Electro-acoustic effect-based in-situ detection method and device for electron beam additive manufacturing

A technology of additive manufacturing and in-situ inspection, applied in the field of additive manufacturing, can solve the problems of difficulty in meeting the requirements of precision and resolution, increase in equipment cost and complexity, and achieve improved cost and complexity, small size, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

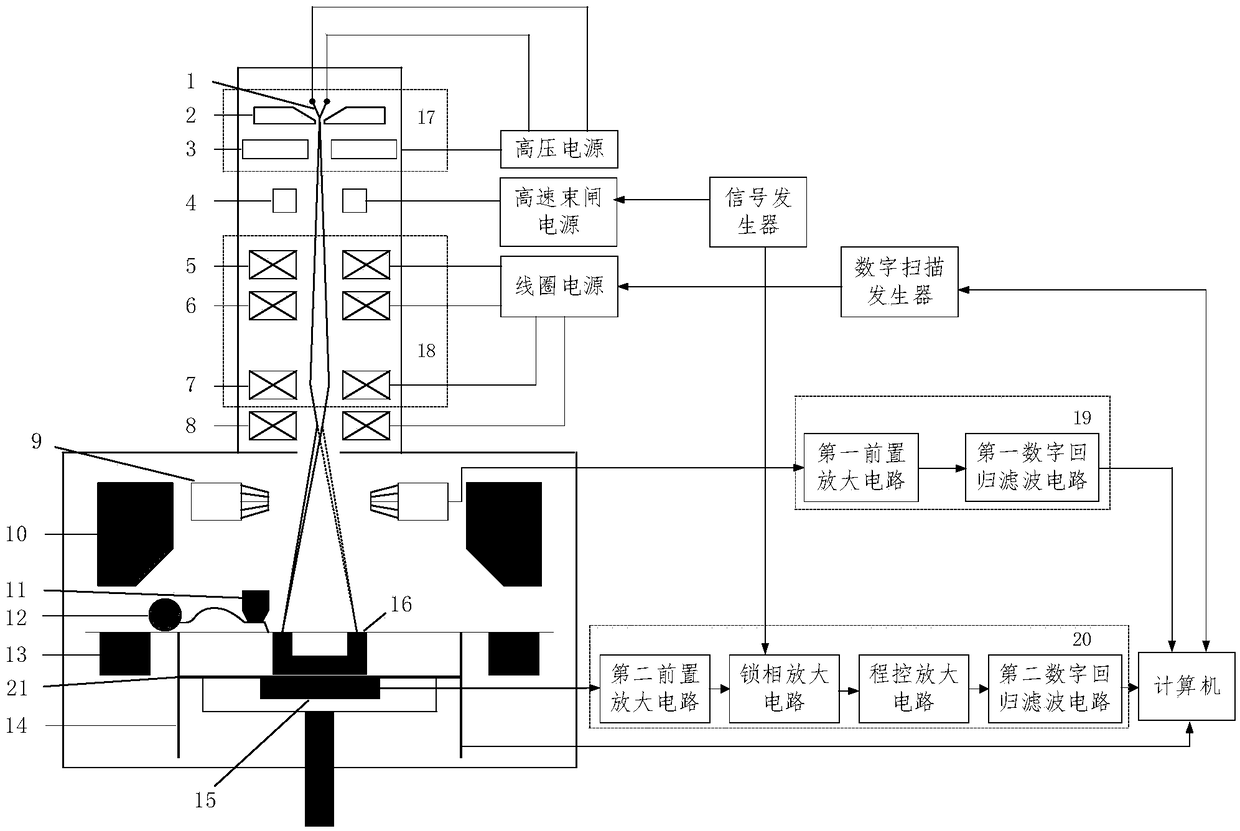

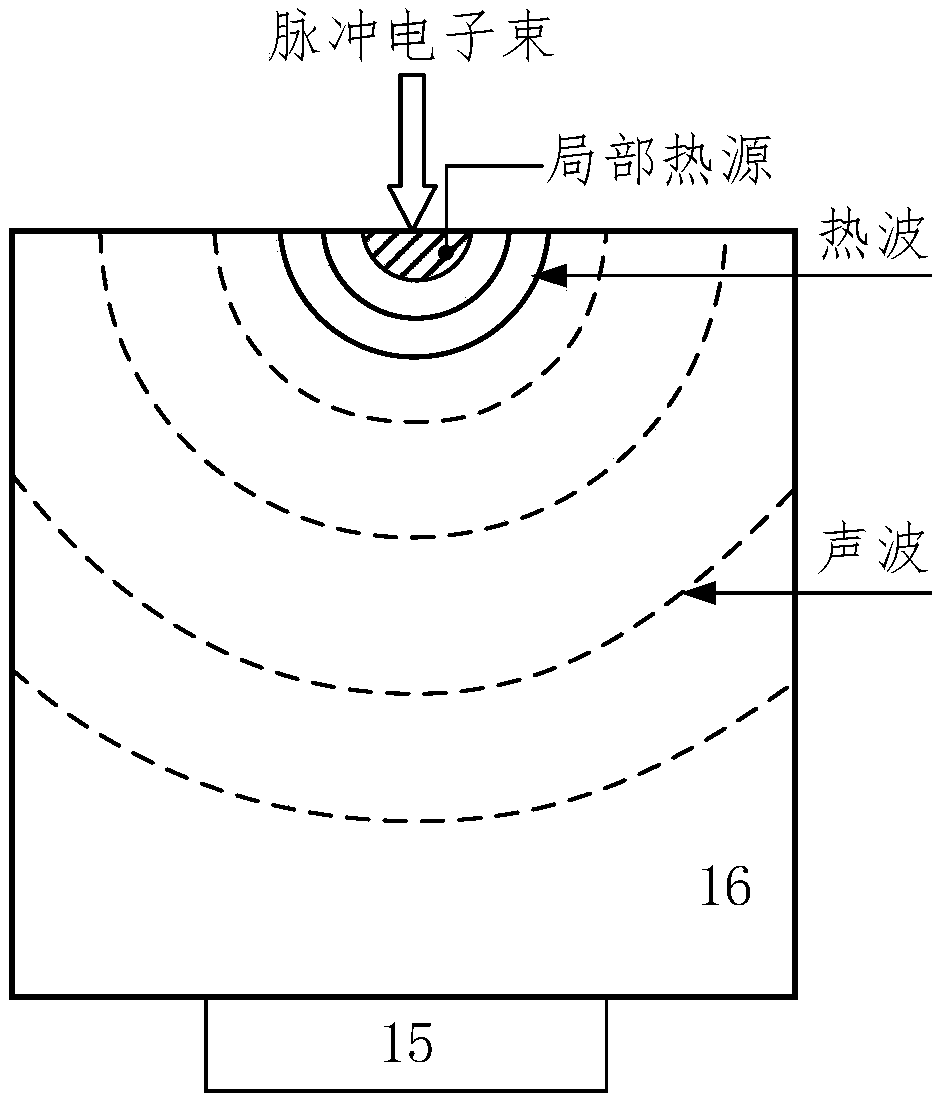

[0035] The invention provides an in-situ detection method and device for electron beam additive manufacturing based on electroacoustic effect.

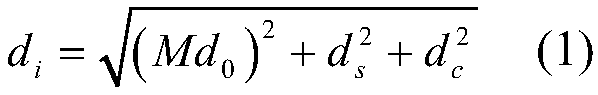

[0036] When the electron beam interacts with the material, it will generate secondary electrons, backscattered electrons, characteristic X-rays, Auger electrons, transmitted electrons and other signals, which can be used to accurately identify the characteristic information of the material surface. Among them, using secondary electrons or backscattered electrons to obtain the distribution of topographic features of the surface area of the workpiece 16 is a common method in scanning electron microscopy (SEM) (reference [3] Lin Feng, Yan Yongnian, Yan Zhangong, etc., an electron beam selected area synchronous Sintering process and three-dimensional layered manufacturing equipment [P], Chinese patent, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com