Online monitoring system and method for performance of condenser in power plant based on cleanness coefficient index

A technology of cleaning factor and monitoring system, applied in steam/steam condensers, lighting and heating equipment, etc., can solve the problems of inability to monitor the performance of the condenser, no performance of the condenser, and complex models.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

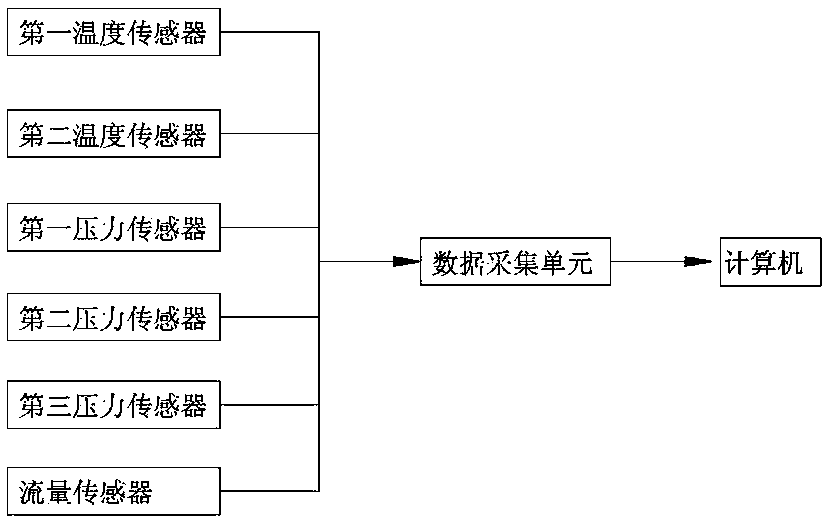

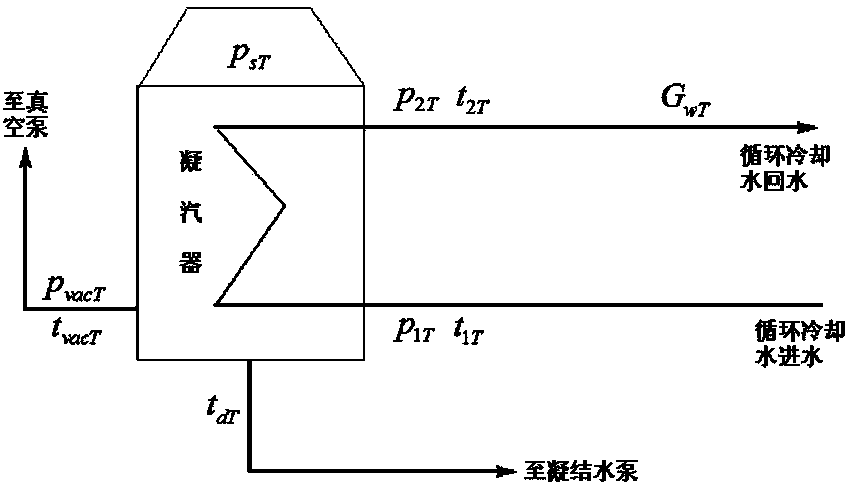

[0125] see figure 1 with figure 2 , the present embodiment is made up of monitoring unit, data acquisition unit and computer;

[0126] The monitoring unit consists of a first temperature sensor arranged on the condenser circulating cooling water inlet pipe and the first pressure sensor , the second temperature sensor set on the condenser circulating cooling water return pipe and a second pressure sensor , the flow sensor arranged on the return water pipeline And the third pressure sensor set at the steam inlet of the condenser constitute;

[0127] The first temperature sensor , the first pressure sensor , the second temperature sensor , the second pressure sensor ,Flow Sensors and a third pressure sensor The output ends are respectively connected to the corresponding input ends of the data acquisition unit;

[0128] The output terminals of the data acquisition unit are connected to the corresponding input terminals of the computer.

[0129] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com