Antibacterial material additive material, preparation method and application

An antibacterial material and additive manufacturing technology, which is applied in additive processing, additive manufacturing, medical science, etc., can solve problems such as weakening of elasticity, and achieve the effect of balancing antibacterial effect and balancing mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

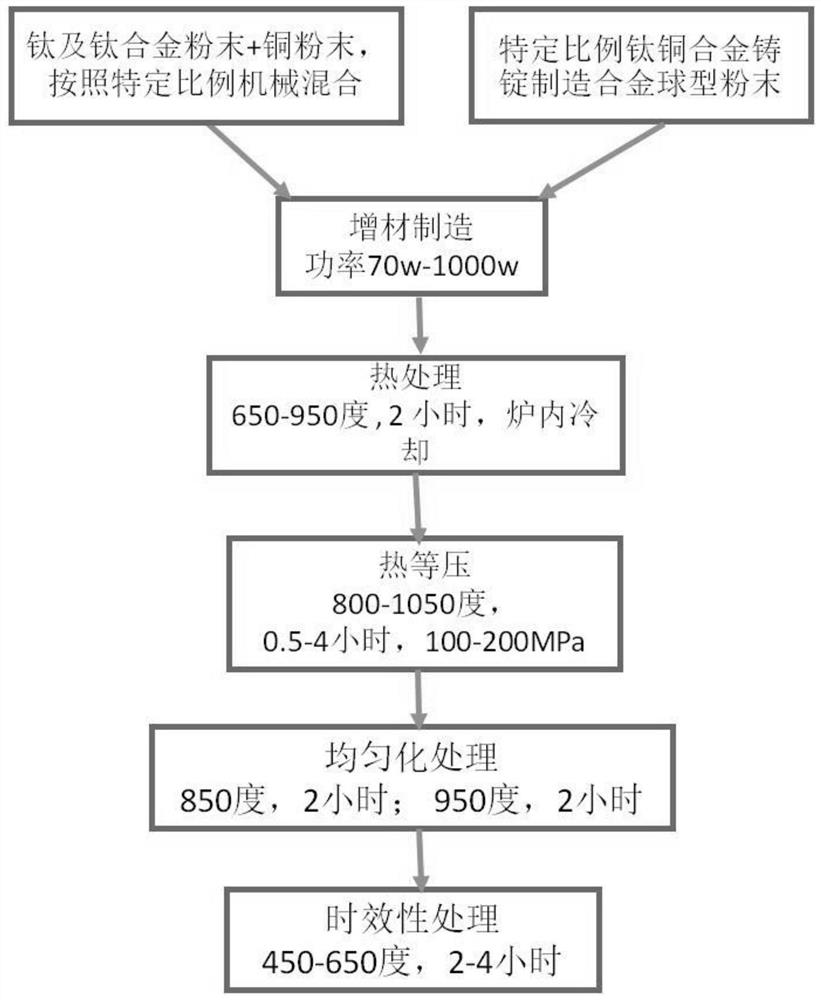

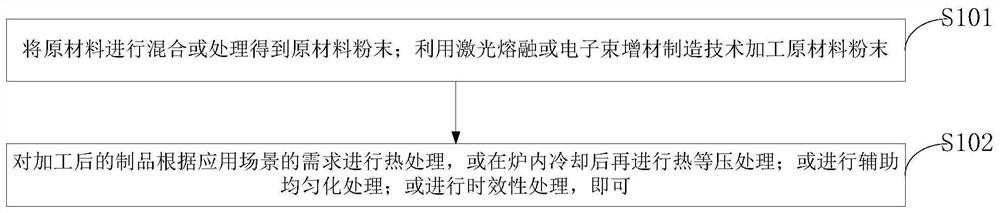

[0033] like figure 2 As shown, the antibacterial material additive preparation method provided by the embodiment of the present invention includes:

[0034] S101, mixing or processing raw materials to obtain raw material powder; processing the raw material powder by using laser melting or electron beam additive manufacturing technology;

[0035] S102, heat treatment is performed on the processed product according to the requirements of the application scenario, or hot isobaric treatment is performed after cooling in the furnace; or auxiliary homogenization treatment is performed; or aging treatment is performed.

[0036] In step S101, the raw material powder obtained by mixing or processing the raw materials provided by the embodiment of the present invention includes:

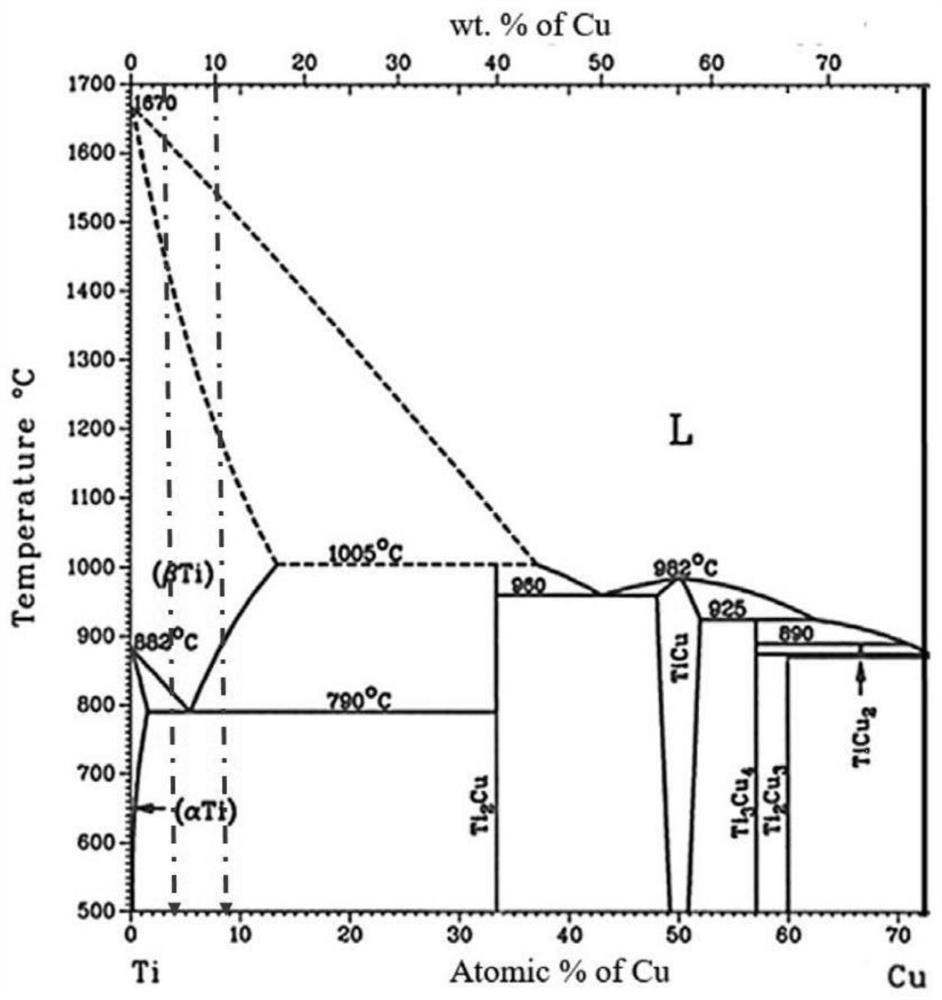

[0037] Mix titanium or titanium alloy spherical powder with copper spherical powder according to a specific ratio, and mechanically mix in a powder mixer for 4-10 hours;

[0038] Or, using a specific propor...

Embodiment 1

[0048] An antibacterial material manufacturing process

[0049] 1. Use titanium or titanium alloy spherical powder and copper spherical powder to mix in a specific proportion, titanium or titanium alloy as the main material, copper proportion is 3%-10%, the two powders are mechanically mixed in a mixer 4- 10h.

[0050] Or directly use a specific proportion of titanium-copper alloy ingot, and use plasma rotating electrode, plasma atomization or gas atomization method to produce spherical alloy powder

[0051] 2. Use laser melting or electron beam additive manufacturing technology to process titanium-copper powder, the powder diameter is less than 15-150um, the indoor oxygen content is less than 100ppm, and the laser power is 70w-1000w.

[0052] 3. Removal of residual stress and selection of main phase structure. Treat at 650-950°C for 2 hours. Cool in furnace.

[0053]4. Heat isobaric treatment (selected according to the usage scenario). Place the product in a closed conta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| laser power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com