Electronic gun for filament feeding type electron beam additive manufacturing equipment

A technology of additive manufacturing and electron gun, which is applied in the direction of electrical components, electrode devices and related parts, accelerators, etc., can solve problems such as excessive emission, unfavorable filament life, and workpiece damage, and achieve good flexibility, suppress discharge damage, Effect of prolonging filament life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

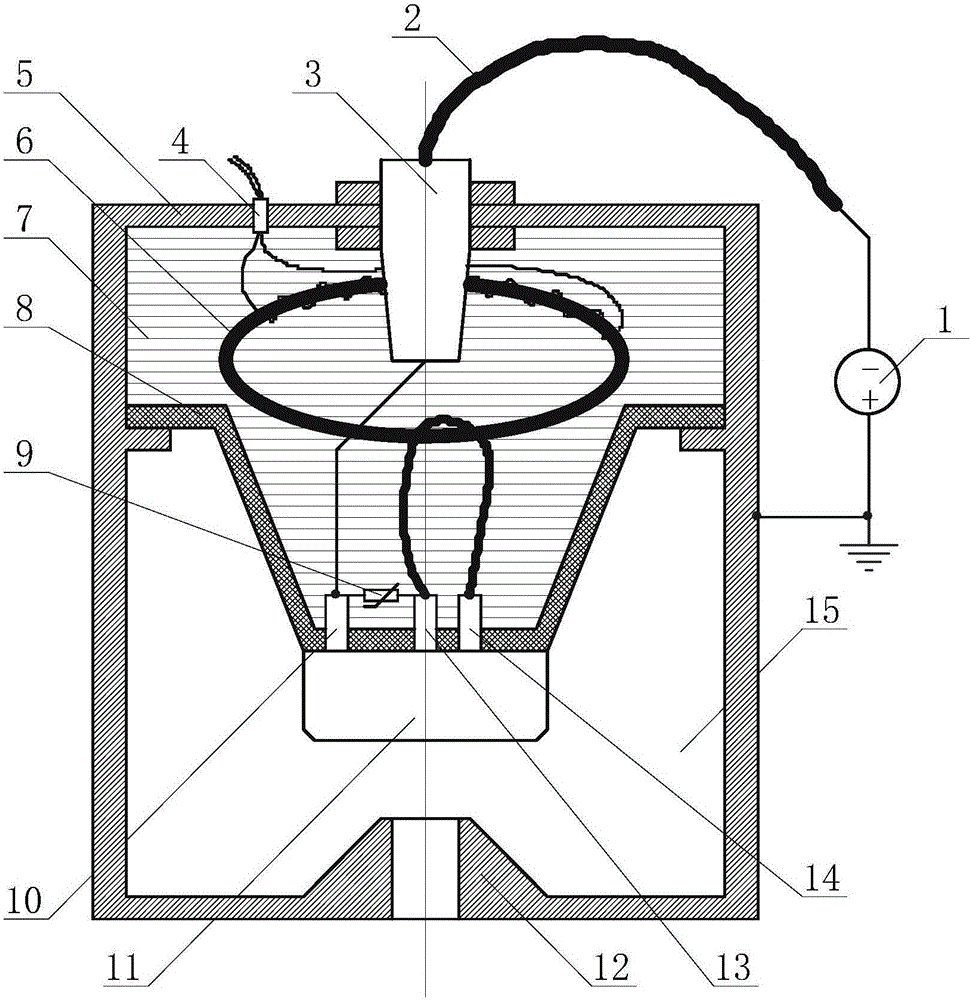

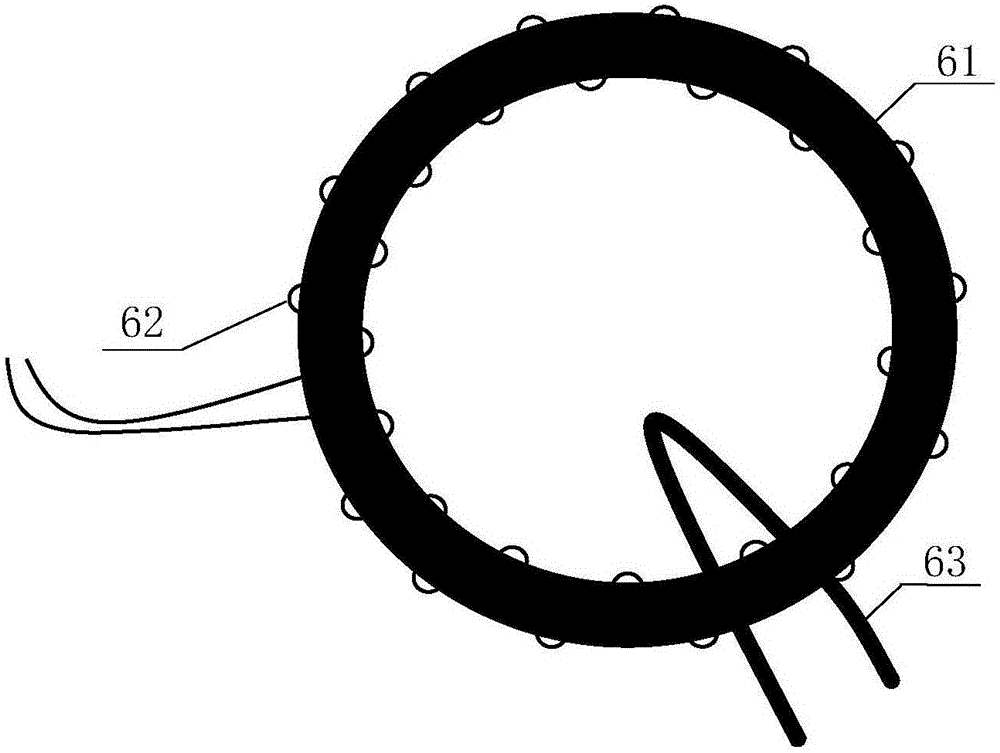

[0018] An electron gun for wire-feeding electron beam additive manufacturing equipment, such as figure 1 As shown, it is mainly composed of high-voltage cable 2, high-voltage cable lead-out 3, electron gun shell 5, filament transformer 6, insulating component 8, voltage stabilizing element 9, beamforming pole electrode 10, cathode beamforming pole assembly 11, anode 12, filament head The end electrode 13 and the filament end electrode 14 are composed.

[0019] The electron gun casing 5 is a closed metal hollow cavity. The insulating assembly 8 spans the electron gun casing 5 and divides the inner cavity of the electron gun casing 5 into upper and lower chambers. The upper chamber is filled with insulating cooling oil 7, and the lower chamber is a vacuum chamber 15. The high-voltage cable lead-out head 3, the focusing electrode 10, the filament head electrode 13 and the filament end electrode 14 are located in the upper chamber. The high-voltage cable lead-out 3 is fixed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com