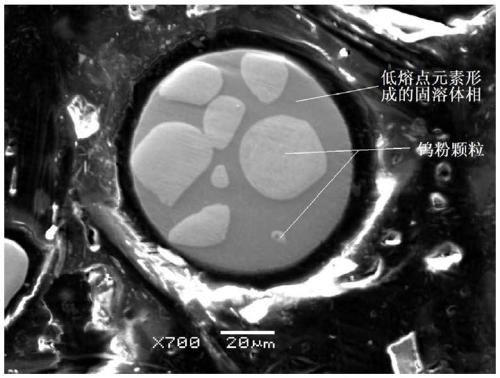

High-specific-gravity tungsten-based alloy formation method based on pre-alloyed powder

ActiveCN110315076APromote meltingNot easy to melt and formAdditive manufacturing apparatusIncreasing energy efficiencyManufactured formSolid solution

The invention discloses a high-specific-gravity tungsten-based alloy formation method based on pre-alloyed powder. The high-specific-gravity tungsten-based alloy formation method based on the pre-alloyed powder comprises the steps that firstly, according to the designed ingredients and proportion of the high-specific-gravity tungsten-based alloy, material mixing, pressing, vacuum sintering and forging machining are sequentially conducted, then a tungsten-based alloy rod is obtained, and pre-alloyed powder is obtained through a plasma-rotating electrode powder manufacturing method; secondly, athree-dimensional model of the high-specific-gravity tungsten-based alloy is established, slicing and designing are conducted, and then slice layers and scanning data are obtained; thirdly, with the pre-alloyed powder as the raw material, according to the slice layers and the scanning data, a powder bed type electron beam additive manufacturing forming device is adopted to form the high-specific-gravity tungsten-based alloy. According to the high-specific-gravity tungsten-based alloy formation method based on the pre-alloyed powder, by utilizing the different melting points between tungsten and other elements in the high-specific-gravity tungsten-based alloy, the pre-alloyed powder with tungsten powder particles being wrapped inside low-melting-point element solid solution is prepared, sothat the shells of the pre-alloyed powder are easy to melt and adhere to one another for formation, and therefore the formation difficulty of the pre-alloyed powder is lowered; and with the pre-alloyed powder as the raw material, preparation of the high-specific-gravity tungsten-based alloy is achieved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

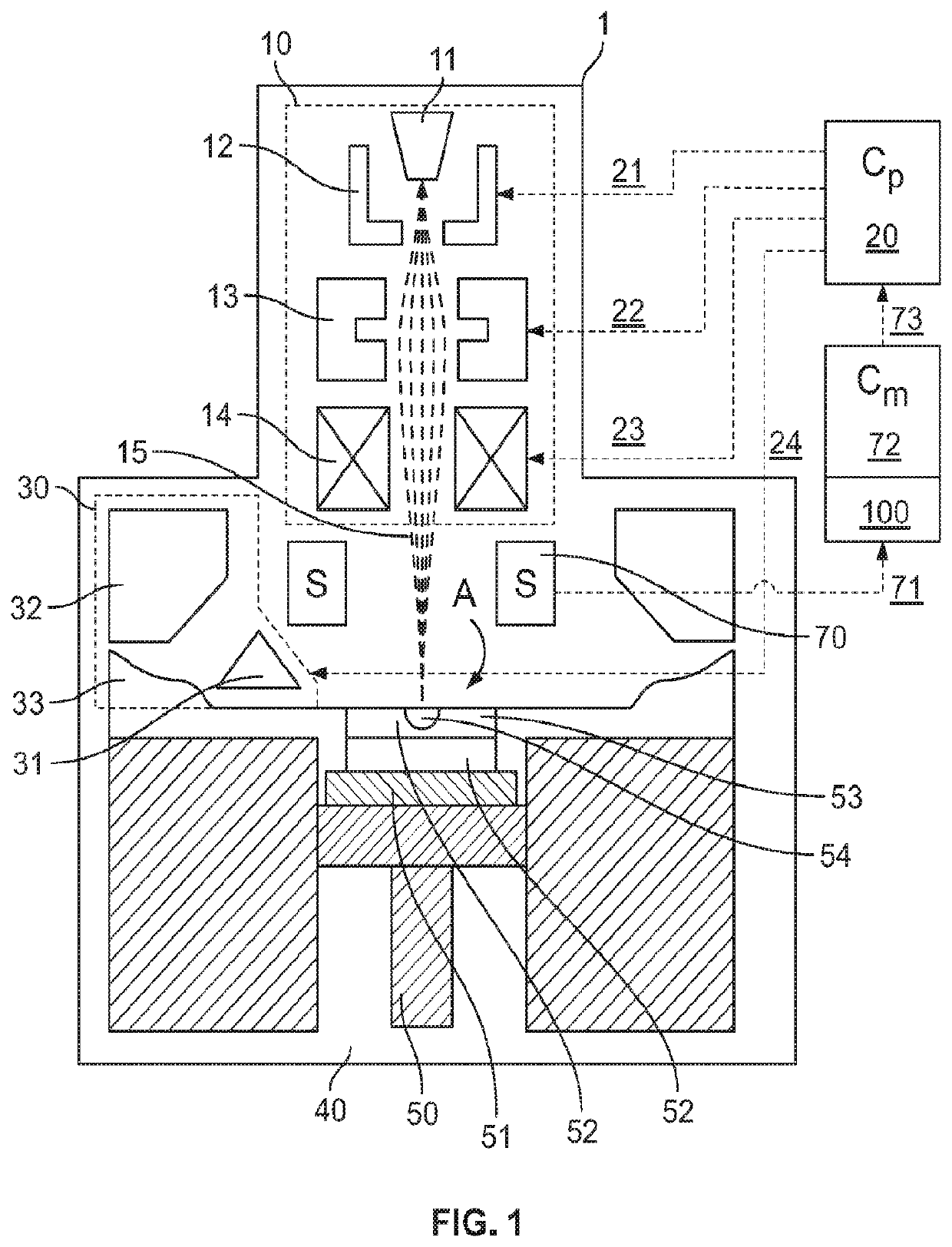

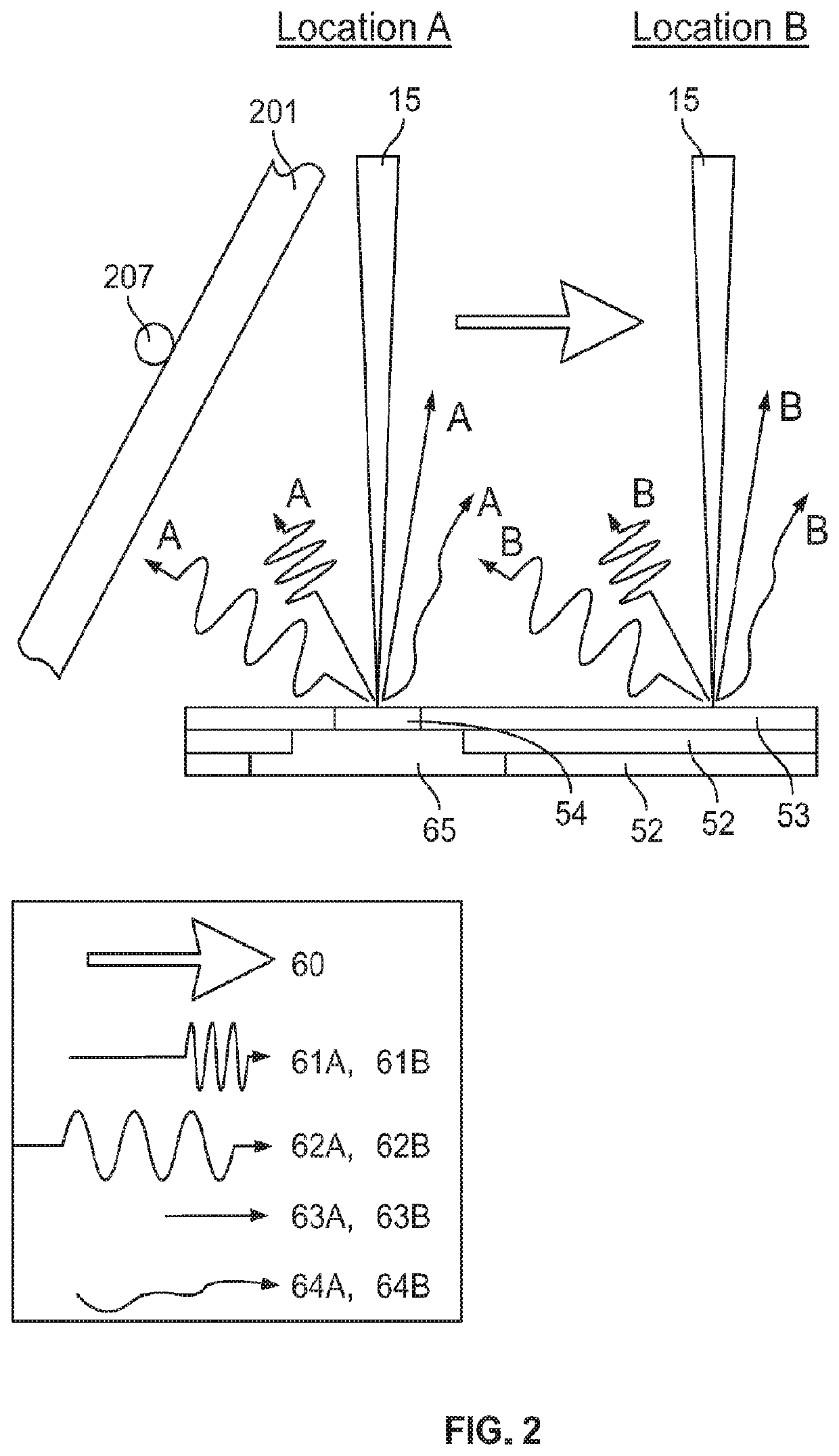

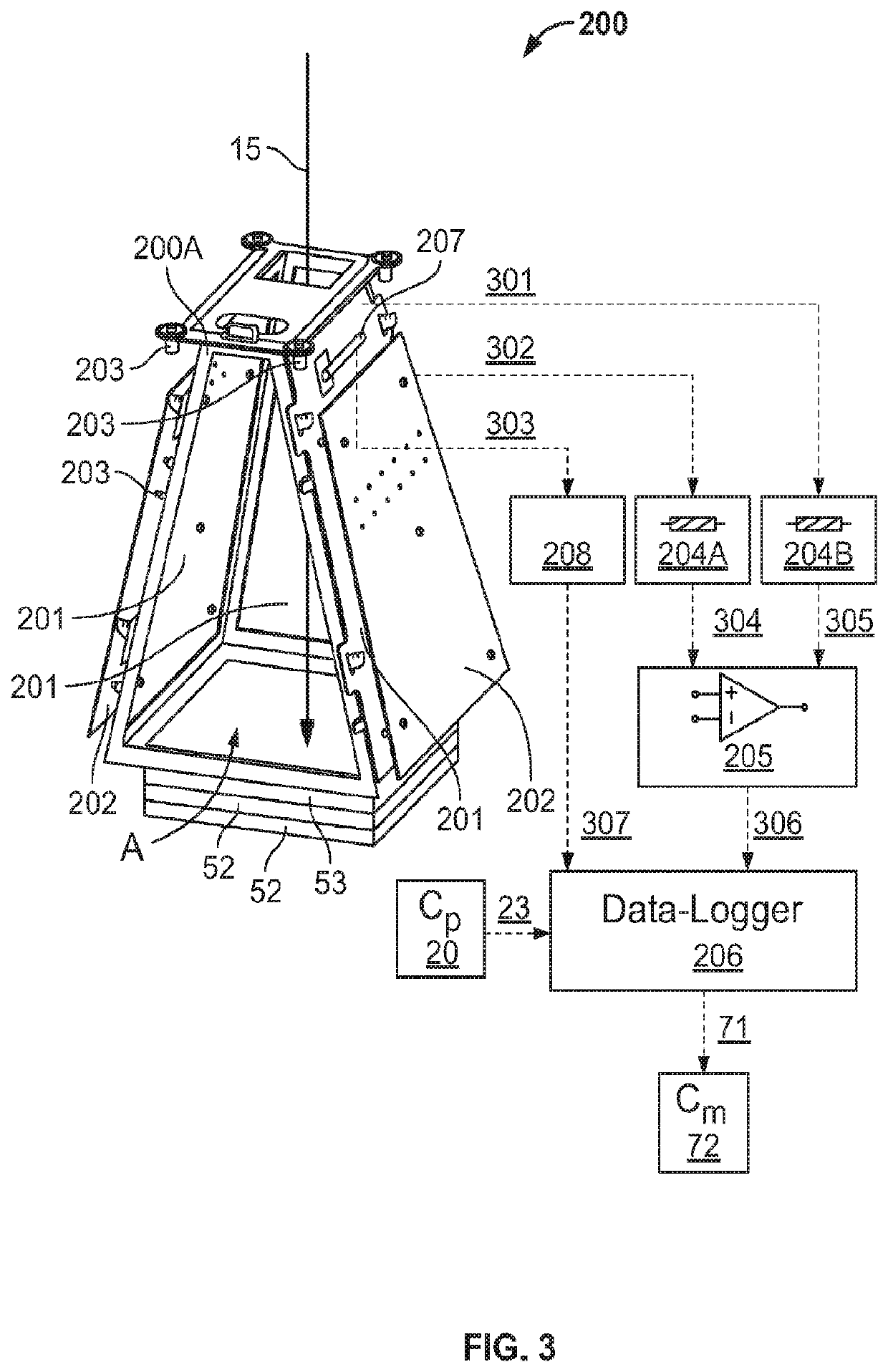

Device For In-Situ Fabrication Process Monitoring And Feedback Control Of An Electron Beam Additive Manufacturing Process

ActiveUS20200215810A1Maintain consistencyMaximize chanceAdditive manufacturing apparatusMaterial analysis using wave/particle radiationControl engineeringProcess engineering

A High Energy Beam Processing (HEBP) system provides feedback signal monitoring and feedback control for the improvement of process repeatability and three-dimensional (3D) printed part quality. Signals reflecting process parameters and the quality of the fabricated parts are analyzed by monitoring feedback signals from artifact sources with a process controller which adjusts process parameters. In this manner, fabricated parts are produced more accurately and consistently from powder feedstock by compensating for process variation in response to feedback signals.

Owner:HOWMEDICA OSTEONICS CORP +1

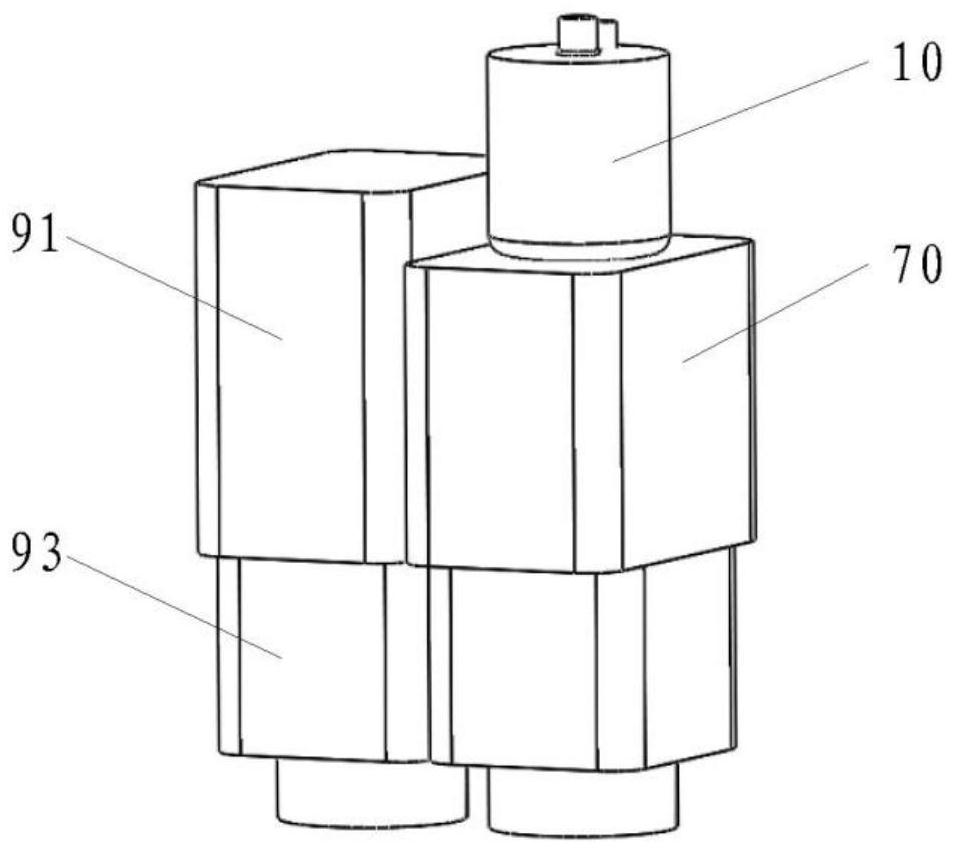

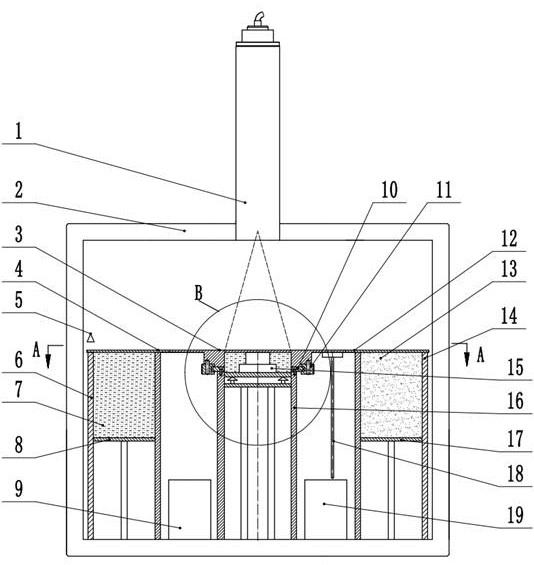

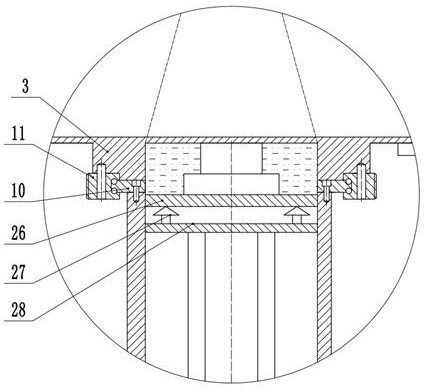

Powder bed electron beam additive manufacturing equipment

PendingCN110899700AReduce powder blowing phenomenonImprove melting qualityAdditive manufacturing apparatusIncreasing energy efficiencyEngineeringHeat conservation

The invention discloses powder bed electron beam additive manufacturing equipment. The equipment comprises a forming cavity, wherein an electronic gun is arranged at the top of the forming cavity, a powder laying platform, a fixed heat insulation frame and a forming surrounding frame are arranged in the forming cavity, a supporting plate is arranged in the forming surrounding frame, a forming bottom plate is arranged on the supporting plate, and first heat preservation structures are arranged on four side faces of the forming surrounding frame and below the supporting plate, the first heat preservation structure comprises a heat preservation plate, the heat preservation plate is arranged on the outer side of a side face of the forming surrounding frame or below the supporting plate, and first heat preservation materials are further arranged in gaps formed between the heat preservation plate and the side face of the forming surrounding frame or the supporting plate. The equipment is advantaged in that the equipment greatly reduces heat transfer of high heat in the forming surrounding frame to a low-temperature area through modes of heat conduction, heat convection, heat radiation and the like, maintains the high-temperature environment in the forming surrounding frame, and effectively eliminates defects of powder blowing, infirm interlayer bonding, need of a post-heat-preservation process and the like.

Owner:西安赛隆增材技术股份有限公司

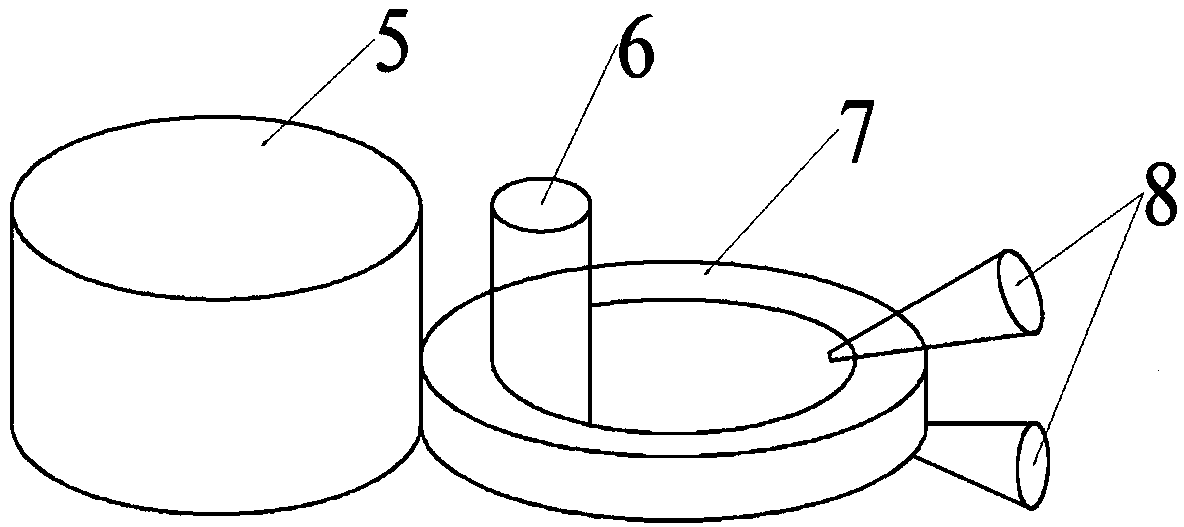

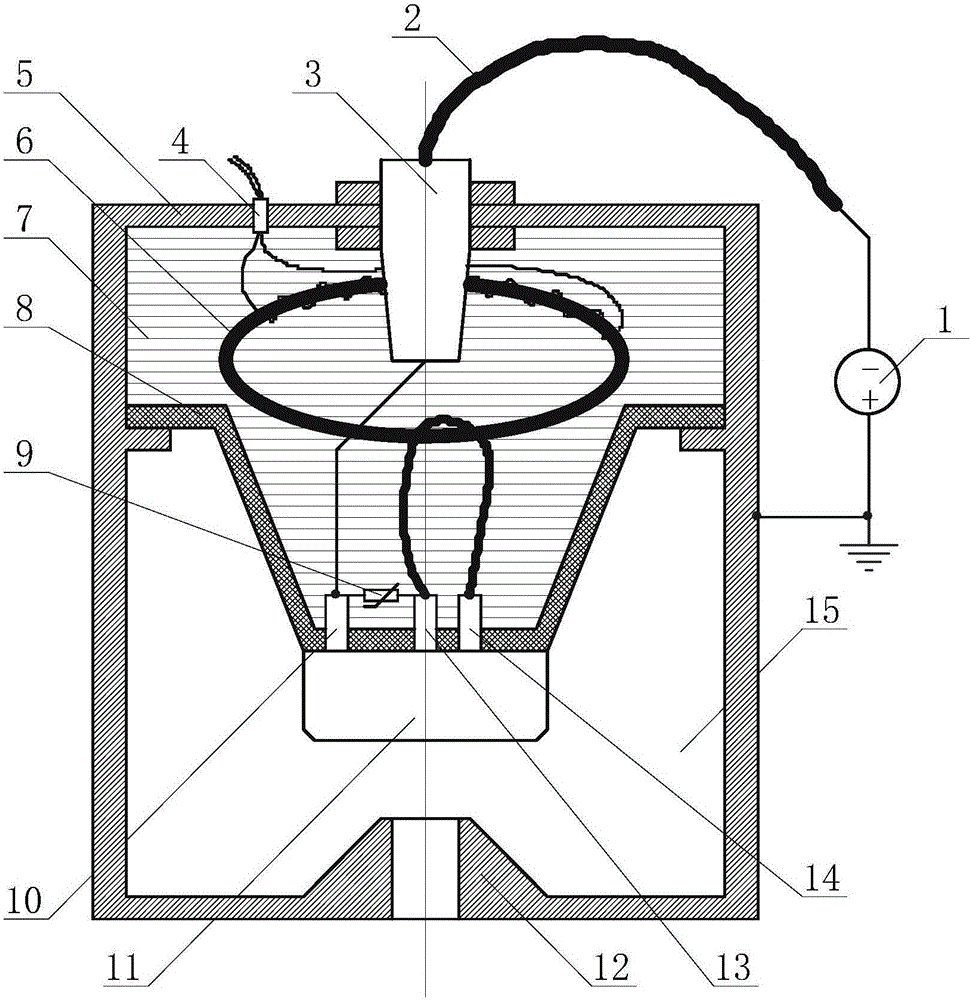

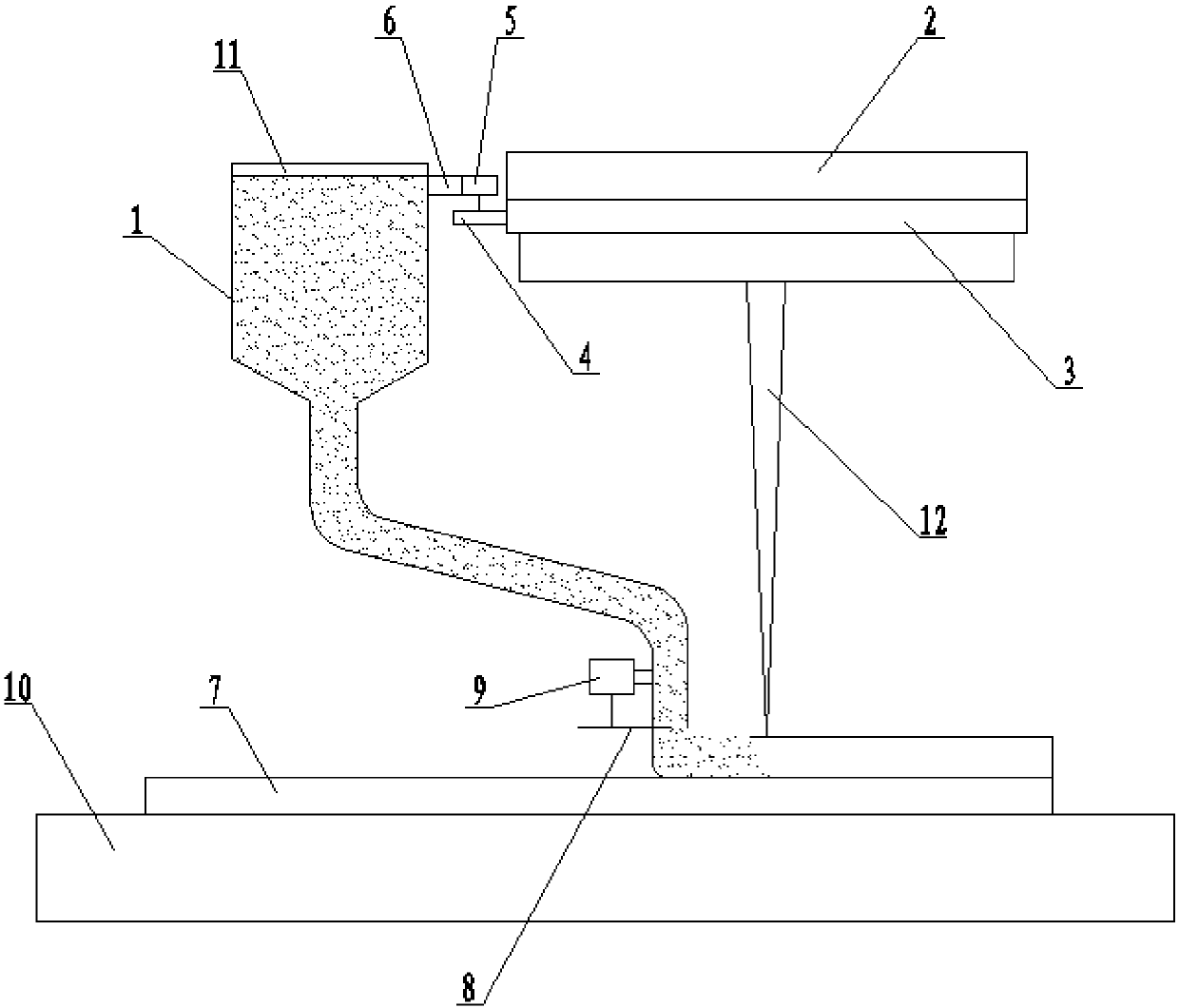

Powder-feeding type electronic beam additive manufacturing device arranged in front

ActiveCN107696480AIncrease profitAvoid wastingAdditive manufacturing apparatusIncreasing energy efficiencyMechanical engineeringElectron

The invention provides a powder-feeding type electronic beam additive manufacturing device arranged in front. The problem that an existing electronic beam selective melting additive manufacturing device is only suitable for additive manufacturing of small precise parts and thus the utilization rate of powder is very low is solved. The powder-feeding type electronic beam additive manufacturing device arranged in front comprises a hopper, an electronic gun, an annular fixing gear guiding rail, a rotating gear, a servo motor, a servo motor support, a sedimentary body, a flow adjusting stop pieceand a stop piece adjusting motor. The annular fixing gear guiding rail is fixedly mounted on a shell of the electronic gun, the rotating gear is engaged with the annular fixing gear guiding rail and fixedly mounted at an output shaft of the servo motor, and the servo motor is fixedly connected with a shell of the hopper through the servo motor support. An outlet of the hopper is perpendicular to the upper surface of a base plate directly facing the outlet, the flow adjusting stop piece is arranged at the outlet of the hopper and fixedly mounted at the output end of the stop piece adjusting motor, and a shell of the stop piece adjusting motor is fixedly connected with the outer wall of the lower end of the hopper. The powder-feeding type electronic beam additive manufacturing device arranged in front is used for electronic beam additive manufacturing.

Owner:黑龙江省工研院资产经营管理有限公司

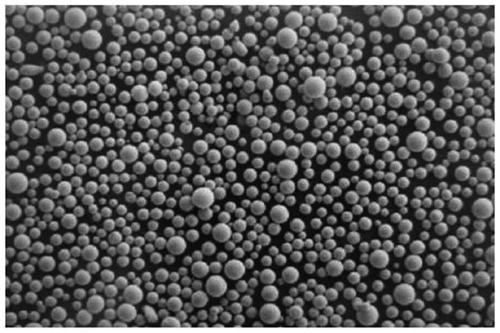

Metal beryllium powder for 3D printing and preparation method and application thereof

ActiveCN111531180AReduce oxygen contentEasy to shapeAdditive manufacturing apparatusTransportation and packagingBeryllium PowderOxygen content

The invention provides metal beryllium powder with high production efficiency for 3D printing and a preparation method and application thereof. The preparation method can comprise the following stepsthat a metal beryllium rod is placed in a vacuum environment; inert gas is introduced into the vacuum environment, wherein the oxygen content in the vacuum environment is not more than 3 ppm; the endface of the metal beryllium rod is melted into a liquid film through electric arcs; the metal beryllium rod is rotated to crush the liquid film into fine particles; and the fine particles are cooled to obtain the metal beryllium powder. The metal beryllium powder can comprise a metal beryllium powder body prepared through adopting the above preparation method. The application can comprise application in the field of laser or electron beam additive manufacturing. The metal beryllium powder has the beneficial effects that the preparation efficiency of the metal beryllium powder is high, and theenergy consumption is low; the prepared metal beryllium powder is good in sphericity, low in oxygen content and good in fluidity, and is a good raw material for 3D printing; and equipment used in theprocess of preparing the spherical metal beryllium powder through is more stable and more reliable, and the production efficiency of the equipment is higher than the production efficiency of other spherical powder preparation equipment.

Owner:西藏智材新材料有限公司

Vacuum electric scanning supersonic spray deposition electron beam additive manufacturing device

PendingCN112776322ASimplify the sintering processPrevent splashAdditive manufacturing apparatusAdditive manufacturing with solidsMolten stateMetallurgy

The invention discloses a vacuum electric scanning supersonic spray deposition electron beam additive manufacturing device. The vacuum electric scanning supersonic spray deposition electron beam additive manufacturing device comprises a forming workbench and an electron beam spray additive device mounted above the workbench, wherein the electron beam spray additive device comprises a cold spraying head, a high-energy electron beam emitter and an electron beam control device. The spraying direction of the cold spraying head can be adjusted, so that sprayed powder particle beams can be scanned on the workbench based on shapes of parts; the electron beam control device is mounted at an emitting opening of the high-energy electron beam emitter and is used for controlling emitting directions of electron beams, so that the electron beams and the powder particle beams sprayed by the cold spraying head are collected at one point, and the surface of a substrate and the powder particles are heated to form a molten state. According to the device, the parts are formed by directionally spraying the powder and heating and sintering in real time; the powder is not needed to be laid layer by layer and sintered; the forming efficiency is greatly improved; the waste of the powder is avoided; the forming cost is reduced; the forming quality consistency is good; the forming quality is improved; the part sintering process is simplified; and the sintering efficiency is improved.

Owner:重庆交通大学绿色航空技术研究院 +1

Preparation method of A100 ultrahigh-strength steel wire for additive manufacturing

The invention provides a preparation method of an A100 ultrahigh-strength steel wire for additive manufacturing. The method is characterized in that an A100 ultrahigh-strength steel ingot is forged and rolled to prepare a bar with high surface quality; and the bar with high surface quality is subjected to drawing pulling and surface treatment in a plurality of times through special technologies so as to obtain the special A100 ultrahigh-strength steel wire for additive manufacturing. According to the method, the special drawing and pulling technology and the special surface treatment technology are carried out to successfully prepare the special high-quality A100 ultrahigh-strength steel wire for additive manufacturing, and the wire can be massively produced with high quality; the wire is applicable to the fields such as the fields of electric arc additive manufacturing, electronic beam additive manufacturing and ultrahigh-strength steel welding; and the wire has a wide application prospect.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Powder bed electron beam additive manufacturing equipment and method

ActiveCN112496352AAvoid mixingGuaranteed not to repeatAdditive manufacturing apparatusEngineeringMechanical engineering

The invention discloses powder bed electron beam additive manufacturing equipment and method, belongs to the field of powder bed additive manufacturing equipment, and solves the problem that an existing powder bed electron beam additive manufacturing equipment can only print a single material and cannot print two materials. The equipment comprises a first powder spreading unit, a second powder spreading unit and a forming cylinder, wherein the first powder spreading unit is located on the first side in a forming chamber; the second powder spreading unit is located on the second side in the forming chamber and used for containing second powder; the forming cylinder is located in the middle of the forming chamber, and the upper surface of the forming cylinder makes contact with the first powder spreading unit and the second powder spreading unit; and the forming cylinder is located in the forming chamber and used for driving a third powder spreading platform arranged on the upper surfaceof the forming cylinder to rotate through a bearing arranged on the forming cylinder and sequentially scraping first powder and the second powder into the forming cylinder, and the upper surface of the third powder spreading platform makes contact with the first powder spreading unit and the second powder spreading unit.

Owner:西安赛隆增材技术股份有限公司

Spherical vanadium alloy powder and preparation method and application thereof

PendingCN111618310ASolve the problem of poor sphericityGood sphericityAdditive manufacturing apparatusTransportation and packagingAlloyVanadium atom

The invention provides a spherical vanadium alloy powder and a preparation method and application thereof. The preparation method comprises the steps that a vanadium alloy bar is arranged in a vacuumenvironment; inert gas is introduced into the vacuum environment for air replacement, and the oxygen content in the vacuum environment after replacement is below 5 ppm; an electric arc is utilized forenabling a liquid film out of the end face of the vanadium alloy bar; the vanadium alloy bar is rotated, and the liquid film is smashed into micro liquid drops under the centrifugal force effect; andcooling is carried out to obtain the spherical vanadium alloy powder. The spherical vanadium alloy powder can comprise powder prepared through the preparation method of the spherical vanadium alloy powder. The application can include application to the field of laser or electronic beam additional materials, and / or application to the field of laser or electronic beam cladding, such as applicationto electronic beam 3D printing. The spherical vanadium alloy powder has the beneficial effects that the preparation efficiency is high, the cost is low, the safety is high, and the problem that the sphere degree of the powder in a traditional production method can be effectively solved.

Owner:四川容克斯科技有限公司

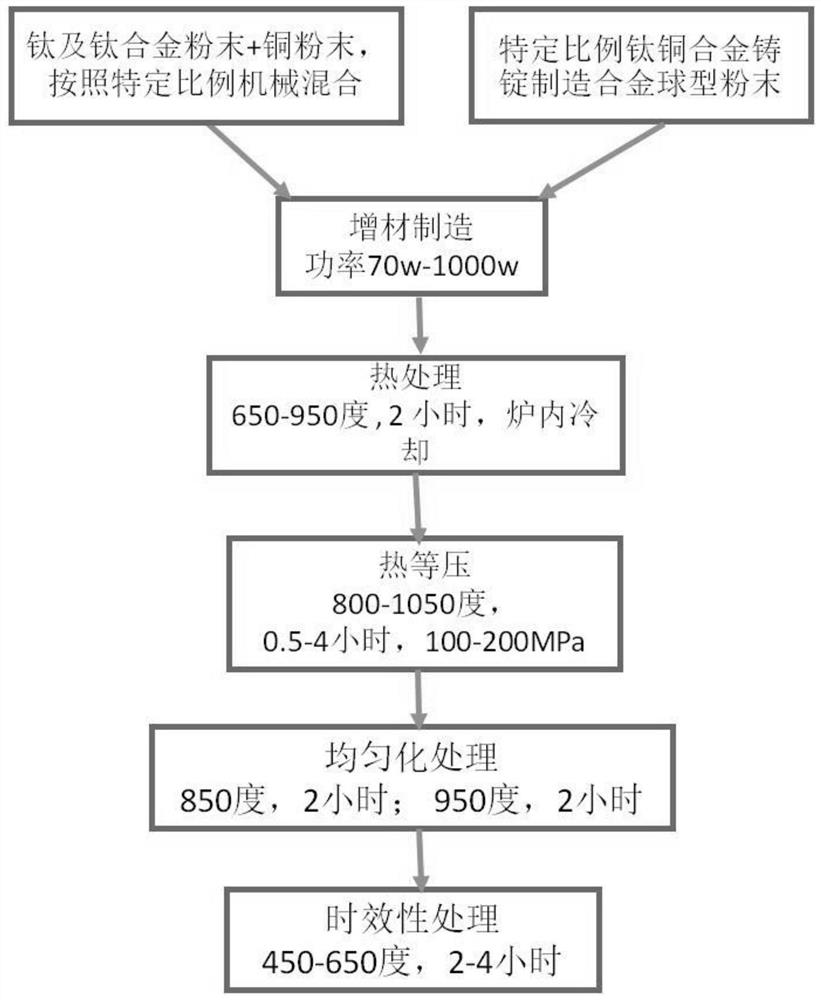

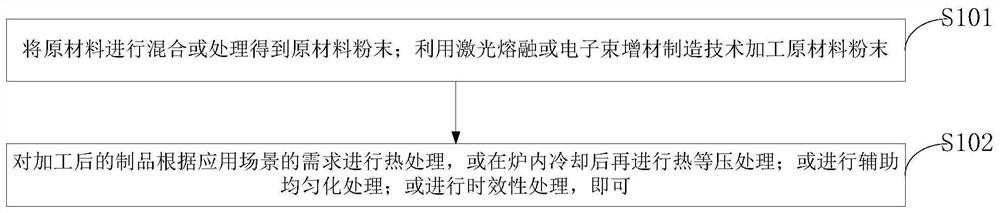

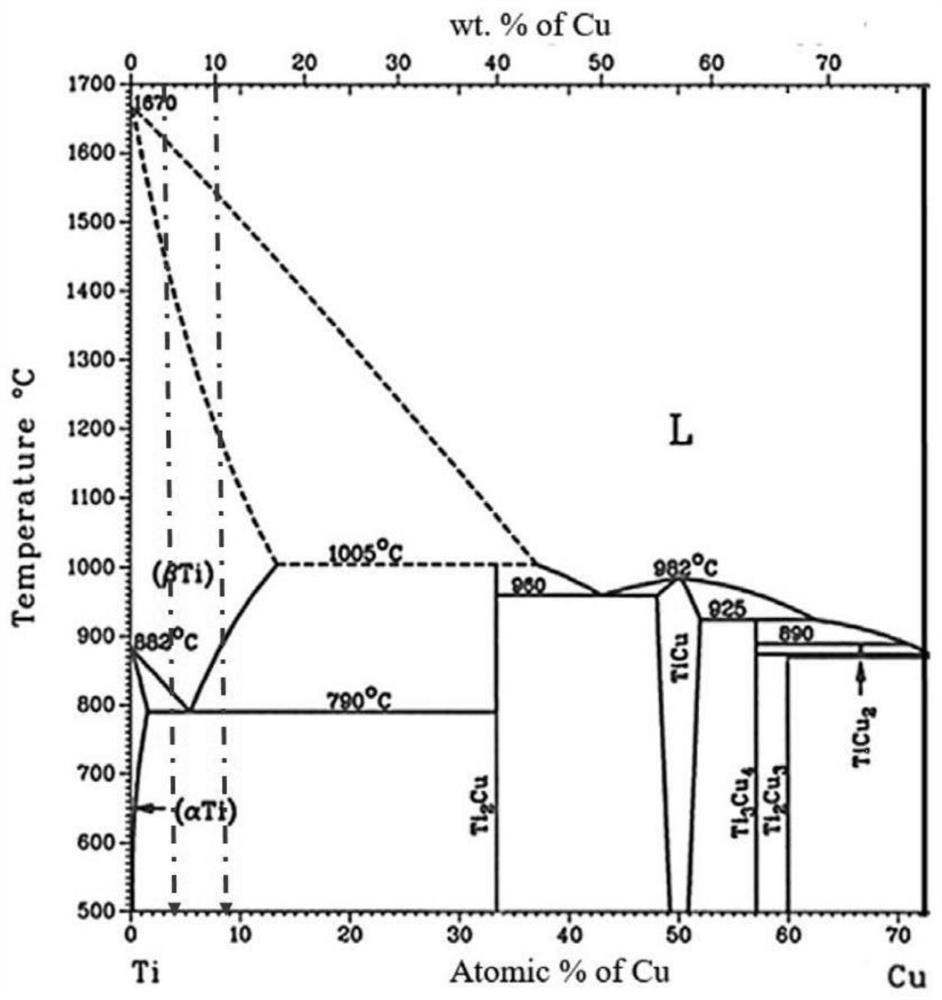

Antibacterial material additive material, preparation method and application

InactiveCN113172237ALong-acting antibacterialBalance of Mechanical PropertiesAdditive manufacturing apparatusTissue regenerationMetallic materialsTi-Cu alloy

The invention belongs to the technical field of metal materials, and discloses an antibacterial material additive material, a preparation method and application. Titanium or titanium alloy spherical powder and copper spherical powder are mixed according to a specific proportion, or a titanium-copper alloy ingot in a specific proportion is utilized, and spherical alloy powder is prepared through a plasma rotating electrode and a plasma atomization or gas atomization method; raw material powder is processed by using a laser melting or electron beam additive manufacturing technology; heat treatment is carried out on a processed product, the product is cooled in a furnace, and then hot isobaric treatment is carried out; homogenization treatment is carried out; and timeliness processing is carried out. According to the alloy additive manufacturing production method and a post-treatment process, compared with an antibacterial coating, common titanium and titanium alloy can have a long-acting antibacterial effect. A mixed material in a specific proportion can be processed by utilizing the advantages of additive manufacturing, a traditional titanium-based material is endowed with the antibacterial characteristic, and the mechanical property and the antibacterial effect of a part can be balanced through the post-treatment process.

Owner:广州柔岩科技有限公司

Systems and methods for designing and fabricating support structures for overhang geometries of parts in additive manufacturing

ActiveUS10010936B2Improve heat transfer performanceReduce gradientAdditive manufacturing apparatusLayered productsContact freeLaser additive manufacturing

Systems and methods are provided for designing and fabricating contact-free support structures for overhang geometries of parts fabricated using electron beam additive manufacturing. One or more layers of un-melted metallic powder are disposed in an elongate gap between an upper horizontal surface of the support structure and a lower surface of the overhang geometry. The powder conducts heat from the overhang geometry to the support structure. The support structure acts as a heat sink to enhance heat transfer and reduce the temperature and severe thermal gradients due to poor thermal conductivity of metallic powders underneath the overhang. Because the support structure is minimally or not connected to the part, the support structure can be removed with minimal or no post-processing step.

Owner:UNIVERSITY OF ALABAMA +1

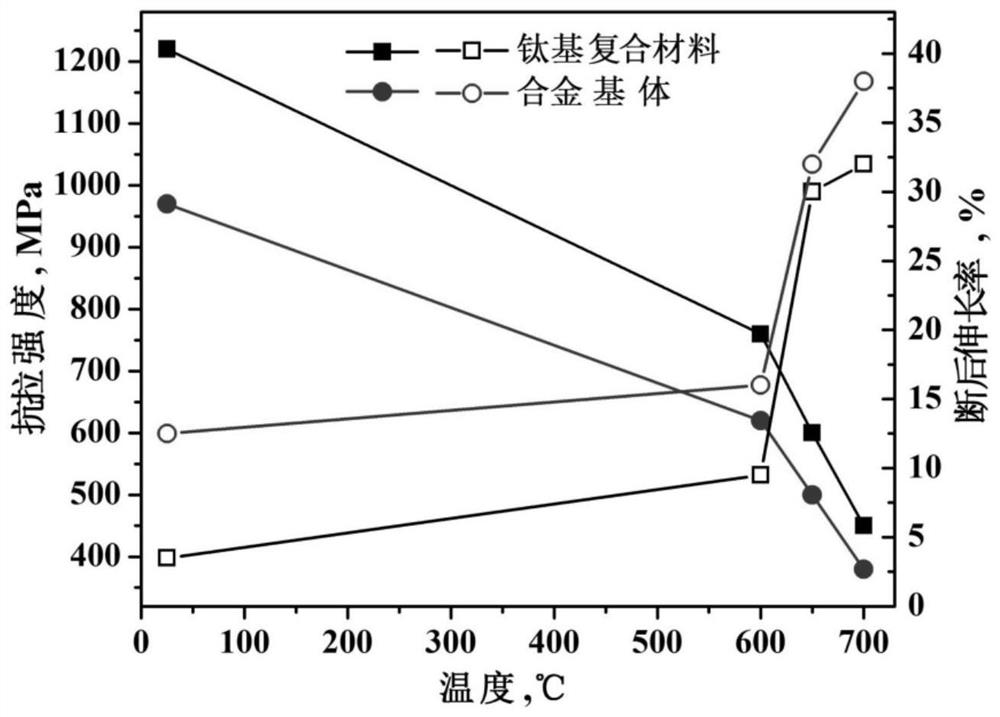

Additive manufacturing method for nano-particle reinforced titanium-based composite material based on electron beam selective melting

ActiveCN113061779AImprove purityAchieve homogenizationAdditive manufacturing apparatusTitanium matrix compositesNanoparticle

The invention relates to an additive manufacturing method for a nano-particle reinforced titanium-based composite material based on electron beam selective melting. The additive manufacturing method comprises the steps that S1, manufacturing titanium-based composite material spherical powder; S2, screening the powder; S3, constructing a digital model; S4, electron beam additive manufacturing; and S5, post-processing. According to the method of the invention, titanium-based composite material spherical pre-alloyed powder is directly used, additive manufacturing of the nano-particle reinforced titanium-based composite material is carried out under the conditions of high vacuum and in-situ annealing, and in-situ synthesis and dense three-dimensional net-shaped uniform distribution of a nano reinforced phase are achieved. According to the nano-particle reinforced titanium-based composite material manufactured through the method, the density reaches up to 99.8%, the oxygen content is lower than 0.12 wt%, the volume fraction of the reinforced phase can reach 5.0% or above, and the mechanical property is close to the level of a conventional forge piece. Therefore, the method provided by the invention is particularly suitable for low-cost manufacturing of high-performance nano-particle reinforced titanium-based composite parts with complex structures.

Owner:NORTHEASTERN UNIV

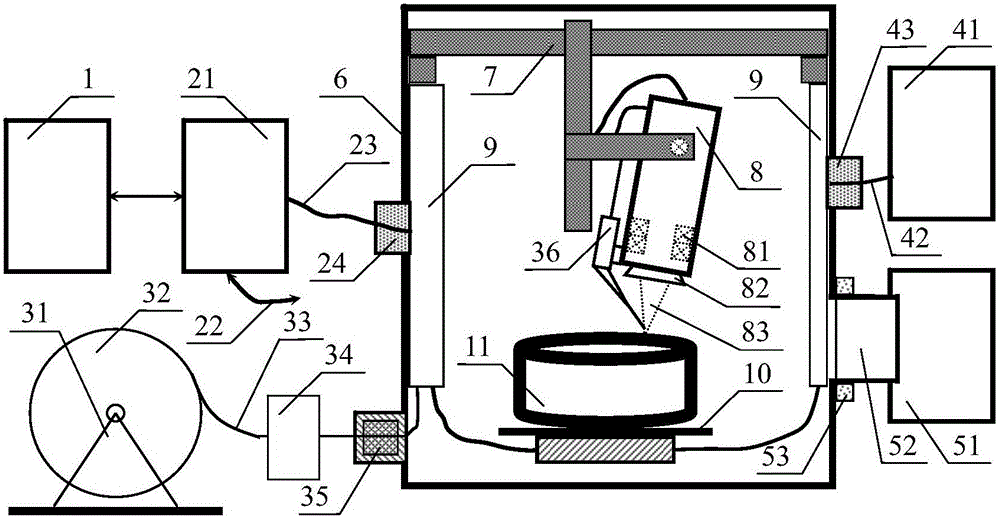

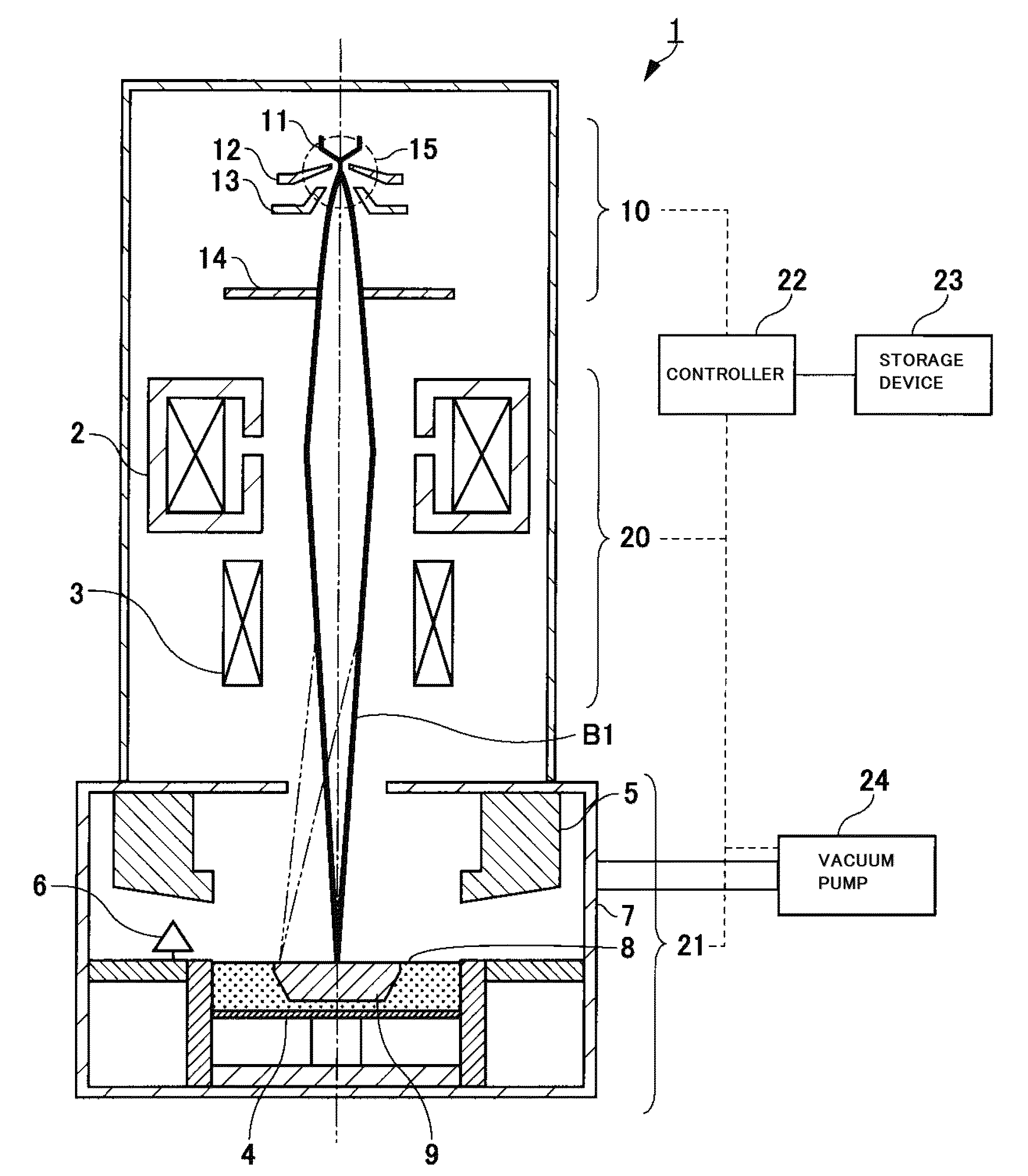

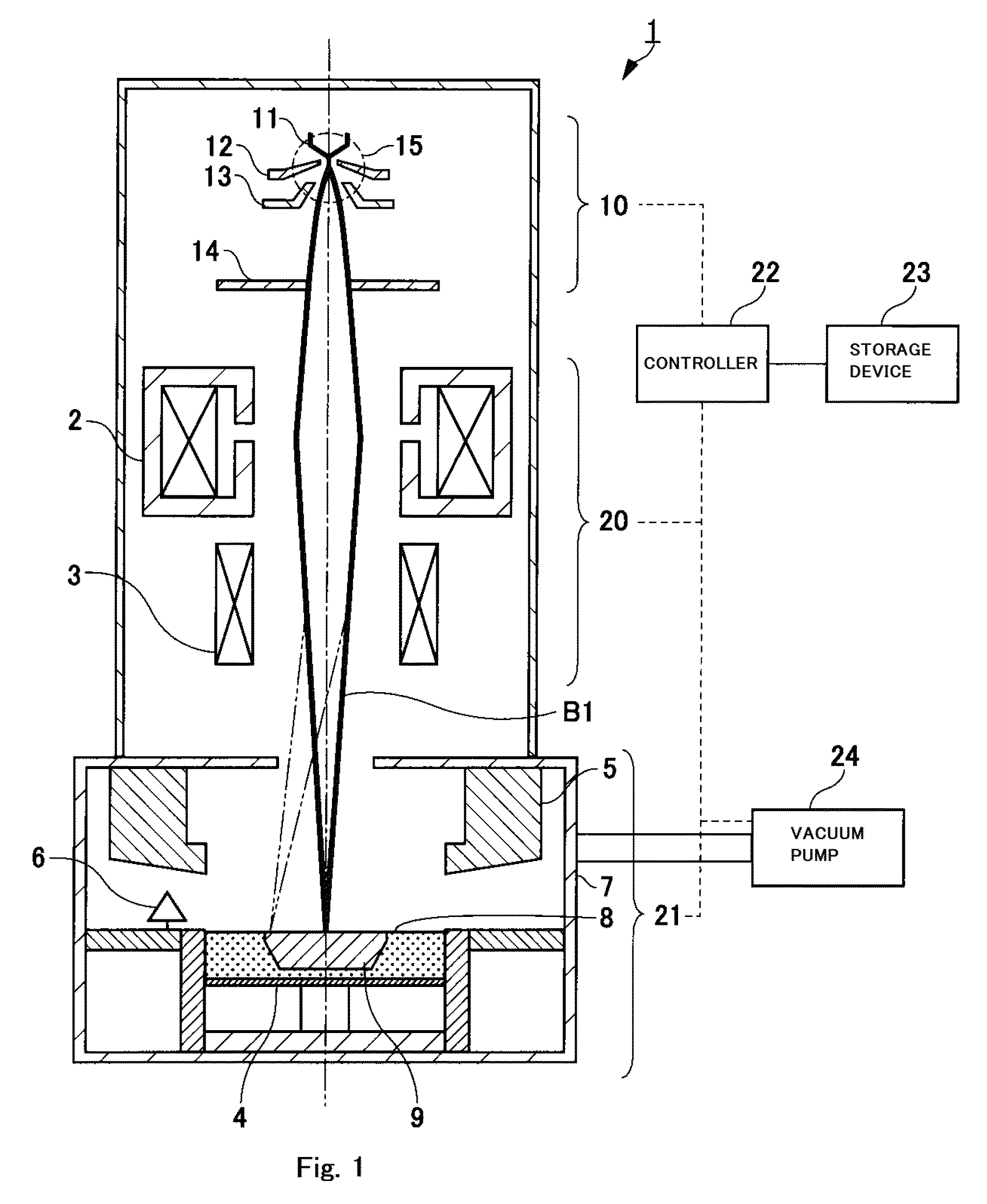

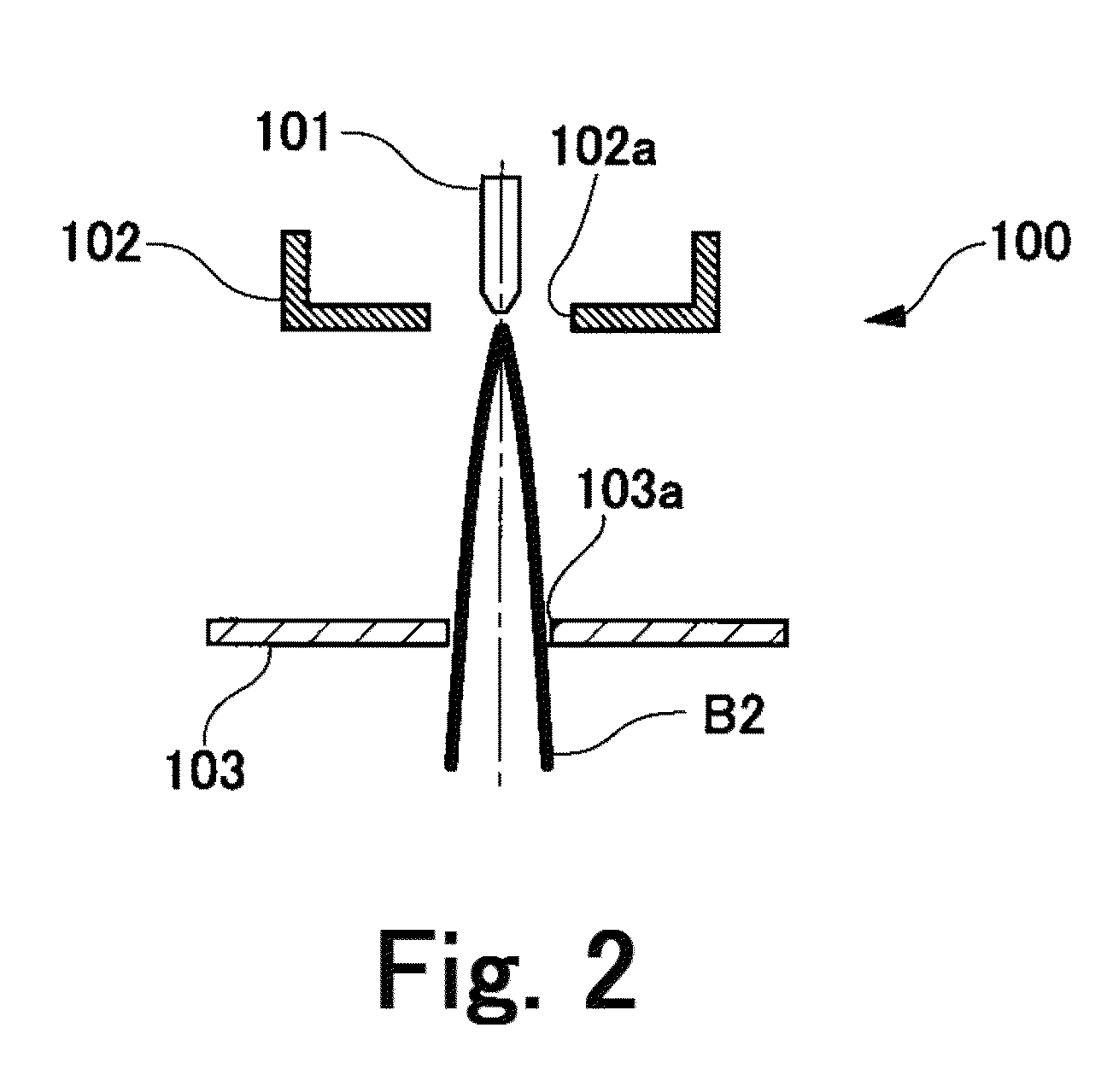

Electron gun, method of controlling same, and electron beam additive manufacturing machine

ActiveUS9269520B2Keep brightnessConstant brightnessAdditive manufacturing apparatusElectrode and associated part arrangementsCurrent limitingThermal electron

There is disclosed a method of controlling an electron gun without causing decreases in brightness of the electron beam if a current-limiting aperture cannot be used. The electron gun (10) has a cathode (11), a Wehnelt electrode (12), a control electrode (13), an anode (14), and a controller (22). The Wehnelt electrode (12) has a first opening (12c) in which the tip of the cathode is inserted, and focuses thermal electrons emitted from the tip of the cathode (11). The thermal electrons emitted from the tip of the cathode (11) are caused to pass into a second opening (13c) by the control electrode (13). The anode (14) accelerates the thermal electrons emitted from the cathode (11) such that the thermal electrons passed through the second opening (13c) pass through a third opening (14b) and impinge as an electron beam (B1) on a powdered sample (8). The controller (22) sets the bias voltage and the control voltage based on combination conditions of the bias voltage and control voltage to maintain the brightness of the beam constant.

Owner:JEOL LTD

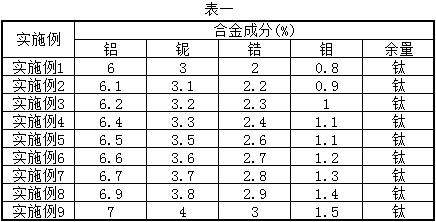

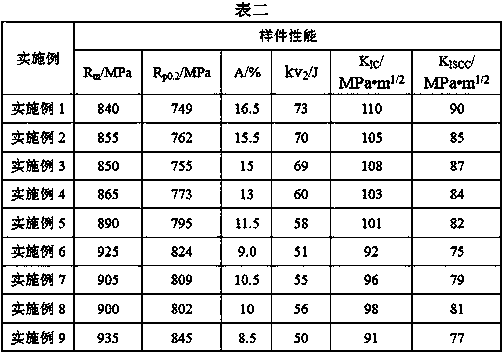

Special titanium alloy wire for 800MPa-grade electron beam additive material and preparation method of special titanium alloy wire

The invention relates to the field of titanium alloy wires for naval architecture and ocean engineering, in particular to a special titanium alloy wire for an 800MPa-grade electron beam additive material and a preparation method of the special titanium alloy wire. The titanium alloy wire comprises, by weight, 6%-7% of aluminum, 3%-4% of niobium, 2%-3% of zirconium, 0.8%-1.5% of molybdenum, and thebalance titanium, wherein aluminum of the alloy elements is an alpha-phase stable element of the titanium alloy wire, molybdenum and niobium of the alloy elements are beta-phase stable elements of the titanium alloy wire, and zirconium of the alloy elements is a neutral element of the titanium alloy wire. The wire can meet the requirement of a manufacturing process of the electron beam additive material, and has good technical application and market prospects on the aspect of manufacturing of electron beam fuse additive materials of naval architecture and ocean engineering components.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com