Additive manufacturing method for nano-particle reinforced titanium-based composite material based on electron beam selective melting

A technology for a titanium-based composite material and a manufacturing method, which is applied in the directions of additive manufacturing, additive processing, etc., can solve the problems that the content of the reinforcement phase is difficult to precisely control, the particle clusters of the reinforcement phase are impermeable, and the content of oxygen and impurities is high. Outstanding mechanical properties at room temperature and high temperature, avoiding cracking and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

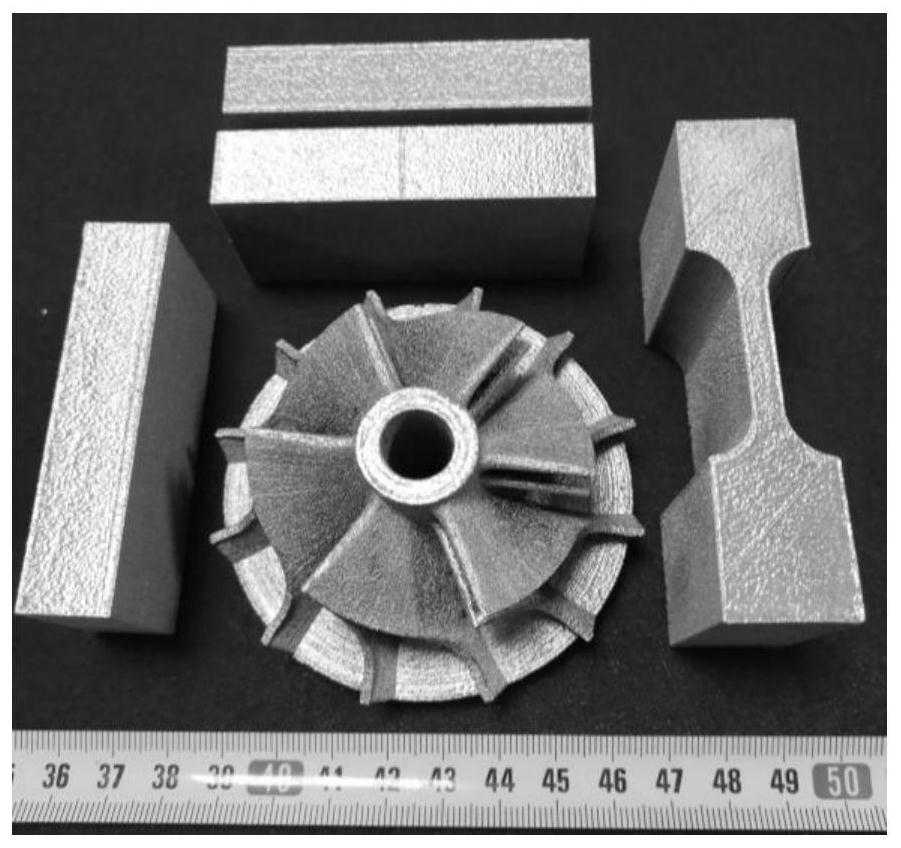

Embodiment 1

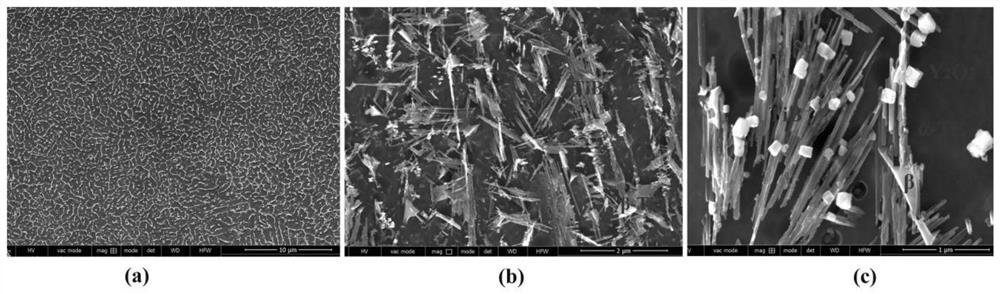

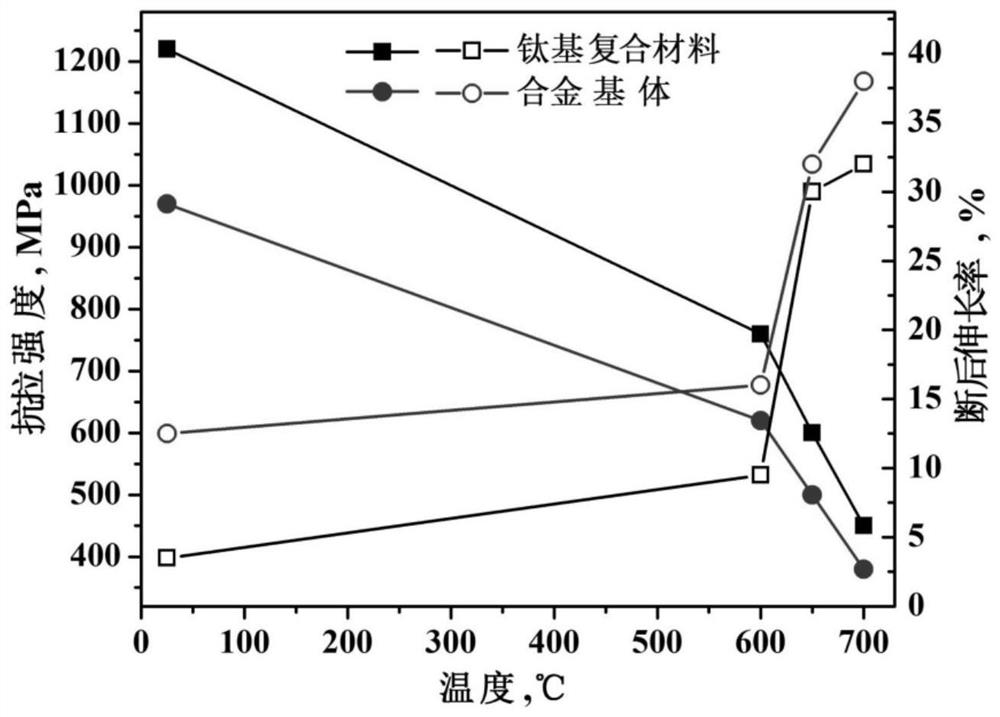

[0045] This embodiment provides a nano-multiphase particle reinforced high-temperature titanium-based composite material with a volume fraction of the reinforced phase of 5.5% (TiB+Y 2 o 3 +Ti 5 Si 3 ) / Ti-6Al-3Sn-4Zr-0.9Mo additive manufacturing method. The composition of chemical elements corresponding to the in-situ self-generated high-temperature titanium-based composite material is as follows in mass ratio: Ti-6Al-3Sn-4Zr-0.9Mo-0.3Si-0.4Y-0.6B, that is, the mass ratio is 6% Al, 3% Sn, 4% Zr, 0.9% Mo, 0.3% Si, 0.4% Y, 0.6% B, and the rest Ti. The nano-reinforcement phase contains in situ self-generated TiB with a volume fraction of 3.4%, 0.95% Y 2 o 3 and about 1.2% Ti 5 Si 3 .

[0046] First, step ① manufactures spherical powder. First, the raw materials are prepared according to the element mass ratio of the titanium-based composite material Ti-6Al-3Sn-4Zr-0.9Mo-0.3Si-0.4Y-0.6B, and the conventional vacuum casting, high-temperature forging and mechanical processi...

Embodiment 2

[0052] The present embodiment provides a kind of nano multi-phase particle reinforced titanium-based composite material whose volume ratio is 5.5% (TiB+Y 2 o 3 ) / Ti-6Al-4V additive manufacturing method. The chemical elements corresponding to the in-situ self-generated high-temperature titanium-based composite material are: Ti-6Al-4V-0.9Y-0.6B, that is, the mass ratio is 6% Al, 4% V, 0.9% Y, 0.6% B, the balance Ti. The in situ self-generated nano-reinforced phase contains 3.4% TiB and 2.1% Y by volume 2 o 3 .

[0053] First, step ① manufactures spherical powder. Firstly, according to the mass ratio of alloy elements of titanium-based composite materials Ti-6Al-4V-0.9Y-0.6B, the raw materials are prepared, and the standard electrode rods for powder making are manufactured by means of conventional vacuum casting, high temperature forging and machining processes. Using the processed Ti-matrix composite electrode rod, the spherical powder was fabricated by the plasma rotating...

Embodiment 3

[0060] This embodiment provides a kind of nano-multiphase particle reinforced high-temperature titanium-based composite material with a volume ratio of 5.5% (TiB+Y 2 o 3 +Ti 5 Si 3 ) / Ti-6Al-3Sn-4Zr-0.9Mo additive manufacturing method. The mass ratio of alloy elements corresponding to the in-situ self-generated high-temperature titanium-based composite material is: Ti-6Al-3Sn-4Zr-0.9Mo-0.3Si-0.4Y-0.6B, that is, the mass ratio is 6% Al, 3% Sn, 4% of Zr, 0.9% of Mo, 0.3% of Si, 0.4% of Y, 0.6% of B, and the balance of Ti. The nano-reinforcement phase contains in situ autogeneous volume ratio of 3.4% TiB, 0.95% Y 2 o 3 and about 1.2% Ti 5 Si 3 .

[0061] The difference between this embodiment and embodiment 1 lies in that: step ① the spherical powder is manufactured by using the crucible-less induction gas atomization method (EIGA). The process parameters of EIGA powder making process are as follows: electrode rod size , Melting temperature 1850℃, argon pressure 3.0MPa....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Room temperature tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com