High-purity wild blueberry anthocyanin industrial purification system and purification method

A wild blueberry and purification method technology, which is applied in the high-purity wild blueberry anthocyanin industrial purification system and its purification field, can solve the problems affecting the activity and application range, uneven separation, chromatographic tailing, etc., and solve the problem of online monitoring , improve separation and purification efficiency, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention designs the best process system and the best process parameters from the two directions of the separation and purification system and the separation and purification method

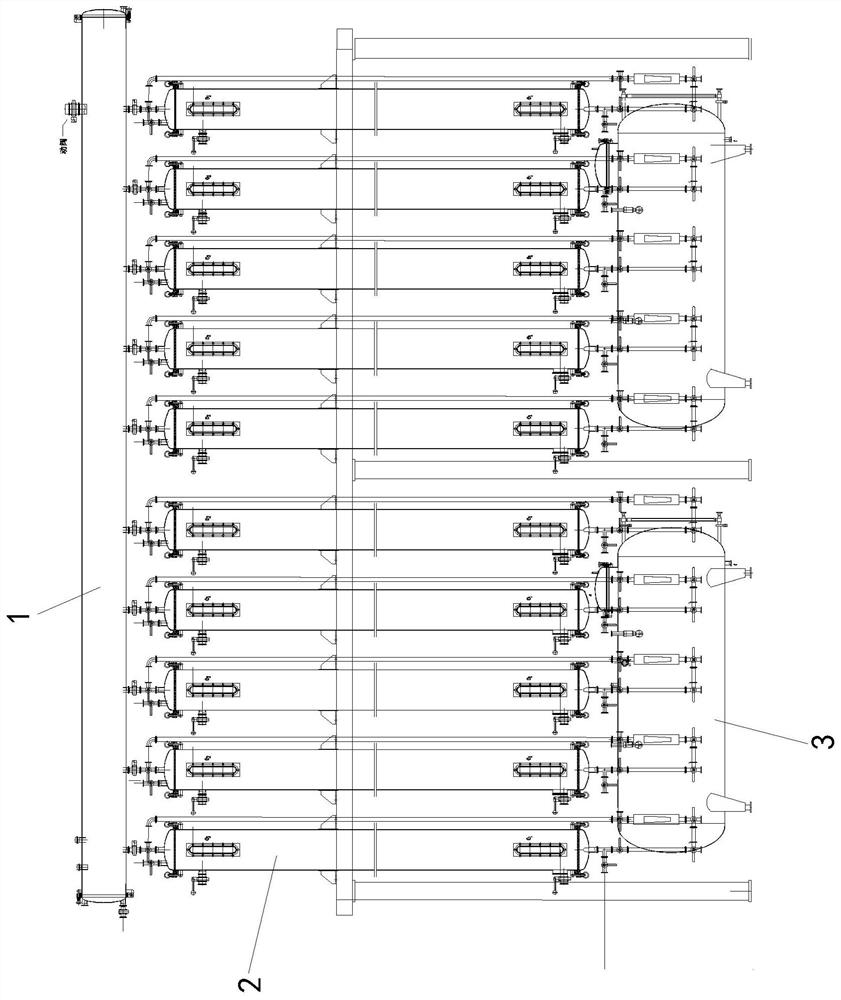

[0021] Separation and purification system:

[0022] The separation and purification system of anthocyanins is concerned with the diameter-to-height ratio of the resin column, the type of macroporous resin filled (selected for the adsorption of wild blueberry anthocyanins), the size of the pipe diameter, the control of the liquid flow rate, and the detection conditions of on-line monitoring There are requirements. The present invention explores all parameters of the system. The data shows that except for the optimal parameter ratio of the system, the process design and system production are carried out in combination with the optimal parameter ratio, and it is applied to the production of anthocyanins in our company.

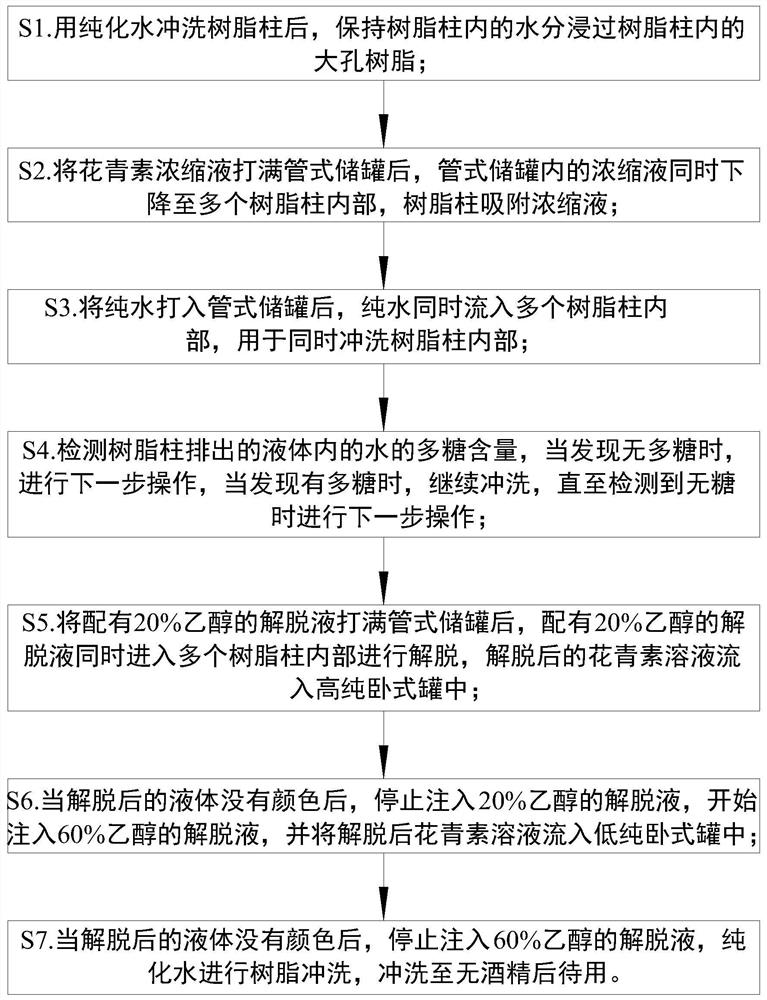

[0023] First, the separation and purification process is: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com