Combined electron beam additive manufacturing device and process

A technology of additive manufacturing and electron beam, which is applied in the field of electron beam additive printing equipment, can solve the problems of low efficiency, high processing cost, and low precision, and achieve the effects of high efficiency, high molding efficiency, and low precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

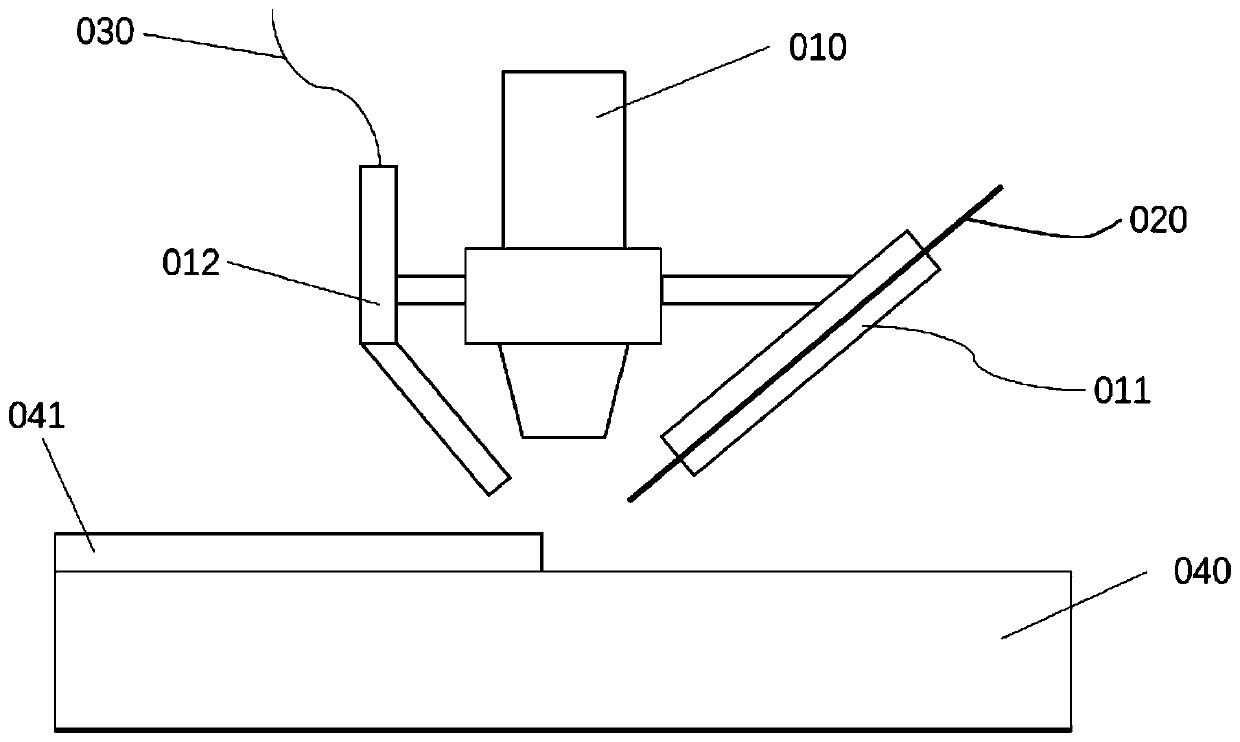

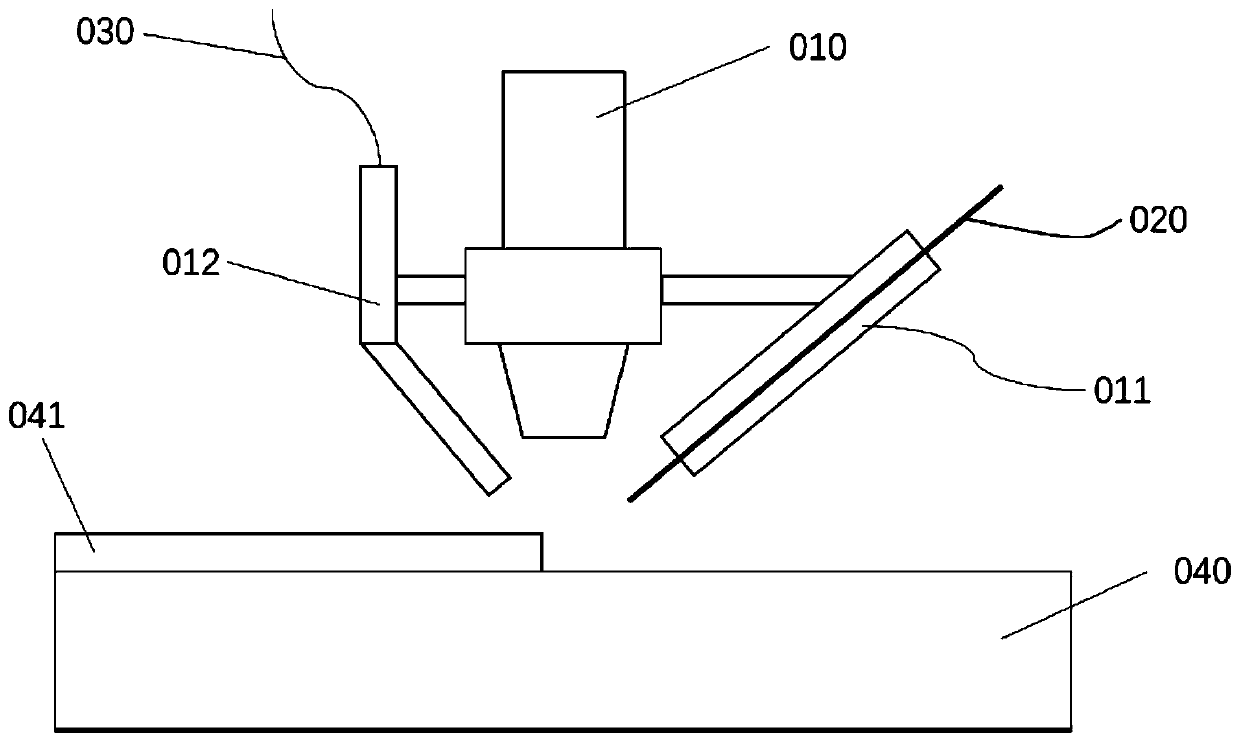

[0027] Such as figure 1 As shown, the composite electron beam additive manufacturing equipment of the present invention includes an electron beam gun 010, a wire feeding nozzle 011, a powder feeding nozzle 012, a metal wire 020, a powder feeding system 030, a forming substrate 040, and a deposition layer 041.

[0028] The wire feeding nozzle 011 and the powder feeding nozzle 012 are installed on the base of the electron beam gun 010, the powder feeding nozzle 012 is connected with the powder feeding system 030, and the metal wire 020 is fed into the wire feeding nozzle 011 through the wire feeder to form a composite electron beam amplifier. material melting system. The base of the electron beam gun 010 is provided with an XYZ three-coordinate movement drive mechanism, and the XYZ three-coordinate movement drive mechanism is connected to the XYZ three-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com