Wire-feeding type electron beam material-increasing manufacturing equipment and operating method thereof

An additive manufacturing and electron beam technology, which is applied in the field of wire-feeding electron beam additive manufacturing equipment, can solve problems such as inability to realize online monitoring, and achieve the effects of eliminating manufacturing defects, improving manufacturing efficiency, and improving manufacturing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

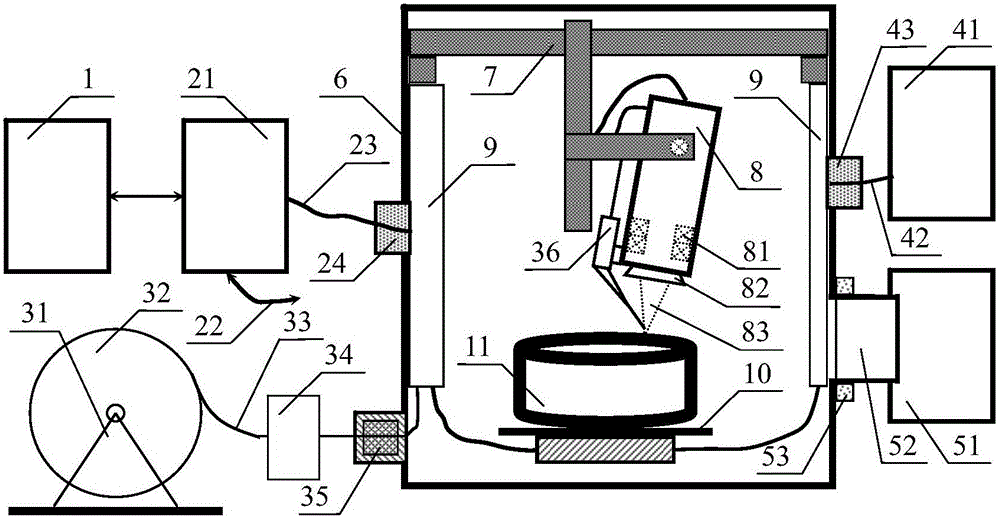

[0025] A wire-feeding electron beam additive manufacturing equipment, such as figure 1 As shown, it is mainly composed of a central control unit 1, a power supply system, a wire feeding system, a cooling liquid circulation system, a vacuum system, a vacuum chamber 6, a moving device 7, an electron gun 8, a wiring trough 9 and a workbench 10. The central control unit 1, the power supply system, the outdoor part of the wire feeding system, the cooling liquid circulation system, and the vacuum pumping system are arranged outside the vacuum chamber 6, and the indoor part of the wire feeding system, the moving device 7, the electron gun 8, the wiring trough 9 and the working The stage 10 is provided inside the vacuum chamber 6 .

[0026] Central control unit 1: responsible for the control and monitoring of the entire equipment, including the setting of the parameters of the electron beam 83, the data processing of the three-dimensional CAD model of the workpiece 11 for layered slic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com