Electron beam additive manufacturing method for nickel base alloy structural component

A nickel-based alloy, additive manufacturing technology, applied in the field of electron beam additive manufacturing, can solve the problems of wasting manpower and material costs, cumbersome processes, inability to select more suitable blank components, etc., to achieve high utilization rate and high energy density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] (1) Substrate pretreatment

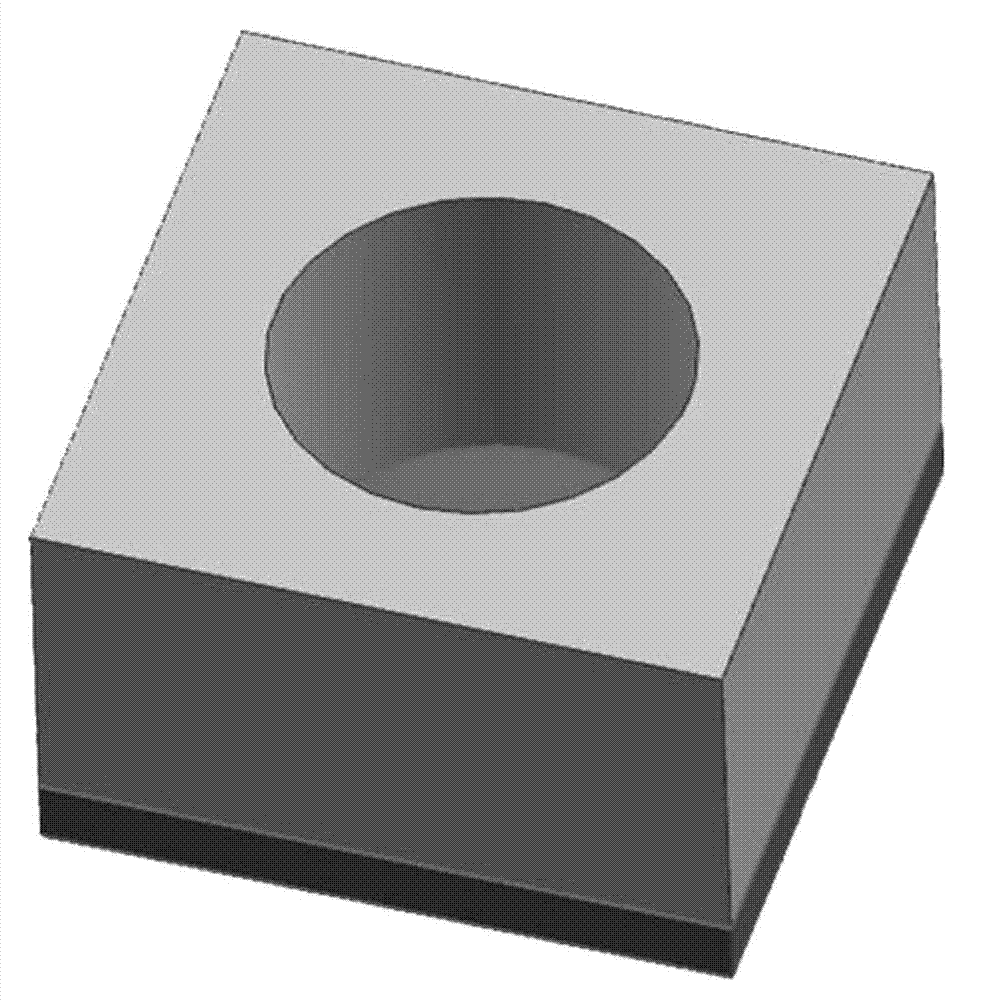

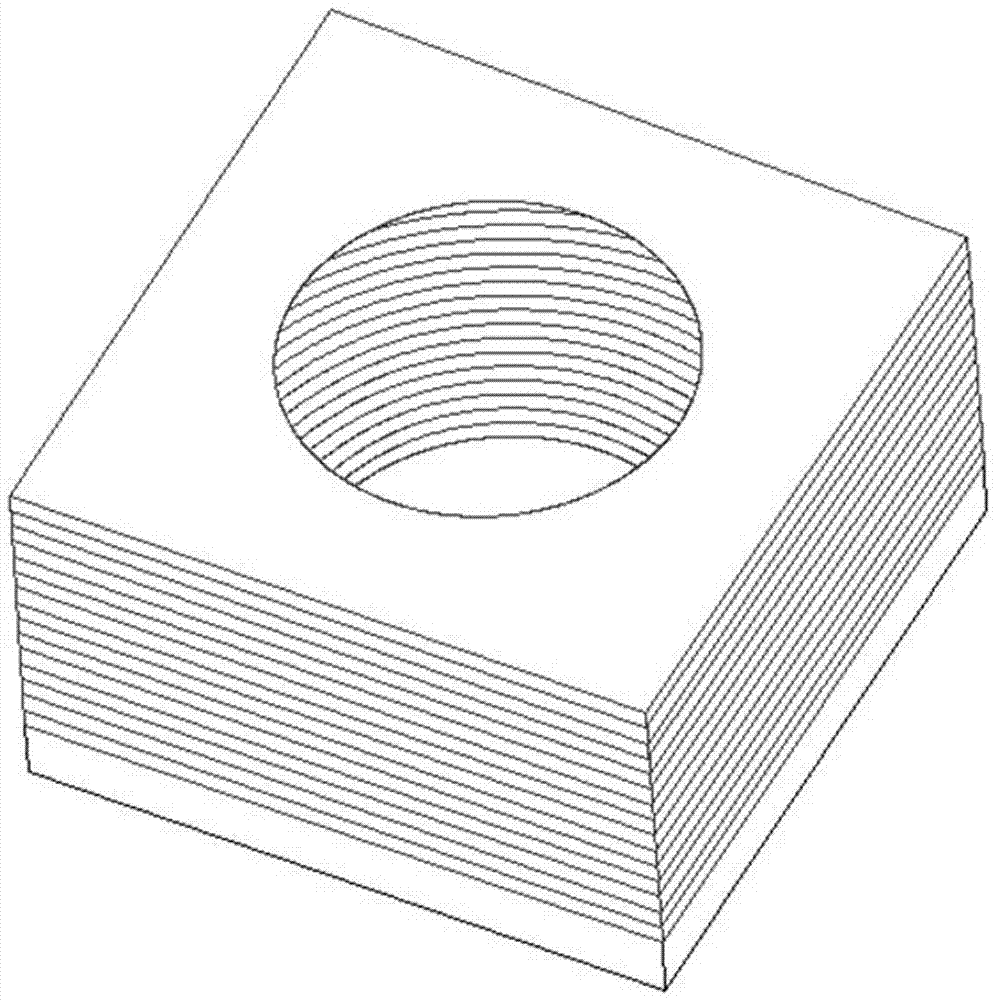

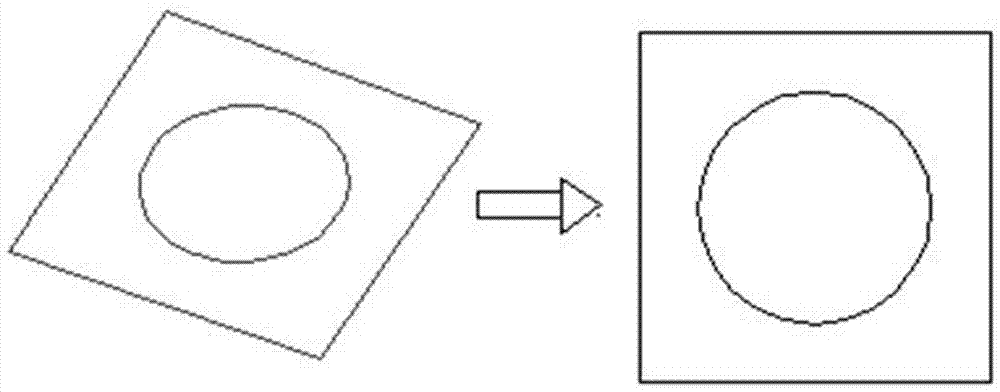

[0027] The substrate of the sample is inconel617 alloy, and the size of the substrate is length × width × height = 100mm × 100mm × 10mm. The substrate is ground and polished with sandpaper to make the surface roughness of the material Ra<10μm, and then washed with 5% to 10% hydrochloric acid About 30 minutes, then wash with clean water, then put it into a drying oven at 100°C for more than 1 hour, take out the treated nickel-based alloy matrix material and cool it to room temperature naturally for use;

[0028] (2) Powder configuration

[0029] Ni powder, Nb powder, Mo powder, Cr powder, rare earth CeO were prepared by vacuum plasma rotating electrode atomization process 2 Five kinds of powders, each particle size is 0.02-0.15mm, and the optimal particle size is 0.07mm; the above-mentioned powders are as follows in terms of mass percentage: Ni powder: 60%, Nb powder: 10%, Mo powder: 10%, Cr powder: 15% %, rare earth CeO 2 Powder: 5% prepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com