Electron beam-friction-stir composite additive manufacturing method

A friction stir and additive manufacturing technology, applied in the field of additive manufacturing, can solve the problem that electron beam-friction stir composite additive manufacturing technology has no relevant reports, and achieve the goal of eliminating internal defects, improving organizational properties, and improving workpiece organization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: This embodiment is realized through the following steps:

[0028] Step 1: Design the 3D model of the workpiece;

[0029] Step 2: Process the 3D model of the workpiece with slicing software and save it as an STL file;

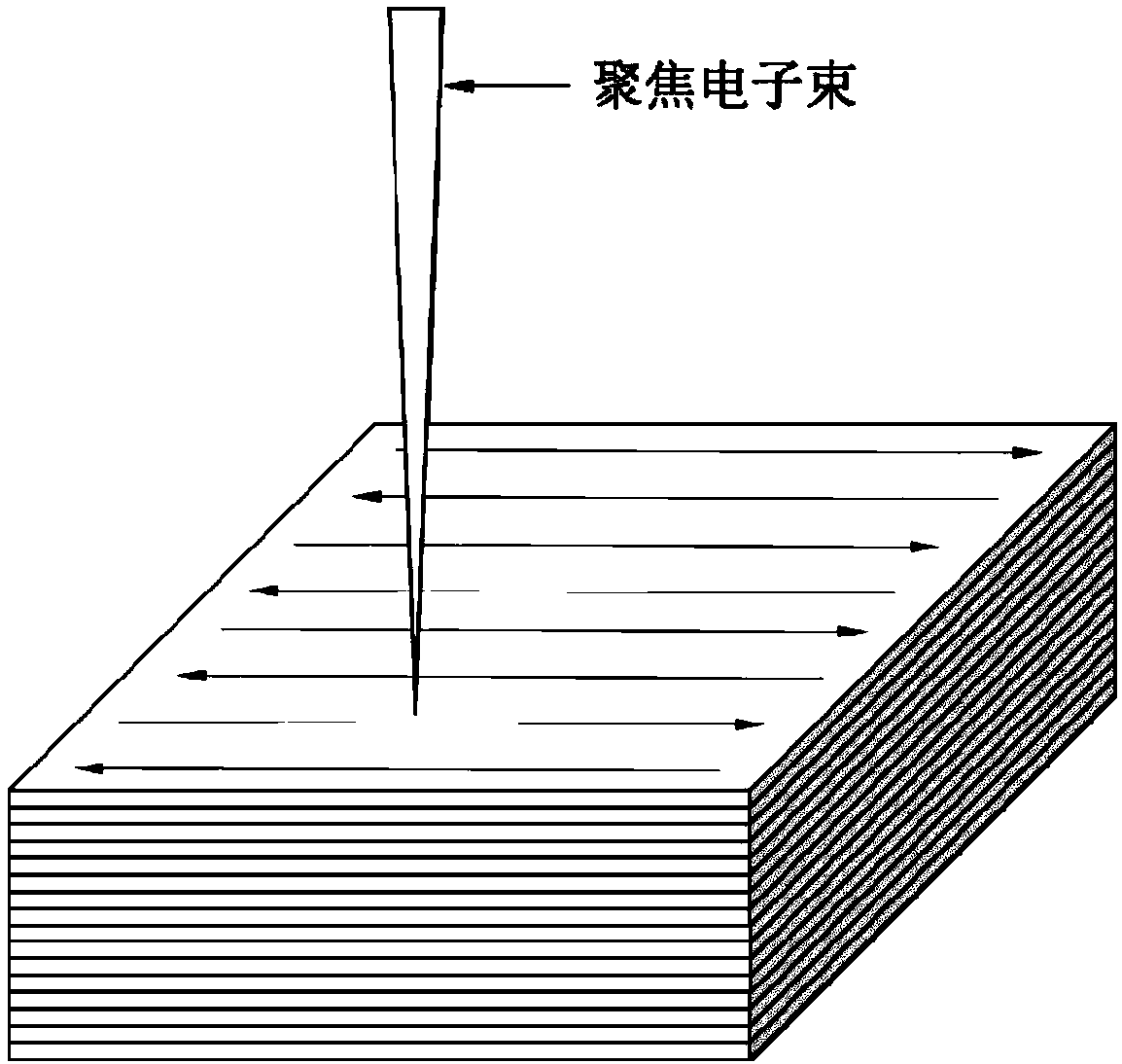

[0030] Step 3: Start the electron beam additive manufacturing device to process the current slice;

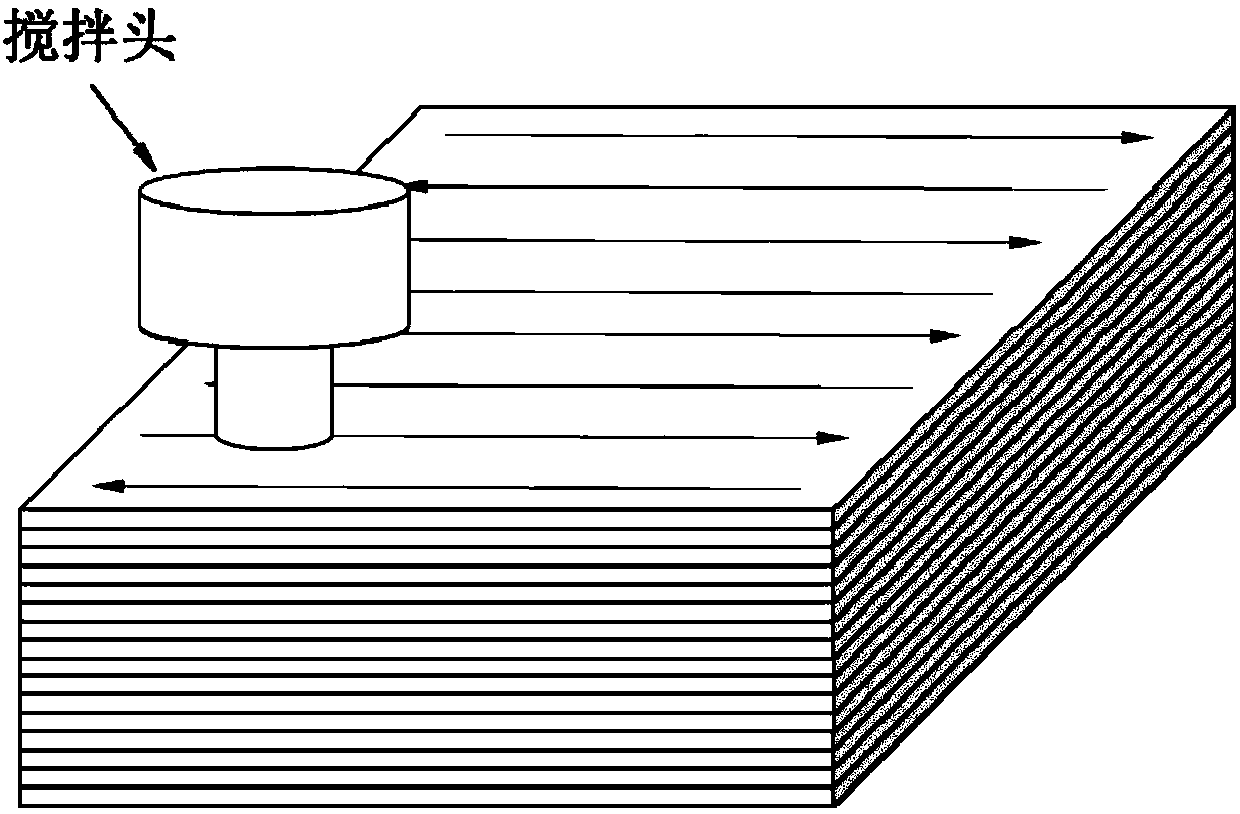

[0031] Step 4: After the processing is completed, the stirring head performs friction stir processing on the slice;

[0032] Step 5: After the processing is completed, the workbench is lowered by one slice thickness;

[0033] Step 6: Repeat steps 3 to 4 for additive manufacturing.

[0034] Among them, the material used in additive manufacturing is 7075 aluminum alloy powder with a particle size of 0.5 μm to 15 μm.

[0035] Among them, the diameter of the spot in the electron beam additive manufacturing process is 0.001 mm to 25 mm.

[0036] Wherein, the line speed of electron beam additive manufacturing is 30mm / min-150mm / min.

[0037] W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com